Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "No cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron beam welding method for variable-section gas turbine casing

ActiveCN102416525AImprove manufacturing levelConvenient welding methodElectron beam welding apparatusSpot weldingVacuum chamber

The invention relates to an electron beam welding method for a variable-section gas turbine casing, relating to a welding method for a gas turbine casing and solving the problem that the existing welding method for a cylinder and a horizontal flange of the same section in the gas turbine casing cannot meet welding requirements for the cylinder and the horizontal flange of the variable section. The method comprises: 1, selecting an electron beam welding machine; 2, cleaning; 3, arranging the cleaned casing and a tool clamp onto a workbench in a vacuum chamber of the welding machine, assemblingthe casing onto a tool, positioning two variable-section horizontal flanges and a cylinder, and carrying out spot welding; and 4, carrying out electron beam welding. The multi-section welding is adopted for the variable-section horizontal flanges with different thicknesses, the welding of the horizontal flanges of different thicknesses for the variable-section casing can be realized through adjusting and selecting the current, voltage, gun distance and other parameters of the welding machine, and the product quality and the production efficiency can be improved greatly. The method can be applied in welding of the variable-section gas turbine casing.

Owner:HARBIN TURBINE

Solder, preparation method thereof and method for connecting sapphire and niobium or niobium alloys by using solder

InactiveCN103056553ASimple processHigh average shear strengthWelding/cutting media/materialsSoldering mediaNanoparticleNiobium alloy

The invention discloses a solder, a preparation method thereof and a method for connecting sapphire and niobium or a niobium alloy by using the solder, relates to the field of solders, preparation methods thereof and connection methods and aim to solve the problems that in the prior art an connector has larger residual stress by using a brazing method for connecting the sapphire and metals, the connector can't resist high temperature, the process is complex and the strength of the connector is not high. The solder is prepared by Ag powder, CuO powder, TiH2 powder, Si3N4 ceramic nanoparticles and a binder. The preparation method of the solder includes the steps of (1) preparing Ag-CuO-TiH2 powder; (2) preparing mixed powder of the solder; and (3) uniformly mixing the mixed powder of the solder with the binder. The method for connecting the sapphire and the niobium or the niobium alloy by using the solder includes the steps of (1) preparing a sapphire sample to be welded and a niobium sample or a niobium alloy sample which are to be welded; (2) coating the solder on the surfaces to be welded, and (3) completing the connection of the sapphire and the niobium or the niobium alloy by means of segmented heating. The solder, the preparation method thereof and the method for connecting the sapphire and the niobium or the niobium alloy by using the solder is applicable to the field of welding.

Owner:HARBIN INST OF TECH

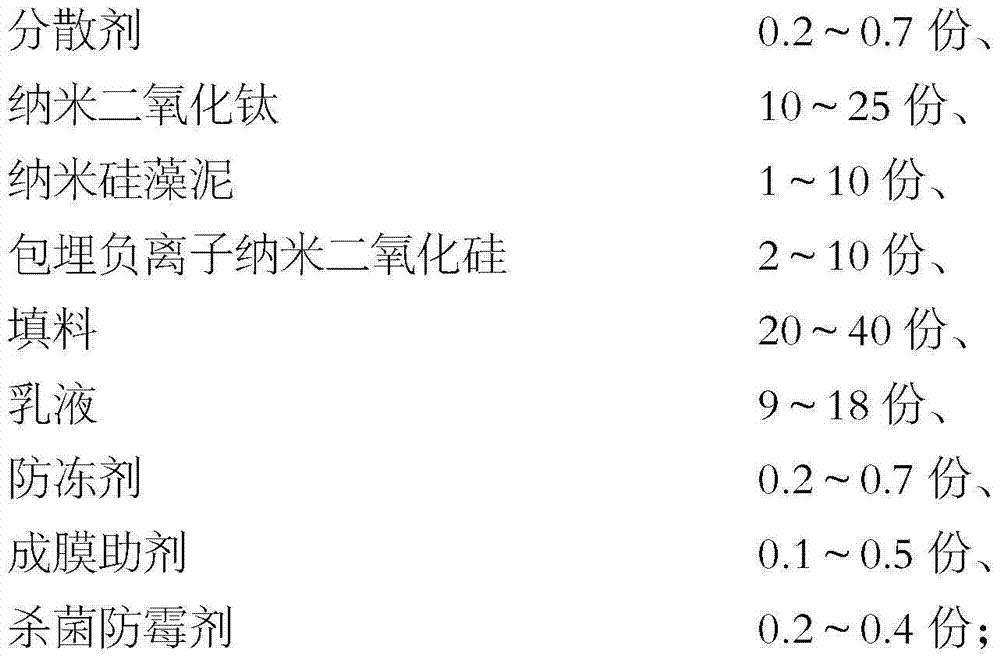

Special-effect heath indoor wall aqueous paint composition and preparation method thereof

The invention relates to a special-effect health indoor wall aqueous paint composition and a preparation method thereof, and belongs to the field of aqueous paint compositions for construction decoration. The paint composition is composed of the following raw materials in parts by weight: 20 to 30 parts of water, 0.2 to 0.5 part of thickening agent, 0.05 to 0.2 part of pH adjuster, 0.1 to 0.3 part of antifoaming agent, 0.1 to 0.4 part of wetting agent, 0.2 to 0.7 part of dispersant, 10 to 25 parts of nano titanium dioxide, 1 to 10 parts of nano diatom ooze, 2 to 10 parts of embedded anionic nano silicon dioxide, 20 to 40 parts of filling material, 9 to 18 parts of emulsion, 0.2 to 0.7 part of anti-freezing agent, 0.1 to 0.5 part of film-forming auxiliary agent, and 0.2 to 0.4 part of bactericidal mildew inhibitor. The paint composition can absorb the harmful components in air, is healthy and environment-friendly, and also has the advantages of excellent color retention, scrubbing resistance, water and alkali resistance, and proper softness of paint film.

Owner:SKSHU PAINT

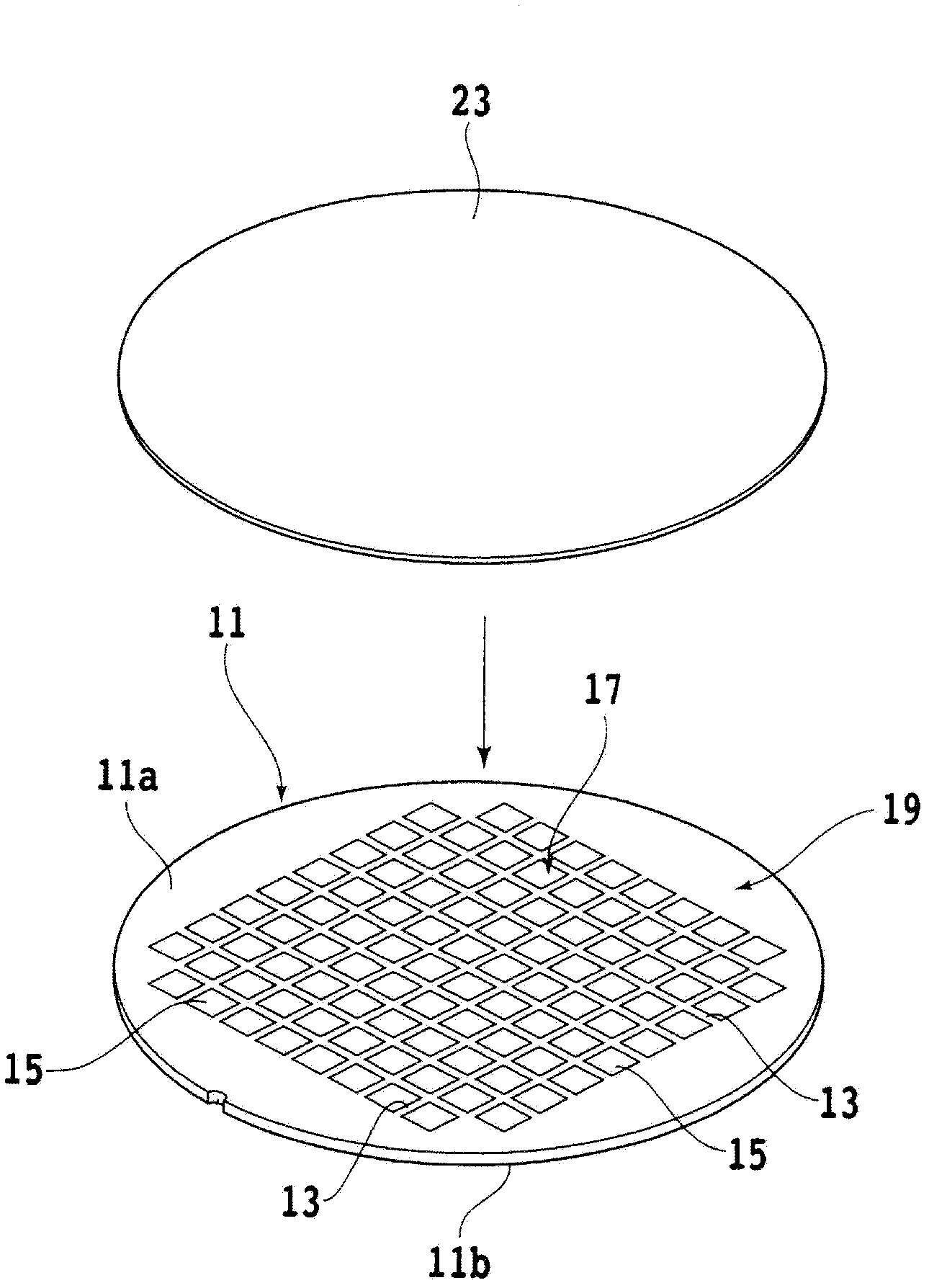

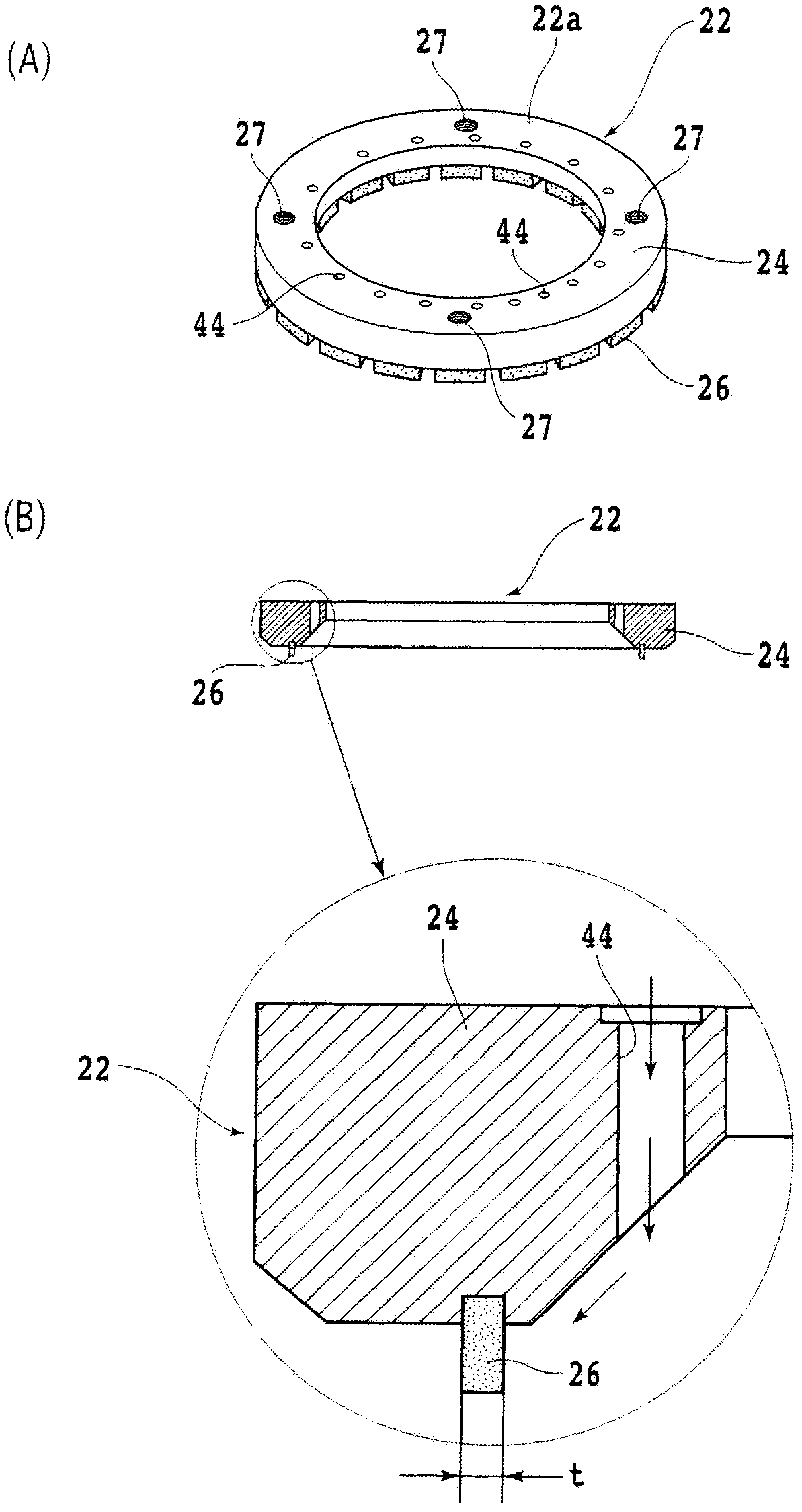

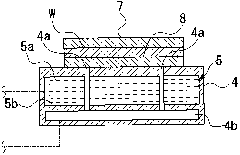

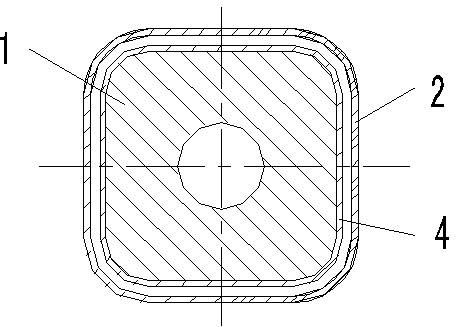

Grinding Wheel

InactiveCN102398227ANo crackingNo cracksSemiconductor/solid-state device manufacturingBonded abrasive wheelsBoron nitrideEngineering

Provided is a grinding wheel, capable of grinding the hard and fragile material to the required thickness without causing cracking upon the surface of the grinding surface. The grinding wheel is used for grinding the to-be-processed objects. The grinding wheel is characterized by being equipped with an annular pedestal which comprises a wheel seat assembling surface to be assembled to the wheel seat, and a plurality of grinding tools having free ends annularly arranged to the annualar pedestal, with the grinding tool being formed by adding boron compound to the diamond grains. The boron compound is anyone selected from the group consisting of B4C (boron carbide), HBN (Hexagon boron nitride) and CBN (cubic boron nitride).

