Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "Injection force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

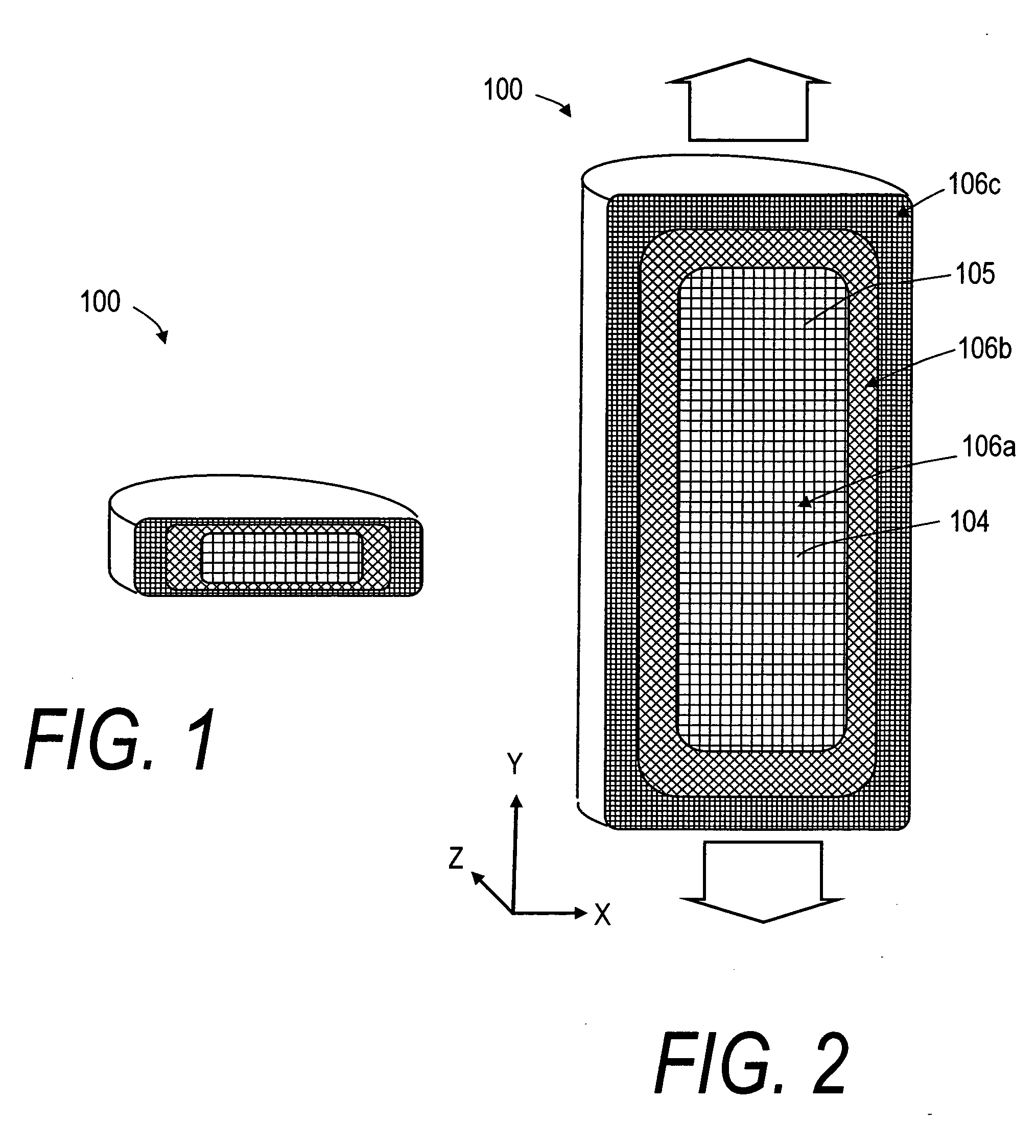

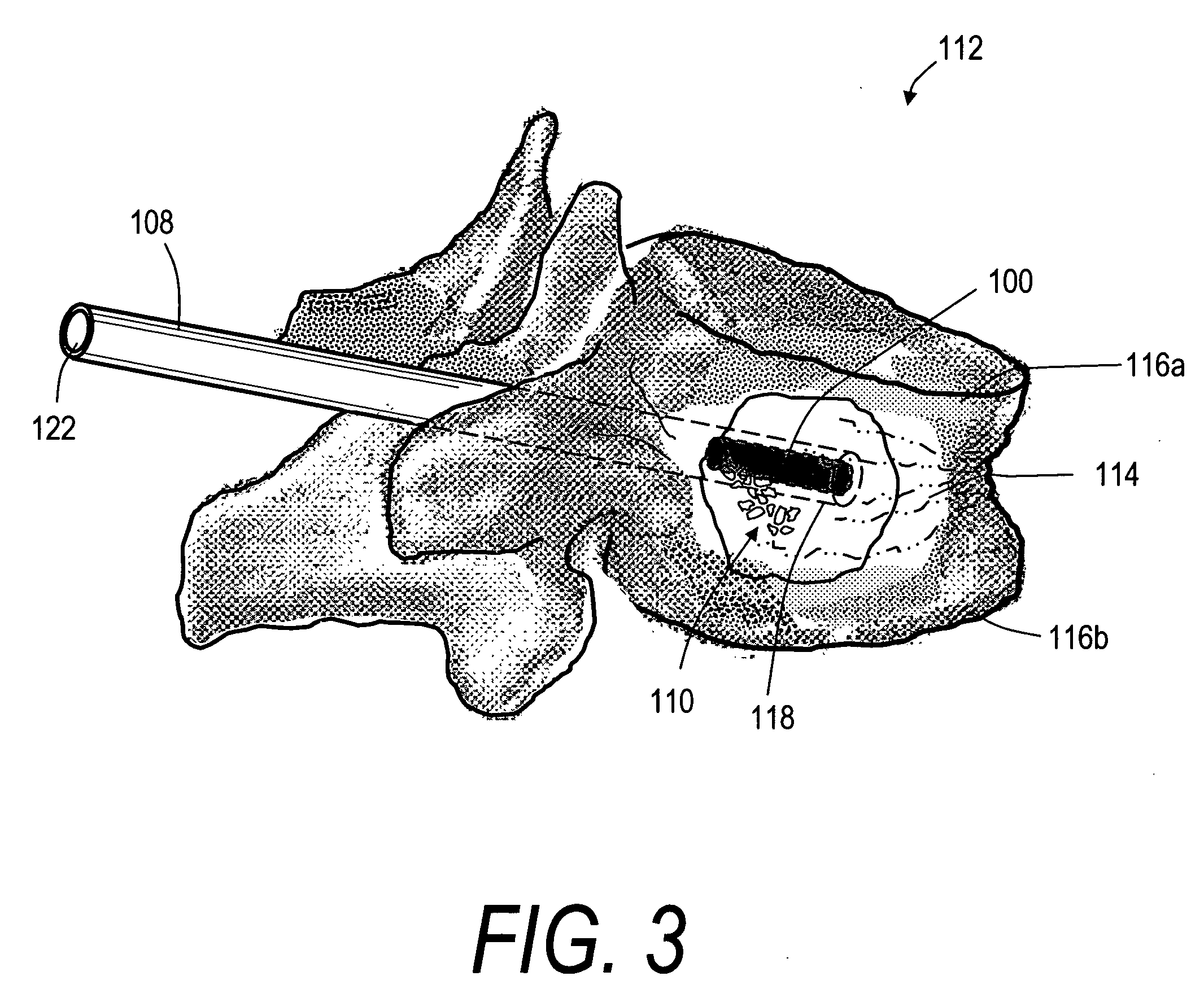

Bone treatment systems and methods

InactiveUS20060106459A1Reduces and eliminates possibilityAvoid thermal damageInternal osteosythesisSpinal implantsFracture reductionHigh pressure

