Rubber composition and vulcanized rubber and preparation method and application thereof

A technology of rubber composition and polymer, which can be used in transportation and packaging, special tires, vehicle parts, etc., and can solve problems such as poor resistance to dynamic ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] According to a preferred embodiment, the preparation method of the vulcanized rubber of the present invention includes the following steps:

[0042] 1. Put the main rubber into the internal mixer for 0.4-0.6min for mastication. The speed of the internal mixer is 85-95rpm and the temperature is 75-85℃;

[0043] 2. Add 1 / 2-3 / 4 of the reinforcing agent, all the silane coupling agent and at least part of the activator into the internal mixer, and mix at 70-160℃ for 2-3min;

[0044] 3. Add the remaining reinforcing agent and all the components of the rubber composition of the present invention except the vulcanizing agent and vulcanization accelerator into the internal mixer for mixing, and keep it at 150-170℃ until the internal mixing temperature reaches 150-170℃ Unload the rubber at 5-7min;

[0045] 4. Pass the rubber material three times on an open mill with a roller distance of 4-6mm and a roller temperature of 50±5℃; park the mixed rubber for 3.5-4.5h;

[0046] 5. The speed of t...

Embodiment 1

[0076] Put the main rubber into the internal mixer for 0.5min to masticate, where the internal mixer rotates at 90rpm and the temperature is 80℃;

[0077] Add 3 / 4 of the total weight of the enhancer, all the silane coupling agent, and all the activator into the internal mixer, and mix for 2.5 minutes;

[0078] Add the remaining reinforcing agent and the components other than the vulcanizing agent and vulcanization accelerator of the rubber composition Z1 of this example into the internal mixer for mixing. After the internal mixing temperature rises to 150°C, keep it at no less than Unload the rubber compound when mixing for 5 minutes in the temperature range of 150℃ and not higher than 170℃;

[0079] Pass the rubber material three times on an open mill with a roller distance of 5mm and a roller temperature of 55°C; park the mixed rubber for 4 hours;

[0080] Adjust the speed of the internal mixer to 60rpm, the temperature is 40℃, add the vulcanizing agent and accelerator after mixing ...

Embodiment 2-3

[0086] Example 2-3 adopts the same method as Example 1 to prepare vulcanized rubber, the difference is:

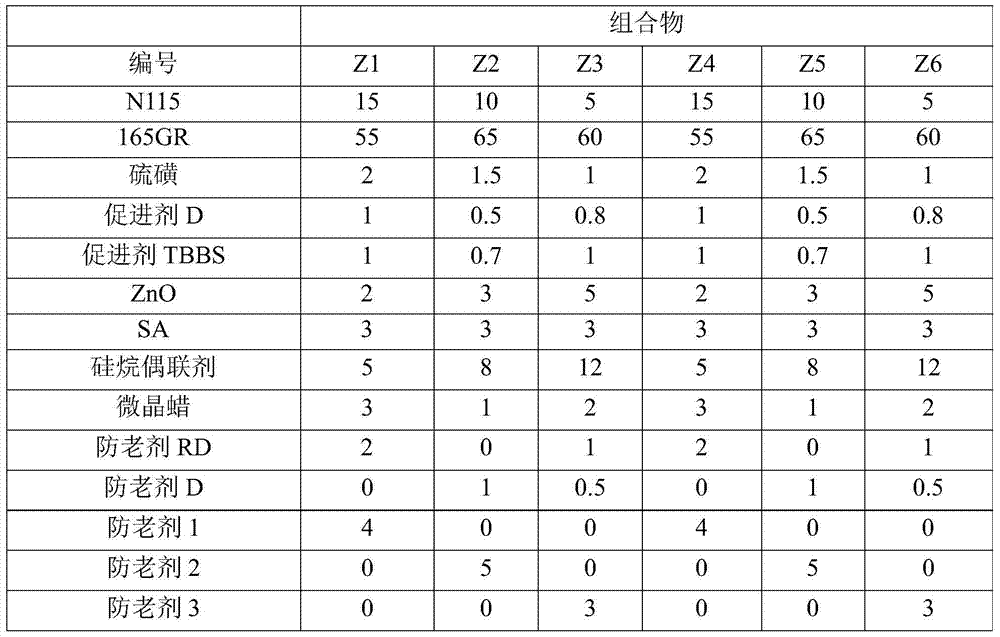

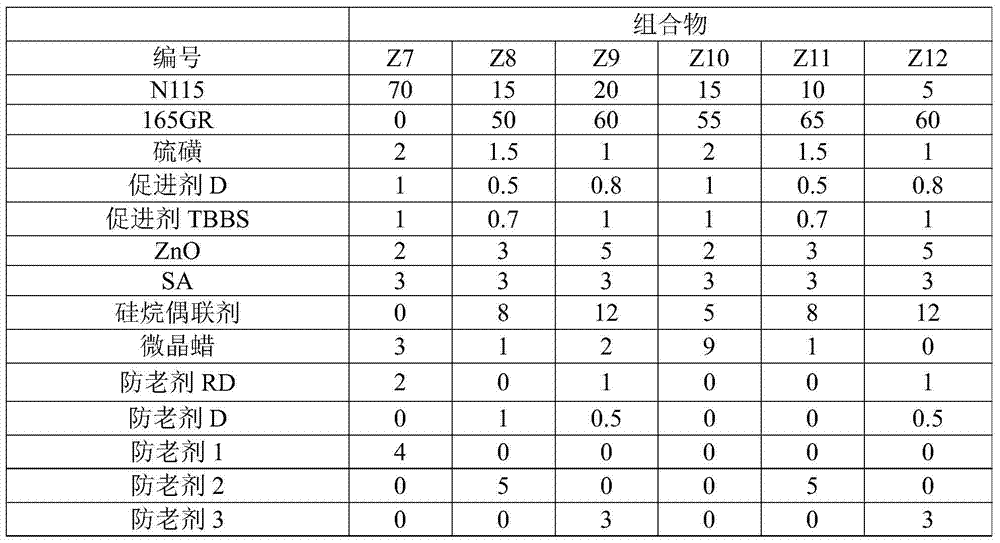

[0087] The type and content of the main rubber in each embodiment are shown in Table 1; and the components other than the main rubber in the rubber composition in each embodiment are shown in Table 2.

[0088] In addition, the rubber compositions in Example 2-3 are Z2 and Z3, the vulcanized rubbers are S2 and S3, and the silane coupling agents in Example 2-3 are KH550 and Si75, respectively; the styrene-butadiene rubber in Example 2 It is the aforementioned emulsion polystyrene-butadiene rubber (ESBR) (brand number 1712), and the styrene-butadiene rubber in Example 3 is the aforementioned product under the brand number SSBR2636.

[0089] The rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com