Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Physically good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of recycled foam material using granite powder as raw material

InactiveCN102786316ANo chemical pollutionFully digestedSolid waste disposalCeramicwareThermal insulationGranolithic

The invention discloses a manufacturing method of a recycled foam material using granite powder as a raw material. The recycled foam material comprises the following formula and components: 70%-90% of granite powder, 6%-25% of flux filler, 1%-5% of pore-forming material, and 1%-5% of polymerization martial. The manufacturing method sequentially comprises the following steps of: controlling the fineness of the particles of the powder to be over 100 meshes; uniformly stirring and mixing; pressing mixture into a required granular material; stacking and forming the granular material; feeding into a high temperature furnace to heat; and finally cooling and taking out to obtain the recycled foam material finished product. A product produced by the manufacturing method has the advantages of fully consuming granite powder waste material, solving the problem of serious environmental pollution existing at a granite processing base for a long time and meeting environmental protection requirements, along with stable physical performance, light weight, thermal insulation, compression resistance, bending resistance, capabilities of being used for building wall or external wall decoration and fulfilling the aims of weight reduction and energy conservation of a building, fire prevention, water prevention and sound isolation performance and capability of being used as a fire-proof material and a wall isolating material.

Owner:宁波振强科技有限公司

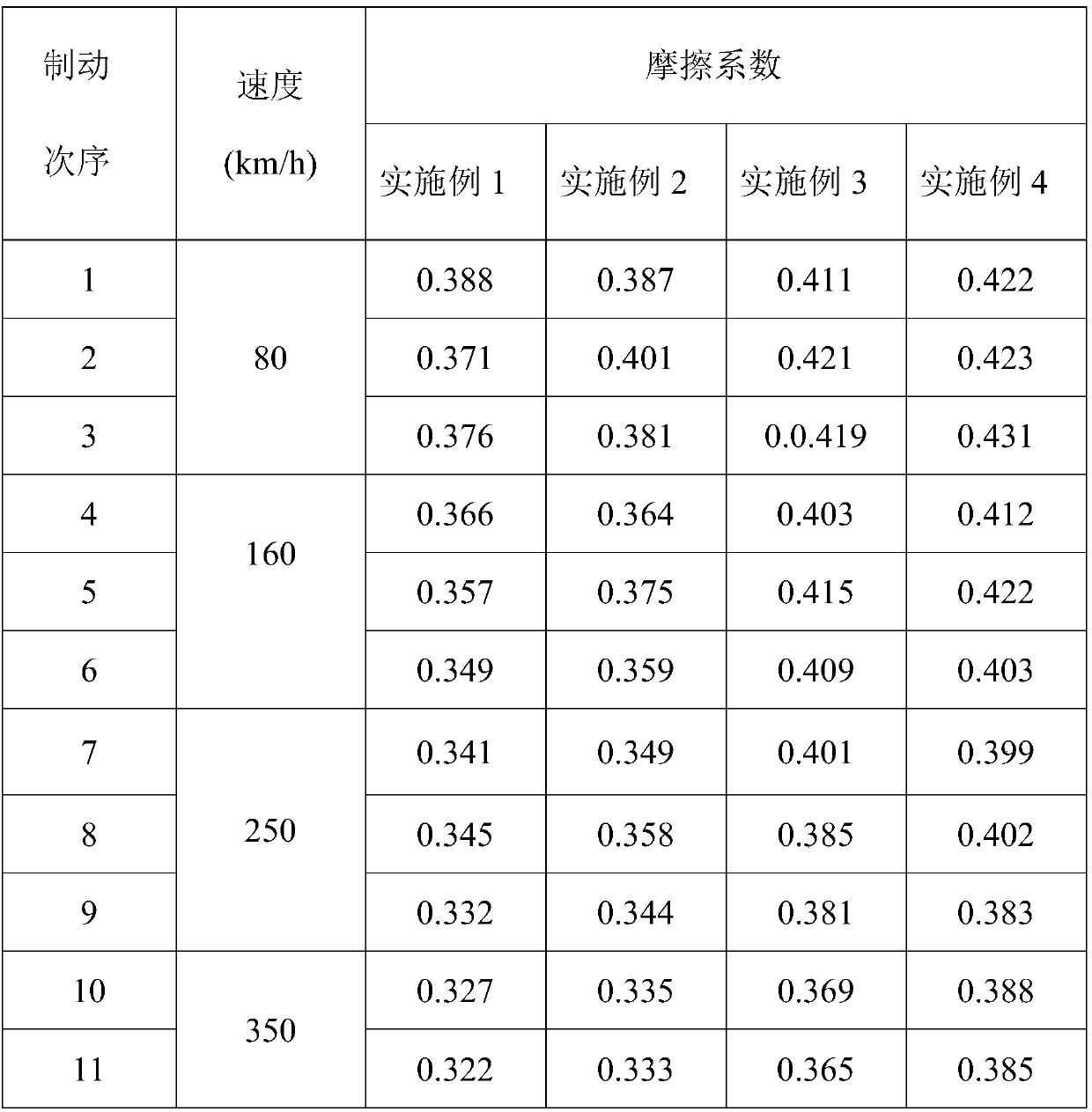

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

Acrylate rubber sizing material for high performance requirements

The invention relates to sizing material used for the acrylic acid ester rubber with high performance requirement. The acrylic acid ester rubber of active chlorine introduced from epoxy gene is chosen, and trimerization thiocyanic acid TCY is adopted as a vulcanizing system; the invention comprises concrete ingredients as follows: 100 parts of AR5160, 60-90 parts of carbon black N330, 1.0-2.0 parts of stearic acid, 8-14 parts of plasticizer, 2.0-2.5 parts of WB-212, 0.1-0.3 part of anti-scorching agent E / C, 2.0-3.0 parts of antioxidant, 1.0-1.5 parts of curing agent TYC, and 1.5-2.5 parts of accelerator BZ; glass with Mooney viscosity of ML1+4 50 is adopted to be vulcanized and transformed into -25 DEG C acrylic acid ester rubber for matching, so as to ensure that the brittleness intensity reaches above -45 DEG C. The sizing material of the acrylic acid ester rubber with high performance requirement is obtained. The sizing material has the advantages that the comprehensive physical property is good, and simultaneously the brittleness temperature is lower. The invention meets the requirement of the vehicle industry to the sealing material, and the technical level achieves the domestic advanced level. The invention is suitable for the ranges of vehicle engine, crank oil seal, gear shifting box oil seal, and heat resistant, oil proof and cold resistant rubber hose, and protecting sleeve, etc.

Owner:天津海程工贸有限公司

Formulation of military sole

The invention relates to a formulation of a sole, in particular to formulation of a military sole, comprising the formulations for forming an outer bottom and a middle layer of the sole, wherein the formulation of the outer bottom based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.7-0.9 part of vulcanizing agent S-80, 2.4-2.6 parts of accelerating agent, 1.9-2.1 parts of magnesium oxide, 4.5-5.5 parts of zinc oxide, 4.5-5.5 parts of antimony oxide, 1.9-2.1 parts of stearic acid, 1.9-2.1 parts of zinc stearate, 20-24 parts of high wear resistance carbon black, 2-4 parts of engine oil 46#, 6-8 parts of dibutyl ester, 1.4-1.6 parts of anti-aging agent, 0.8-1.2 parts of paraffin wax and the like; and the formulation of the middle layer based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.9-1.1 parts of sulphur, 2.5-2.7 parts of accelerating agent, 4.5-5.5 parts of zinc oxide, 1.9-2.1 parts of magnesium oxide, 3.8-4 parts of antimony oxide, 6.3-6.7 parts of decabromodiphenyl oxide, 1.9-2.1 parts of stearic acid and the like. The sole prepared by the formulation has good wear resistance and folding resistance, and has the performances of oil resistance, acid-base resistance, inflaming retarding, static electricity prevention and the like, thus meeting the military requirements.