A system for treating an abnormal vertebral body such as a compression fracture. In an exemplary embodiment, the system includes a biocompatible flow-through implant structure configured with a three-dimensional interior web that defines flow openings therein for cooperating with a two-part hardenable bone cement. The flow-through structure is capable of compacted and extended shapes and in one embodiment provides a gradient in flow openings for controlling flow parameters of a bone cement injected under high pressure into the interior thereof. The flow-through implant structure is configured for transducing cement injection forces into a selected direction for moving apart cortical endplates of a vertebra to reduce a fracture. In one embodiment, the flow-through implant structure is coupled to an Rf source for applying Rf energy to a two-part bone cement to accelerate curing of the cement to thereby allow on-demand alterations of cement viscosity. The Rf system allows for control of bone cement polymerization globally or regionally to prevent cement extravasion and to direct forces applied to a vertebra to reduce a fracture.

Owner:DFINE INC

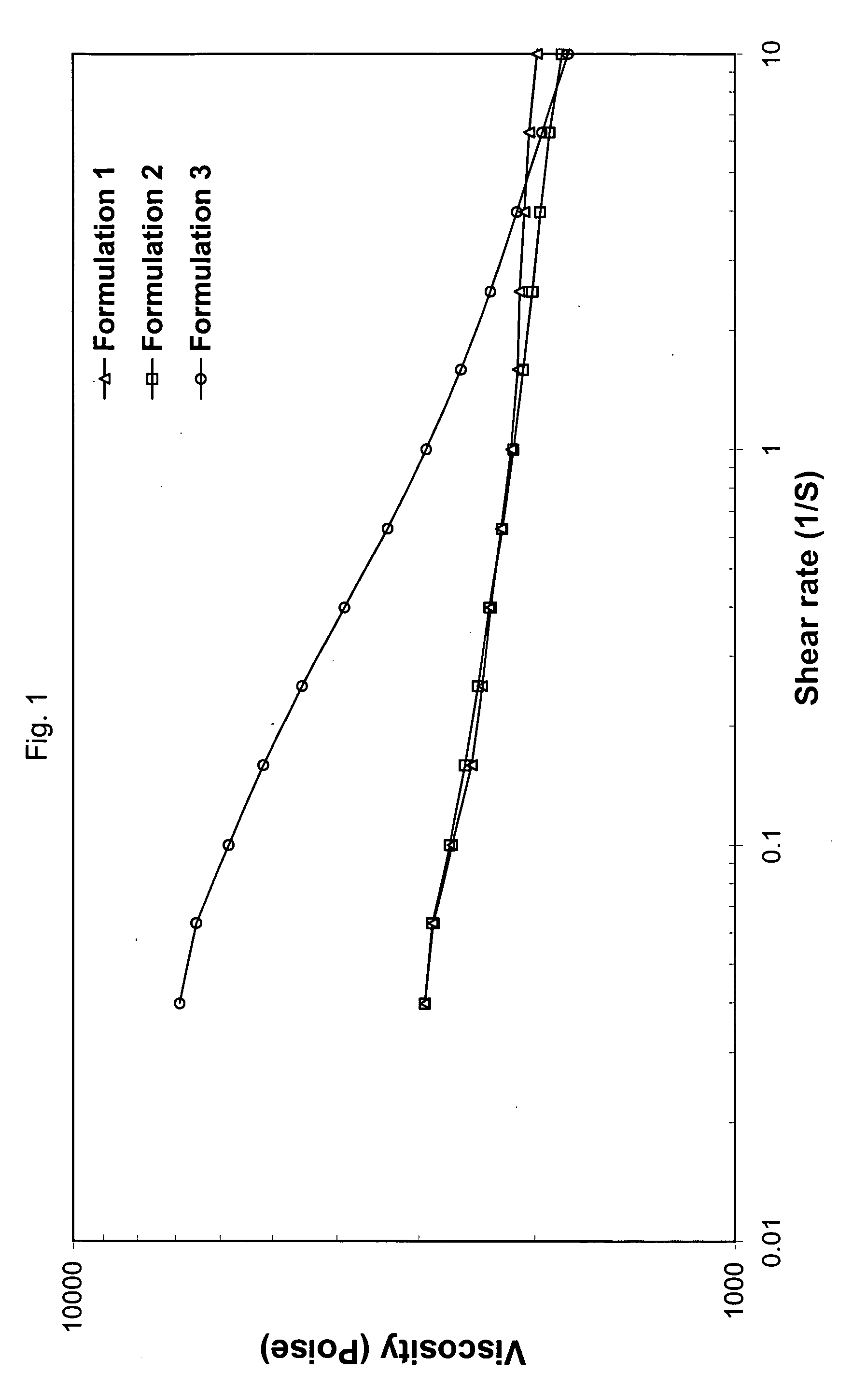

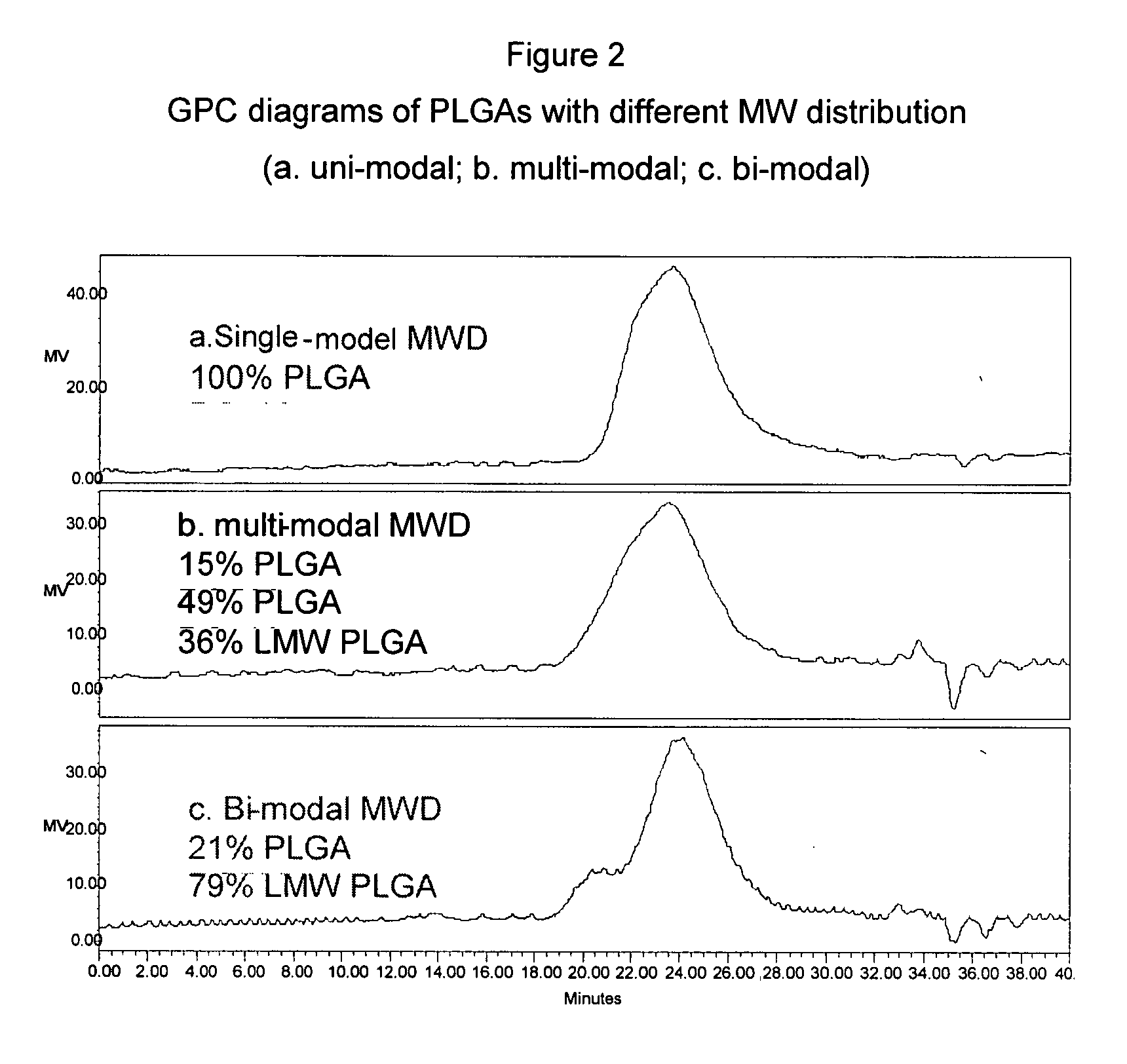

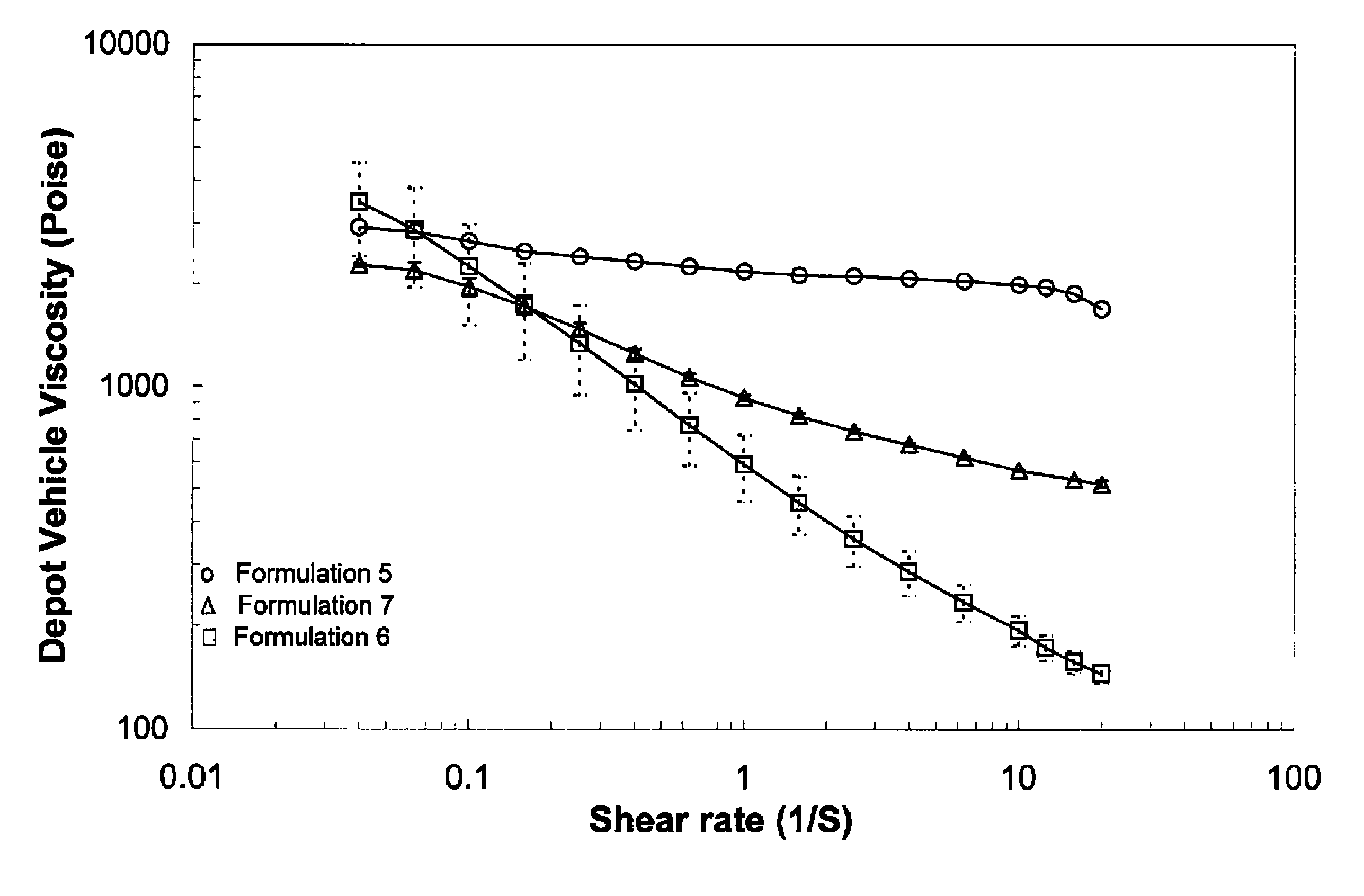

Injectable multimodal polymer depot compositions and uses thereof

InactiveUS20040022859A1Effective distributionBeneficial agent loading ratePowder deliveryAerosol deliverySolventPolymer chemistry

