Simulated leather texture polyurethane leather for automobile and preparation method of simulated leather texture polyurethane leather

A technology of polyurethane leather and imitation leather, which is applied to chemical instruments and methods, vehicle parts, pre-treated surfaces, etc. It can solve the problems of low VOC and environmental protection, poor aging resistance, heavy odor, etc., and improve the bonding firmness , Improve mechanical properties, clear surface texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A kind of artificial leather texture polyurethane leather for automobiles, comprising successively laminated 1.5mm thick base cloth layer superfine fiber non-woven fabrics (weight per unit area is 200g / m 2 ), a 0.05mm thick TPU hot melt adhesive layer, a composite layer consisting of a 0.05mm thick TPU film layer and a 0.05mm thick PU layer.

[0067] The preparation raw material of described TPU hot-melt adhesive layer comprises following raw material component by weight part:

[0068]

[0069] The preparation method of the polyester polyol is as follows: mix 1 mol of sebacic acid, 2.5 mol of terephthalic acid and 4.0 mol of ethylene glycol, then add 0.003 mol of isopropyl zirconate, heat up to 160°C for polycondensation reaction to obtain decane Diacid polyester polyol (weight average molecular weight 1500);

[0070] The flame retardant comprises by weight percentage: 30wt% dimethyl phosphite, 35wt% ammonium polyphosphate, 35wt% pentaerythritol;

[0071] The prepa...

Embodiment 2

[0081] A kind of artificial leather texture polyurethane leather for automobiles, comprising successively stacked 3.0mm thick base cloth layer superfine fiber non-woven fabrics (weight per unit area is 400g / m 2 ), a 0.1mm thick TPU hot melt adhesive layer, a composite layer consisting of a 0.1mm thick TPU film layer and a 0.1mm thick PU layer.

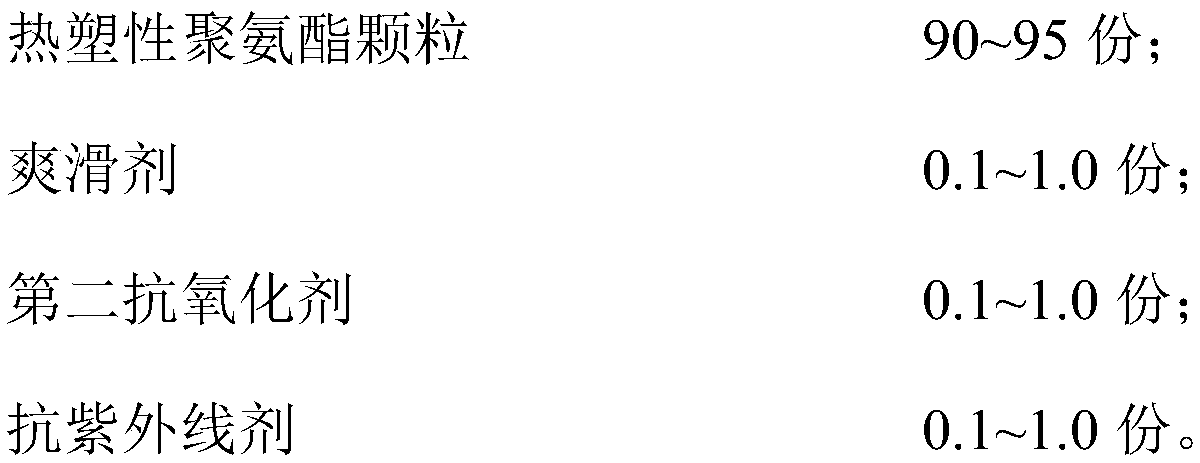

[0082] The preparation raw material of described TPU hot-melt adhesive layer comprises following raw material component by weight part:

[0083]

[0084]The preparation method of the polyester polyol is as follows: mix 1 mol of sebacic acid, 2.5 mol of terephthalic acid and 4.0 mol of ethylene glycol, then add 0.003 mol of isopropyl zirconate, heat up to 200°C for polycondensation reaction to obtain decane Diacid polyester polyol (weight average molecular weight 2000);

[0085] The flame retardant comprises by weight percentage: 20wt% dimethyl phosphite, 40wt% ammonium polyphosphate, 40wt% pentaerythritol;

[0086] The preparation...

Embodiment 3

[0096] A kind of artificial leather texture polyurethane leather for automobiles, comprising successively laminated 0.1mm thick base cloth layer superfine fiber non-woven fabrics (weight per unit area is 200g / m 2 ), a 0.01mm thick TPU hot melt adhesive layer, a composite layer consisting of a 0.05mm thick TPU film layer and a 0.05mm thick PU layer.

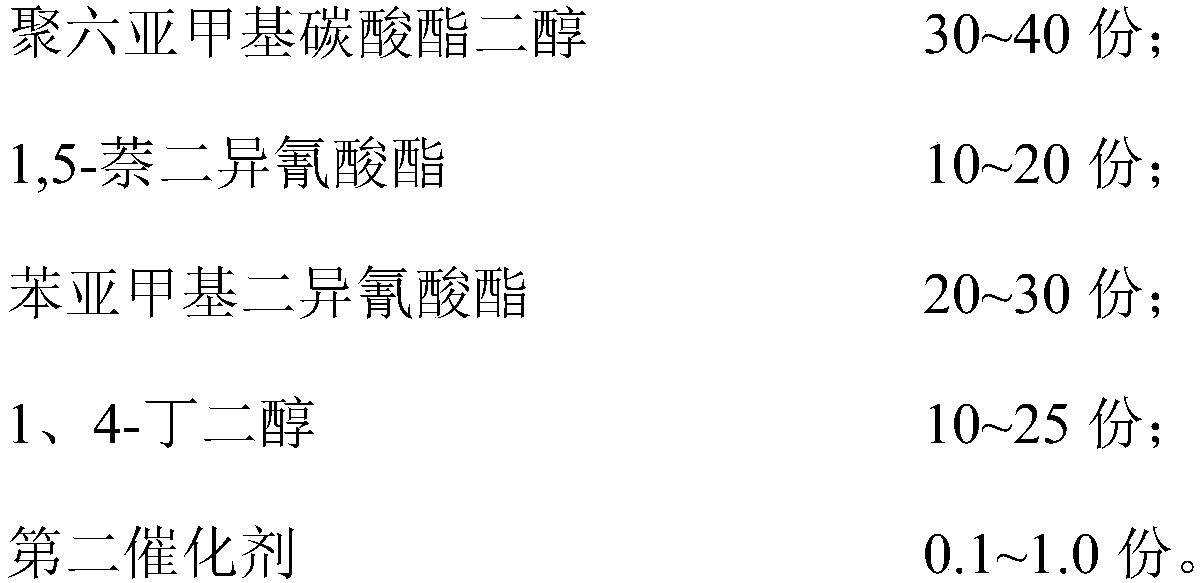

[0097] The preparation raw material of described TPU hot-melt adhesive layer comprises following raw material component by weight part:

[0098]

[0099] The preparation method of the polyester polyol is as follows: mix 1 mol of sebacic acid, 2.5 mol of terephthalic acid and 4.0 mol of ethylene glycol, then add 0.003 mol of isopropyl zirconate, heat up to 160°C for polycondensation reaction to obtain decane Diacid polyester polyol (weight average molecular weight 1500);

[0100] The flame retardant comprises by weight percentage: 25wt% dimethyl phosphite, 35wt% ammonium polyphosphate, 35wt% pentaerythritol;

[0101] The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com