Owner:DISCO CORP

Nanometer calcium carbonate composite resin-based taphole printing ink and preparation method thereof

The invention relates to the technical field of taphole resin, and particularly relates to nanometer calcium carbonate composite resin-based taphole printing ink and a preparation method thereof. The nanometer calcium carbonate composite resin-based taphole printing ink is prepared by uniformly mixing epoxy, a glycidol type active diluting agent, a latent curing agent, an imidazole type curing accelerant and inorganic powder. By using the epoxy of which the viscosity is 4-6Pa*s / 25 DEG C, the viscosity of the nanometer calcium carbonate composite resin-based taphole printing ink disclosed by the invention can be reduced, the crosslinking density of the nanometer calcium carbonate composite resin-based taphole printing ink can also be increased, the hardness of a cured substance and the glass transition temperature of the nanometer calcium carbonate composite resin-based taphole printing ink are increased. By adding the inorganic powder, agglomeration of nanometer calcium carbonate powder is prevented, the dispersion effect of mixed materials is enhanced, the rheological property of the nanometer calcium carbonate composite resin-based taphole printing ink can also be improved, the thixotropy of the nanometer calcium carbonate composite resin-based taphole printing ink is improved, and the expansion coefficient of the nanometer calcium carbonate composite resin-based taphole printing ink is effectively reduced; besides, the heat conductivity of the nanometer calcium carbonate composite resin-based taphole printing ink can also be improved, so that difference of curing degree of the printing ink in holes can be reduced and problems of internal cavity or incomplete curing are prevented.

Owner:SHENZHEN BANMING SCI & TECH CO LTD

Processing technique of planet carrier of coal cutter

InactiveCN103506816AIncrease profitImprove processing efficiencyOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a processing technique of a planet carrier of a coal cutter. The processing technique of the planet carrier of the coal cutter comprises the steps of workblank forging or casting, destressing heat treatment, chemical component sampling and analyzing, rough machining, flaw detection, hardening and tempering, and finish machining. The finish machining relates to the steps of (1) milling four holes for installation of a planet wheel in the circumferential direction; (2) finish-turning the end face of a spline end and an outer circle, drilling, boring and reaming an inner hole, punching and tapping; (3) milling a spline; (4) turning around a workpiece to finish-turn the end face of the other end and an outer circle, and drilling, boring and reaming an inner hole. All steps of the rough machining and all steps of the finish machining are achieved on one machining device. According to the processing technique of the planet carrier of the coal cutter, multi-step machining is achieved by means of the one machining device, and therefore the integration level is high; due to the fact that grinding is replaced with turning during the finish machining, machining efficiency is improved, and the accuracy of a finished surface can be guaranteed.

Owner:常熟天地煤机装备有限公司

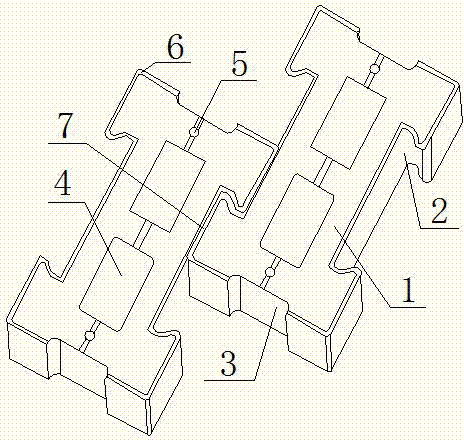

Ecological interlocking block and ecological interlocking block type slope protection construction method

InactiveCN104846781AIncreased durabilityImprove stabilityCoastlines protectionReceptacle cultivationBrickEcological environment

The invention relates to an ecological interlocking block and an ecological interlocking block type slope protection construction method. The ecological interlocking block comprises a block body; the left side and the right side of the block body are symmetrically provided with wedge-shaped mortises; the front side and the rear side of the block body are symmetrically provided with connecting grooves; the interior of the block body is provided with two through holes. The ecological interlocking block type slope protection construction method particularly comprises the following steps of slope levelling processing, pavement of composite geo-membrane, pouring of C20 plain concrete foundation, pavement of ecological interlocking brick, coping of concrete capping and construction of slope top. The ecological interlocking block type slope protection construction method has the advantages that every interlocking brick block and the adjacent six interlocking brick blocks generate super-strong connecting functions and the integral stability is high under washing through river water; the slope protection durability and stability is improved along with growing of plants in central holes of the interlocking bricks, a function of protecting river ecological environment is achieved; slope protection, ecological restoration and decoration are integrated, the structure is stable and economic, and the construction is convenient, and the ecological interlocking block type slope protection construction method can be applied to treatment engineering of medium or small rivers.

Owner:JINAN URBAN CONSTR GRP

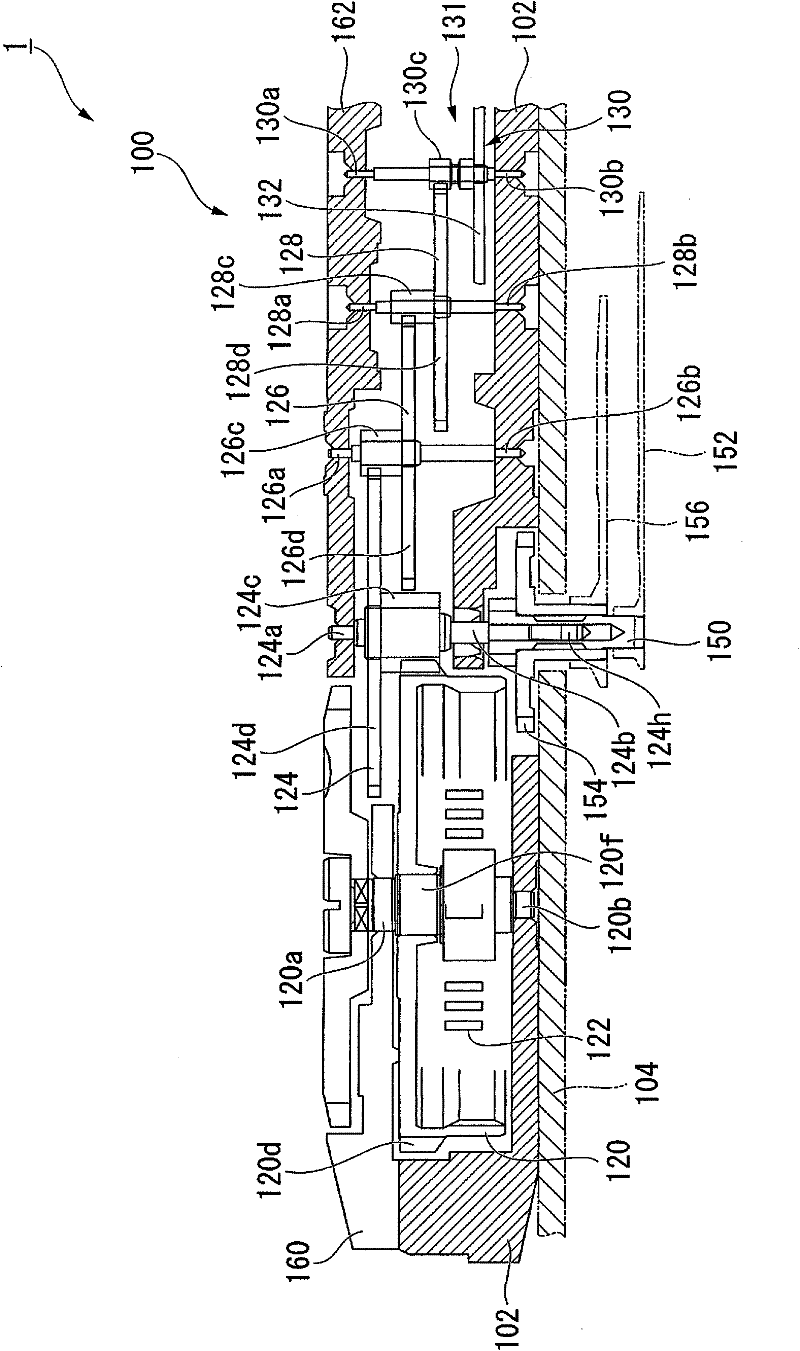

Gear for clock and clock

The invention provides a high-quality gear for clocks and a clock. The gear which can be manufactured with high efficiency thus has a low cost. Meanwhile, the gear has the characteristics of delicacy, high-precision shape, high wear resistance and high working reliability. The gear (130) for clocks comprises a tooth-shaped gear part (132) formed through photoetching. The gear part is made of materials which can survive the photoetching and has higher hardness and toughness than silicon (Si).

Owner:SEIKO INSTR INC

Metal powder injection molding method for large part

InactiveCN107309430ANo cracksNo deformationTransportation and packagingMetal-working apparatusHigh volume manufacturingRoom temperature

The invention discloses a metal powder injection molding method for a large part. The metal powder injection molding method includes the following steps that a, metal powder and a bonding agent are mixed evenly, and feed particles are prepared; b, an injection molding machine is used for injecting the feed particles into a die to form a blank; c, the blank is put into a sintering furnace to be heated, a bonding agent is removed along with temperature rising of the sintering furnace, and first-time sintering is conducted in the sintering furnace; and d, a sintered part obtained after first-time sintering is cooled to the room temperature and then overturned by 180 degrees, second-time sintering is conducted, and a finished product is discharged out of the furnace and is obtained. By means of the metal powder injection molding method for the metal part, the blank obtained after the bonding agent is removed is subjected to second-time sintering, the sintered part is overturned before second-time sintering is conducted, the sintering shrinkage rate of all parts is consistent, cracking and deformation cannot be generated on the obtained finished product, the overall density is uniform, compactness is higher than 99.5%, in addition, the overall technological process is shortened, and the production efficiency is high. The metal powder injection molding method is suitable for various kinds of metal raw materials and is also suitable for parts with different thicknesses, and large-batch production can be conducted.

Owner:江苏理成科技有限公司

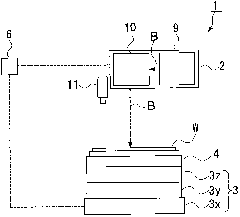

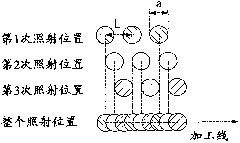

Laser processing device and laser processing method

InactiveCN102189345ASuppresses sudden changes in stressNo crackingLaser beam welding apparatusLaser processingBeam diameter

The invention discloses a laser processing device and a laser processing method, for processing in the process of cutting fragile material having high residual stress without crack and the like. A device for processing by irradiating laser to an object to be processed comprises a laser irradiation mechanism. The pulse oscillation laser of the laser irradiation mechanism irradiates the object to be processed in a certain repetitive frequency while scanning. The repetitive frequency is H. The beam diameter of the laser is a. The scanning time of the laser on the same processing line is n. When the displacement distance L by irradiating pulse laser for one time is n / 2*a, the laser irradiation mechanism sets the laser scanning speed S as L / (1 / H); the irradiation start position of the laser whose scanning time is 1 is L1; the irradiation start position Ln of the laser whose scanning time is n is L1+(L / n)*(n-1); therefore, the laser irradiation mechanism irradiates laser by shifting the irradiation start position in the event of scanning each time.