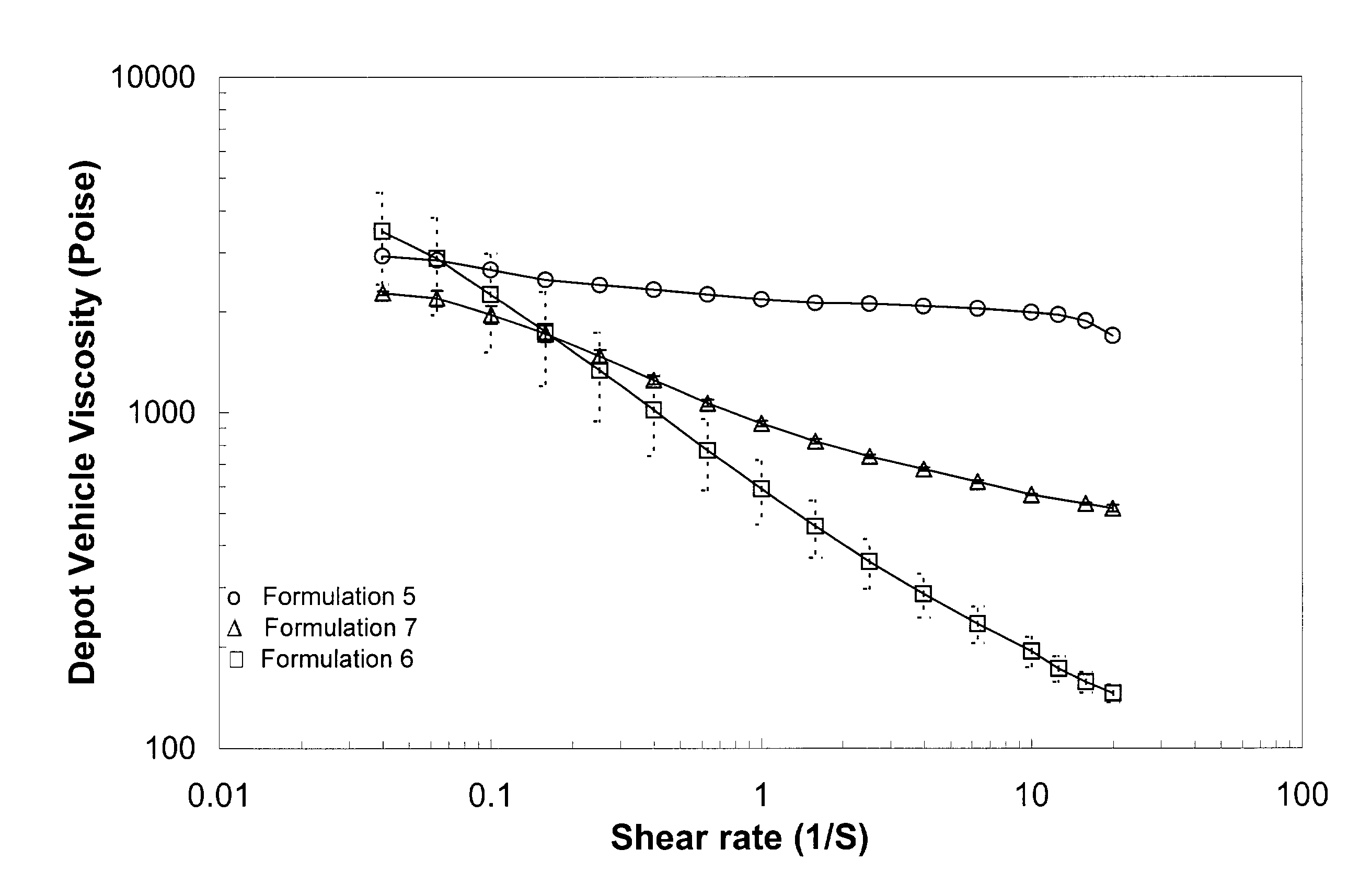

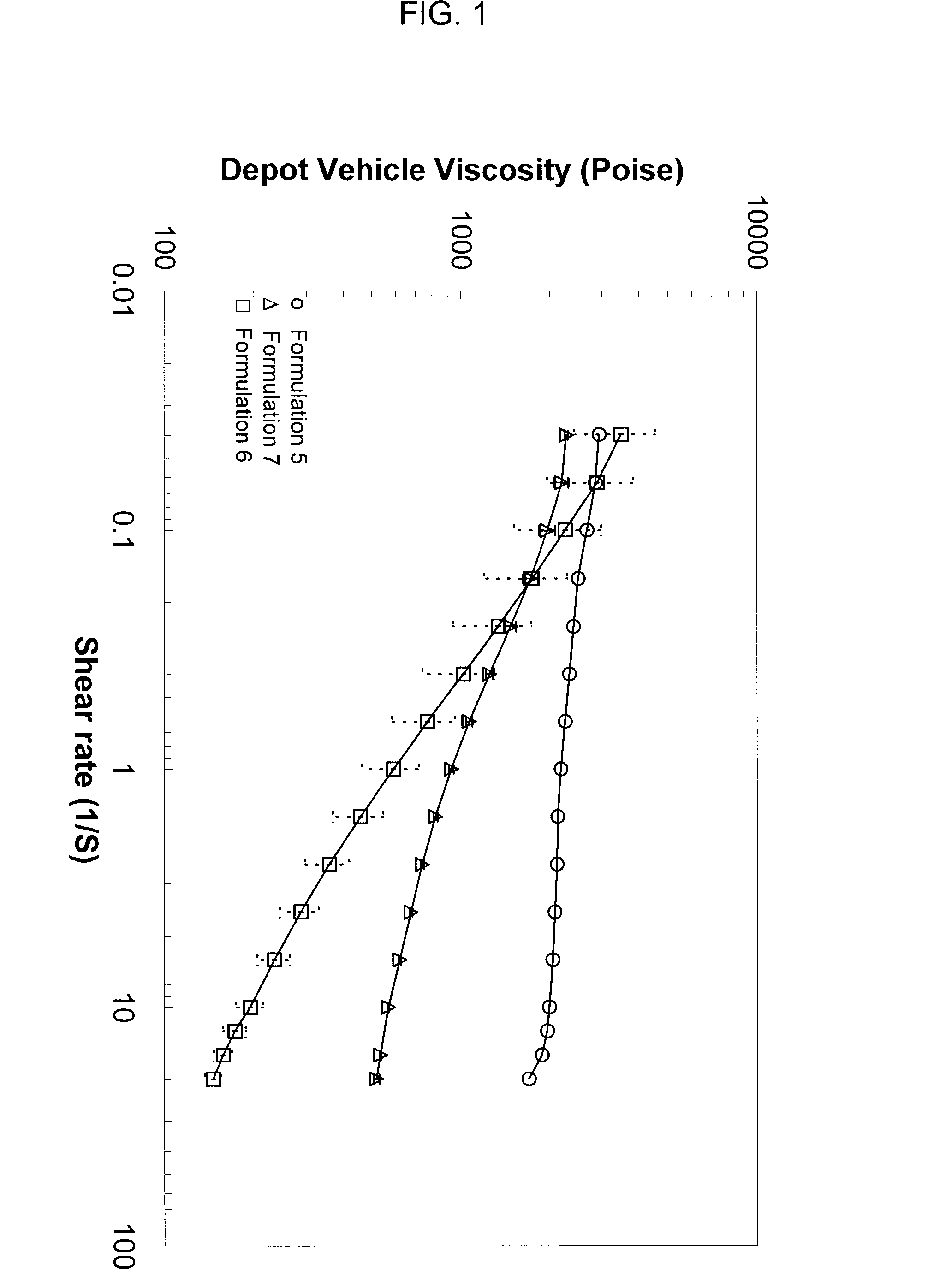

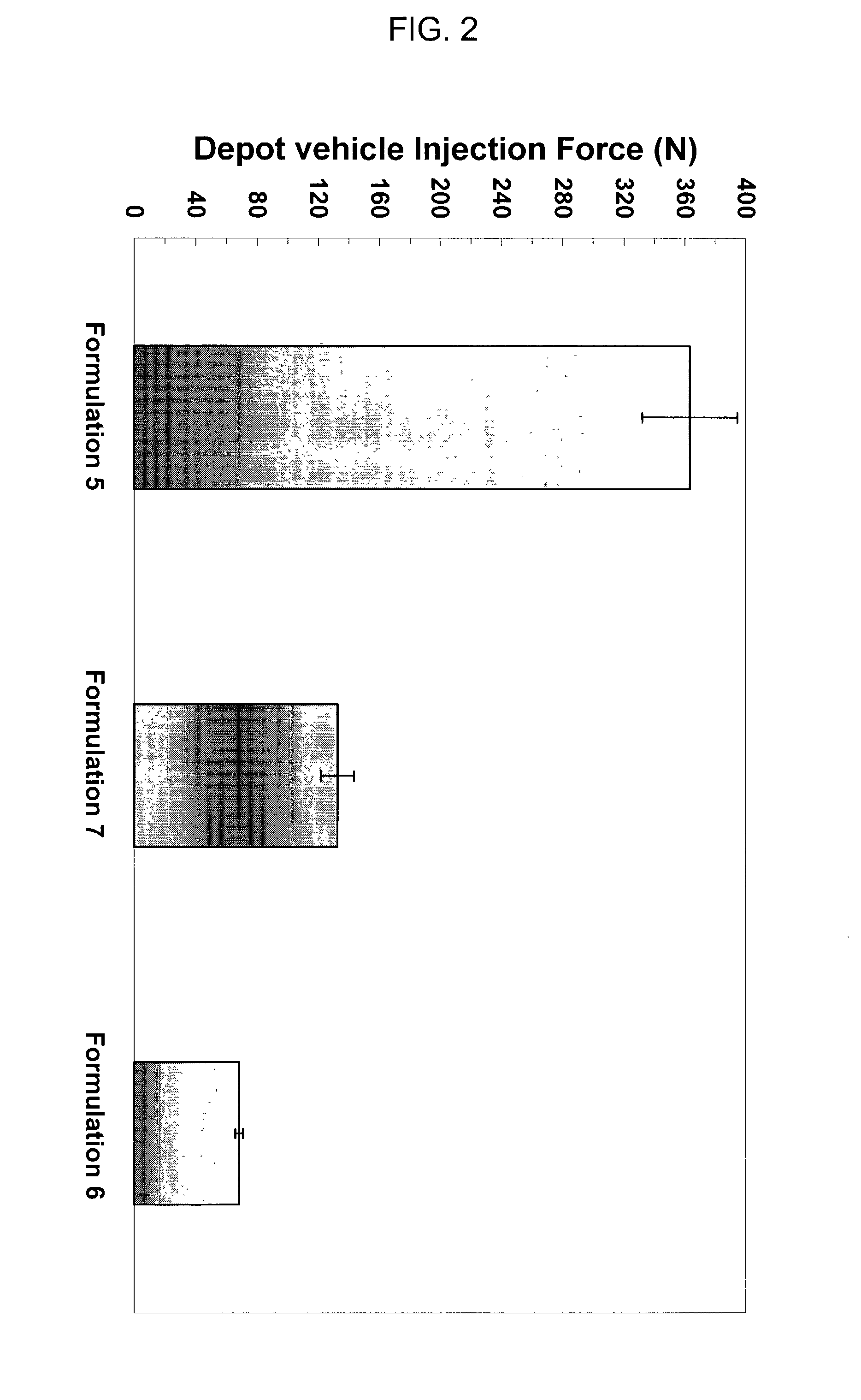

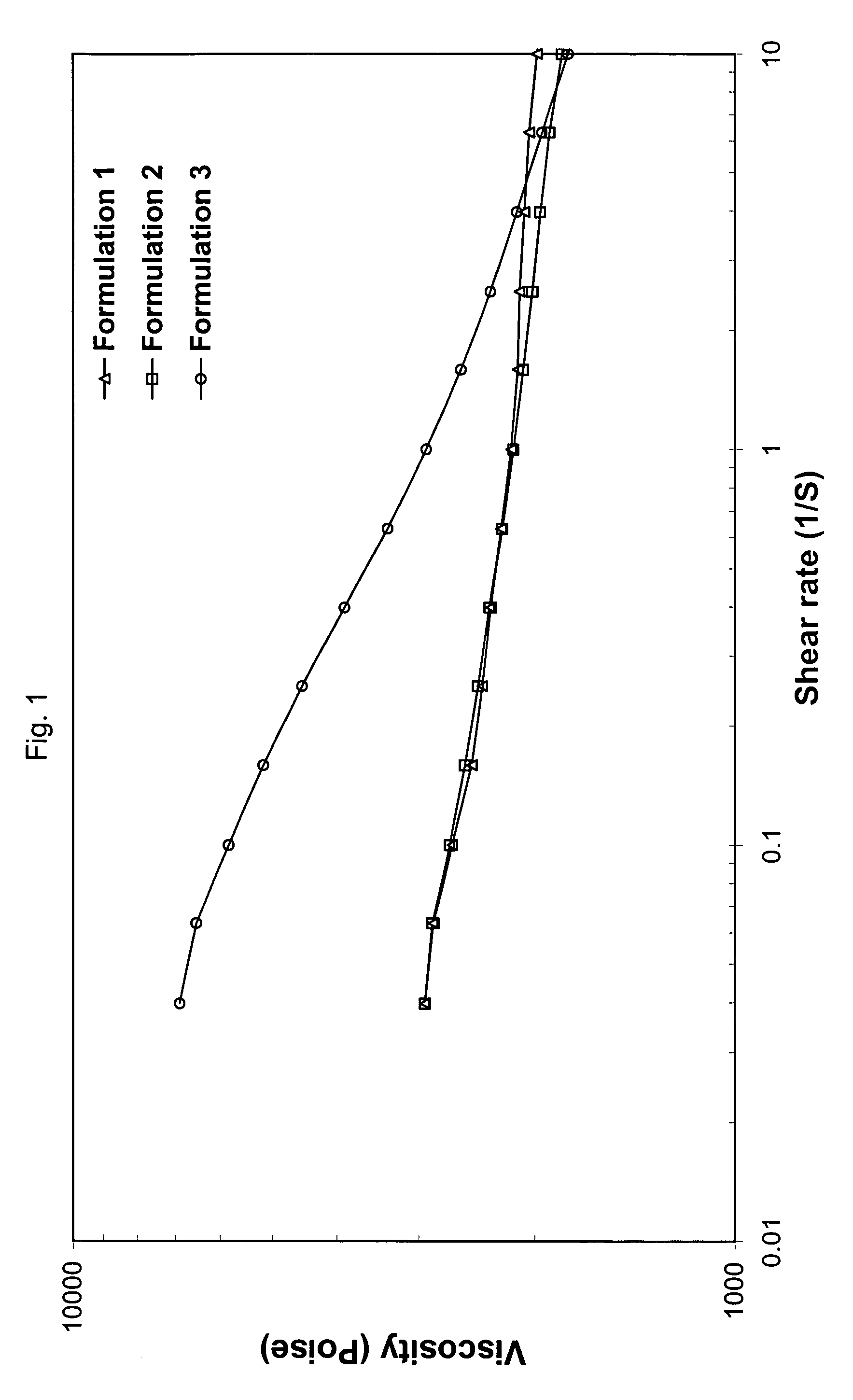

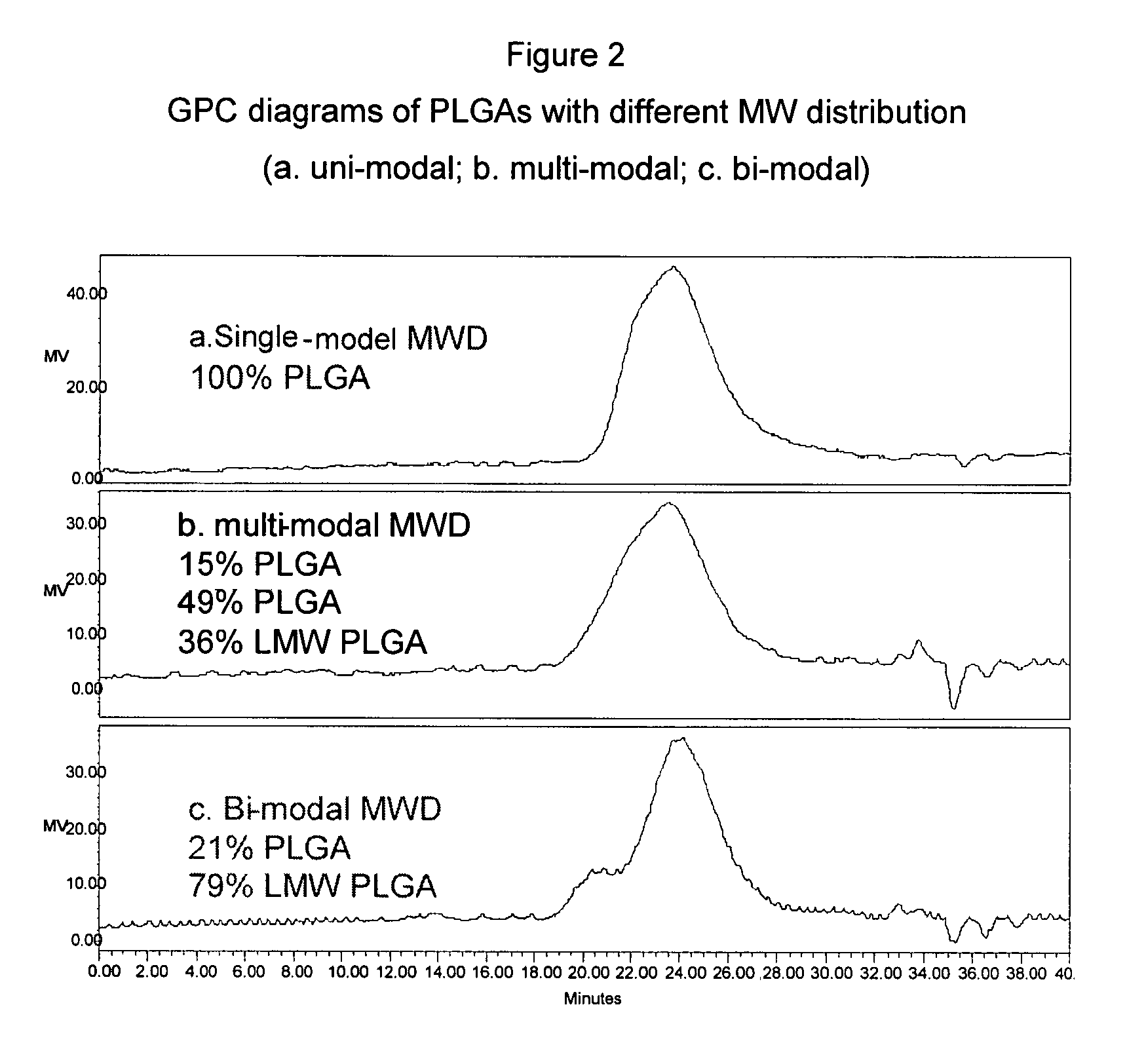