Owner:JIHUA 3513 IND

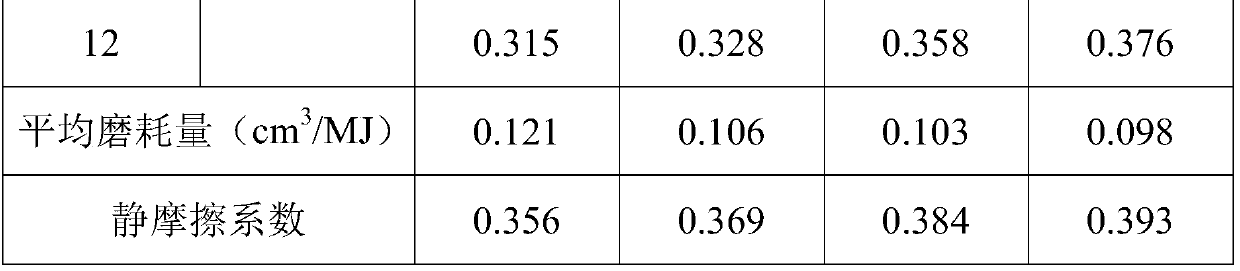

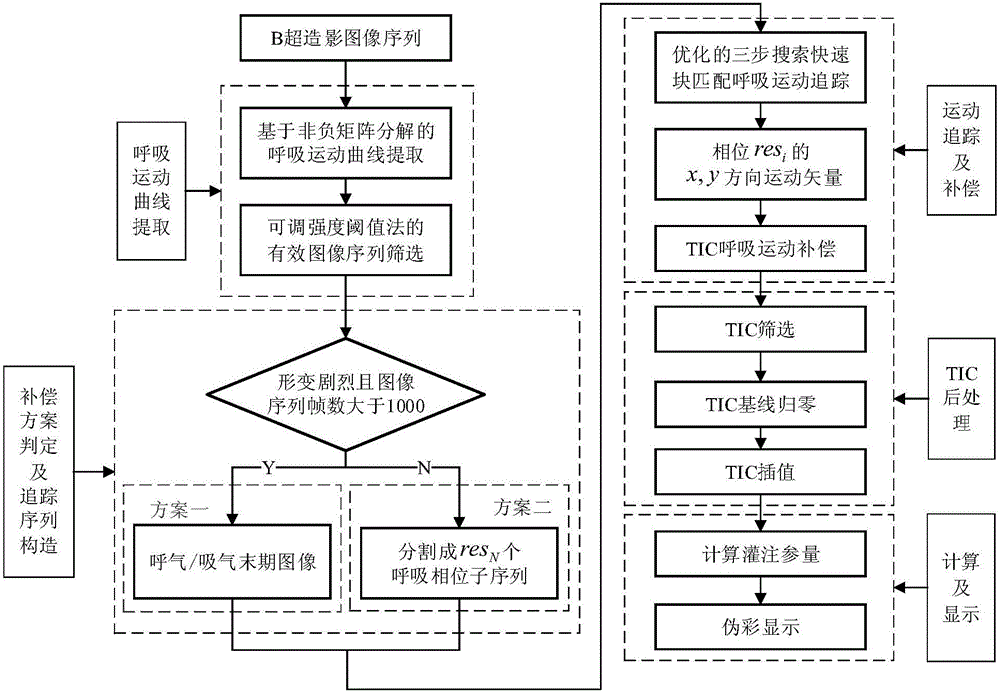

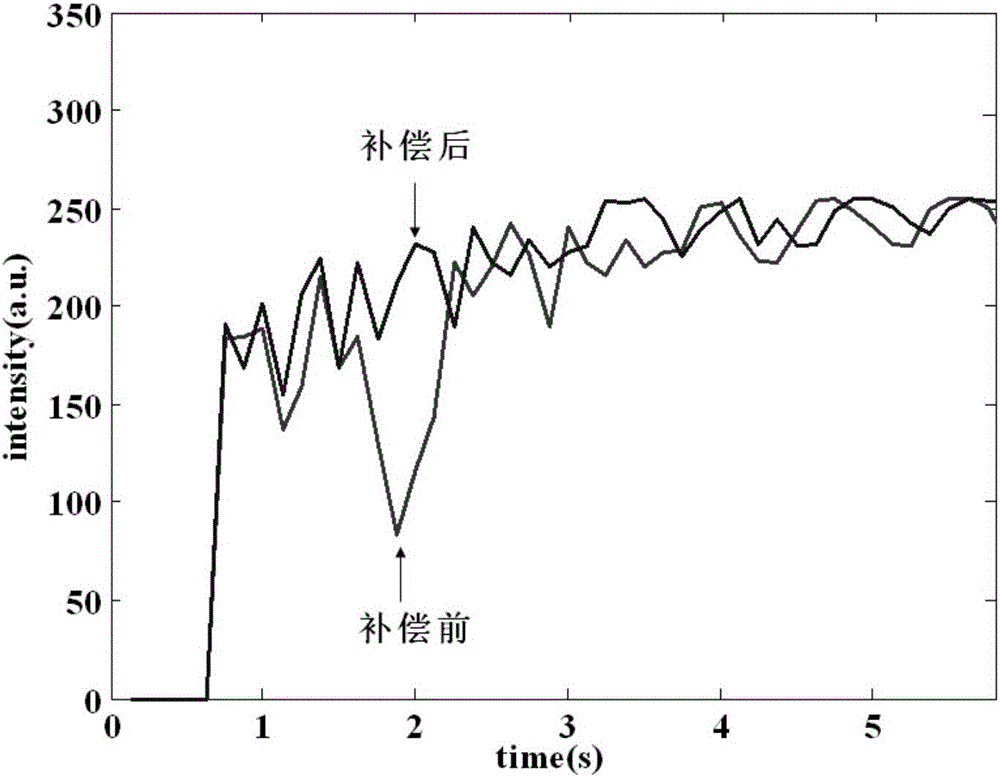

Ultrasound contrast perfusion parameter imaging method based on respiratory motion compensation

ActiveCN106056589AAvoid difficult choicesPhysically goodUltrasonic/sonic/infrasonic diagnosticsImage enhancementMatrix decompositionSonification

The invention provides an ultrasound contrast perfusion parameter imaging method based on respiratory motion compensation. Tracking sequences are built for respiratory phase subsequences at the last stages of exhalation and inhalation by combining a respiratory motion curve obtained through nonnegative matrix decomposition and two respiratory motion compensation schemes based on frame selection and respiratory phase segmentation, block matching respiratory motion displacement vector tracking calculation based on coarse-to-fine three-step search is performed, targeted characteristic compensation is performed on TIC of subsequence images corresponding to all respiratory phases, and finally, a perfusion parameter image after respiratory motion compensation is obtained. Compared with other perfusion parameter motion compensation methods, the method avoids complex manual frame selection and can well adapt to the organs in the abdomen, and the motion curve obtained through nonnegative matrix decomposition has good physiological significance.

Owner:XI AN JIAOTONG UNIV +1

Recycled foam material using granite powder as raw material

InactiveCN102786317ANo chemical pollutionFully digestedWaste processingSolid waste disposalEnvironmental resistancePrill

The invention discloses a recycled foam material using granite powder as a raw material. The formula composition of the recycled foam material comprises the following components in percentage by weight: 70-90 percent of granite powder, 6-25 percent of fluxing filler, 1-5 percent of pore forming material and 1-5 percent of polymeric material. A manufacturing method of the recycled foam material sequentially comprises the following steps of: controlling the fineness of the particles of the powder to be over 100 meshes; uniformly stirring and mixing; pressing mixture into a required granular material; stacking and forming the granular material; feeding into a high temperature furnace to heat; and cooling and taking out to obtain a finished product. The recycled foam material has the advantages of fully consuming granite powder waste material, solving the problem of serious environmental pollution existing at a granite processing base for a long time and meeting environmental protection requirements. The product has the advantages of stable physical performance, light weight, thermal insulation, compression resistance, bending resistance, capabilities of being used for building wall or external wall decoration and fulfilling the aims of weight reduction and energy conservation of a building, fire prevention, water prevention and sound isolation performance and capability of being used as a fire-proof material and a wall isolating material.

Owner:宁波振强科技有限公司

Regenerative foam material taking granite powder as raw material and preparation method of regenerative foam material

The invention discloses a regenerative foam material taking granite powder as a raw material and a preparation method of the regenerative foam material. A formula of the regenerative foam material comprises the following components in parts by weight: 40-69 parts of granite powder, 2-8 parts of fly ash, 6-25 parts of fluxing filler, 1-5 parts of pore forming material, and 1-5 parts of polymeric material. The preparation method of the regenerative foam material sequentially comprises the following steps that grain fineness of the powder is controlled above 100 meshes; the powder is stirred and mixed uniformly; a mixture is pressed to a required granular material; the granular material is sent to a high-temperature furnace for warming, cooled and taken out; and a finished product is obtained. The regenerative foam material and the preparation method have the advantages that granite powder waste can be digested sufficiently; a long-term severe environmental pollution problem of a granite processing base can be solved; and environmental requirements can be met. The regenerative foam material is stable in physical property, light in weight, heat-insulated, compression-resistant and fracture-resistant, and can be used for building wall or external wall decoration; objectives of building weight reduction and energy saving can be achieved; in addition, the regenerative foam material has fireproof, waterproof and soundproof properties, and can be used for fireproof materials and wall partitioning materials.