Owner:MITSUBISHI MATERIALS CORP

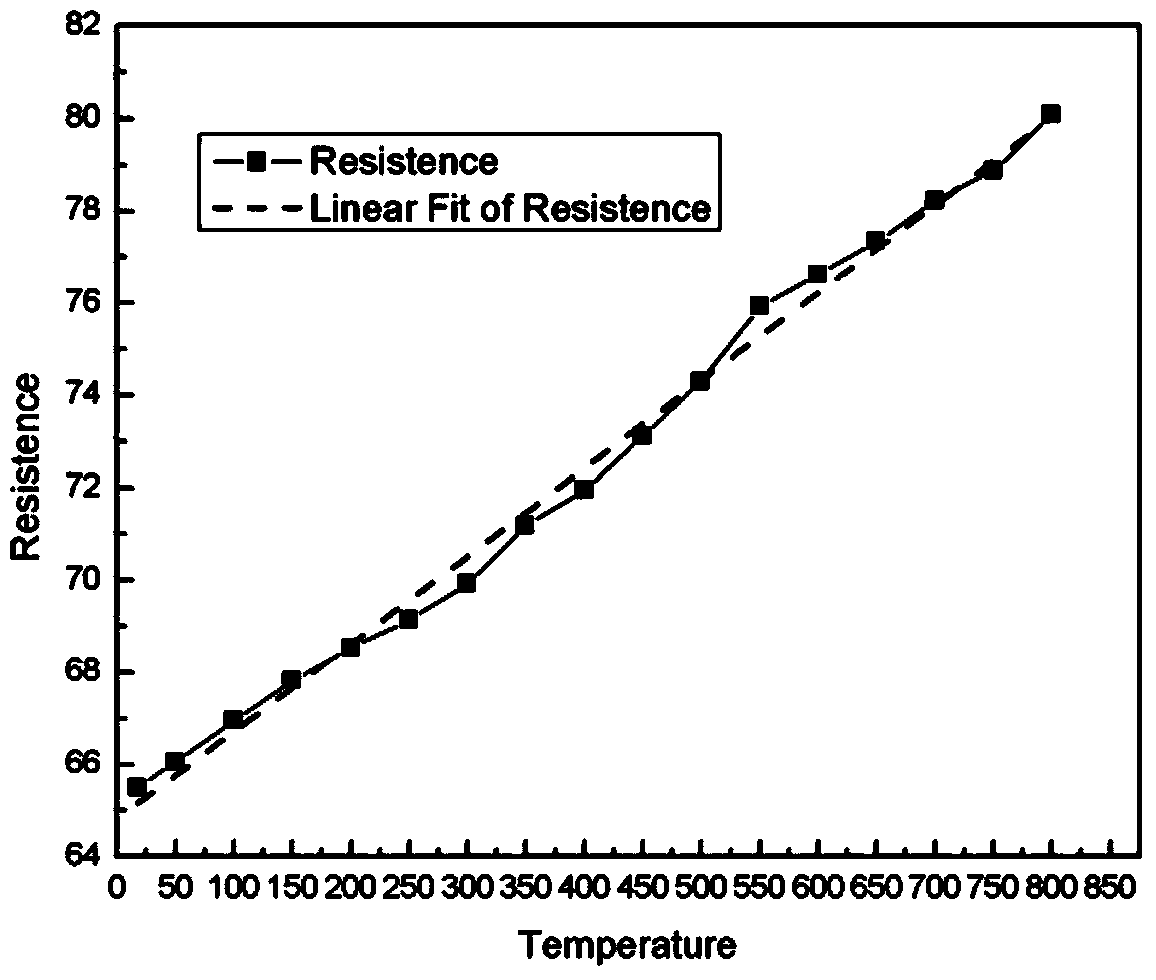

Thin film strainometer and preparation method thereof

InactiveCN103921500AImprove antioxidant capacityImprove stabilityElectrical/magnetic solid deformation measurementCeramic layered productsWorking environmentAlloy substrate

The invention provides a thin film strainometer and a preparation method thereof. The preparation method comprises the following steps: carrying out surface treatment on an alloy substrate; depositing a NiCrAlY transit layer on the alloy substrate; preparing an Al2O3 coupling layer; arranging an Al2O3 ceramic insulating layer; arranging a thin film strainometer function layer, arranging a thermal oxidation Al2O3 protective layer and finally arrange an Al2O3 ceramic protective layer. According to the thin film strainometer and the preparation method thereof, NiCrAlY alloy is adopted as a function layer, and the Al2O3 protective layer formed on the surface of the NiCrAlY alloy through aluminum separation and oxidation is more dense and stable, so that good protection of the thin film strainometer function layer is achieved; the function layer and the transit layer both adopts the same NiCrAlY alloy material and treatment technique, have the same thermal expansion coefficient and are not likely to fall off under high temperature work environment; the temperature strain does not occur, and the service life of the thin film strainometer is prolonged.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

