Environmentally-friendly wood-plastic integrated wallboard and production method thereof

An integrated wall and wood-plastic technology, applied in chemical instruments and methods, gas treatment, construction, etc., can solve problems such as the emission of harmful gases such as formaldehyde, material procurement and dispersion, and short service life. The effect of strong pollution and shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Ingredients

[0048] Weigh each component according to the following weight percentages and mix them uniformly:

[0049] Polyvinyl chloride resin: 10%;

[0050] Polychlorohexene resin: 12%;

[0051] Wood flour: 2%;

[0052] Calcium carbonate powder: 15%;

[0053] Polyethylene wax: 2%;

[0054] Stearic acid: 2%;

[0055] Chlorinated polyethylene 135A: 2%;

[0056] Toner: 4%;

[0057] AC-02 foaming agent: 3%;

[0058] (2) Pretreatment of adsorption purifier

[0059] Weigh the components of the adsorption purifier according to the following weight percentages:

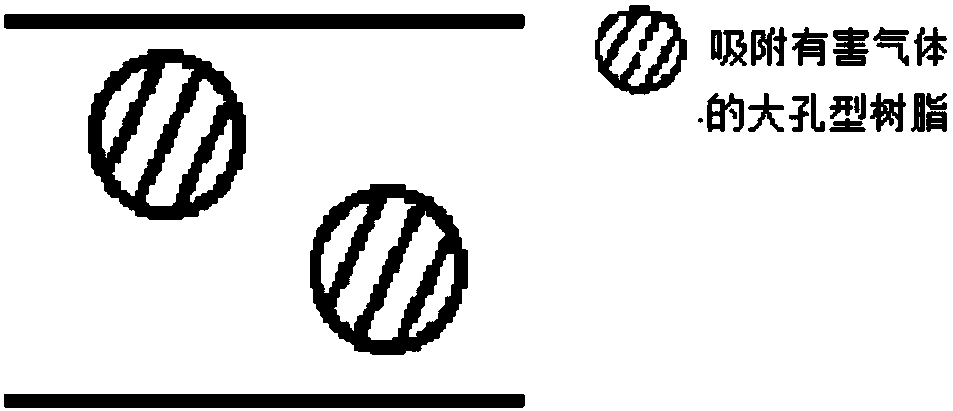

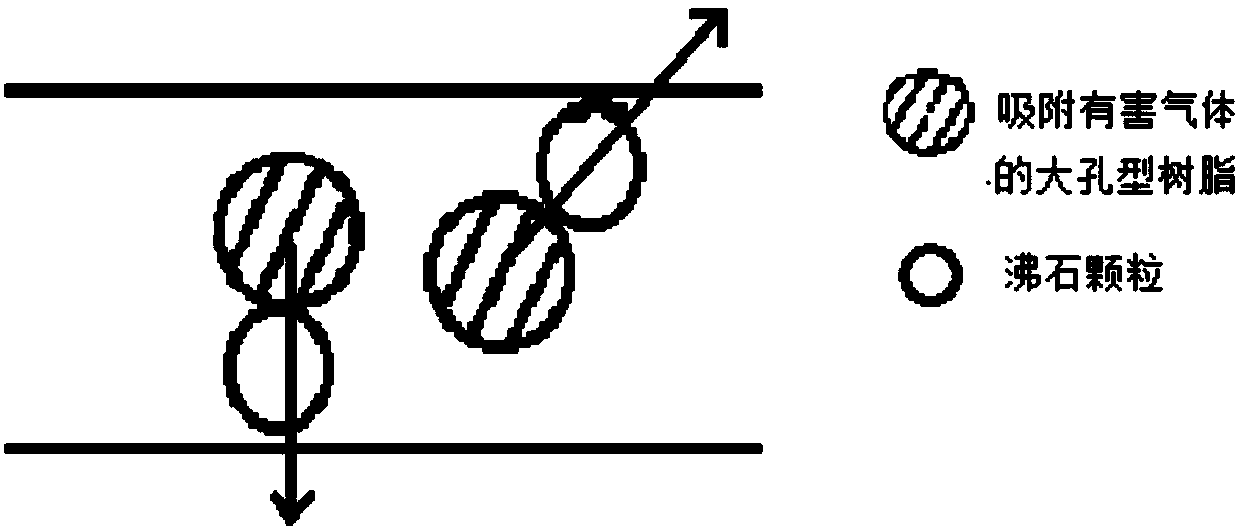

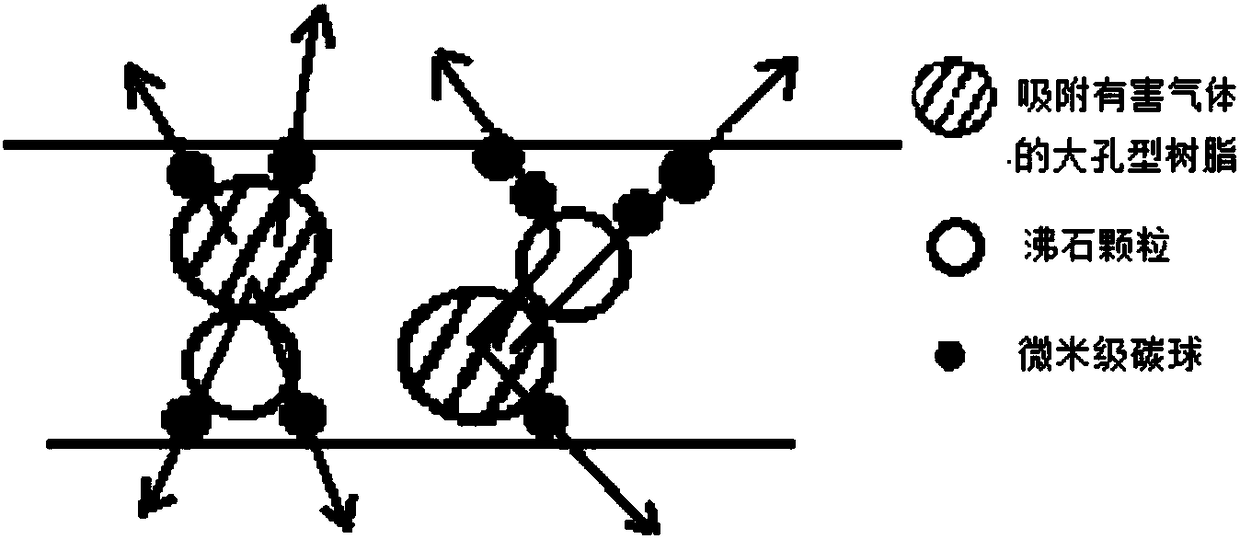

[0060] Zeolite particles: 12%, sieved to below 80 mesh;

[0061] Macroporous resin: 8%, sieved to below 60 mesh;

[0062] Micron carbon spheres: 4%, sieved to below 200 mesh;

[0063] Mix the components of the adsorption purifier evenly, soak in saturated salt water twice the weight of the adsorption purifier for 18 hours, then drain the saturated salt water, rinse with absolute ethanol, and then ri...

Embodiment 2

[0069] (1) Ingredients

[0070] Weigh each component according to the following weight percentages and mix them uniformly:

[0071] Polyvinyl chloride resin: 20%;

[0072] Polychlorohexene resin: 16%;

[0073] Wood flour: 3%;