Owner:宁波振强科技有限公司

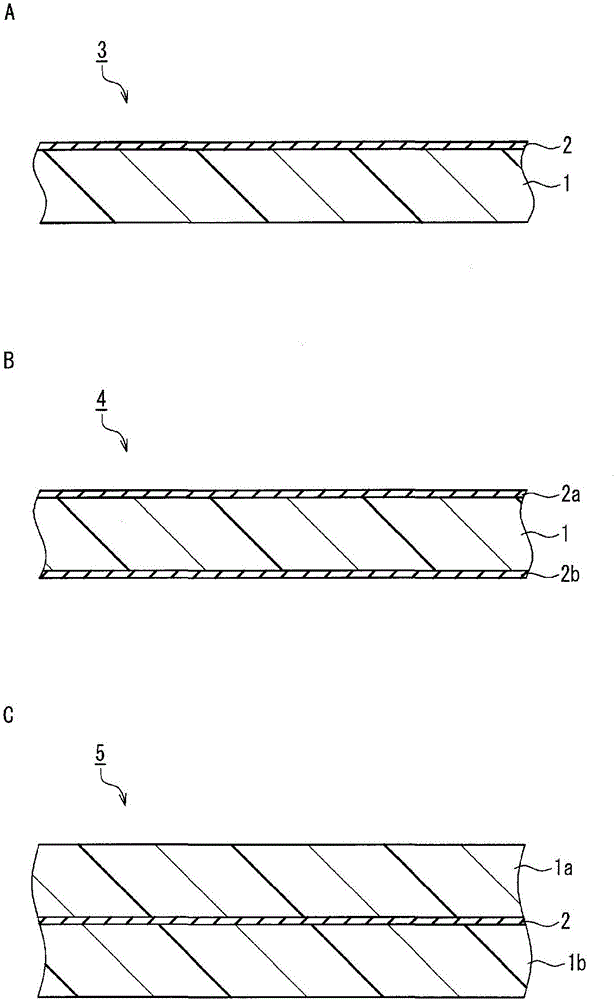

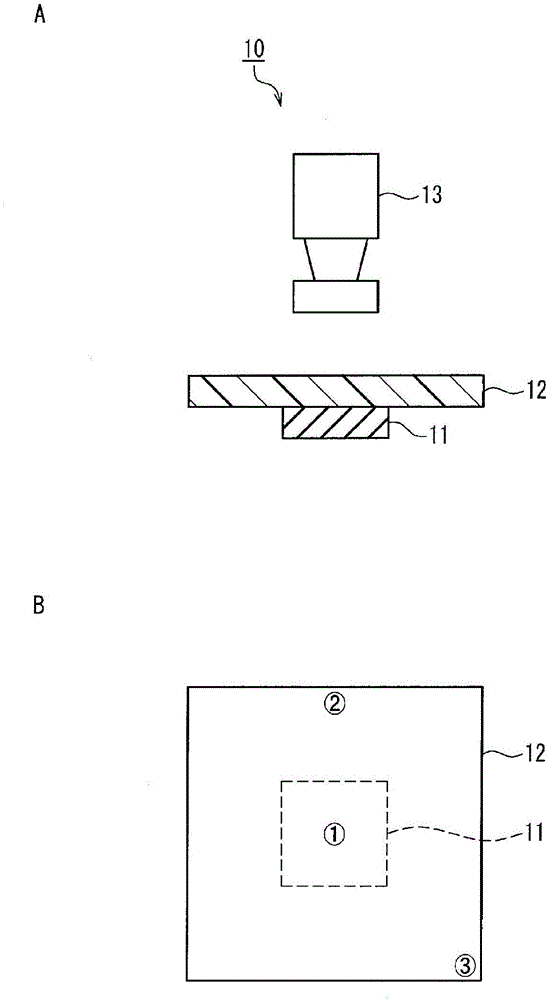

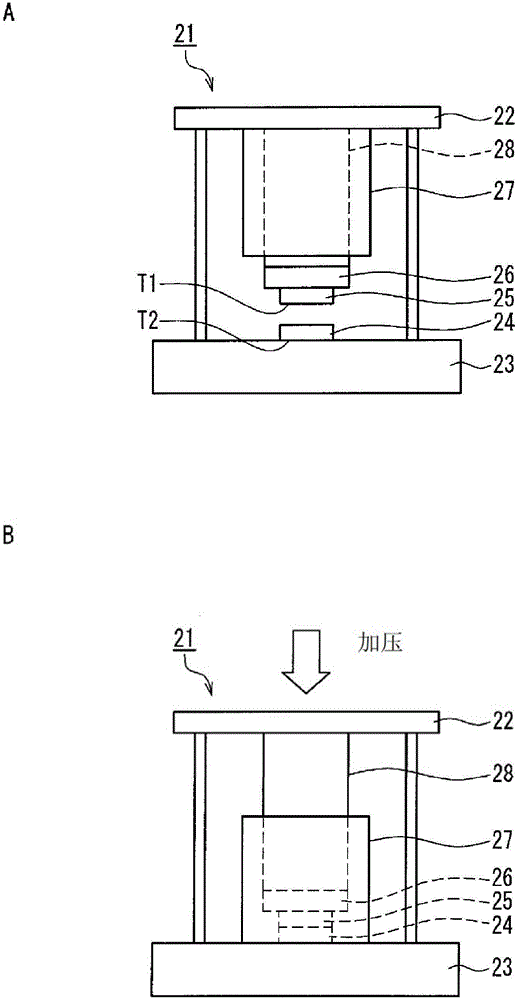

Heat-storage, thermally conductive sheet

InactiveCN106463485AReduce thermal resistanceImprove heat storage capacitySemiconductor/solid-state device detailsSynthetic resin layered productsIn planeInorganic particle

A heat-storage, thermally conductive sheet (3, 4, 5) which comprises a heat-storage sheet (1, 1a, 1b) comprising a matrix resin and heat-storage inorganic particles and a heat-diffusing material (2, 2a, 2b) integrated with the heat-storage sheet, wherein the heat-storage inorganic particles are constituted of a substance that undergoes an electronic phase transition and has a latent heat due to the electronic phase transition of 1 J / cc or greater, the heat-storage inorganic particles are contained in an amount of 10-2,000 parts by mass per 100 parts by mass of the matrix resin, the heat-storage sheet has a thermal conductivity of 0.3 W / mK or greater, and the heat-diffusing material has a thermal conductivity in a plane direction of 20-2,000 W / mK. Due to this, a heat-storage, thermally conductive sheet which is high in heat storage property and thermal conductivity, is physically stable, and has the excellent property of diffusing heat in plane directions is provided.

Owner:FUJI POLYMER INDUSTRIES CO LTD

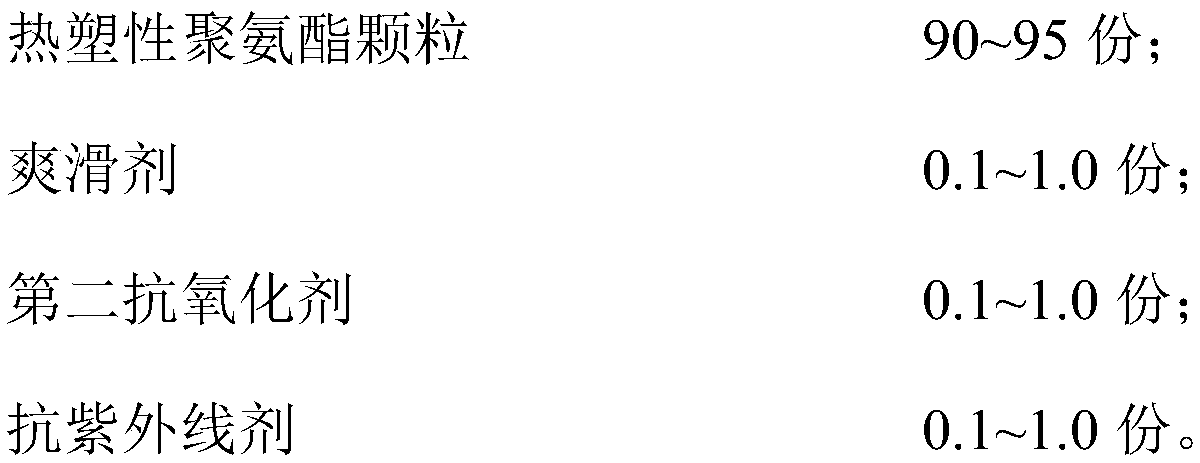

Simulated leather texture polyurethane leather for automobile and preparation method of simulated leather texture polyurethane leather

PendingCN109530190AImprove bond firmnessImprove mechanical propertiesSynthetic resin layered productsLaminationUltimate tensile strengthAntibacterial agent

The invention relates to simulated leather texture polyurethane leather for an automobile. The simulated leather texture polyurethane leather is characterized by comprising a base cloth layer, a hot melt adhesive layer and a skin layer which are successively laminated; and the hot melt adhesive layer comprises a TPU hot melt adhesive layer or an EVA hot melt adhesive layer. According to the simulated leather texture polyurethane leather for the automobile, since a new TPU hot melt adhesive film is adopted, the bonding strength of the simulated leather texture polyurethane leather is greatly improved, and the maximum bonding strength can be 8.0 kg / 25 mm; by using a specific PU film, the specific TPU film and specific base cloth, comprehensive physical performance of the prepared polyurethane leather is excellent, the hand feeling of molded products is greasy and smooth, the leather texture is clear, the hand feeling of the leather is not less than that of genuine leather, and the simulated leather texture polyurethane leather can completely replace PVC artificial leather and the genuine leather; and meanwhile, antibacterial agent compositions are added, and the simulated leather texture polyurethane leather has certain antibacterial effect.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

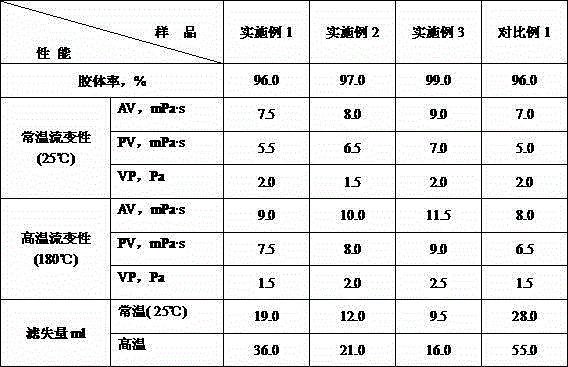

High-performance organic rectorite used for oil-based drilling fluids and a producing method thereof

InactiveCN105524602AComprehensive performance is stableMake up for the lack of cation exchange capacityDrilling compositionCationic exchangeAmmonium

High-performance organic rectorite used for oil-based drilling fluids is disclosed and comprises rectorite and a quaternary ammonium salt. The organic rectorite comprises 65-75 parts by weight of the rectorite and 25-35 parts by weight of the quaternary ammonium salt. A producing method of the organic rectorite includes A) grading the rectorite, or grading and purifying the rectorite, B) performing sodium modification / lithiation pretreatment, C) performing an organification reaction on the quaternary ammonium salt, D) filtering and washing, and E) ageing, drying and smashing. The organic rectorite is advantageous in that the graded and purified rectorite raw material and the quaternary ammonium salt with a long chain are adopted as main components, and the maximum allowed adding amount of the quaternary ammonium salt is greatly increased. By steps of sodium modification / lithiation composite modification pretreatment, high-temperature wet organification, washing, filtration, ageing, drying, smashing, and the like, comprehensive properties of the organic rectorite can be better and stabler, a disadvantage that cation exchange capacity of the rectorite is insufficient is overcome, and characteristics of the organic rectorite such as good colloidality and excellent high-temperature stability are fully exerted.