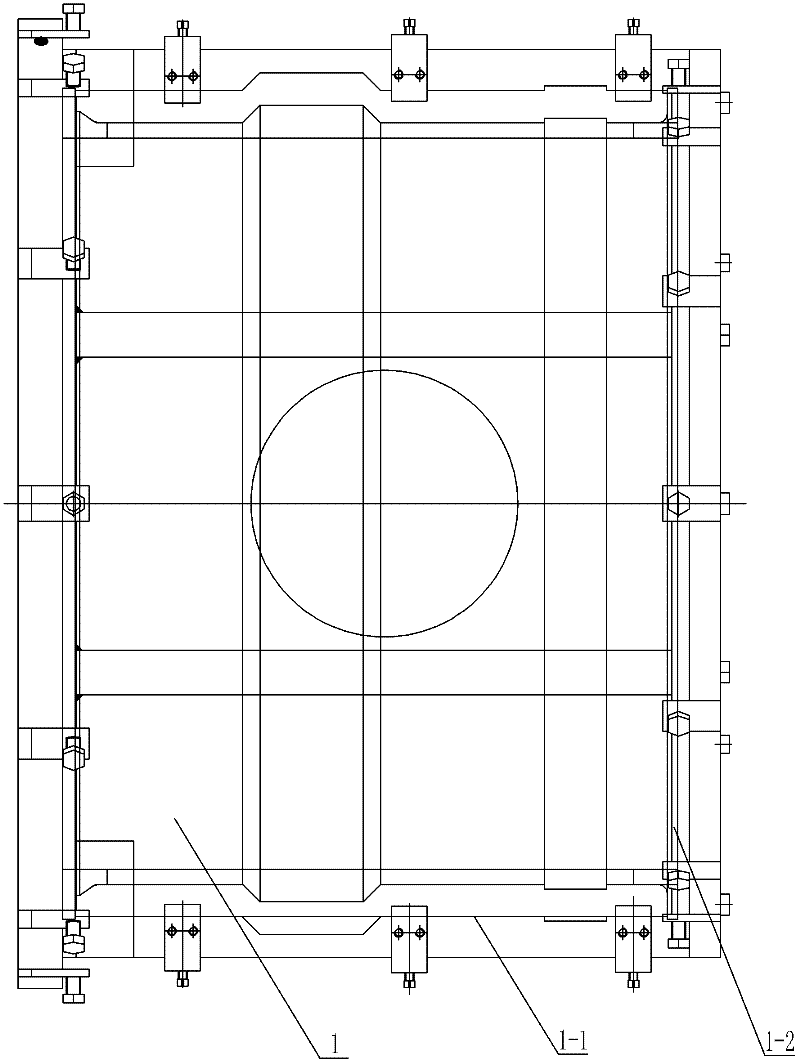

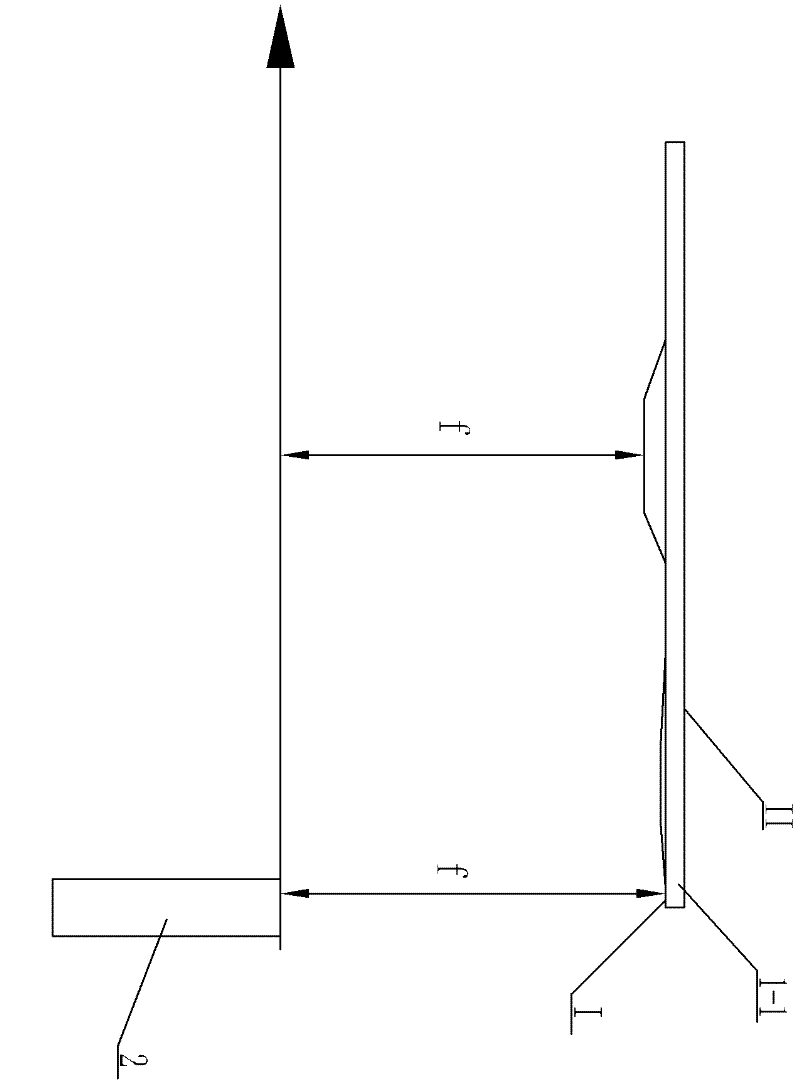

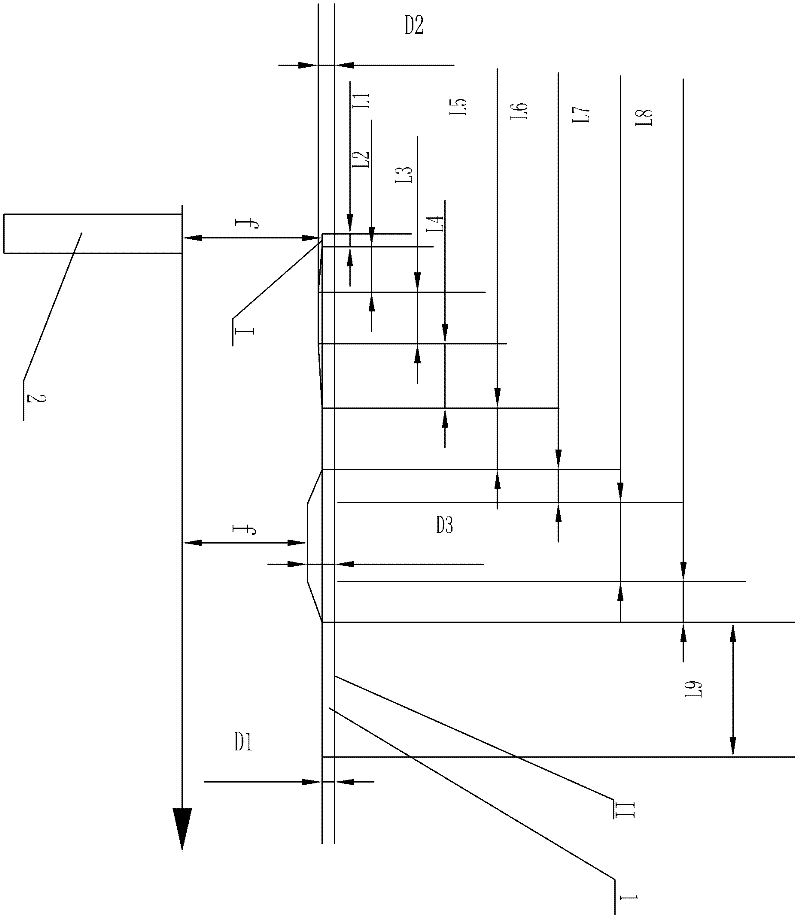

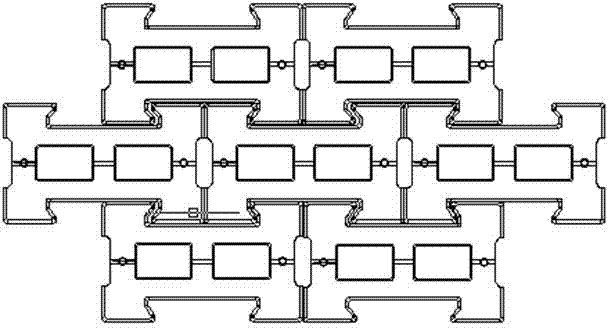

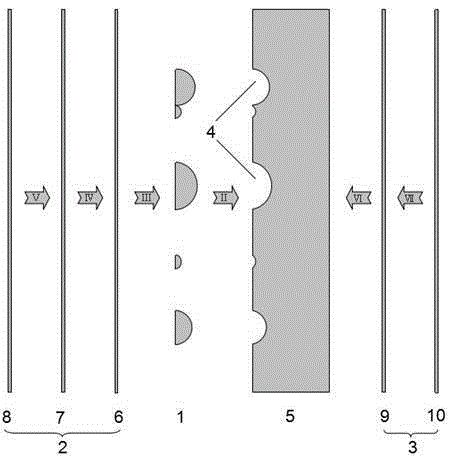

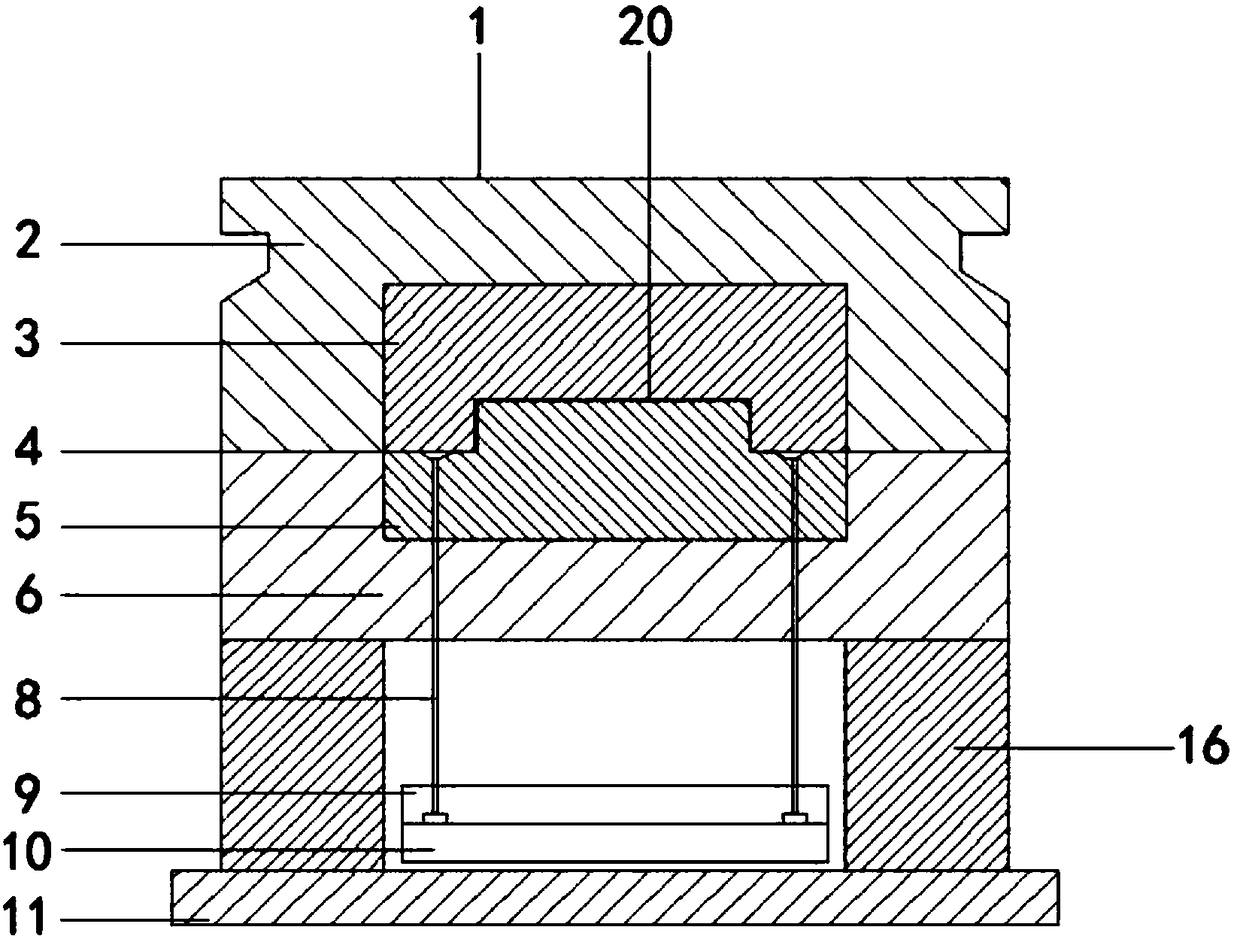

Plate hot press

InactiveCN103950076AImprove bindingNo cracksPlywood pressesVeneer pressesHydraulic cylinderPressure transmission

The invention relates to a plate hot press. A conventional plate hot press is provided with a pressure transmission device at the lower part only, and only upward and downward stress is borne during power transmission, so that the bonding force of the periphery of a hot-pressed plate is weaker than that of the upper and lower surfaces of the hot-pressed plate, and the possibilities of cracking, ungluing and the like are increased. The plate hot press comprises a lower pressure transmission device for enabling the upper and lower surfaces of a plate at the lower part to bear stress, wherein the lower pressure transmission device comprises lower hydraulic cylinders I, II, III and IV connected with a lower pressure plate. The plate hot press also comprises a left pressure transmission device comprising left hydraulic cylinders I and II connected with a left pressure plate, a right pressure transmission device comprising right hydraulic cylinders I and II connected with a right pressure plate, a front pressure transmission device comprising front hydraulic cylinders I and II connected with a front pressure plate, and a rear pressure transmission device comprising hydraulic cylinders I and II connected with a rear pressure plate.

Owner:济南福迪木业有限公司

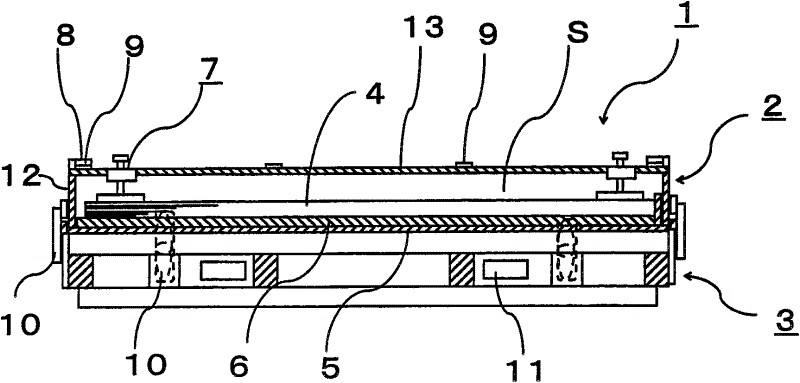

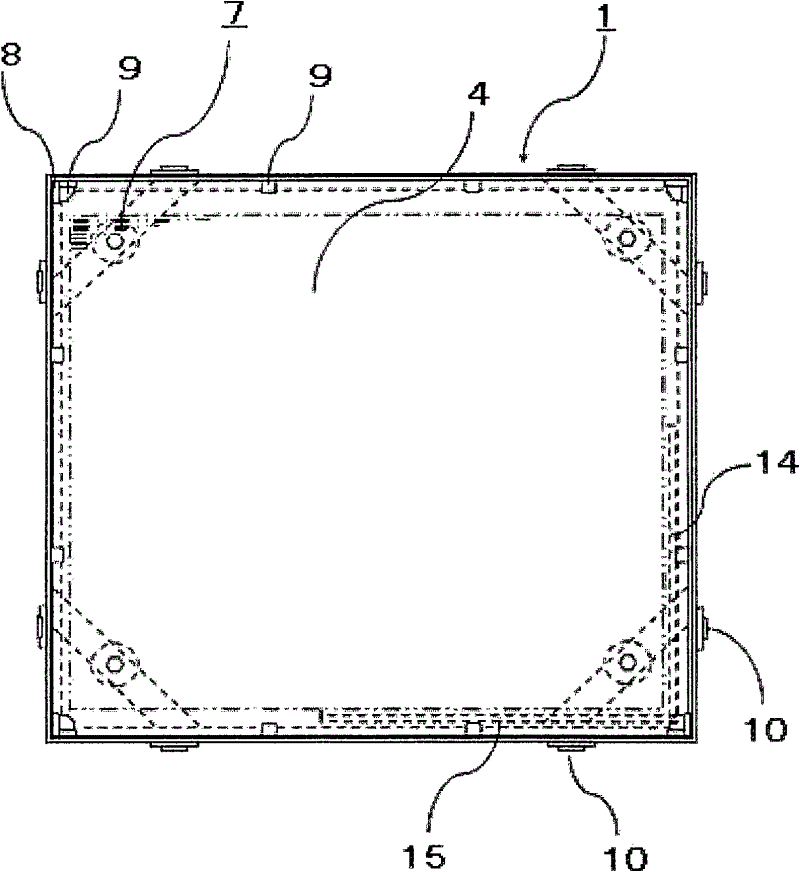

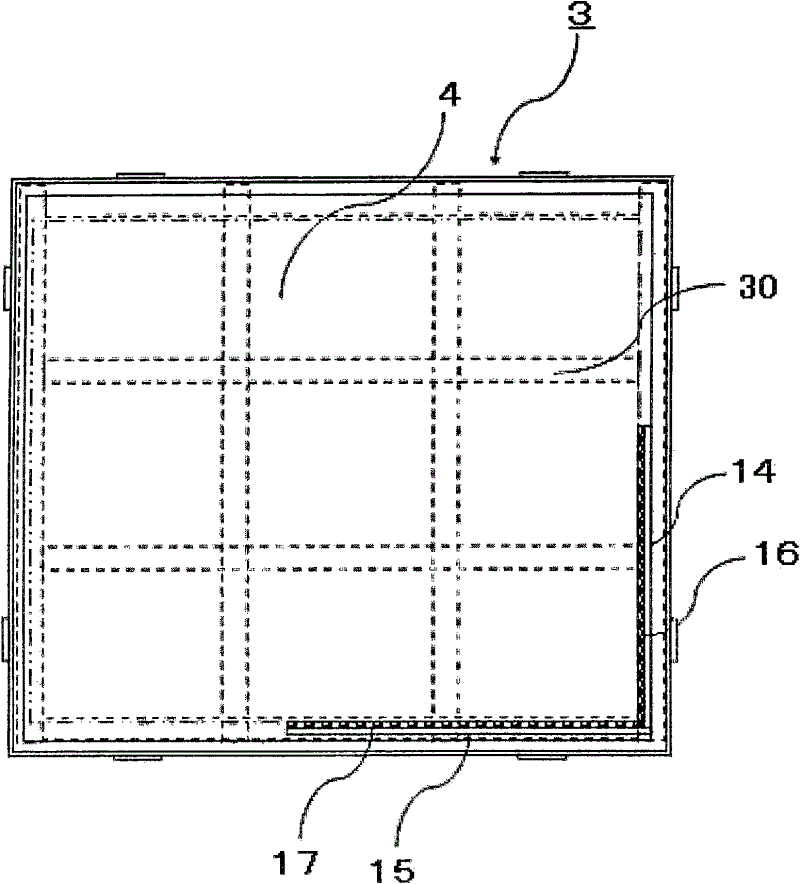

Large plate-shaped body packaging box

InactiveCN102616487ALower the altitudeNo incisionContainers to prevent mechanical damageRigid containersEngineering

The invention provides a large plate-shaped body packaging box, a method for transporting plate-shaped bodies by using the plate-shaped body packaging box, a method for loading the plate-shaped bodies, and a method for taking the plate-shaped bodies out. Dust is prevented from invading the packaging box, height during conveying is reduced, the packaging box can be easily stored in a storage room with a low top, and the plate-shaped bodies are efficiently and stably stored and transported. The plate-shaped body packaging box comprises a pedestal (3) with a veneer material, a plate-shaped body packaging box body (1) loaded on the pedestal (3), and an upper cover (2) which encircles the plate-shaped bodies (4) loaded on the pedestal (3) and can be assembled and disassembled relative to the pedestal (3), wherein the pedestal (3) is a supporting body with an open upper surface and comprises plate-shaped body protection materials (6) and side plates (14 and 15), a plurality of plate-shaped bodies (4) are fixed on the upper surface of the veneer material (5) in an approximately horizontally laminated state, and the side plates (14 and 15) are arranged on two sides in an L shape in the four sides; and the upper cover (2) consists of a top cover (13) which covers the upper surface of the plate-shaped body packaging box body (1) and side covers (12) on the four sides, has a shape of a box body with an open lower surface, and is provided with pressing pieces (7) which press the upper parts of the plate-shaped bodies.

Owner:ASAHI GLASS CO LTD

Repair method for steel storage tank corrosion pit

InactiveCN105345388AReduce the difficulty of repairReduce the possibility of using open flamesMolten spray coatingFiberCarbon fibers

The invention relates to a repair method for a steel storage tank corrosion pit and belongs to the technical field of welding. A pit after repair comprises three parts, including aluminum for filling up the pit, an aluminum-sprayed erosion resistant coating on the inner surface and a carbon fiber sheet back-up coat on the outer surface. In the repair method, the aluminum for filling up the pit plays the roles of smoothing tank wall and facilitating construction of the erosion resistant coating in later period and delaying of tank wall corrosion because the erosion resistant coating is used as a positive pole after corrosion perforation; the aluminum-sprayed erosion resistant coating on the inner surface can isolate direct contact between stored matter and steel of the tank wall and play the roles of delaying or even stopping further erosion and protecting the tank wall; the carbon fiber sheet back-up coat on the outer surface plays the roles of solidifying the tank body and shearing internal pressure so as to prevent discarding of the storage tank caused by the fact that the tank wall is thinned and cannot bear internal pressure. The combined use of the three parts can lastingly and effectively protect and solidify the storage tank.

