Method for preparing spherical lithium titanate from inorganic titanium sources

A technology of inorganic titanium and lithium titanate, applied in the direction of inorganic chemistry, chemical instruments and methods, titanium compounds, etc., to achieve the effects of convenient industrial production, good appearance, and superior electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

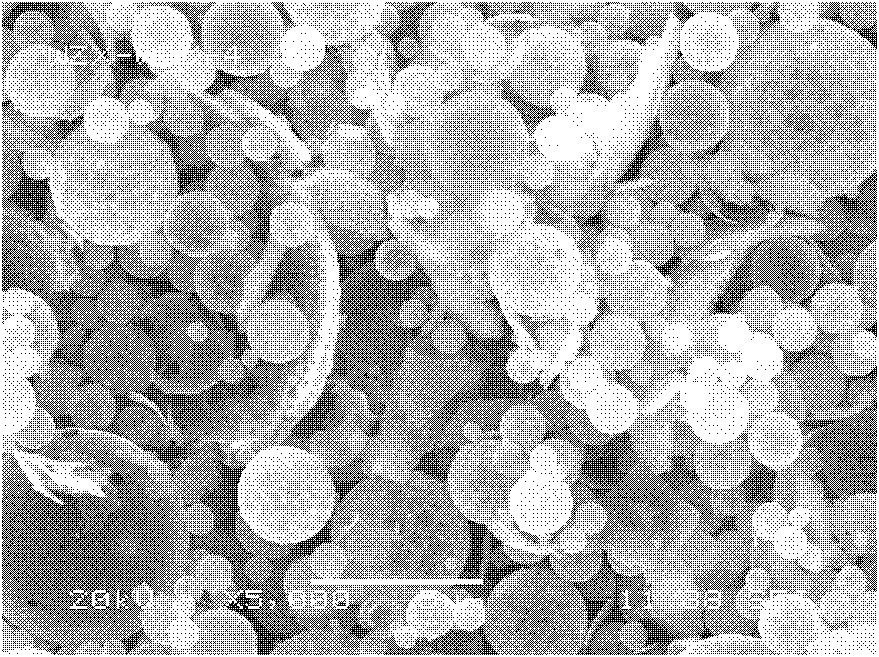

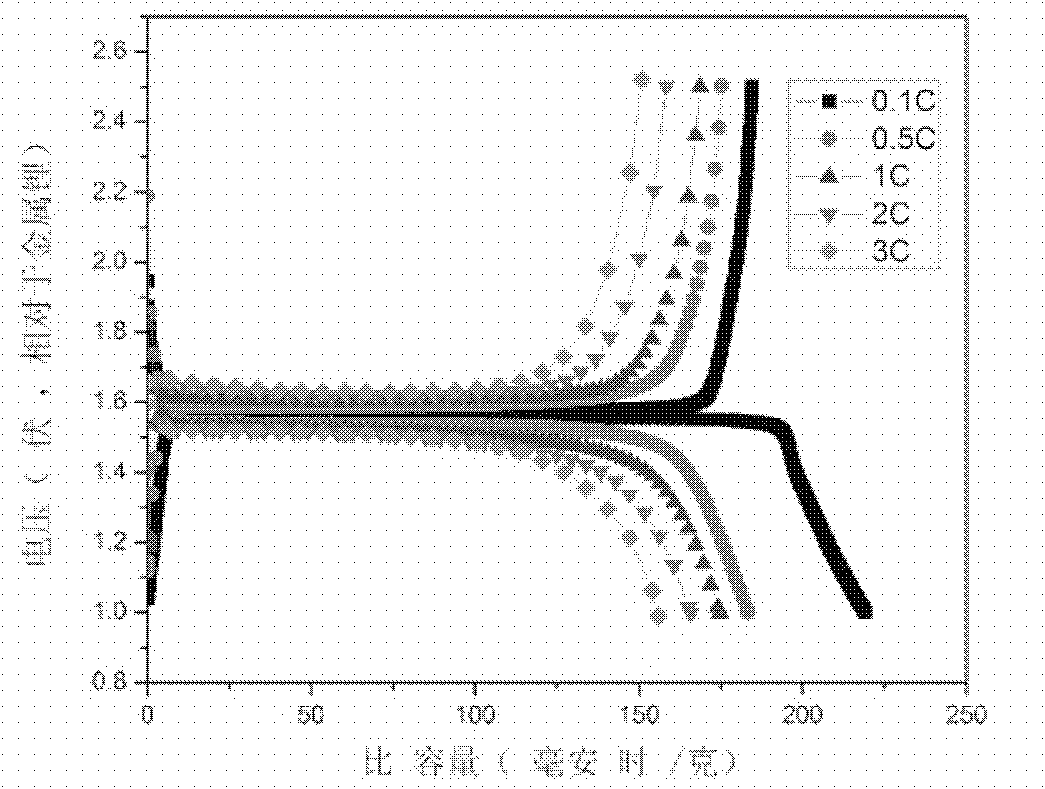

Image

Examples

Embodiment 1

[0039] The titanium source is 15g of chemically pure titanium sulfate, which is dissolved in water. In the experiment, 10wt.% ammonia water is used to adjust the pH to 3, and the titanium precipitate is obtained by filtration; the precipitate is beaten with distilled water, and hydrogen peroxide solution is added. The molar ratio of hydrogen peroxide and titanium is The ratio is 1. During the reaction process, use 0.5mol / L ammonia water to adjust the pH of the solution to 7, then react in a stirred reactor at 20°C, filter to obtain a titanium solution after 10 minutes, and then pour it into a 1000ml beaker; Lithium hydroxide solution was added to the solution, and the molar ratio of lithium hydroxide to titanium was 4:5; the solution was stirred for 10 minutes and then spray-dried. A precursor of lithium titanate, a negative electrode material for lithium ion batteries, is obtained; the precursor is calcined at 600° C. for 12 hours in an argon atmosphere to obtain lithium titan...

Embodiment 2