Owner:WUHAN HUAKUANG COLLOID CHEM CO LTD

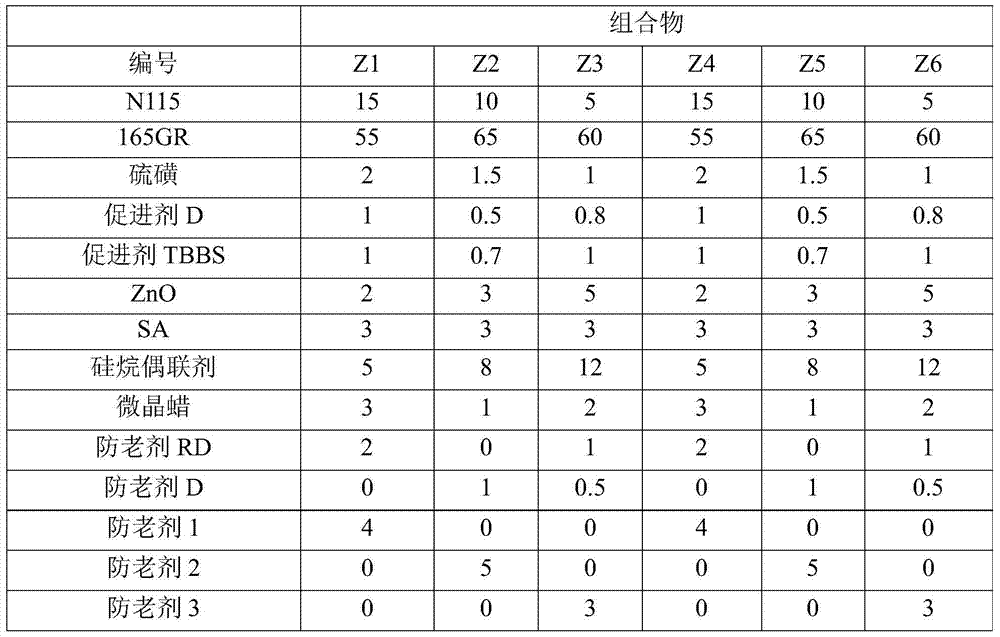

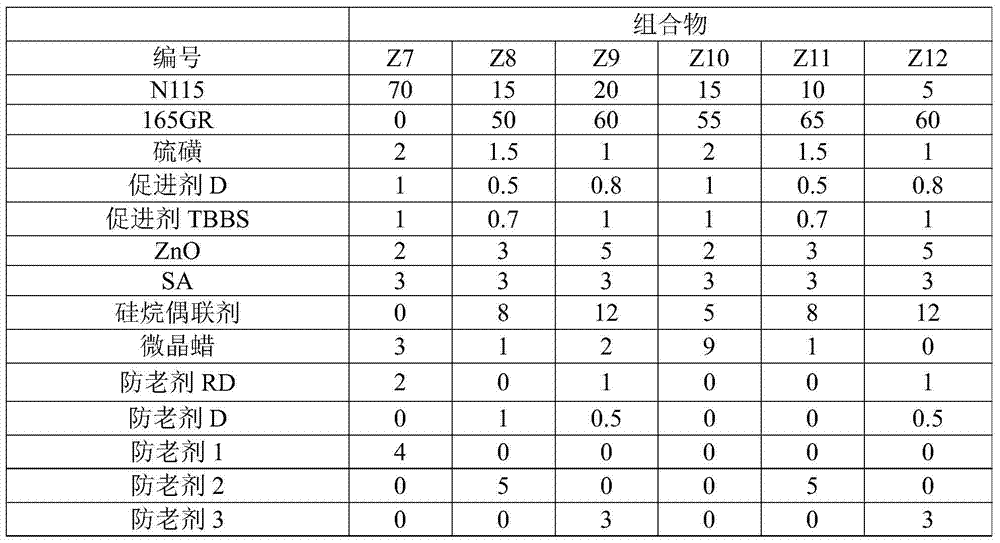

Rubber composition and vulcanized rubber and preparation method and application thereof

ActiveCN107022125AGood resistance to dynamic ozonePhysically goodSpecial tyresRubber materialVulcanization

The invention belongs to the field of rubber material and rubber processing application, the invention relates to a rubber composition, a preparation method of vulcanized rubber, the vulcanized rubber produced by the method and application of the vulcanized rubber in preparation of tires; the rubber composition comprises main body rubber, a reinforcing agent, a vulcanizing agent, a vulcanization accelerator, an activator and an antioxidant, the main body rubber comprises a first polymer and styrene butadiene rubber (SBR), the first polymer is at least one selected from the group consisting of ethylene propylene rubber (EPR), chlorinated butyl rubber (CR), chlorosulfonated polyethylene (CSM) and polyvinyl chloride (PVC); the vulcanized rubber formed by the rubber composition has good resistance to dynamic ozone, and also has good comprehensive physical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

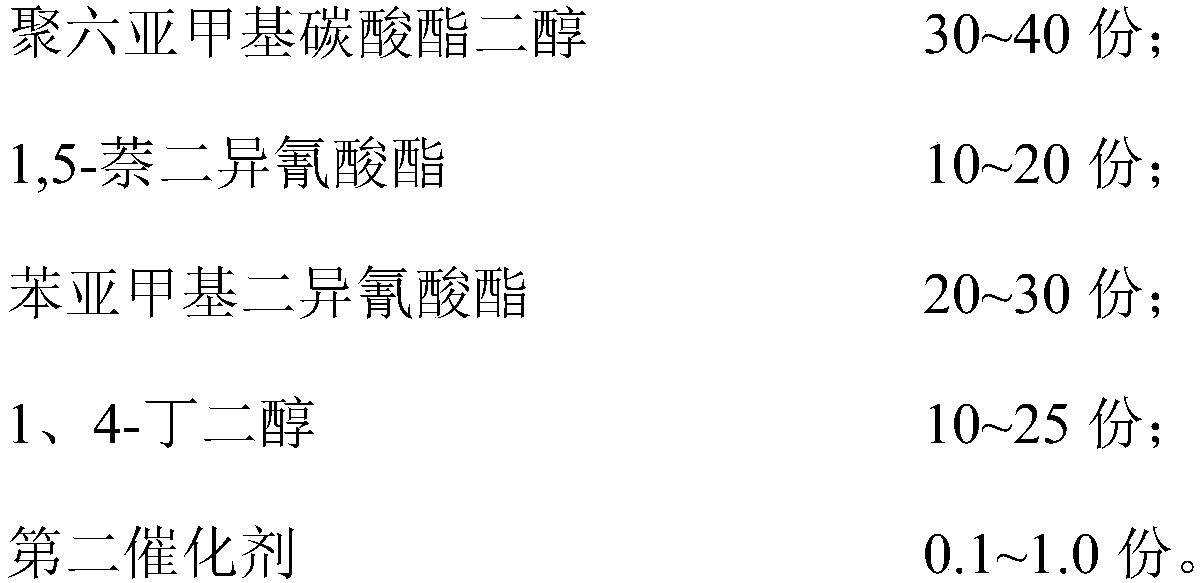

Process for preparing high-performance urethane elastomer

The invention discloses a method for producing a high-performance polyurethane elastomer, comprising the following steps in turn: (A). macromolecular polylol, diisocyanate (OCN-R-NCO) and micromolecular polylol are mixed according to the mass portion of 100 to 27-65 to 1-5 to synthesize a prepolymer; and (B). the prepolymer obtained in step A and chain extender micromolecular polylol generate chain extension crosslinking reaction according to the mass portion of 100 to 3-10, and then the polyurethane elastomer is produced through casting and sulfuration techniques. The polyurethane elastomer prepared according to the method has more superior comprehensive physical characteristics than a polyurethane elastomer synthesized by the prior formula, and has low interior heat build-up under the condition of dynamic abrasiveness and superior tear strength; and various physical characteristics of the polyurethane elastomer are all superior to the cast polyurethane elastomer prepared by the prior formula. The production process of the method is easy, practical, environment-friendly and energy-saving, and the production cost is low.

Owner:汕头市澄海区盐鸿工业胶辊有限公司

Polyester/carbon nano tube-nucleating agent composite material and preparation method thereof

InactiveCN102532817AImprove performanceReduced spherulite sizeMaterials preparationDimethyl terephthalate

The invention belongs to the technical field of high polymer material preparation, and in particular relates to a polyester / carbon nano tube-nucleating agent composite material and a preparation method thereof. The composite material provided by the invention comprises the following components in parts by weight: 78 parts of dimethyl terephthalate, 61-100 parts of 1,3-propylene glycol, 0.0078-0.78 part of ester exchange catalyst, 0.0078-0.78 part of polymerization catalyst, 0.05-5 parts of carbon nano tube and 0.02-2 parts of nucleating agent. The invention also provides the preparation method of the polyester / carbon nano tube-nucleating agent composite material. The preparation method comprises two steps, namely ester exchange and polymerization. For the composite material provided by the invention, the addition of the nucleating agent enhances the heterogeneous nucleation crystallization capability, improves the crystallization speed, reduces the sphaerocrystal size of dimethyl terephthalate and improves mechanical property; at the moment, the strength-increasing and toughening capabilities are mainly exerted by the addition of the carbon nano tube so that the great improvement of the property of the composite material can be realized only by less filling, thus the application field of the composite material is greatly expanded.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Heat-resistant acrylic ester rubber

InactiveCN101445575AGood comprehensive physical propertiesGood post-processing performanceEthyl esterEthyl fumarate

The invention relates to a heat-resistant acrylic ester rubber which is made by copolymerization of methyl acrylate, ethyl acrylate, vinyl monochloroacetate and regulating agent. Calculating by mass percentage, the detailed mixture ratio is: methyl acrylate, 5-40%; ethyl acrylate, 50-94%; vinyl monochloroacetate, 1-10%; and regulating agent, 0.0001-1%; batch process emulsion polymerization technique is used in the process of synthesis; the initiation temperature in the process of polymerization is 10-50 DEG C and the condensation temperature is 40-70 DEG C. The invention has very excellent physical and mechanical properties and post-processing property, thus meeting requirements of the motorcycles and oil-resistant and heat-resistant rubber tubes on material, the formed product of the invention has the advantages of excellent heat-resistance and oil resistance and high tensile-strength, the application of the product ranges from leakproof material of motorcycles, oil-resistant and heat-resistant tubes to protecting jackets and the like.

Owner:JIUJIANG SHILONG RUBBER

Red-base golden-dot ceramic glaze and preparation method thereof

The invention relates to a red-base golden-dot ceramic glaze and a preparation method thereof, belonging to the technical field of ceramics. The red-base golden-dot ceramic glaze comprises the following raw materials in percentage by mass: 30-35.5% of fusion cake, 21.5-27% of potassium feldspar powder, 14.5-19% of silicon dioxide, 6.6-7% of lithium carbonate and 21.9-27.4% of ferric oxide. The fusion cake comprises the following raw materials in percentage by mass: 1.5-2% of potassium oxide, 15.5-17.5% of sodium oxide, 6.9-8% of calcium oxide, 2.1-3.1% of barium oxide, 2.4-3.4% of aluminum oxide and 66-71.6% of silicon dioxide. The red-base golden-dot ceramic glaze can also contain 1% of manganese peroxide. The glaze color of the red-base golden-dot ceramic glaze has the artistic effects of the particular ceramic glaze material, and the red-base golden-dot ceramic glaze has the golden or orange metal bright dot grains on the dark red ceramic glaze surface. After a long-time experiment under the temperature condition of -30 DEG C, cracking or shedding does not appear on the glaze surface, and the glaze can resist corrosion of common acids and alkalis.