Owner:WUHAN UNIV

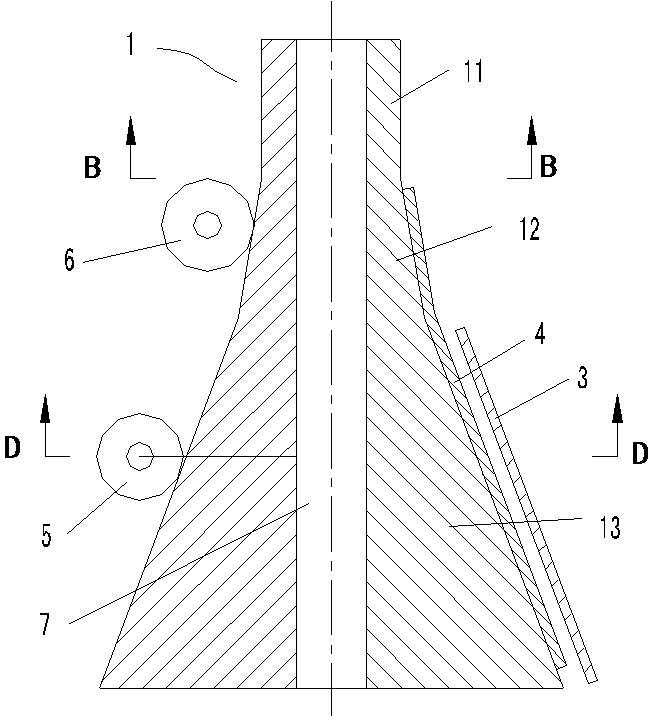

Method and device for preparing tube blank by means of differential temperature pushing from equal circular cross section to variable square cross section

InactiveCN102632136AImprove plasticityHigh tensile strengthShaping toolsSquare cross sectionEngineering

The invention discloses a method for preparing a tube blank by means of differential temperature pushing from an equal circular cross section to a variable square cross section. The method includes the steps: 1) heating a cylindrical section; 2) pushing a transitional section; 3) pushing the variable square cross section by turning on a linear heating device, keeping the temperature of a flange of the tube blank range from 350 DEG C to 400 DEG C, pushing the tube blank at the speed of 25-30mm / s until forming and then unloading; and 4) turning off an annular heating device and the linear heating device and performing ejection. A device for preparing the tube blank by means of differential temperature pushing from the equal circular cross section to the variable square cross section comprises a heating sleeve, the annular heating device and the linear heating device, wherein the heating sleeve is arranged outside the cylindrical section in a surrounding manner, the annular heating device is arranged on the outer side of the transitional section in a surrounding manner, and the linear heating device extends along a filleted flange of the variable square cross section. By the aid of the method, the tube blank can simultaneously have fine plastic deformation at the flange and better tensile strength on a tension side of a mould, cracking or thinning of the tube blank during pushing can be assuredly avoided, and the quality of the tube blank is improved.

Owner:CHONGQING UNIV

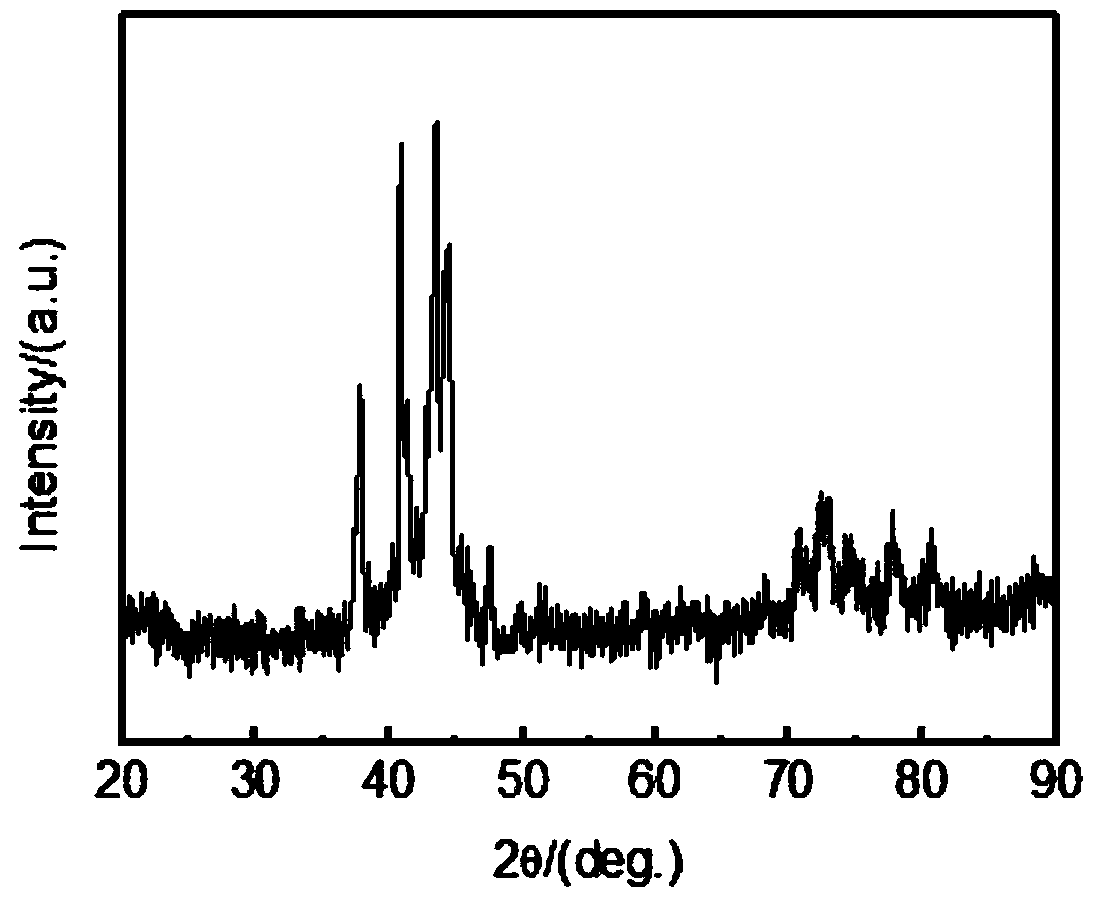

Preparation method of solder for magnetron cathode assembly

ActiveCN111098061AEvenly distributedGood dynamic fluidityWelding/cutting media/materialsSoldering mediaMetallurgySlurry

The invention discloses a preparation method of a solder for a magnetron cathode assembly. The preparation method is characterized by comprising the following steps of (1) material selecting; (2) proportioning; (3) grinding and uniform mixing; (4) preparing of an organic carrier; and (5) preparing of solder slurry. The preparation method is simple in production process, low in cost and easy to realize automation.

Owner:佛山市海欣光电科技有限公司

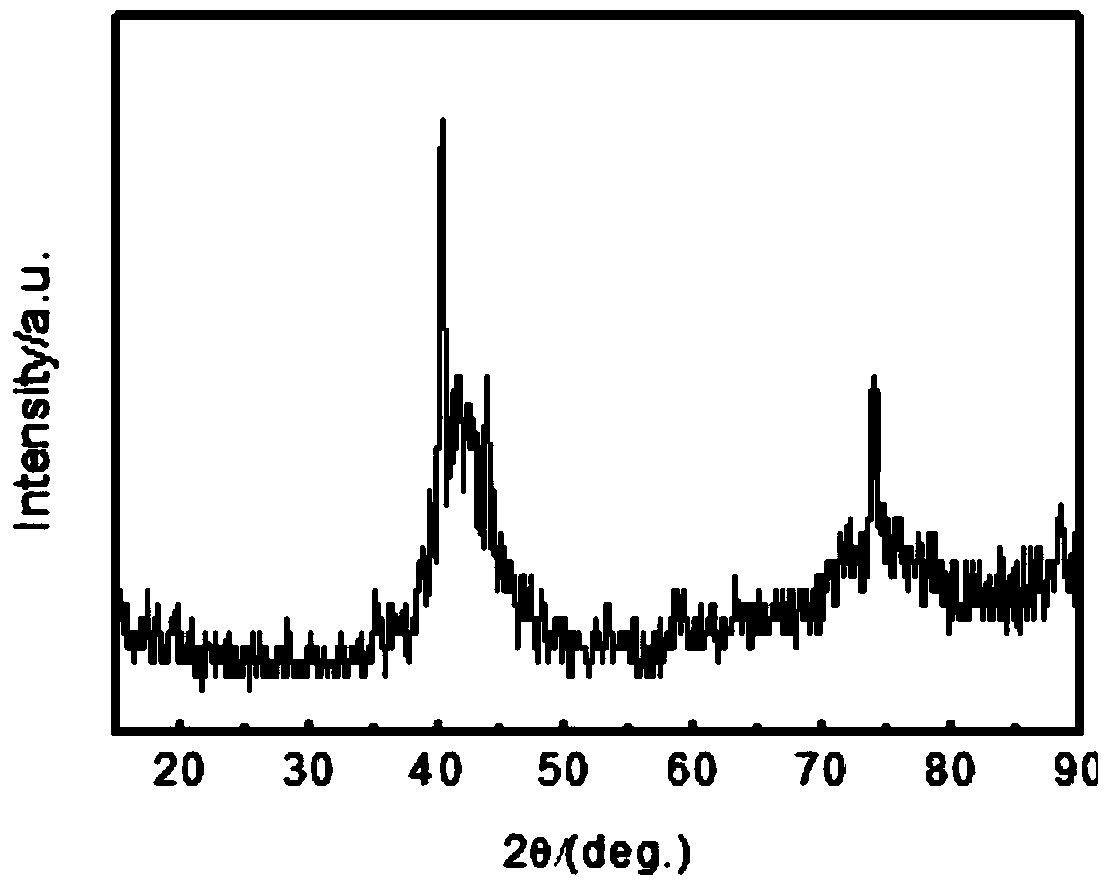

Preparation method of corrosion-resistant and wear-resistant molybdenum-based amorphous coating for boiler tube bundle

InactiveCN104313532AExtended service lifeImprove corrosion resistanceMolten spray coatingWear resistantAlloy

The invention discloses a preparation method of a corrosion-resistant and wear-resistant molybdenum-based amorphous coating for a boiler tube bundle. The method comprises the following steps: firstly, preparing molybdenum-based amorphous alloy powder by adopting an aerosol method, wherein the molybdenum-based amorphous alloy powder is formed by mixing the following raw materials in percentage by mass: 7.0-11.0% of Fe, 11.0-20.0% of Cr, 1.0-10.0% of Ni, 6.0-9.0% of Si, 0.5-2.0% of Al, 2.6-8.0% of C, 0.5-5.5% of W, 0-2% of Y and the balance of Mo and unavoidable impurities; secondly, preparing and obtaining the corrosion-resistant and wear-resistant molybdenum-based amorphous coating on the surface of the boiler tube bundle by adopting a plasma spraying technology. The molybdenum-based amorphous coating prepared by the invention has excellent corrosion resistance, wear resistance and high-temperature stability, and can protect the heat erosion surface of the boiler tube bundle better in an environment with the combined effect of heat corrosion and erosion, so that the service life of the boiler tube bundle is effectively prolonged.

Owner:CHANGAN UNIV

Machining method for hollow body metal part

The invention relates to the technical field of metal part machining, in particular to a machining method for a hollow body metal part. The machining method comprises the steps that a, according to a drawing of a to-be-machined part, the part is divided into a plurality of sub parts, and drawings of all the sub parts are drawn; b, according to the drawings of all the sub parts, corresponding molds are manufactured; c, metal powder and a binder are evenly mixed and then are prepared into feeding particles; d, the feeding particles are injected into all the molds through an injection molding machine to from corresponding sub part blanks; e, all the sub part blanks are welded together, so that a part blank is constituted; and f, the part blank is placed in a sintering furnace to be subjected to degreasing sintering, and after sintering is completed, a finished product is obtained. According to the machining method for the hollow body metal part, the quality of a manufactured product is good, and the pass percent is high.

Owner:江苏理成科技有限公司

Method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy through reciprocation extrusion

ActiveCN107774732AReduce defectsNo ruptureExtrusion containersExtrusion control devicesUltimate tensile strengthThermal treatment

The invention discloses a method for preparing a nano quasi-crystal reinforced Mg-Zn-Y alloy through reciprocation extrusion. The method comprises the following steps: A, preparing cast Mg-Zn-Y alloyaccording to atom percentages of set component elements as follows: 0.5-6% of Zn, 0.08-1.2% of Y and the balance of Mg, and the content ratio of atoms of Zn and Y is (5-7):1; B, annealing the cast Mg-Zn-Y alloy for 8-20 hours at 380-420 DEG C, and performing furnace cooling; C, keeping the temperature of the annealed Mg-Zn-Y alloy at 300-400 DEG C for 2-4 hours, and performing thermal extrusion, wherein the extrusion temperature is 300-400 DEG C, and the extrusion ratio is (9-60):1; D, putting the Mg-Zn-Y alloy after thermal extrusion processing in the step C into a thermal treatment furnace,heating to 540-600 DEG C, keeping the temperature for 5-20 minutes, and performing quenching; and E, keeping the temperature of the Mg-Zn-Y alloy obtained in the step D at 200-380 DEG C for 2-4 hours,and performing reciprocation extrusion, thereby obtaining the alloy. By adopting the method, a magnesium alloy which is excellent in yield strength, tension strength and ductility can be prepared.

