Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

A technology of powder metallurgy and friction materials, which is applied in the field of powder metallurgy materials, can solve the problems that synthetic friction materials cannot meet the technical requirements and the wear performance requirements are very strict, so as to improve its own shear strength and compressive strength, excellent mechanical properties, Effect of improving high temperature friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

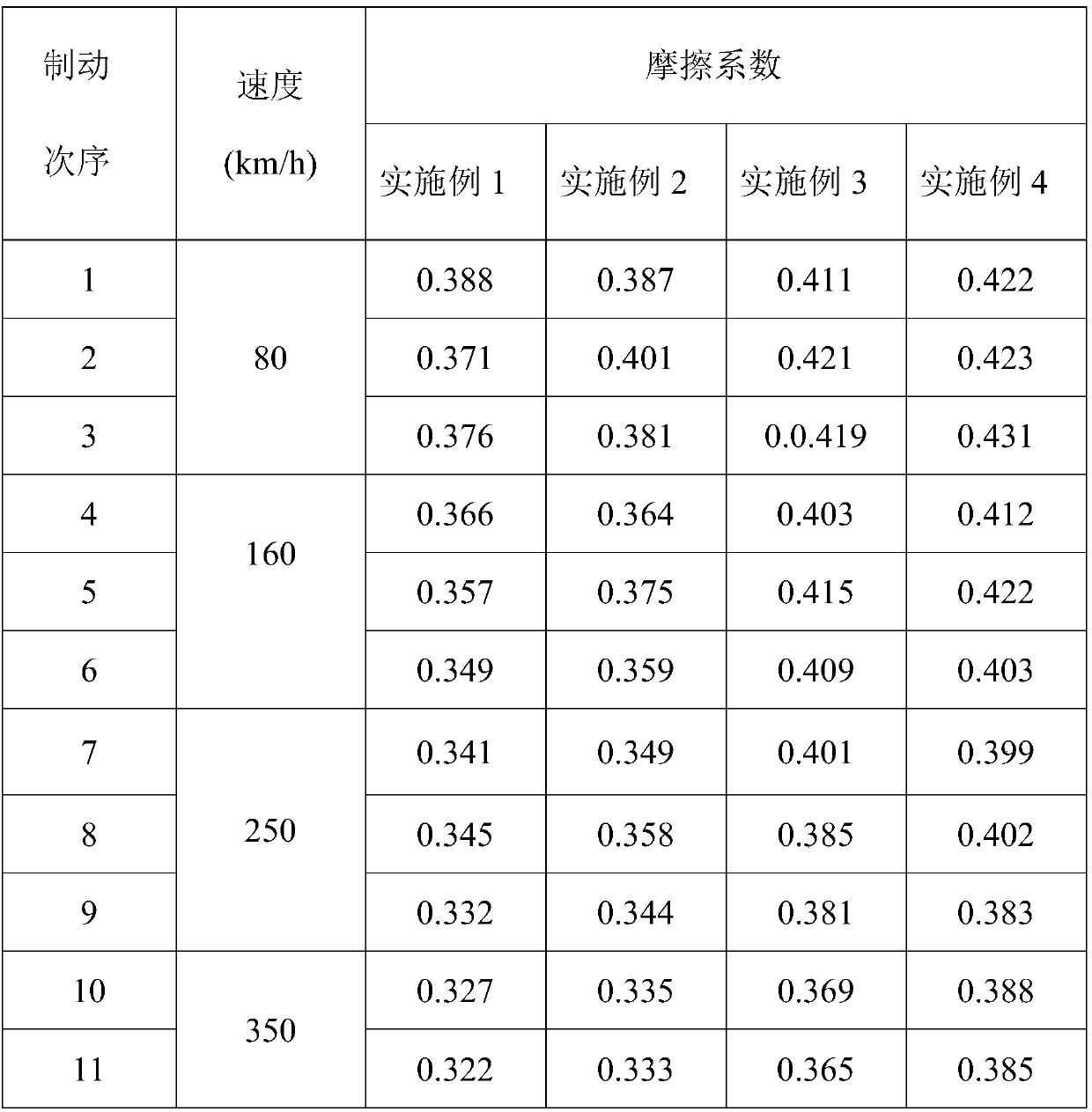

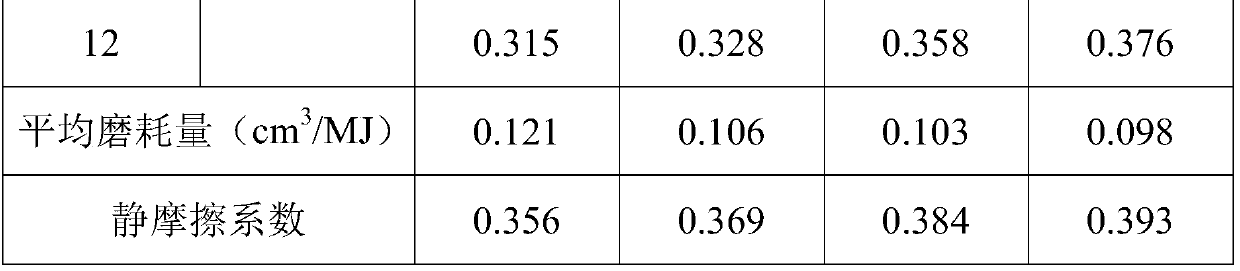

Examples

Embodiment 1

[0031] This embodiment provides a powder metallurgy friction material for high-speed train braking, specifically as follows:

Embodiment 5

[0032] The present embodiment 5kg includes the following raw materials: copper powder 2750g, iron powder 500g, copper-plated flake graphite 600g, copper-plated graphite particles 450g, ferrochrome powder 500g, molybdenum disulfide powder 100g, alumina fiber 100g;

[0033] Wherein, the copper powder is electrolytic copper powder, and the particle size distribution range is 50-100 mesh;

[0034] The iron powder adopts atomized iron powder, and the particle size distribution range is 50-100 mesh;

[0035] The copper-coated flake graphite adopts artificial copper-plated flake graphite by electroless plating, the copper content is 40wt%, and the particle size distribution range is 20-80 mesh; the copper-coated graphite particle copper content is 25wt%;

[0036] The particle size distribution range of the molybdenum disulfide is 100-150 mesh;

[0037] The particle size distribution range of the ferrochromium powder is 80-150 mesh, and the chromium content is 50wt%, and the iron con...

Embodiment 2

[0042] This embodiment provides a powder metallurgy friction material for high-speed train braking, specifically as follows:

[0043] The present embodiment 5kg includes the following raw materials: copper powder 2250g, iron powder 1000g, copper-plated flake graphite 600g, copper-plated graphite particles 400g, ferrochrome powder 500g, molybdenum disulfide powder 150g, alumina fiber 100g;

[0044] Wherein, the copper powder is electrolytic copper powder, and the particle size distribution range is 50-100 mesh;

[0045] The iron powder is atomized iron powder, and the particle size distribution range is 150-200 mesh;

[0046] The copper-coated graphite flakes are copper-plated with artificial graphite flakes by electroless plating, and the copper content is 42wt%, and the particle size distribution range is 80-120 mesh; the copper-coated graphite particles have a copper content of 28wt%;

[0047] The particle size distribution range of the molybdenum disulfide is 250-300 mesh;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com