Owner:SHENYANG JIANZHU UNIVERSITY

Environmental-friendly PP edge sealing strip and preparation method thereof

The invention relates to the technical field of edge sealing strips, in particular to an environmental-friendly PP edge sealing strip and a preparation method thereof. The environmental-friendly PP edge sealing strip comprises the following raw materials in parts by weight: 75-125 parts of PP resin, 10-25 parts of nanometer active calcium carbonate, 10-25 parts of talcum powder, 0.5-3 parts of dioctyl adipate, 2-10 parts of a modifying auxiliary agent, 0.3-1.5 parts of a lubricating agent, 1.0-3.0 parts of an antistatic agent, 0.1-0.8 part of an ultraviolet absorbent, 0.2-1.5 parts of an antioxidant and 0.5-1.5 parts of a toner. The environmental-friendly PP edge sealing strip does not contain phthalate, heavy metals and other harmful substances, and is environment-friendly, light, non-toxic, high in impact resistance, good in flexibility, strong in weather resistance and excellent in comprehensive physical properties.

Owner:XIONG YI PLASTIC PROD CO LTD

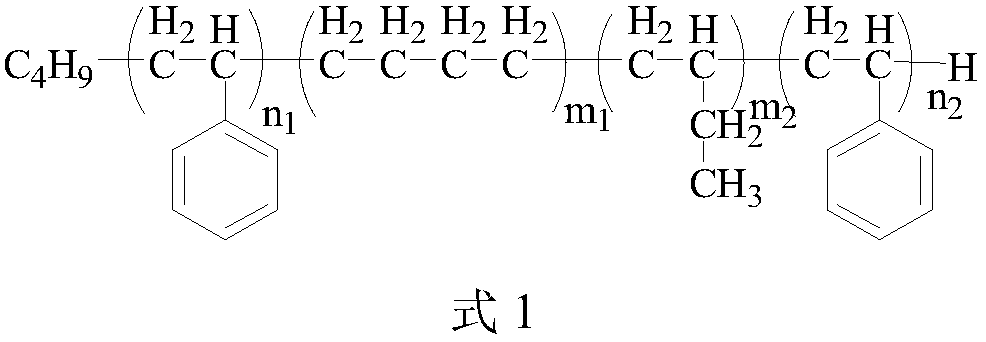

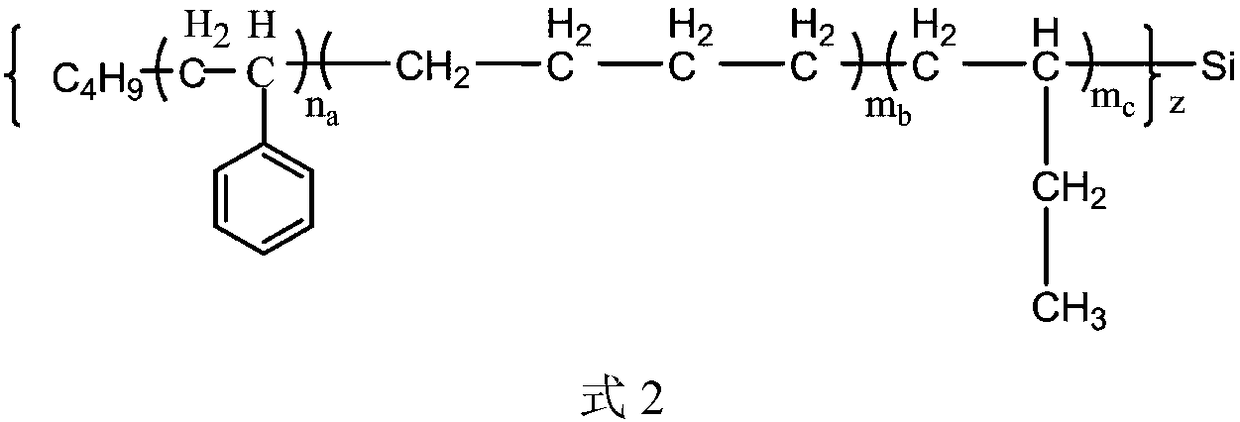

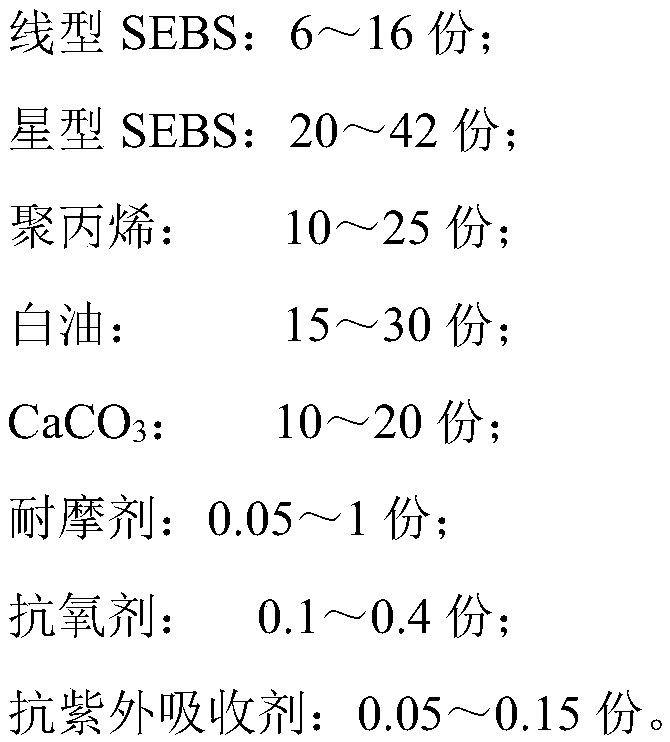

Solid tread rubber material, preparation and application thereof

The invention discloses a solid tread rubber material. The solid tread rubber material comprises linetype SEBS and starlike SEBS, and further comprises polypropylene, white oil, CaCO3, a wear-resistant agent, an antioxidant and an ultraviolet absorbent. The invention further provides a preparation method of the linetype SEBS, the starlike SEBS and the solid tread rubber material. In addition, theinvention further provides an application of the solid tread rubber material in preparing a solid tyre. Compared with a conventional pneumatic tyre, the solid tyre prepared by the formula material isanti-explosion and anti-puncture, enhanced in safety performance obviously, more excellent in wear resistance and rebound resilience and excellent in comprehensive physical performance. In addition, the formula material used for manufacturing the solid tyre is simple and energy-saving in manufacturing process and processing equipment. In the production process, no pollutants are discharged, and the rubber material can be repeatedly recycled, so that the rubber material is more environmentally friendly. The solid tread rubber material has a very wide market application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nickel oxide high-temperature purple silk-gloss ceramic glaze and preparation method thereof

The invention provides nickel oxide high-temperature purple silk-gloss ceramic glaze and a preparation method thereof, and belongs to the field of ceramic. The nickel oxide high-temperature purple silk-gloss ceramic glaze is obtained by firstly preparing a nickel oxide high-temperature purple silk-gloss ceramic glaze material, and then glazing and sintering at high temperature, wherein the nickeloxide high-temperature purple silk-gloss ceramic glaze material is prepared from the following raw materials according to the mass percent of each raw material: 45 percent to 35 percent of potassium feldspar powder, 4.5 percent to 6 percent of silicon dioxide, 4.5 percent to 10 percent of kaolin, 10 percent to 20 percent of zinc oxide, 30 percent to 40 percent of a frit and 1 percent to 2 percentof nickel oxide. The frit is prepared from the following raw materials according to the mass percent of each raw material: 1 percent to 3 percent of potassium oxide, 12 percent to 20 percent of sodiumoxide, 2 percent to 8 percent of calcium oxide, 10 percent to 35 percent of barium carbonate and 40 percent to 60 percent of silicon dioxide. By adopting the method provided by the invention, a phenomenon in a firing process of a traditional glaze material that a lot of poisonous heavy metal is volatilized is overcome; meanwhile, phenomena that needle holes and cracks are formed in the surface ofa fired product are effectively prevented.

Owner:SHENYANG JIANZHU UNIVERSITY

TPO thermoplastic polyolefin polymer non-asphalt-based self-adhesive-film waterproof coiled material and preparation method thereof

ActiveCN113388336APhysically goodGood initial tear strengthRoof covering using flexible materialsFilm/foil adhesivesThermoplasticPolyester

The invention provides a TPO thermoplastic polyolefin polymer non-asphalt-based self-adhesive-film waterproof coiled material and a preparation method thereof. The waterproof coiled material comprises a polyester fabric tire base, a TPO thermoplastic polyolefin polymer base material and a non-asphalt-based self-adhesive glue according to a mass ratio of (15-20): (20-45): (20-45), wherein the TPO thermoplastic polyolefin polymer base material comprises polypropylene, ethylene propylene rubber, a light stabilizer, a flame retardant and an antioxidant, and a mass ratio of the polypropylene to the ethylene propylene rubber to the light stabilizer to the flame retardant to the antioxidant is (35-45): (55-65): (5-10): (6-8): (7-11); and the non-asphalt-based self-adhesive glue comprises styrene butadiene rubber, styrene butadiene rubber, a polyhydroxy polymer, a tackifier and an anti-ultraviolet agent, wherein a mass ratio of the styrene butadiene rubber to the styrene butadiene rubber to the polyhydroxy polymer to the tackifier to the anti-ultraviolet agent is (100-140): (80-100): (3-5): (10-14): (2-5). The waterproof coiled material is more stable in chemical performance and high in cohesiveness with post-poured concrete during construction.

Owner:广东禹能建材科技股份有限公司

Green background sliver crackle high-temperature crystal glaze and preparation method thereof

The invention discloses green background sliver crackle high-temperature crystal glaze and a preparation method thereof, and belongs to the field of ceramic. The green background sliver crackle high-temperature crystal glaze is formed by firstly preparing a green background sliver crackle high-temperature crystal glaze material and then performing glazing and high temperature sintering. The greenbackground sliver crackle high-temperature crystal glaze comprises the following raw materials in mass percent: 33 to 43 percent of frits, 23 to 33 percent of calcined zinc oxide, 13 to 23 percent ofsilicon dioxide, 1 to 5 percent of kaolin, 2 to 8 percent of titanium dioxide, 1 to 4 percent of bentonite, 1 to 6 percent of chalk powder, and 1 to 5 percent of copper carbonate. The frit comprises the following raw materials in mass percent: 1 to 3 percent of potassium oxide, 10 to 20 percent of sodium oxide, 4 to 10 percent of calcium oxide, 1 to 5 percent of diboron trioxide, and 65 to 75 percent of silicon dioxide. The method ensures that ceramic enamel produces sliver flaky crystals during the production of green ceramic glaze, the crystals are uniformly distributed, and a special artistic effect is realized.