Owner:SOUTHWEST JIAOTONG UNIV

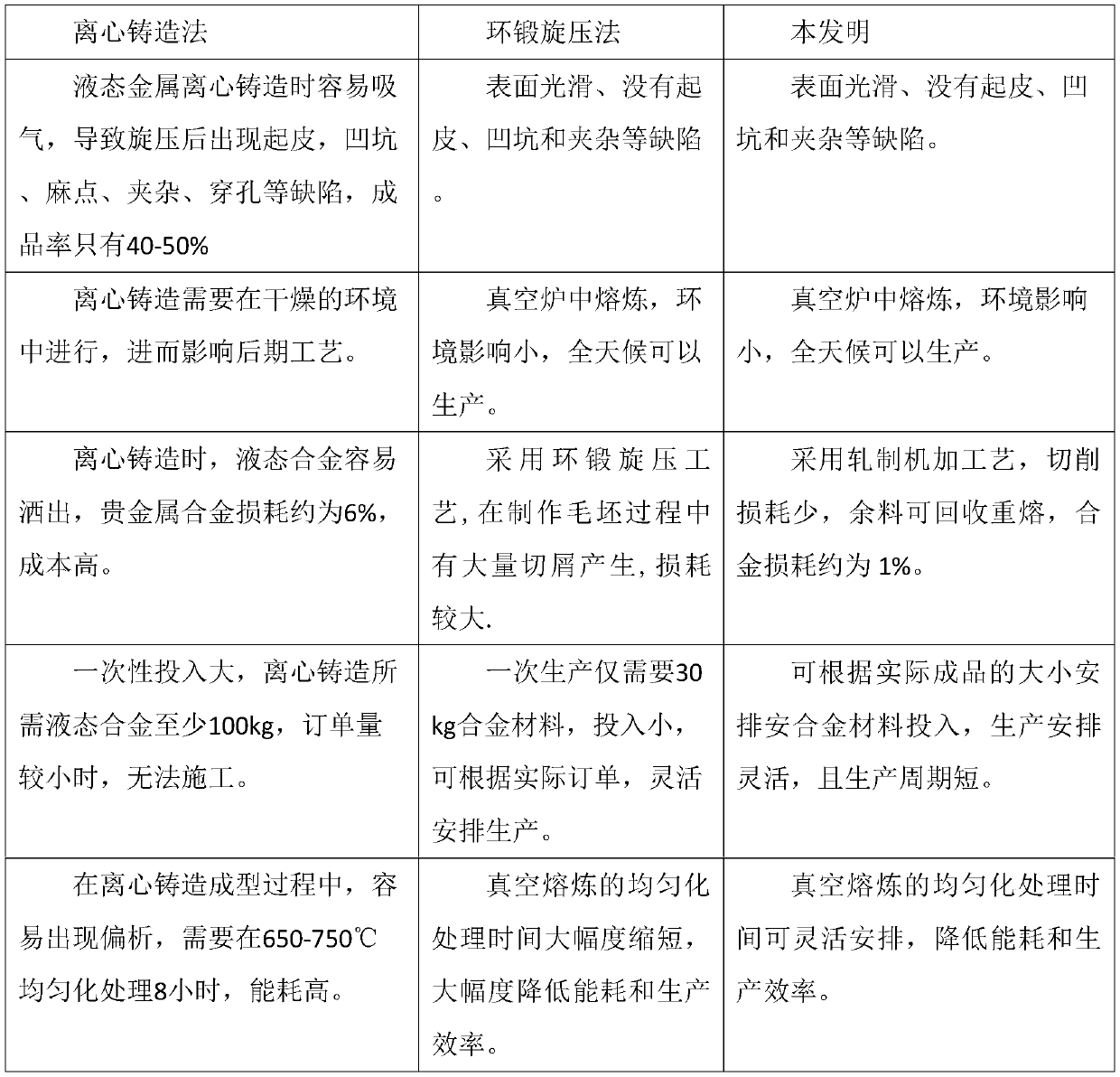

Preparation method of high-hardness silver-copper-nickel alloy conductive ring

InactiveCN111069497AHigh hardnessIncrease productivityMetal rolling arrangementsWire cuttingNickel alloy

The invention discloses a preparation method of a high-hardness silver-copper-nickel alloy conductive ring and belongs to the technical field of preparation of conductive slip rings. The preparation method of the high-hardness silver-copper-nickel alloy conductive ring comprises the following steps: (1) smelting a silver-copper-nickel alloy into an ingot, and carrying out homogenization heat treatment, forging and rolling to form an alloy plate blank; and (2) performing heat treatment and wire cutting on the alloy plate blank obtained in the step (1) to obtain the silver-copper-nickel alloy conductive ring. The high-hardness silver-copper alloy conductive ring prepared by the method does not have the phenomena of inclusions, pits, perforations, defects and the like, is uniform in texture and good in performance.

Owner:GRIKIN ADVANCED MATERIALS

Nickel oxide high-temperature purple silk-gloss ceramic glaze and preparation method thereof

The invention provides nickel oxide high-temperature purple silk-gloss ceramic glaze and a preparation method thereof, and belongs to the field of ceramic. The nickel oxide high-temperature purple silk-gloss ceramic glaze is obtained by firstly preparing a nickel oxide high-temperature purple silk-gloss ceramic glaze material, and then glazing and sintering at high temperature, wherein the nickeloxide high-temperature purple silk-gloss ceramic glaze material is prepared from the following raw materials according to the mass percent of each raw material: 45 percent to 35 percent of potassium feldspar powder, 4.5 percent to 6 percent of silicon dioxide, 4.5 percent to 10 percent of kaolin, 10 percent to 20 percent of zinc oxide, 30 percent to 40 percent of a frit and 1 percent to 2 percentof nickel oxide. The frit is prepared from the following raw materials according to the mass percent of each raw material: 1 percent to 3 percent of potassium oxide, 12 percent to 20 percent of sodiumoxide, 2 percent to 8 percent of calcium oxide, 10 percent to 35 percent of barium carbonate and 40 percent to 60 percent of silicon dioxide. By adopting the method provided by the invention, a phenomenon in a firing process of a traditional glaze material that a lot of poisonous heavy metal is volatilized is overcome; meanwhile, phenomena that needle holes and cracks are formed in the surface ofa fired product are effectively prevented.

Owner:SHENYANG JIANZHU UNIVERSITY

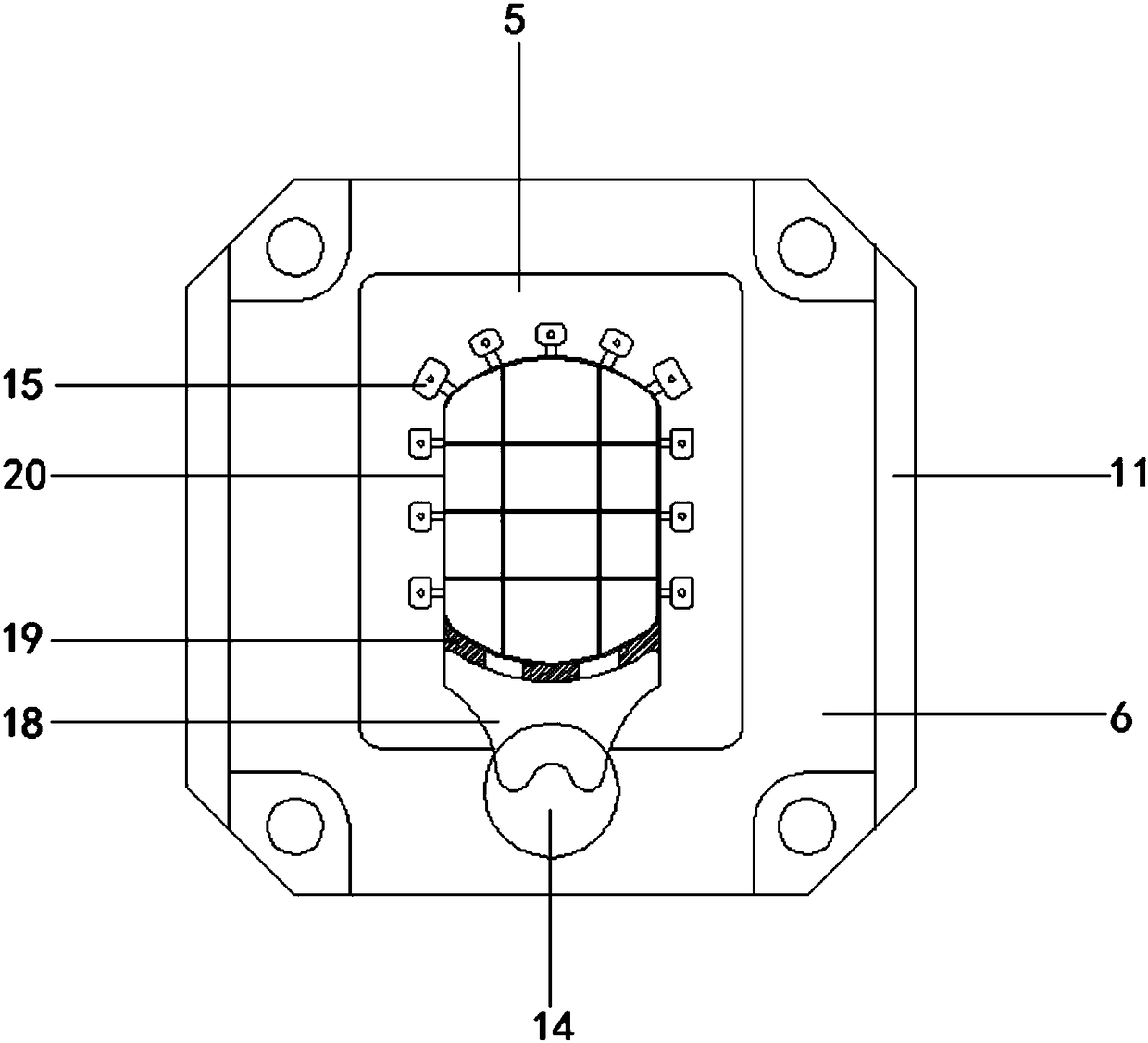

Air-flotation ultra-precision grinding device and grinding method thereof

InactiveCN103286673AEfficient grindingNo deep cutsLapping machinesLapping toolsEngineeringAir cavity

The invention discloses an air-flotation ultra-precision grinding device and a grinding method thereof. The air-flotation ultra-precision grinding device comprises a disc, tool bars, diamond pellets, and an air cavity. The disc is in a circular structure. The disc is provided with a plurality of layers of circularly arranged cavity holes centered on the circle center of the disc, and the air cavity, wherein the cavity holes are used for fitting the tool bars equal in diameter and the air cavity is used for communicating compressed air. The tool bars are arranged in the cavity holes. The diamond pellets equal in diameter are bonded to the front ends of the tool bars. The tail end of each tool bar is mounted in the cavity hole and communicated with the air cavity to form a piston end, the piston ends of the tool bars are communicated through the air cavity, and the diamond pellets can float up and down in the cavity holes of the tool bars. The diamond pellets on an air-floating pellet grinder can float up and down in a micro form so that constant pressure machining is achieved, and ultra-deep cut marks and cracks are avoided.