[0041] The titanium source is ilmenite at 120°C, the ratio of acid to mineral is 1.2:1, 5g of hydrolyzed high-titanium slag after hydrochloric acid leaching for 2 hours, beat the titanium slag with distilled water, add hydrogen peroxide solution, and the molar ratio of hydrogen peroxide to titanium It is 6: 1, and the pH of the solution is adjusted to 10.5 with 30wt.% ammonia water in the experiment, and then reacted in a stirred reactor at 35°C for 50 minutes, filtered to obtain a titanium solution, and poured into a beaker with a volume of 1000ml; Add lithium hydroxide solution, the molar ratio of lithium hydroxide to titanium is 4:5; stir for 10 minutes, spray and dry under the conditions of inlet air temperature 140°C, outlet air temperature 120°C and feed rate 100ml / h to obtain a lithium ion battery The precursor of the material lithium titanate; the precursor is calcined at 900° C. for 5 hours in an argon atmosphere to obtain lithium titanate, a negative electrode materia...

Embodiment 3

[0043] The titanium source is 10g of chemically pure titanium tetrachloride, which is dissolved in water. In the experiment, 0.1mol / L sodium hydroxide solution is used to adjust the pH to 4, and the titanium precipitate is obtained by filtration; the titanium precipitate is beaten with distilled water, and hydrogen peroxide is added. Solution, the molar ratio of hydrogen peroxide and titanium is 10: 1, adjust the pH of the solution with 20wt.% ammonia water to be 12, react in a stirred reactor at 80°C, react for 360min, filter to obtain the solution of titanium; Lithium acetate solution was added to the solution, and the molar ratio of lithium to titanium was 4:5; stirred for 10 minutes, and spray-dried at an inlet air temperature of 200°C, an outlet air temperature of 140°C and a feed rate of 1000ml / h to obtain a lithium-ion battery The precursor of the material lithium titanate; the precursor is calcined at 800° C. for 12 hours in a nitrogen atmosphere to obtain lithium titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com