Owner:SHENYANG JIANZHU UNIVERSITY

Copper carbonate high-temperature purple ceramic glaze and preparation method thereof

The invention belongs to a copper carbonate high-temperature purple ceramic glaze and a preparation method thereof, which belong to the field of ceramics. The copper carbonate high-temperature purpleceramic glaze is prepared by the steps of firstly preparing a copper carbonate high-temperature purple ceramic glaze material, glazing and sintering at high temperature. The copper carbonate high-temperature purple ceramic glaze material is prepared from the raw materials in percentage by mass: 42 percent to 52 percent of potassium feldspar, 6 percent to 10 percent of chalk powder, 15 percent to 25 percent of silicon dioxide, 1 percent to 4 percent of kaolin, 4 percent to 8 percent of sodium pyroborate, 4 percent to 10 percent of dolomite, 2 percent to 6 percent of zinc oxide, 1 percent to 4 percent of stannic oxide, 0.5 percent to 2 percent of copper carbonate, and 2 percent to 5 percent of titanium dioxide. The glaze formula is subjected to long-time adjustment and multiple experiments,a ceramic glaze surface has a uniform color and wide sintering temperature, and meanwhile, the stability of physical and chemical properties of the ceramic glaze is achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

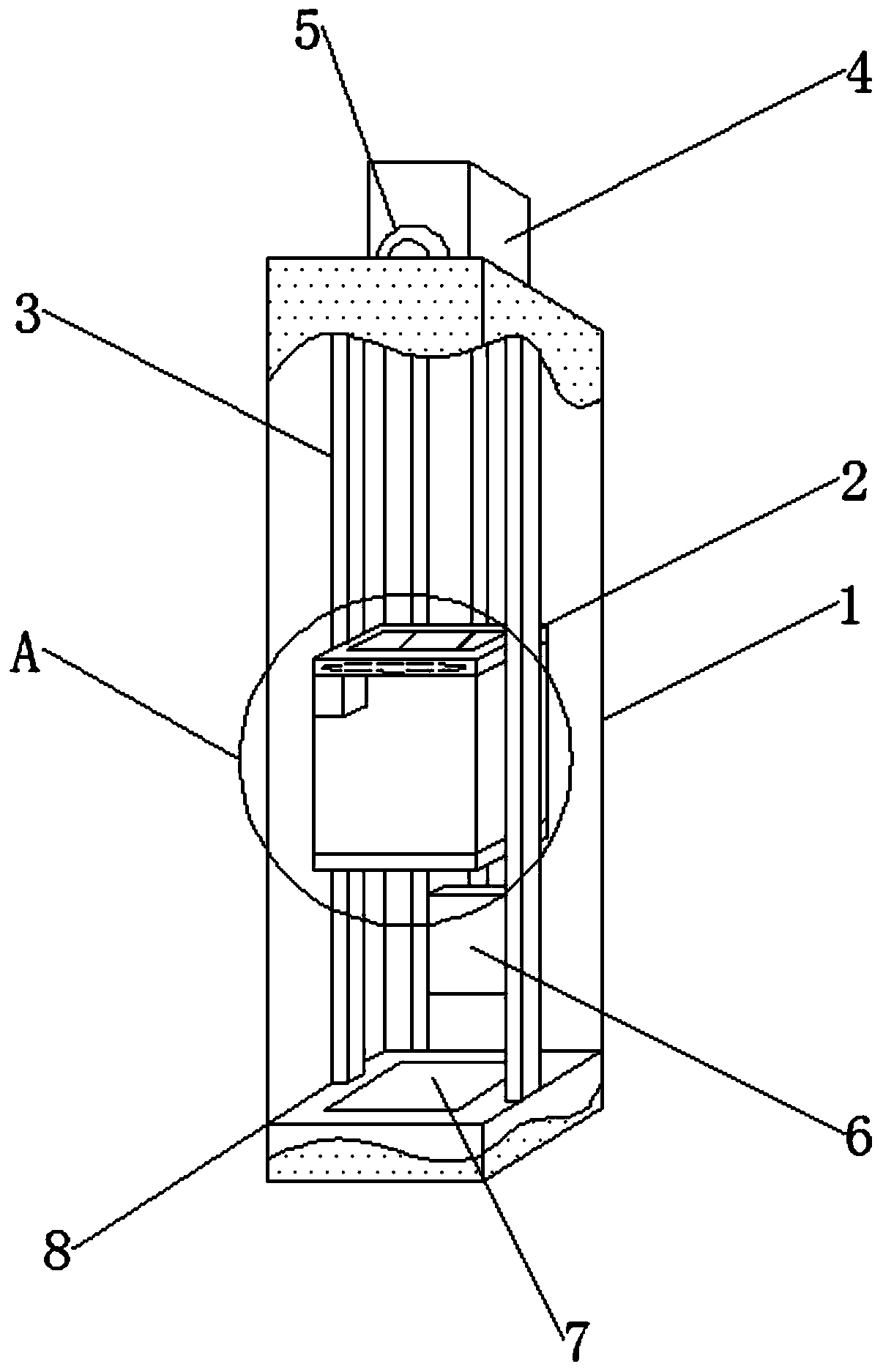

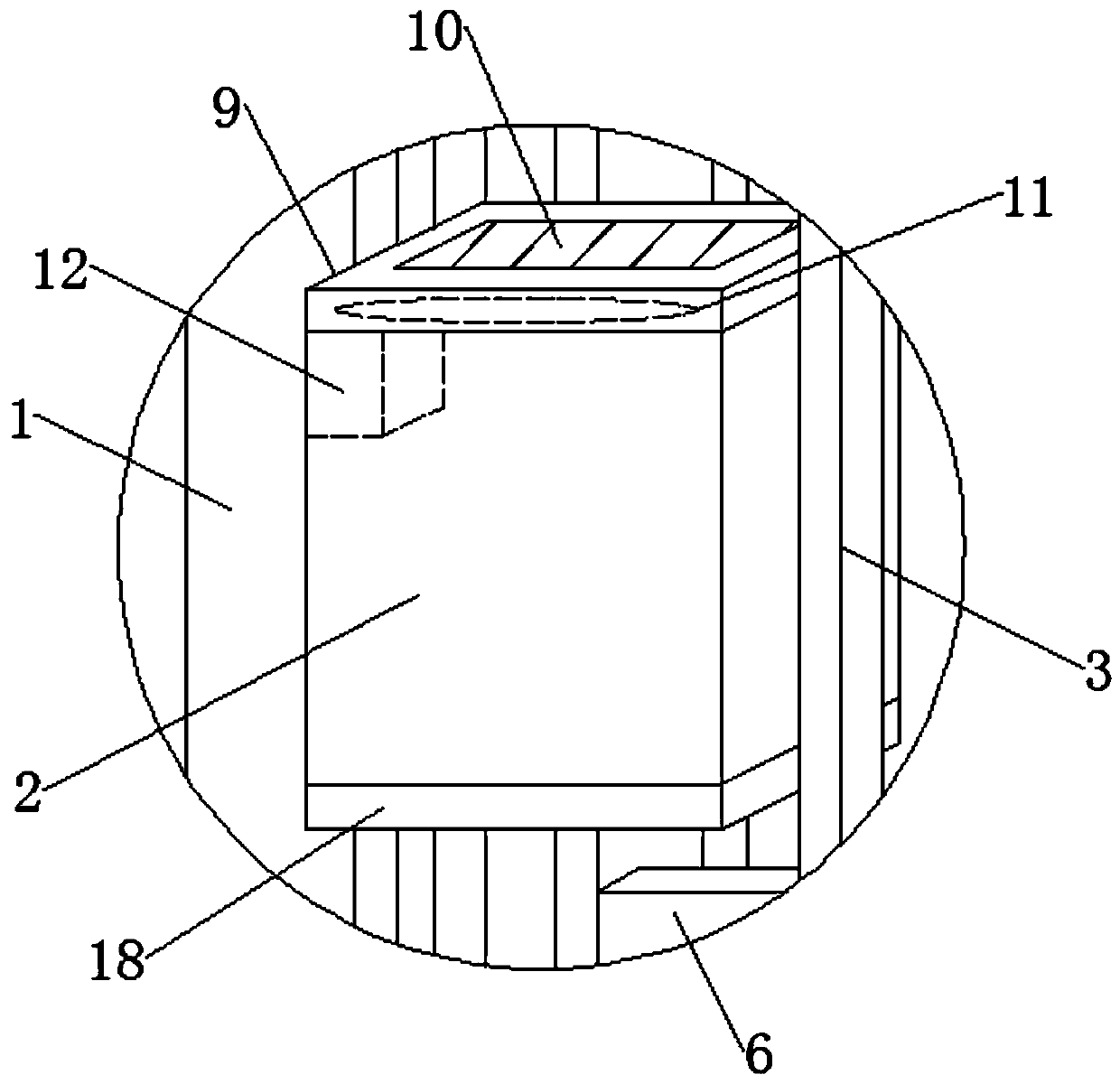

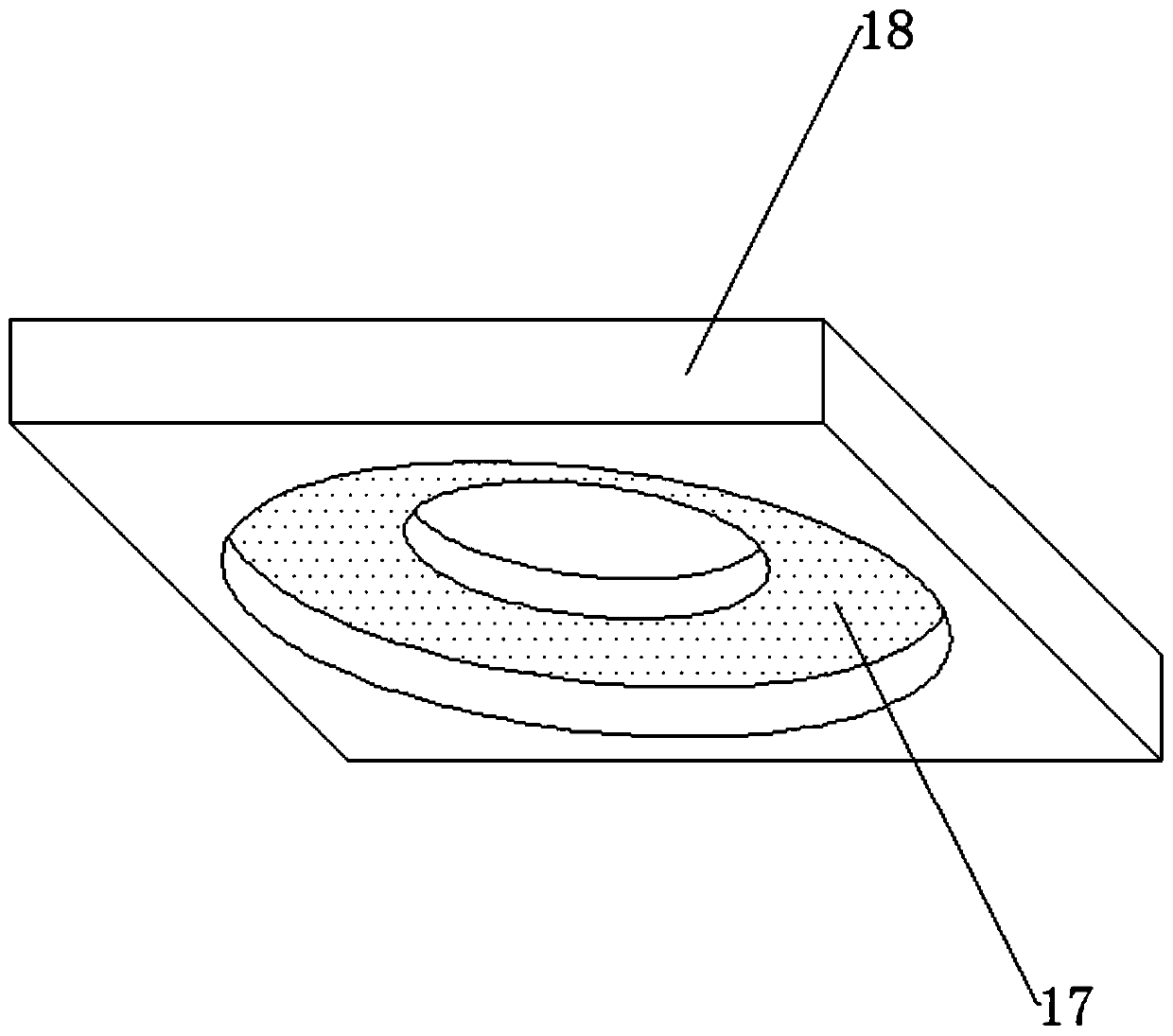

Safety protection device with pre-deceleration function for buffering elevator out-of-control falling

InactiveCN109823935AReduce harmReduce casualtiesAlkali metal salt explosive compositionsElevatorsAerodynamic dragEnergy absorption

The invention discloses a safety protection device with a pre-deceleration function for buffering the elevator out-of-control falling, and belongs to the technical field of elevator safety. Accordingto the safety protection device with the pre-deceleration function for buffering the elevator out-of-control falling, when an elevator is suddenly failed so as to cause the lift car out-of-control falling, the opening and the running of the pre-deceleration mechanism are timely ensured through a starting mechanism, and the lift car is