Owner:ZHEJIANG UNIV OF TECH

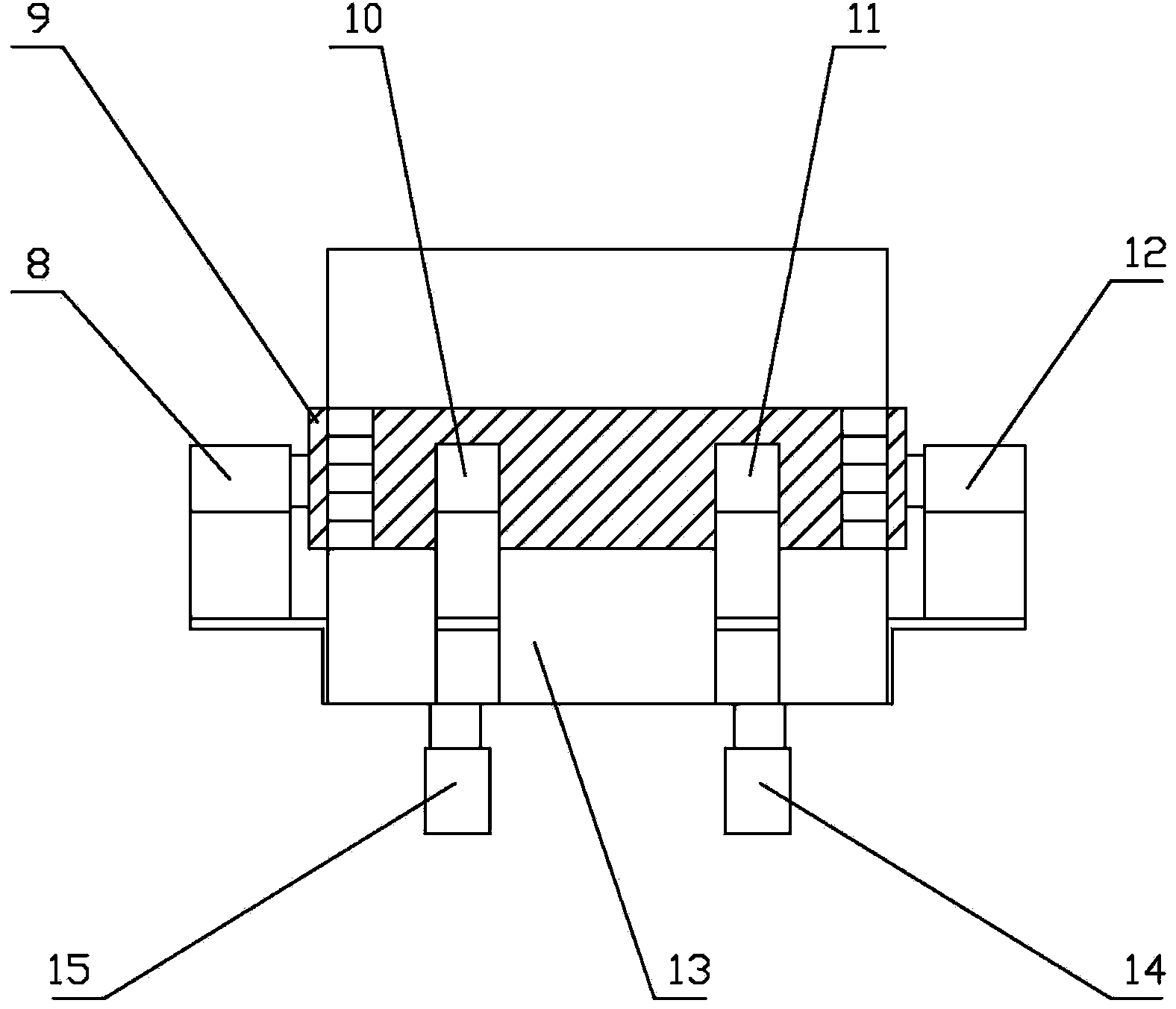

Multipurpose waveband pressure wave device for metal honeycomb carrier

InactiveCN102744308AMeet the requirements of different pressure wave heightsReasonable structural designFixed frameHoneycomb

The invention discloses a multipurpose waveband pressure wave device for a metal honeycomb carrier. The multipurpose waveband pressure wave device comprises a left fixing frame and a right fixing frame, an upper guide rod and a lower guide rod are respectively arranged between the left fixing frame and the right fixing frame, a sliding plate is slidably matched between the upper guide rod and the lower guide rod, fixing plates are respectively fixedly installed between the sliding plate and the left fixing frame and between the sliding plate and the right fixing frame, a driving pressure wave rolling wheel and a driven pressure wave rolling wheel which are corresponding are rotatably installed on the fixing plate on the left side and the sliding plate respectively, the driving pressure wave rolling wheel is driven by a motor to rotate, the driven pressure wave rolling wheel is driven by the motor and a screw rod to move, and a screw rod nut is installed on the screw rod in a matched mode and fixedly connected with the outer side of the sliding plate. The multipurpose waveband pressure wave device is reasonable in structure design and meets the requirements of an identical corrugated belt for different pressure wave heights, cracking or deformation and the like cannot occur in shrunk edges of an initial section and a terminate section in pressing simultaneously, product quality is guaranteed, and waste material quantity is reduced.

Owner:浙江欧信环保科技有限公司

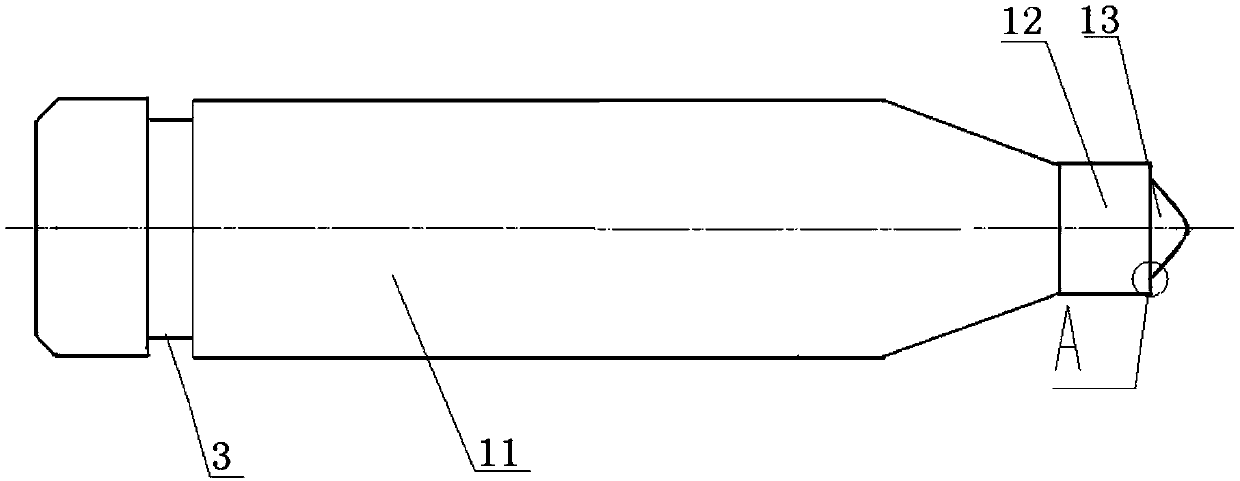

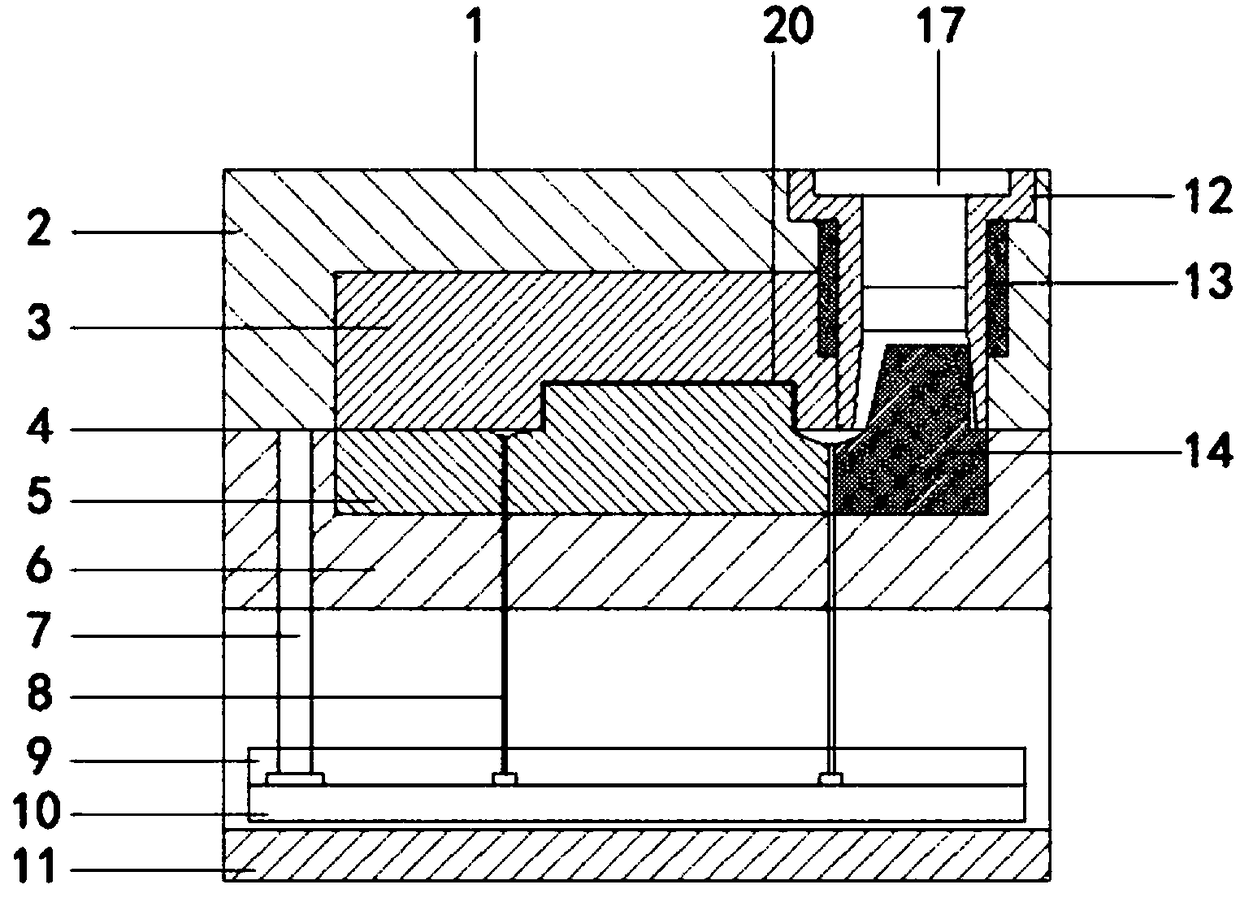

Spin riveting puncher pin

The invention relates to a spin riveting puncher pin. One end is provided with a connecting handle, and the other end is provided with a spin riveting head. The spin riveting head is composed of an equal-diameter section and an ejection head, one end of the equal-diameter section is joined with the end face of a transition section, and the ejection head protruding in the axial direction is arranged in the center of the end face of the other end. The axial length of the outer edge of the end face, provided with the ejection head, of the equal-diameter section is larger than the axial length ofthe root part of the ejection head of the end face, and a slope is formed from the root part of the ejection head to the edge. The slope is an axial extrusion face of the spin riveting puncher pin. The spin riveting puncher pin is suitable for being used in a swing exhibition rivet method, key effects on the machining quality of parts and durability of the puncher pin are achieved, the riveted parts are good in consistency, and the machining efficiency and the yield are greatly improved.

Owner:XIAN AVIATION BRAKE TECH

Pressure casting die

The invention provides a pressure casting die which comprises a die body, a fixed die fixing plate, a fixed die insert, a die joint, a movable die insert and a movable die fixing plate. According to the external physical characteristic, the die body is in a cuboid shape, the fixed die fixing plate is arranged at the top end of the die body, the fixed die insert is arranged inside the fixed die fixing plate, and the fixed die insert is connected with the fixed die fixing plate through a bolt manner; the movable die fixing plate is arranged below the fixed die fixing plate, and the movable die fixing plate and the fixed die fixing plate are connected through a guide column and a guide sleeve. The pressure casting die is improved, the advantages that structure design is reasonable, side pouring gate feeding is reasonably carried out for pouring a pressure casting, the size accuracy of the pressure casting is high, the surface is smooth and bright, and technological defects such as deformation, cracks, flash and the like which influence the appearance and the product performance are avoided are achieved, and the problems and shortcomings provided in the background technology are solved.

Owner:湖北昊昌汽车零部件制造有限公司

Multifunctional casting moulding sand and manufacture method thereof

InactiveCN106111883AImprove breathabilityReduce air permeabilityFoundry mouldsFoundry coresDry mixingGranularity

The invention discloses multifunctional casting moulding sand, which is prepared from the following raw materials in parts by weight: quartz sand, limestone sand, clay, bentonite, zircon sand, attapulgite, corn powder, straw powder and water. The moulding sand is prepared from the following steps: uniformly dry-mixing the raw materials in the above parts by weight except for water, uniformly mixing the obtained dry mixed material with the water in above parts by weight, and storing for standby after placing statically. By strictly controlling the quartz sand, due to the granularity of the zircon sand, the surface of a casting is smooth, the breathability is good, good binding property is realized after the bentonite and clay are matched for use, and the cost is reduced; the regenerable low-cost crop corn powder is taken as a binder, the cost is low and resource is saved; the moulding sand of the present invention contains no coal powder, generates no pollutional waste gas and no toxic and pollutional harmful gas in the casting process, and is environment-friendly.