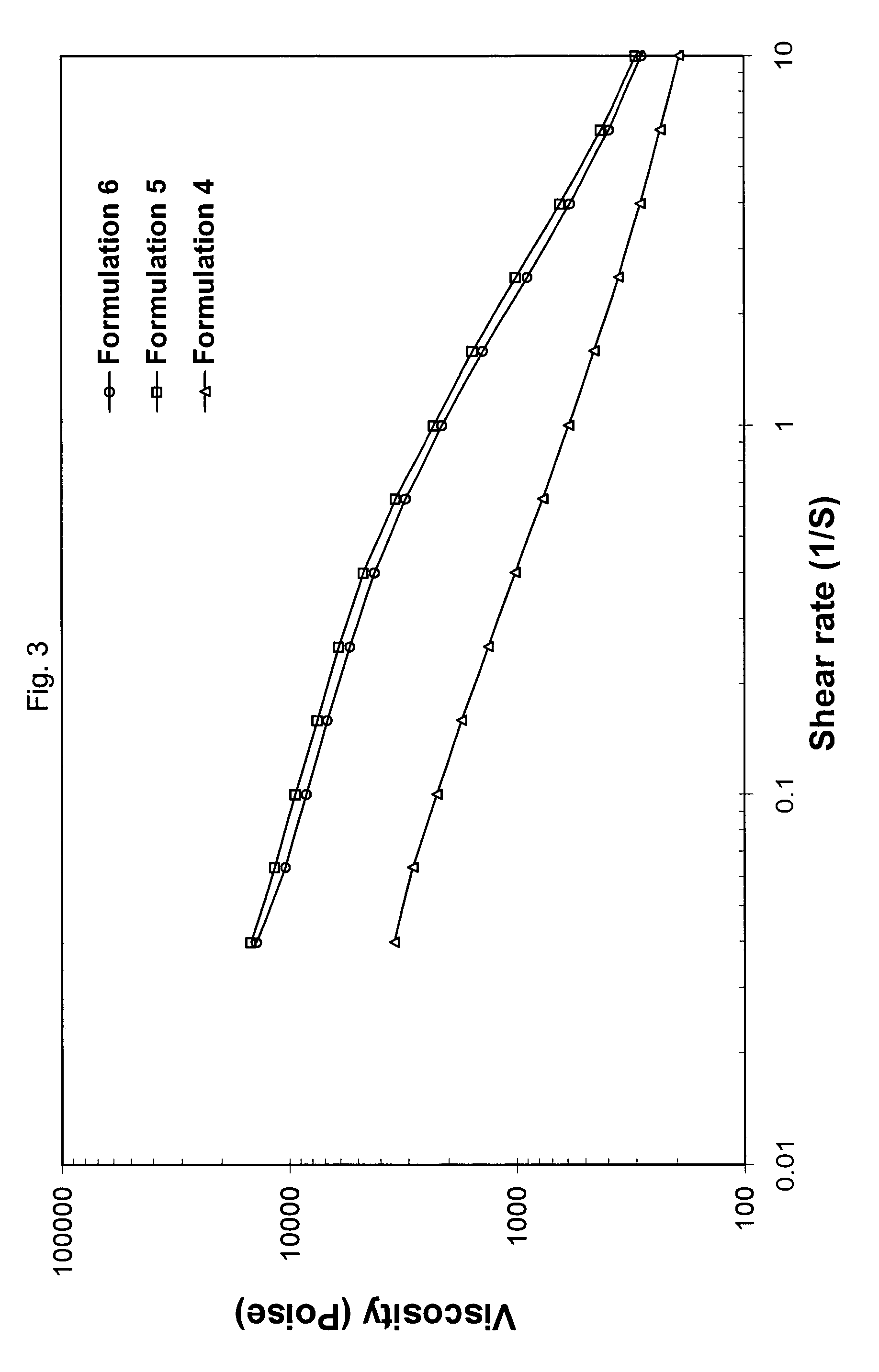

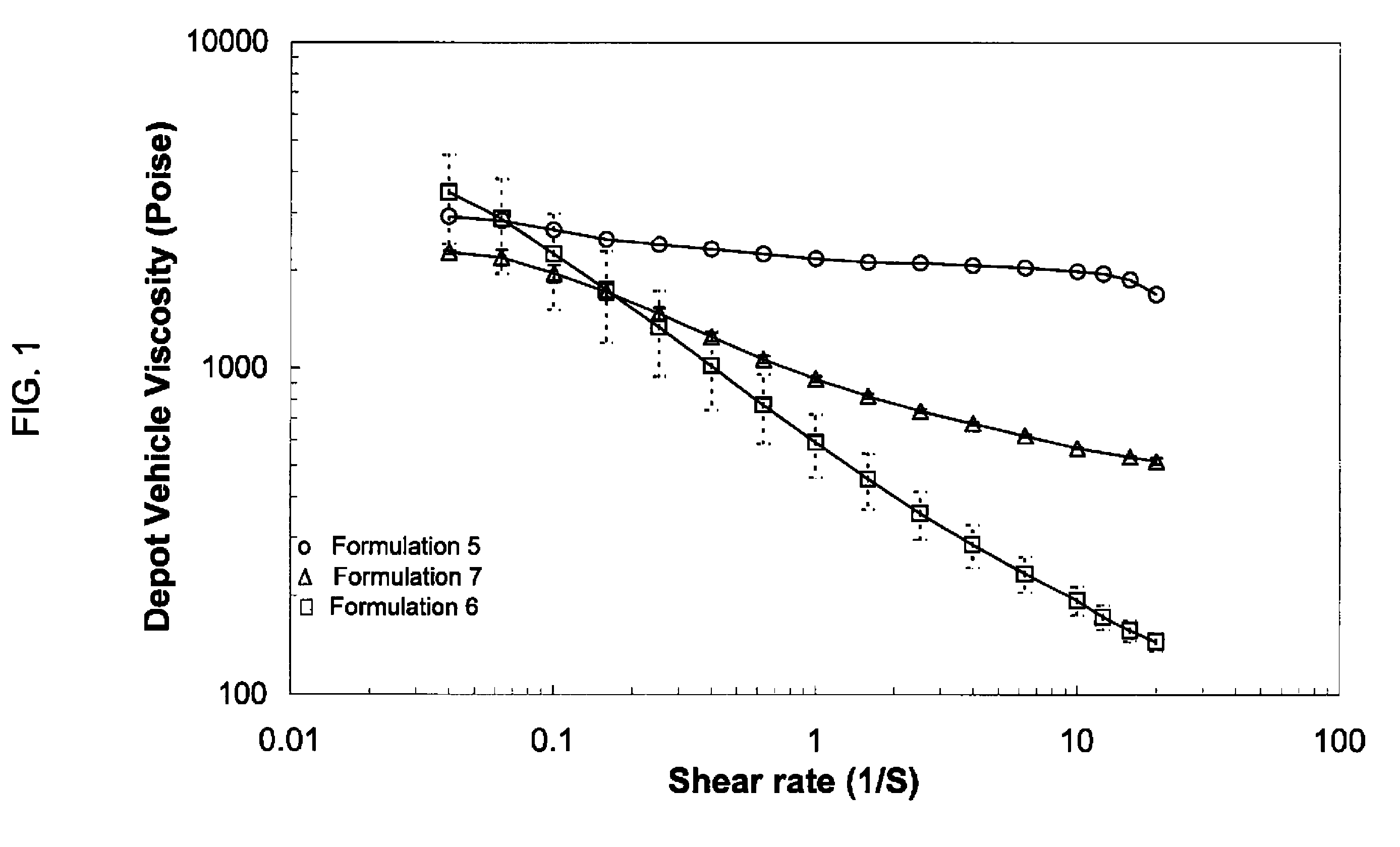

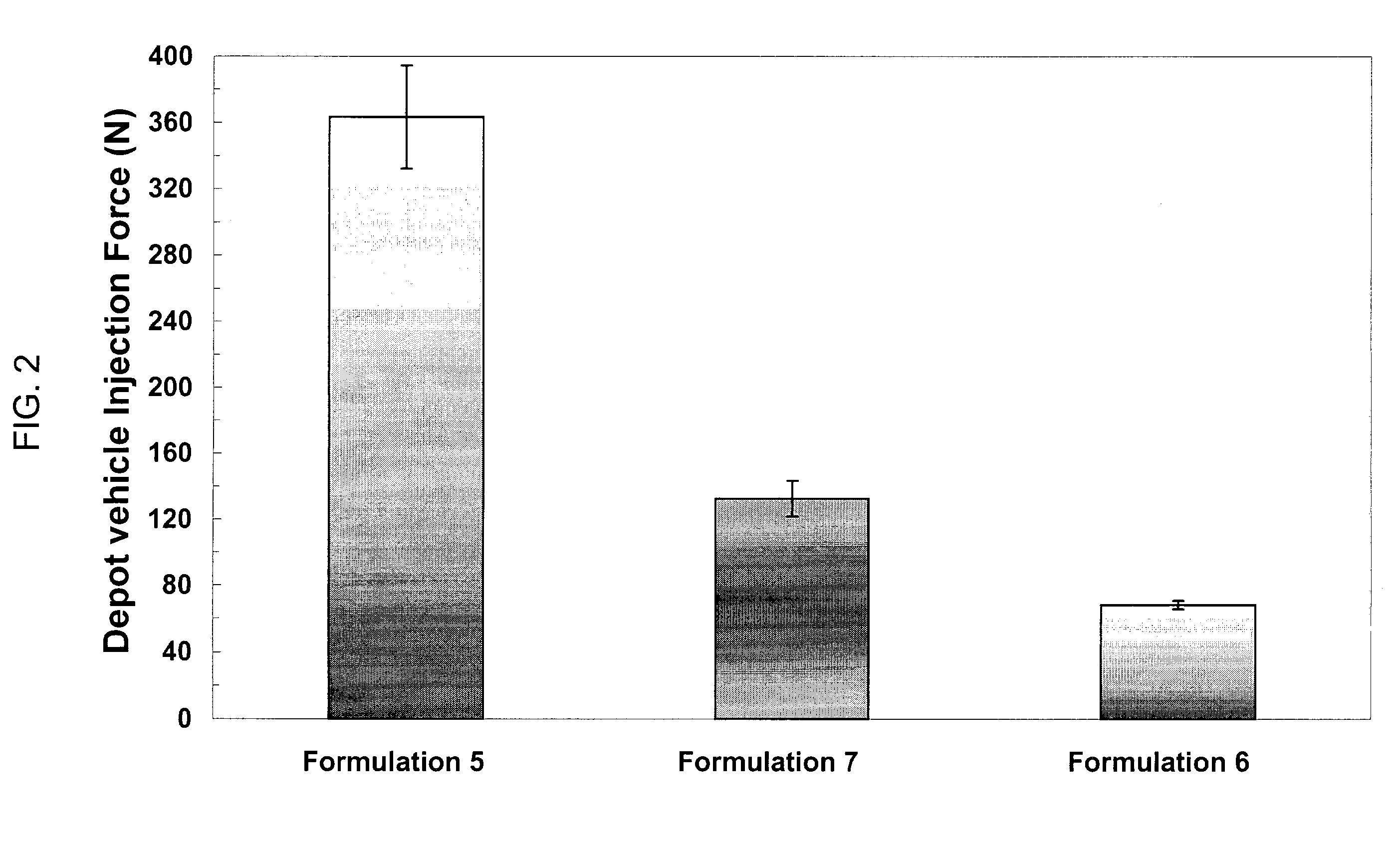

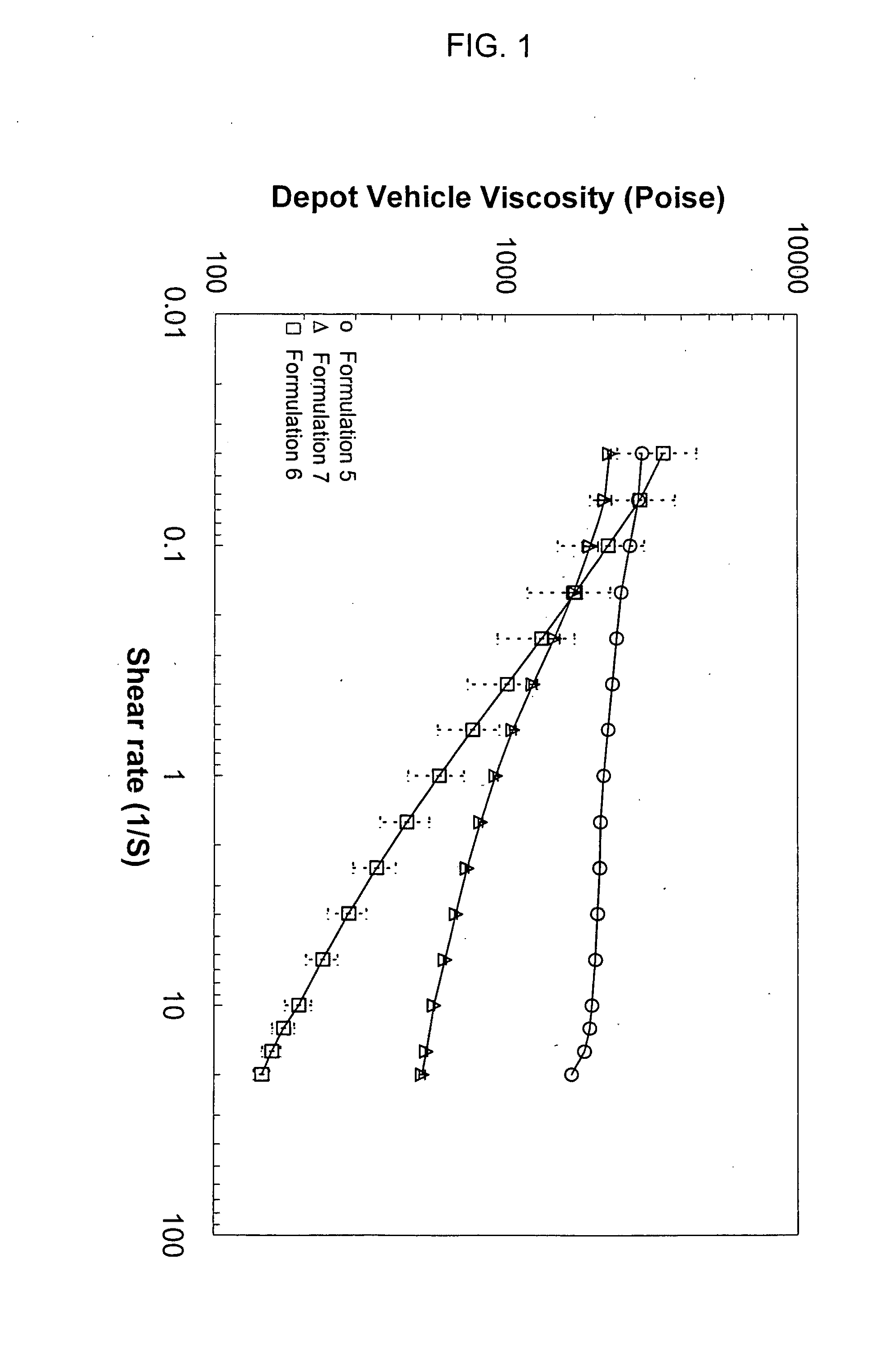