pre-decelerated for the first time by utilizing air resistanceduring the lift car falling process; through the cooperation of an annular electromagnet arranged on the bottom part of the lift car and a fixed electromagnet arranged on a buffer on a shaft bottom ofthe elevator, the lift car is pre-decelerated for the second time by utilizing a giant magnetic field force; meanwhile, a first-time pre-deceleration unit is promoted and corrected according to a magnetic field distribution characteristic of the annular electromagnet; and finally, through the combined action of an energy absorption layer and the buffer on the bottom part of the annular electromagnet, a giant impact force generated during the lift car falling is absorbed and stopped, so that the harm on passengers in the lift car is remarkably reduced, and the personal casualty is reduced.

Owner:朱爱民

Tin dioxide-containing dark purple dotted metal crystal ceramic glaze and preparation method thereof

The invention discloses tin dioxide-containing dark purple dotted metal crystal ceramic glaze and a preparation method thereof, and belongs to the technical field of ceramic. The tin dioxide-containing dark purple dotted metal crystal ceramic glaze is prepared by the following steps: firstly preparing a tin dioxide-containing dark purple dotted metal crystal ceramic glaze material, then glazing, and sintering at high temperature, wherein the tin dioxide-containing dark purple dotted metal crystal ceramic glaze material comprises the following raw materials in percent by mass: 45-35% of potassium feldspar, 25-15% of silicon dioxide, 8-4% of kaolin, 11-5% of dolomite, 10-20% of talcum, 15-8% of sodium pyroborate, 3-1% of cobalt carbonate and 5-1% of tin dioxide. By the preparation method, ceramic glaze forms red dotted crystals in a dark purple ceramic glaze surface, the ceramic glaze surface has a smooth effect, and the stablephysical and chemical properties of the ceramic glaze are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

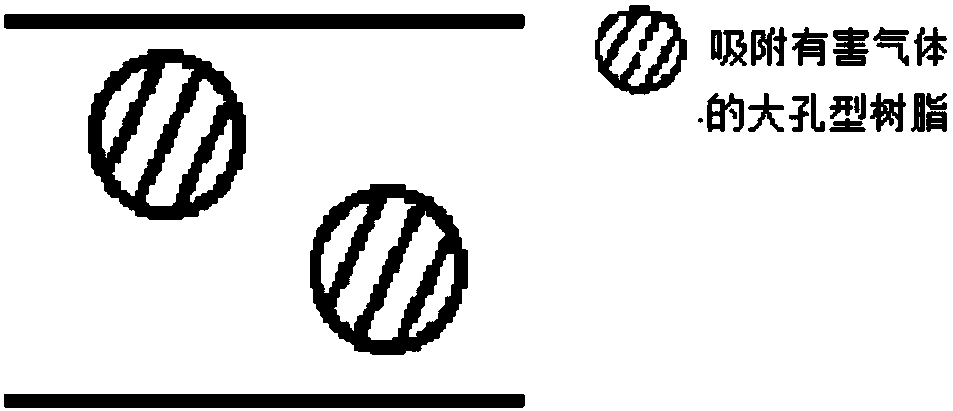

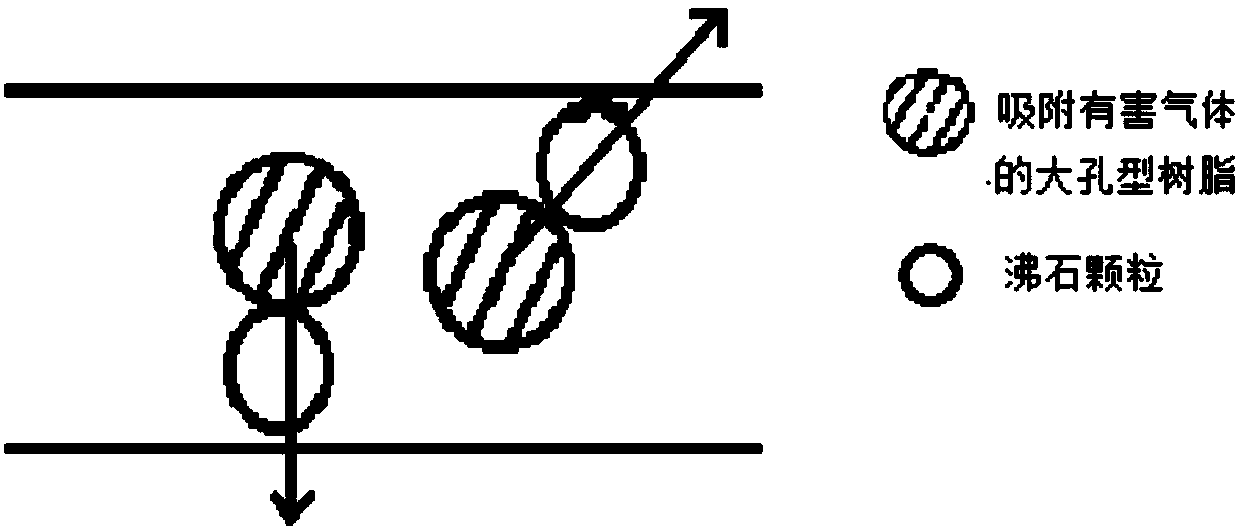

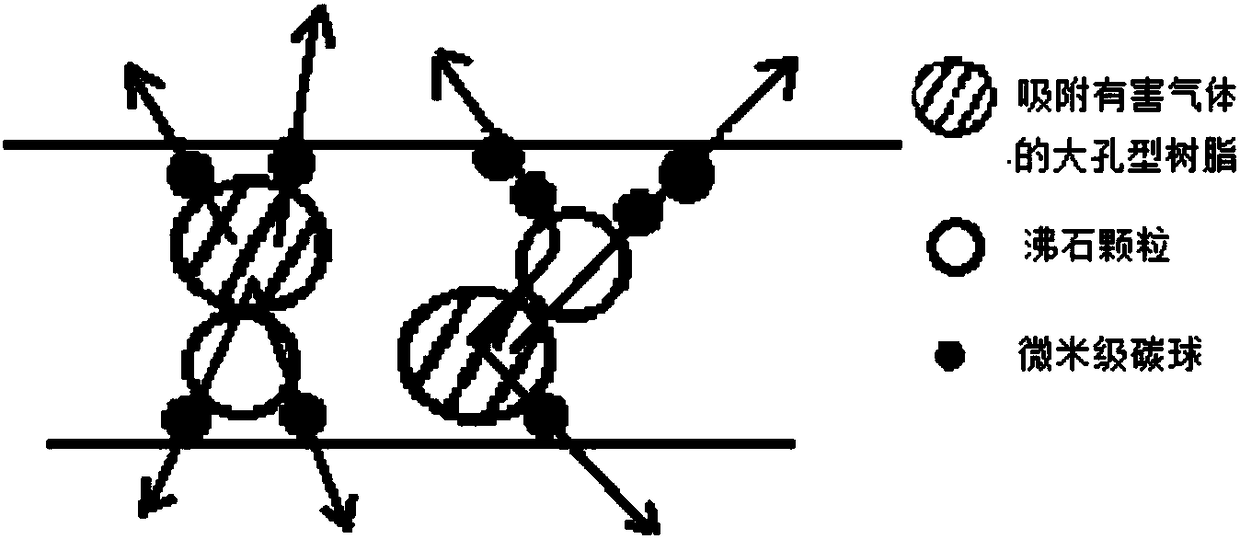

Environmentally-friendly wood-plastic integrated wallboard and production method thereof

