Method for preparing phosphotungstic heteropoly acid with Keggin structure

A technology of phosphotungstic heteropolyacid and tungstate, which is applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of reducing the safety of large-scale industrial production, complex preparation process, and large amount of organic solvents. Achieve the effect of high product output rate, simple process and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

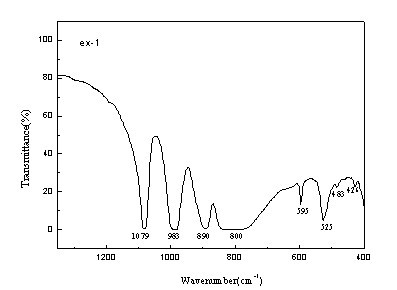

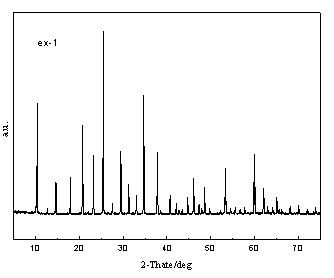

[0028] Weigh 16.5 grams of sodium tungstate dihydrate, add 50 mL of deionized water, and stir until the sodium tungstate is completely dissolved; adjust the pH of the solution to 7.0 with 3 mol / L hydrochloric acid; continue stirring for 2 hours, and then transfer to 100 mL of polytetrafluoroethylene In an ethylene-lined autoclave, stand at 135°C for 10 hours, cool naturally, transfer the solution into a beaker, add 0.5mol / L phosphoric acid solution dropwise to pH=2.25, stir for 4 hours, add potassium chloride When the solution is saturated, crystallize overnight at 15°C, purify, filter, and dry to constant weight to obtain 13.48 g of white product. 3 PW 12 o 40 29H 2O meter, yield is 95%. The FT-IR spectrum of the product phosphotungstic acid is shown in figure 1 . figure 1 From figure 1 It can be seen that the product is at 1079cm -1 、983cm -1 、890cm -1 、800cm -1 、595cm -1 、525cm -1 、483 cm -1 、426 cm -1 There is an obvious absorption peak at , which is compl...

Embodiment 2

[0030] Weigh 16.5 grams of sodium tungstate dihydrate, add 100 mL of deionized water, and stir until the sodium tungstate is completely dissolved; adjust the pH of the solution to 7.0 with 3 mol / L hydrochloric acid, continue stirring for 2 hours, and then transfer to 100 mL of polytetrafluoroethylene In the lined high-pressure reactor, keep it at a constant temperature of 120°C for 10 hours, cool it naturally, transfer the solution into a beaker, add 2mol / L phosphoric acid solution dropwise to pH=2.5, stir for 4 hours, add potassium chloride to Saturated, crystallized overnight at 15°C, purified, filtered, and dried to constant weight to obtain 12.1 g of white product, press H 3 PW 12 o 40 29H 2 O meter, productive rate is 85.5%.

Embodiment 3

[0032] Weigh 16.5 grams of sodium tungstate dihydrate, add 50 mL of deionized water, and stir until the sodium tungstate is completely dissolved; adjust the pH of the solution to 6.5 with 3mol / L hydrochloric acid, continue stirring for 2 hours, and then transfer to 100 mL of polytetrafluoroethylene In a lined high-pressure reactor, keep it standing at 150°C for 10 hours, cool naturally, transfer the solution into a beaker, add 0.5mol / L phosphoric acid solution to pH=2.5, stir for 2 hours, add sodium chloride to the solution Saturated, crystallized overnight at 15°C, purified, filtered, and dried to constant weight to obtain 11.2 g of white product, press H 3 PW 12 o 40 29H 2 O meter, productive rate 79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com