Owner:娄土岭

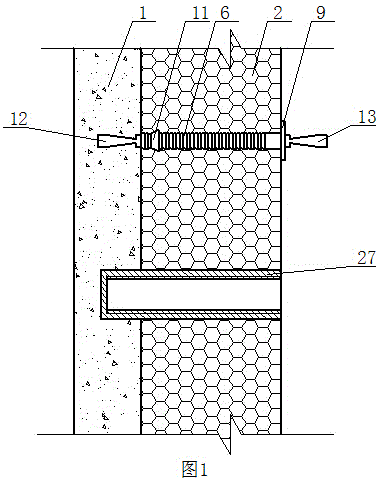

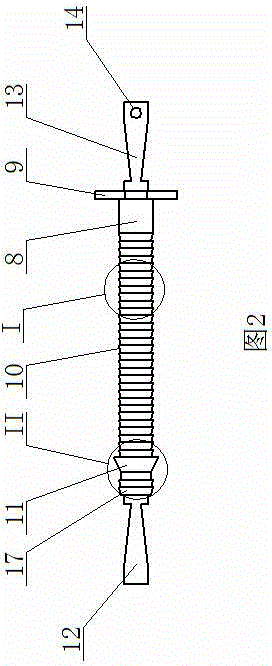

On-site construction method for sandwich composite wall

InactiveCN104060715AImprove insulation effectEasy constructionWallsBuilding material handlingProduction lineThreaded rod

The invention provides an on-site construction method for a sandwich composite wall. The on-site construction method for the sandwich composite wall comprises the following steps: (1) manufacturing a concrete external wall on an industrialized production line; compounding an insulating layer on the external wall; embedding a first casing pipe in the external wall body and the insulating layer; enabling a non-metallic connecting rod to penetrate the insulating layer, enabling a first anchoring body on the connecting rod to be placed in the external wall, and enabling a second anchoring body on the connecting rod to be located at the outer side of the insulating layer to form a two-layer composite wall; (2) transporting the two-layer composite wall to a construction site; arranging a template at the outer side of the insulating layer in the two-layer composite wall, and arranging a second casing pipe between the port of the first casing pipe and the template to form a cavity between the insulating layer and the template; (3) pouring concrete in the cavity for maintenance to form an internal wall; (4) removing a threaded rod and the template, and then, filling and leveling up the cavities of the casing pipes with the concrete to form the sandwich composite wall after the maintenance. According to the on-site construction method provided by the invention, compounding of the external wall and the insulating layer is finished during industrialized production, and pouring of the internal wall is finished at the construction site, so that the defects of the prior art are solved.

Owner:山东万斯达建筑工业化研究院有限公司

New process for producing heating tube for washing machine

InactiveCN104057248AModerate densitySimple processOther washing machinesTextiles and paperVolumetric Mass DensityPulp and paper industry

The invention relates to the technical field of washing machine heating tube production, and discloses a new process for producing a heating tube for a washing machine. The new process comprises the following steps: (1) filling a tube, (2) filling powder, (3) contracting the tube, (4) sealing the tube, and (5) performing oil pressurizing. The new process for producing the heating tube for the washing machine is simple, few in production procedures, low in cost, and less in sizing reduction, the density of insulating medium magnesium oxide filled inside is moderate, obvious wrinkle and crack phenomena in direct formation can be avoided, the processing quality of the product is ensured, the consistency of the product appearance is better, and the reliability of the product quality is greatly improved.

Owner:ANHUI NINGGUO CITY TIANCHENG TECH DEV

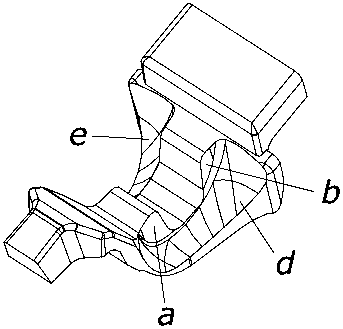

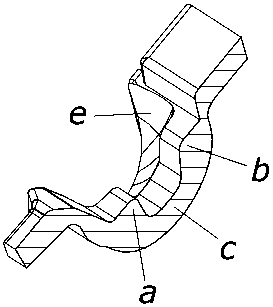

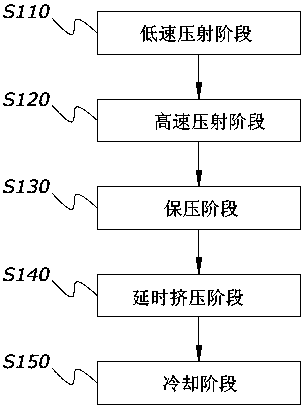

Seven-series aluminum alloy small piece and die casting method thereof

ActiveCN109877289AHigh strengthDense core tissueFurnace typesHeat treatment furnacesDie castingThick wall

The invention discloses a seven-series aluminum alloy small piece and a die casting method thereof. The die casting method of the seven-series aluminum alloy small piece is used on a horizontal cold chamber die casting machine and sequentially comprises the steps of a low-speed injection stage, a high-speed injection stage, a pressure maintaining stage when an injection punch stops, a delay extrusion stage for extruding an extrusion package in a die and a cooling stage with continuous dwell pressure; the extrusion pressure of the delay extrusion stage is 130-150 bar, and the extrusion time is2.5-3s, and the delay extrusion stage is delayed by 0.05s compared with the pressure maintaining stage; as the extrusion package of the forming die adopts a delay extrusion method, no filler is neededduring pressure maintaining, and the filler which is not completely solidified in a cavity is extruded in volume through the extrusion package of the die, so that the core structure of the aluminum alloy small piece is denser, the die casted aluminum alloy small piece avoids the situation that structural looseness occurs at the core part position with thicker wall thickness, and defects such as local cracks, cracks, pore expansion, voids and shrinkage cannot occur after the later heat treatment; and the heat-treated aluminum alloy small piece is indeed much higher in strength than materials using traditional die casting materials.

Owner:CHITWING DONGGUAN TECH

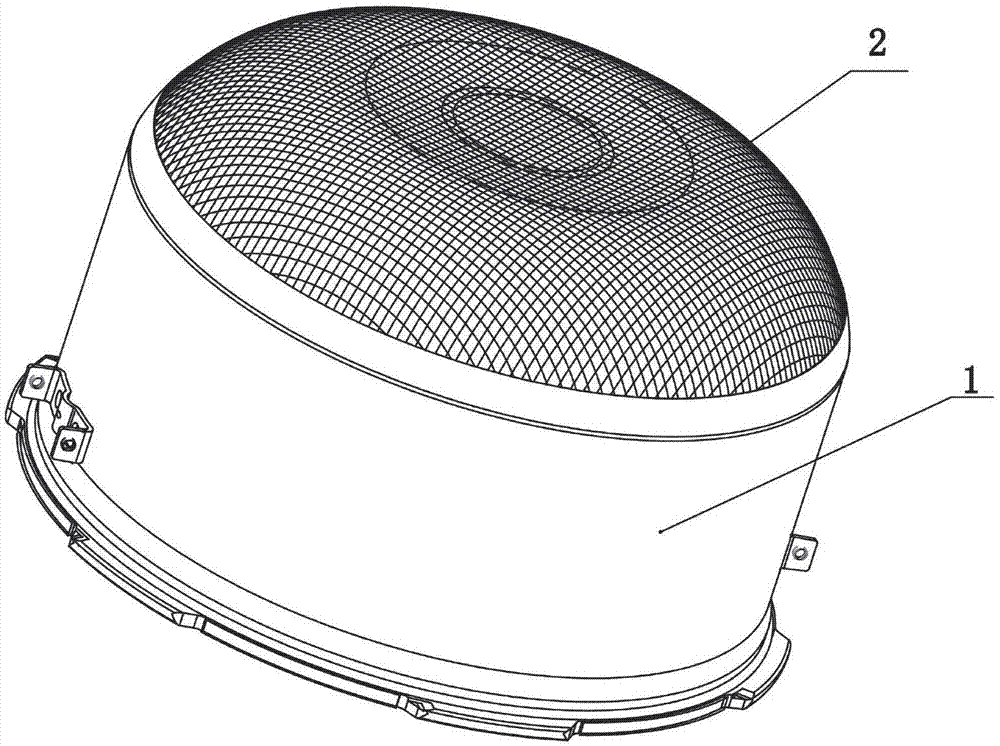

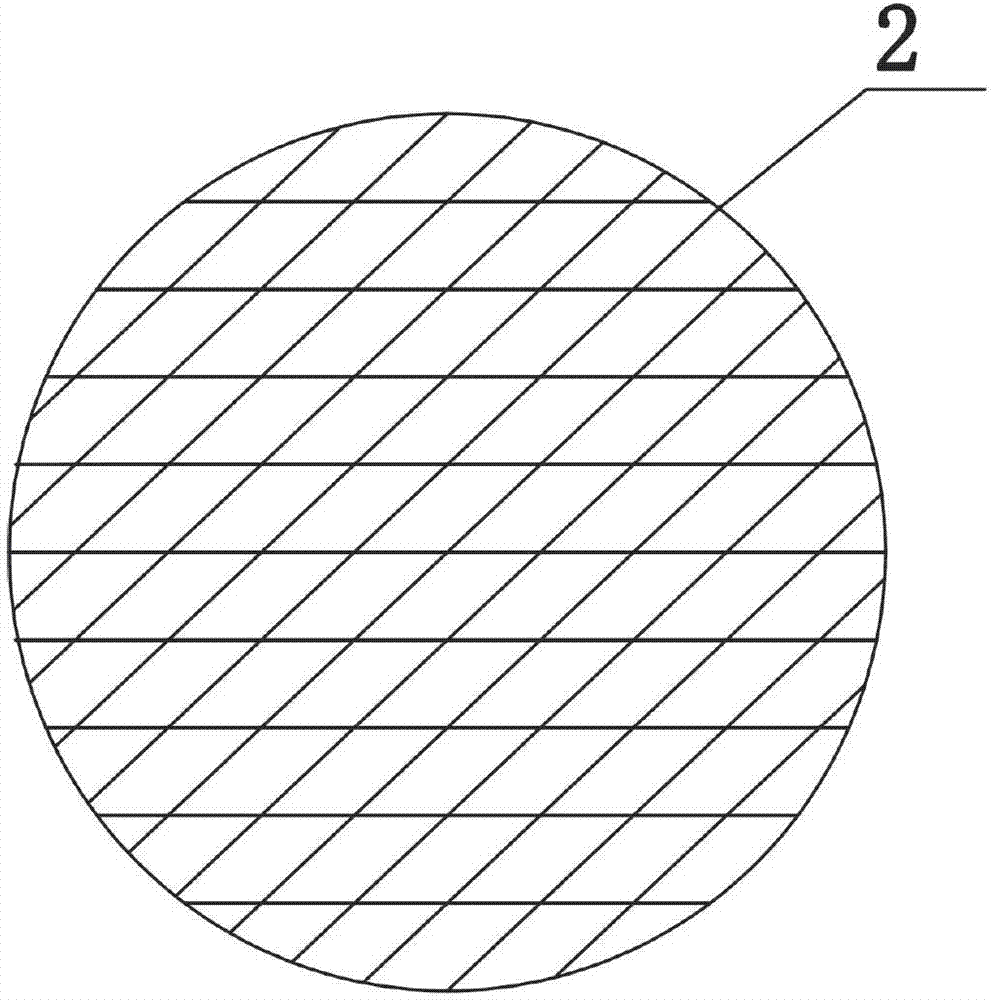

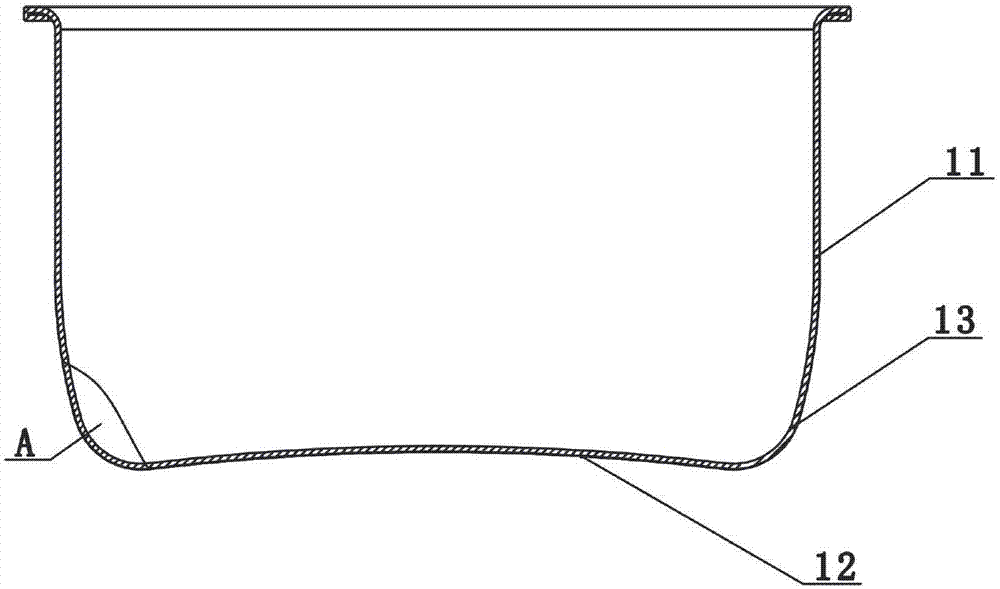

Electromagnetic heating cookware and three-dimensionally heated electromagnetic cooking appliance

ActiveCN102920310AFirmly connectedNo cracksCooking-vessel materialsPressure-cookersEngineeringElectromagnetic heating

The invention relates to an electromagnetic heating cookware and a three-dimensionally heated electromagnetic cooking appliance. The electromagnetic heating cookware is formed by stretching aluminum plates and is a cylindrical cookware with a bottom. The cookware comprises a pot body, a pot bottom, a transition part and a magnetic conduction heating element which is embedded into the outer side of the transition part, wherein the transition part is connected with the pot body and the pot base; the transition part is arc; the heat conduction heating element is a metal stretching net with a high extending property; the metal stretching net is compressed and connected to the corresponding part of the aluminum plate in advance and is stretched and formed into a cookware together with the aluminum plate. The three-dimensionally heated electromagnetic cooking appliance comprises a shell, the cookware and an electromagnetic wire coil for inducing the cookware to be heated three-dimensionally; the cookware is the cookware for electromagnetic heating; and the electromagnetic cooking appliance is an electric cooker, or an electric pressure cooker or an electric stewpan.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com