Method for electrocatalytic reduction of carbon dioxide using multi-metal oxygen cluster ionic liquid as electrocatalyst

A technology of polymetallic oxygen clusters and ionic liquids, which is applied in the fields of chemical engineering and the environment, can solve problems such as slow reaction rates and difficulties in obtaining electronic products, and achieve the effects of improving efficiency, reducing initial reduction obstacles, and easily obtaining raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The first step [C 2 mim] 3 PMo 12 o 40 Synthesis of Ionic Liquids

[0023] The synthesis process is to add 150ml containing 0.5734g (0.003mol) [C 2 mim] Br aqueous solution, stirring and dripping 150ml containing 1.8252g (0.001mol) aqueous solution of phosphomolybdic acid, the mixture gradually becomes turbid, after the reaction is finished, the mixed solution is left to stand and filtered, ethanol is repeatedly rinsed, and the product obtained is placed in 60 ℃ in a vacuum oven for 48 hours to obtain a yellow solid [C 2 mim] 3 PMo 12 o 40 .

[0024] The second step [C 2 mim] 3 PMo 12 o 40 Electrocatalytic reduction of CO as an electrocatalyst 2

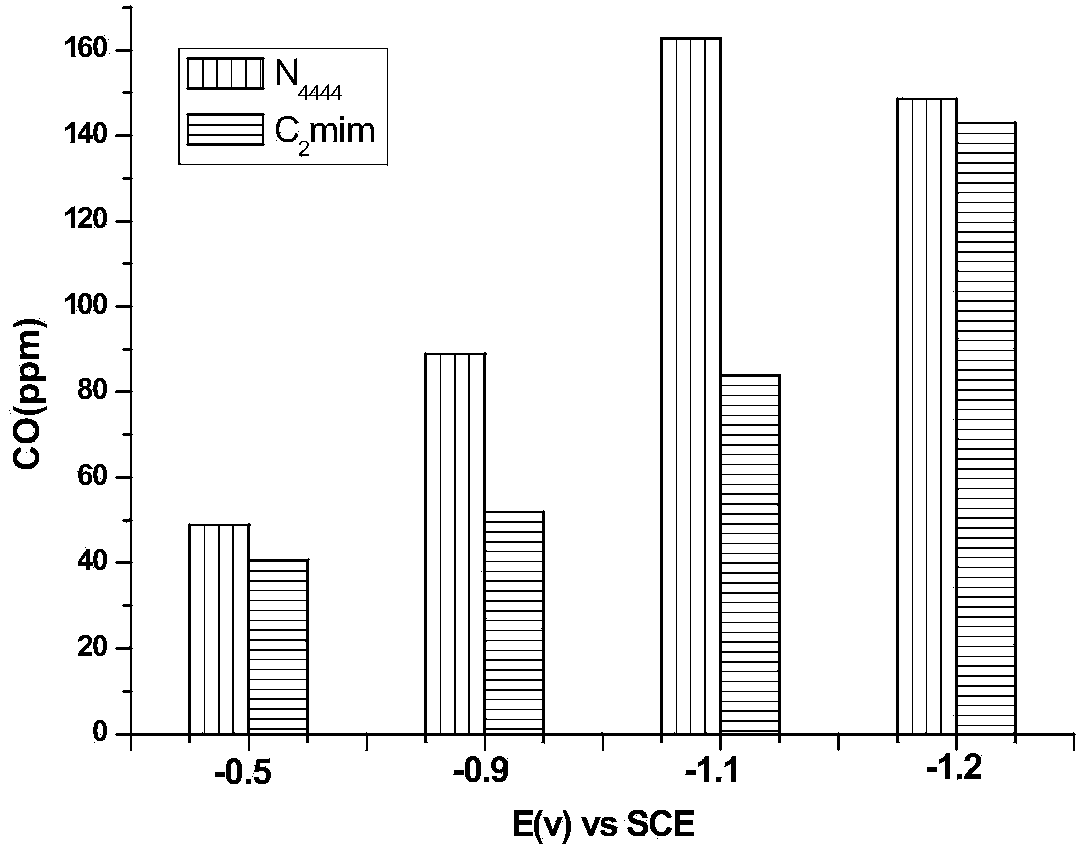

[0025] Will [C 2 mim] 3 PMo 12 o 40 Ionic liquid (0.0509g), potassium perchlorate (2.771g), and DMF (100mL) were added to a quartz reactor with a three-electrode system, electrolyzed at a constant voltage (-0.5V) for 4 hours, and gas products were taken every hour for detection. The gaseous product is CO, 40...

Embodiment 2

[0027] The first step [C 2 mim] 3 PMo 12 o 40 Synthesis of Ionic Liquids

[0028] The synthesis process is to add 150ml containing 0.5734g (0.003mol) [C 2 mim] Br aqueous solution, stirring and dripping 150ml containing 1.8252g (0.001mol) aqueous solution of phosphomolybdic acid, the mixture gradually becomes turbid, after the reaction is finished, the mixed solution is left to stand and filtered, ethanol is repeatedly rinsed, and the product obtained is placed in 60 ℃ in a vacuum oven for 48 hours to obtain a yellow solid [C 2 mim] 3 PMo 12 o 40 .

[0029] The second step [C 2 mim] 3 PMo 12o 40 Electrocatalytic reduction of CO as an electrocatalyst 2

[0030] Will [C 2 mim] 3 PMo 12 o 40 Ionic liquid (0.0509g), potassium perchlorate (2.771g), and DMF (100mL) were added to the quartz reactor of the three-electrode system, electrolyzed at a constant voltage (-0.9V) for 4 hours, and gas products were taken every hour for detection. The gaseous product is CO, 5...

Embodiment 3

[0032] The first step [C 2 mim] 3 PMo 12 o 40 Synthesis of Ionic Liquids

[0033] The synthesis process is to add 150ml containing 0.5734g (0.003mol) [C 2 mim] Br aqueous solution, stirring and dripping 150ml containing 1.8252g (0.001mol) aqueous solution of phosphomolybdic acid, the mixture gradually becomes turbid, after the reaction is finished, the mixed solution is left to stand and filtered, ethanol is repeatedly rinsed, and the product obtained is placed in 60 ℃ in a vacuum oven for 48 hours to obtain a yellow solid [C 2 mim] 3 PMo 12 o 40 .

[0034] The second step [C 2 mim] 3 PMo 12 o 40 Electrocatalytic reduction of CO as an electrocatalyst 2

[0035] Will [C 2 mim] 3 PMo 12 o 40 Ionic liquid (0.0509g), potassium perchlorate (2.771g), and DMF (100mL) were added to the quartz reactor of the three-electrode system, electrolyzed at a constant voltage (-1.1V) for 4 hours, and gas products were taken every hour for detection. The gaseous product is CO, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com