[0074] Calcium carbonate powder: 20%;

[0075] Polyethylene wax: 3%;

[0076] Stearic acid: 3%;

[0077] Chlorinated polyethylene 135A: 3%;

[0078] Toner: 6%;

[0079] AC-02 foaming agent: 4%;

[0080] (2) Pretreatment of adsorption purifier

[0081] Weigh the components of the adsorption purifier according to the following weight percentages:

[0082] Zeolite particles: 14%, sieved to below 100 mesh;

[0083] Macroporous resin: 10%, sieved to below 65 mesh;

[0084] Micron carbon spheres: 5%, sieved to below 250 mesh;

[0085] Mix the components of the adsorption and purification agent evenly, soak in saturated saline that is 2.5 times the weight of the adsorption and purification agent for 19 hours, then drain the saturated salt water, ri...

Embodiment 3

[0091] (1) Ingredients

[0092] Weigh each component according to the following weight percentages and mix them uniformly:

[0093] Polyvinyl chloride resin: 30%;

[0094] Polychlorohexene resin: 20%;

[0095] Wood flour: 4%;

[0096] Calcium carbonate powder: 25%;

[0097] Polyethylene wax: 4%;

[0098] Stearic acid: 4%;

[0099] Chlorinated polyethylene 135A: 4%;

[0100] Toner: 8%;

[0101] AC-02 foaming agent: 5%;

[0102] (2) Pretreatment of adsorption purifier

[0103] Weigh the components of the adsorption purifier according to the following weight percentages:

[0104] Zeolite particles: 16%, sieved to below 200 mesh;

[0105] Macroporous resin: 15%, sieved to below 70 mesh;

[0106] Micron carbon spheres: 6%, sieved to below 300 mesh;

[0107] Mix the components of the adsorption and purification agent evenly, soak in saturated saline that is 3 times the weight of the adsorption and purification agent for 20 hours, then drain the saturated salt water, rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com