The invention discloses an environmentally-friendly wood-plastic integrated wallboard and a production method thereof, belonging to the field of environmentally-friendly high-molecular materials. According to the invention, polyvinyl chloride resin and polychlorohexene resin are used as substrates; wood powder and calcium carbonate powder are used as fillers; polyethylene wax is used as a lubricant; stearic acid is used as a stabilizer; chlorinated polyethylene 135A is used as a toughness and impact modifier; foaming AC-02 is used as a foaming regulator; and macroporous resin, micron-sized carbon spheres and zeolite particles are compounded to form an adsorption purifying agent, so adsorption and desorption discharge channels for harmful gases are formed inside the integrated wallboard. According to the invention, zeolite particles, macroporous resin and micron-sized carbon spheres are added into the integrated wallboard to form the adsorption purifying agent, so the adsorption and desorption channels are formed inside the integrated wallboard; and thus, the internal structure of the wallboard is more abundant, the combination of macro-holes, small holes and micropores makes the porosity of the formed adsorbent larger, the channels for desorption and discharge of harmful gases from the integrated wallboard are increased, and the adsorption and discharge of harmful gases are more thorough and environment-friendlier.

Owner:辽宁新世界科技股份有限公司

Heat-resistant flame-retardant silicone-rubber cable material and preparation method thereof

InactiveCN108440972AImprove temperature resistanceImprove securityRubber insulatorsChemistryMagnesium

The invention discloses a heat-resistant flame-retardant silicone-rubber cable material. Raw materials of the material comprise trifluorobenzene based silicone rubber, a compatilizer, magnesium hydroxide, a mixed flame retardant and a flame retardant synergist. The invention also discloses a preparation method of the heat-resistant flame-retardant silicone-rubber cable material. The silicone-rubber cable material provided by the invention has the advantages of good heat resistance, good flame retardancy, high safety, soft texture and excellent comprehensive physical properties, can be used fora long time under a high temperature condition, and has a long service life.

Owner:天长市荣盛有机硅科技有限公司

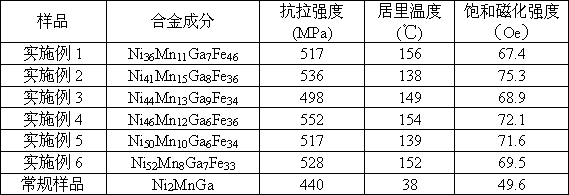

Memory alloy driven by magnetic field to deform and preparation method thereof

ActiveCN108085564AImprove mechanical propertiesImprove magnetic propertiesRoom temperatureShape-memory alloy

The invention provides a memory alloy driven by a magnetic field to deform and a preparation method thereof and belongs to the field of shape memory alloys. The alloy has the capacity of being controlled by the external magnetic field to deform at room temperature, and is a magnetic control shape memory alloy capable of generating restorable deformation in the manner that martensite twin boundaries are driven by the change of the external magnetic field to migrate and reversely migrate at room temperature. The chemical formula of the alloy is NixMnyGazFej, wherein x is larger than or equal to36 and smaller than or equal to 52, y is larger than or equal to 11 and smaller than or equal to 22, z is larger than or equal to 7 and smaller than or equal to 12, j is larger than or equal to 33 andsmaller than or equal to 48, x+y+z+j is equal to 100, and x, y, z and j show mole percent contents. Compared with existing materials, a Fe-Ga intermetallic compound exists in the microstructure of the magnetic control shape memory alloy, and the alloy has the wide magnetoelastic strain temperature range, the high magnetoelastic strain amount and the good mechanical performance, and can be importantly applied to the fields such as high-precision drivers and actuators used at room temperature.

Owner:HANGZHOU KAIERDA ELECTRIC WELDING MACHINE

Nuclear radiation resistant vulcanized rubber and preparation method thereof

The invention belongs to the technical field of special rubber, and particularly relates to nuclear radiation resistant vulcanized rubber and a preparation method thereof. The radiation-resistant rubber composition comprises the following raw material components in parts by weight: 80-90 parts of EPM rubber, 30-50 parts of a radiation-resistant auxiliary agent, 40-60 parts of a filling agent, 3-8 parts of a vulcanizing agent, 1.5-3.0 parts of an accelerant, 10-20 parts of a plasticizer and 2-5 parts of an anti-aging agent, and is characterized in that the radiation-resistant auxiliary agent comprises lead oxide, bismuth oxide, barium sulfate and / or antimony trioxide. The nuclear radiation resistant vulcanized rubber obtained according to the preparation method has stable protection and shielding performance on nuclear radiation in the actual use process, also has excellent comprehensive physical performance, and has the advantages of stable performance, safety and reliability.

Owner:河北宇通特种胶管有限公司

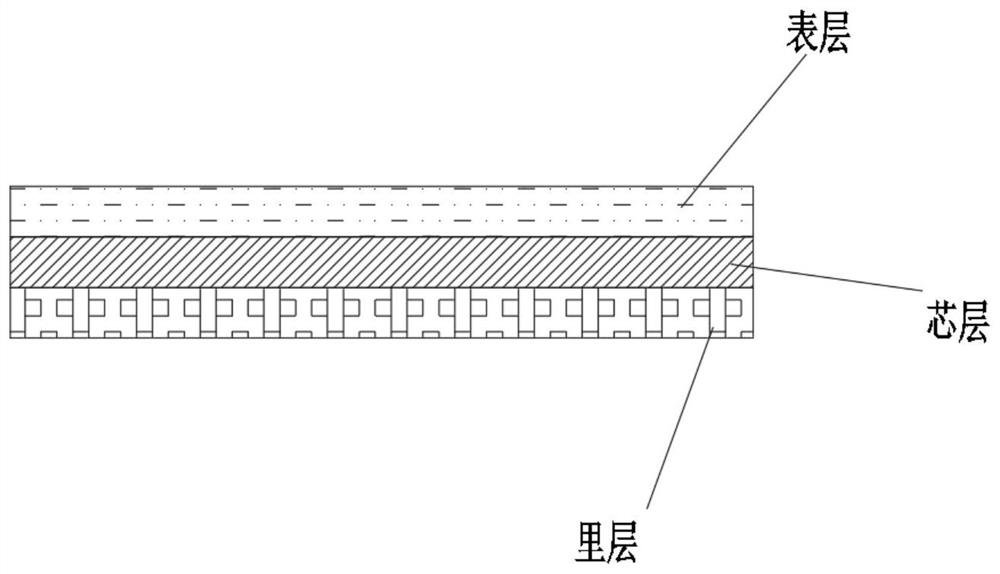

Sterile composite roll film for seed storage and production process thereof

PendingCN113071174APhysically goodInhibition of germinationAgricultural articlesSynthetic resin layered productsBiotechnologyPolyvinyl alcohol

The invention belongs to the technical field of composite films and production processes thereof, and particularly relates to a sterile composite roll film for seed storage and a production process thereof. The invention relates to a sterile composite roll film for seed storage. The sterile composite roll film for seed storage consists of a surface layer, an inner layer and a core layer positioned between the surface layer and the inner layer. The surface layer, the inner layer and the core layer located between the surface layer and the inner layer are bonded through a solvent-free composite technology to obtain the sterile composite roll film for seed storage. The inner layer and the outer layer both have a high-ultraviolet-resistance effect, the core layer is mainly composed of a three-layer co-extruded nylon water bag film, and meanwhile the surface of a PET film and the surface of a nano composite film are both coated with polyvinyl alcohol. Therefore, the sterile composite roll film for seed storage, which is high in toughness, strong in antibacterial activity and capable of inhibiting seed germination, is achieved, and meanwhile, the production process is relatively simple, and the process cost and the efficiency are both superior to those of production processes of other products.

Owner:陈仁志

Safe and nontoxic PP edge strip and preparation method thereof

The invention relates to the technical field of edge strips, in particular to a safe and nontoxic PP edge strip and a preparation method thereof. The safe and nontoxic PP edge strip comprises the following raw materials in parts by weight: 100-120 parts of PP resin, 10-20 parts of nano activated calcium carbonate, 5-15 parts of talcum powder, 3-8 parts of titanium dioxide, 5-10 parts of light activated calcium, 0.3-1.5 parts of polystyrene, 1.0-3.0 parts of an antistatic agent, 1-3 parts of an ultraviolet light absorber, 0.5-1.5 parts of an antioxidant and 0.5-1.5 parts of a defoaming agent. The safe and nontoxic PP edge strip does not contain dibutyl phthalate, heavy metals or other harmful substances, is environmentally friendly, light and non-toxic, has high impact resistance and good flexibility, and is high in weather fastness and excellent in comprehensive physical property.

Owner:柳州市家富连装饰有限公司

High-temperature purple cobalt oxide ceramic glaze and preparation method thereof

The invention relates to a high-temperature purple cobalt oxide ceramic glaze and a preparation method thereof, belonging to the ceramic field. The high-temperature purple cobalt oxide ceramic glaze is prepared by the steps of firstly preparing a high-temperature purple cobalt oxide ceramic glaze material, and carrying out glazing and high-temperature sintering, wherein the high-temperature purplecobalt oxide ceramic glaze material contains the following raw materials in percentage by mass: 35%-45% of feldspar powder, 15%-25% of silicon dioxide, 4%-8% of spherical clay, 5%-11% of dolomite, 10%-20% of talcum, 8%-15% of sodium pyroborate, 2%-5% of cobalt oxide and 1%-4% of manganese dioxide. By virtue of long-term adjustment and multiple experiments of a glaze formula, long-term experimentsat -30 DEG C show that the phenomenon that a glaze surface cracks or falls does not appear, and the glaze surface can resist ordinary acid-base corrosion.

Owner:SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com