Spin riveting puncher pin

A technology of riveting punches and riveting punches, which is applied in the field of rotary riveting punches, can solve problems affecting riveting quality and low processing efficiency, and achieve the effects of good riveting quality, improved riveting efficiency, and improved riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

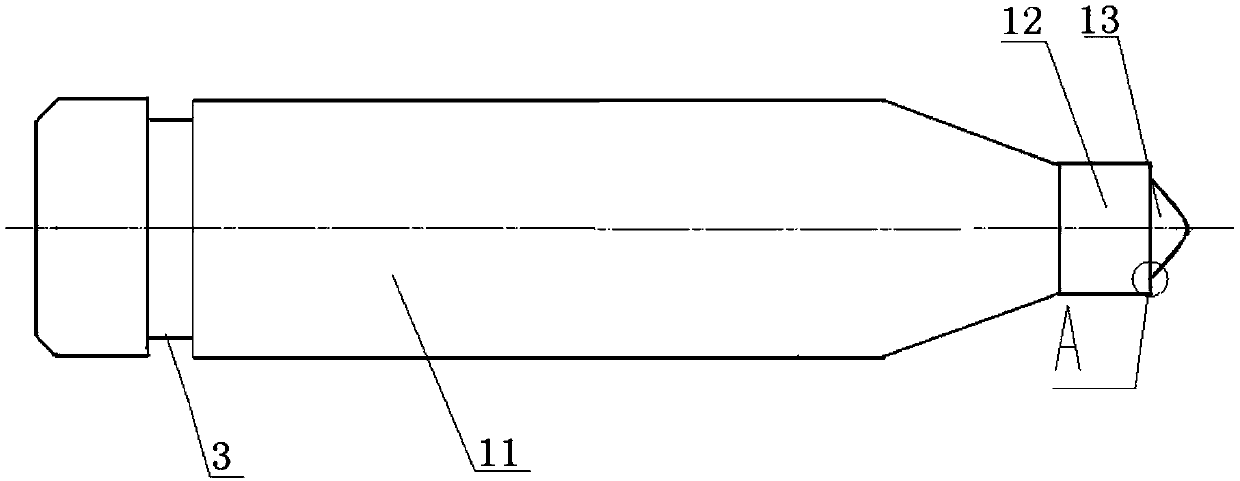

[0036] This embodiment is a spin riveting punch with a rod shape. One end of the riveting punch 9 is a connecting handle, and the other end is a riveting head, and the transition section between the connecting handle and the riveting head is a cone. The rivet head is composed of an equal-diameter section 12 and a plug 13; one end of the equal-diameter section connects with the end face of the transition section, and the center of the other end end face is an axially protruding plug. The axial length of the outer edge of the end face of the equal-diameter section is greater than the axial length of the root of the end face, so that the root of the plug forms a slope to the outer edge. The slope is the axial extrusion surface 2 of the rivet punch. The included angle between the axial extrusion surface and the space vertical surface is the axial extrusion angle α of the rivet head; the axial extrusion angle α=1°˜3°.

[0037] The plug 13 is conical, the conical surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com