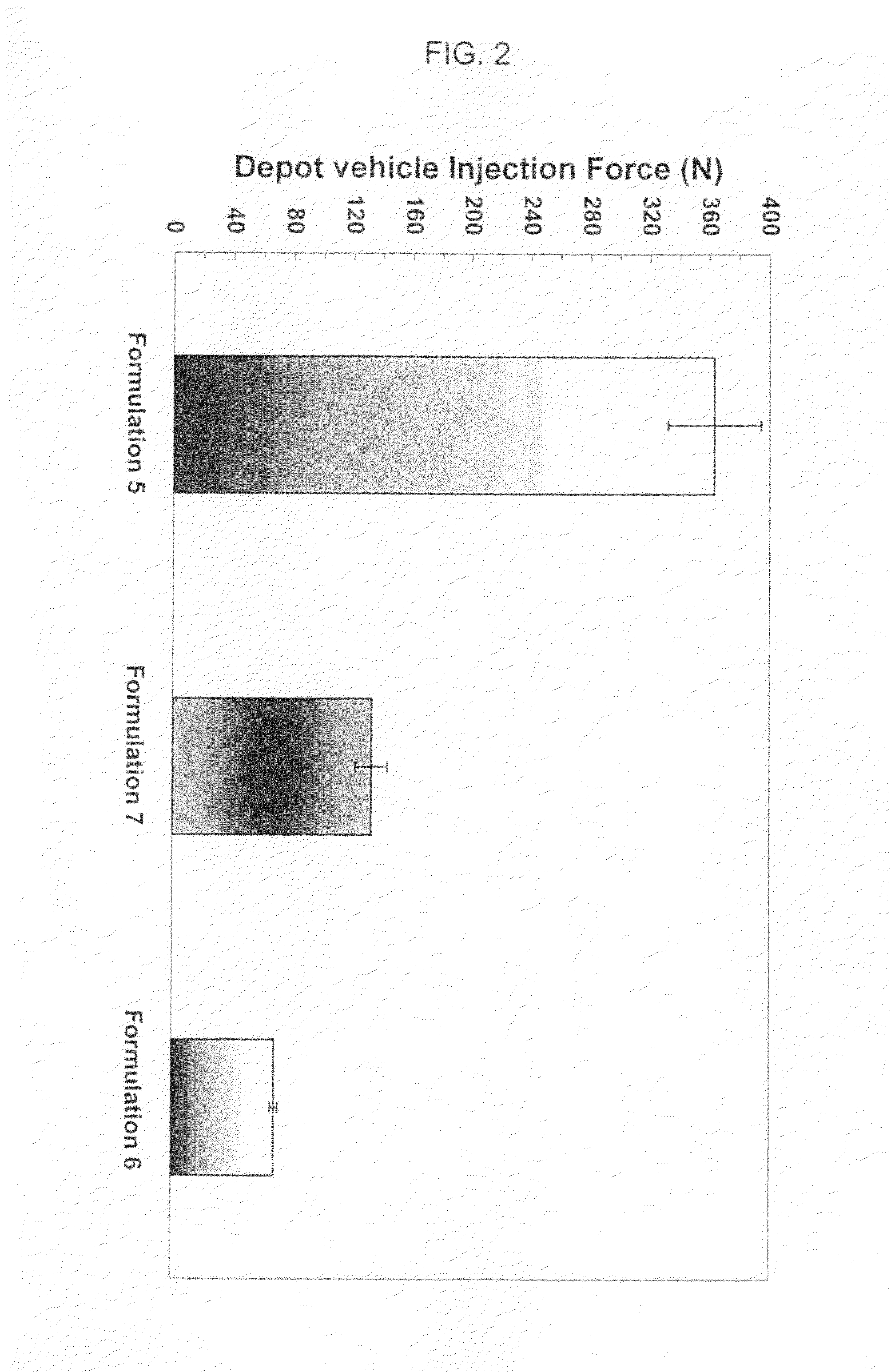

Injectable depot compositions are provided that include a polymer matrix having a plurality of bioerodible, biocompatible polymers wherein wherein each polymer of the plurality of polymers has a specified weight average molecular weight; and the polymer matrix has a broad molecular weight distribution of the plurality of polymers; a solvent having a miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith; and a beneficial agent. The compositions are have substantially improved the shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

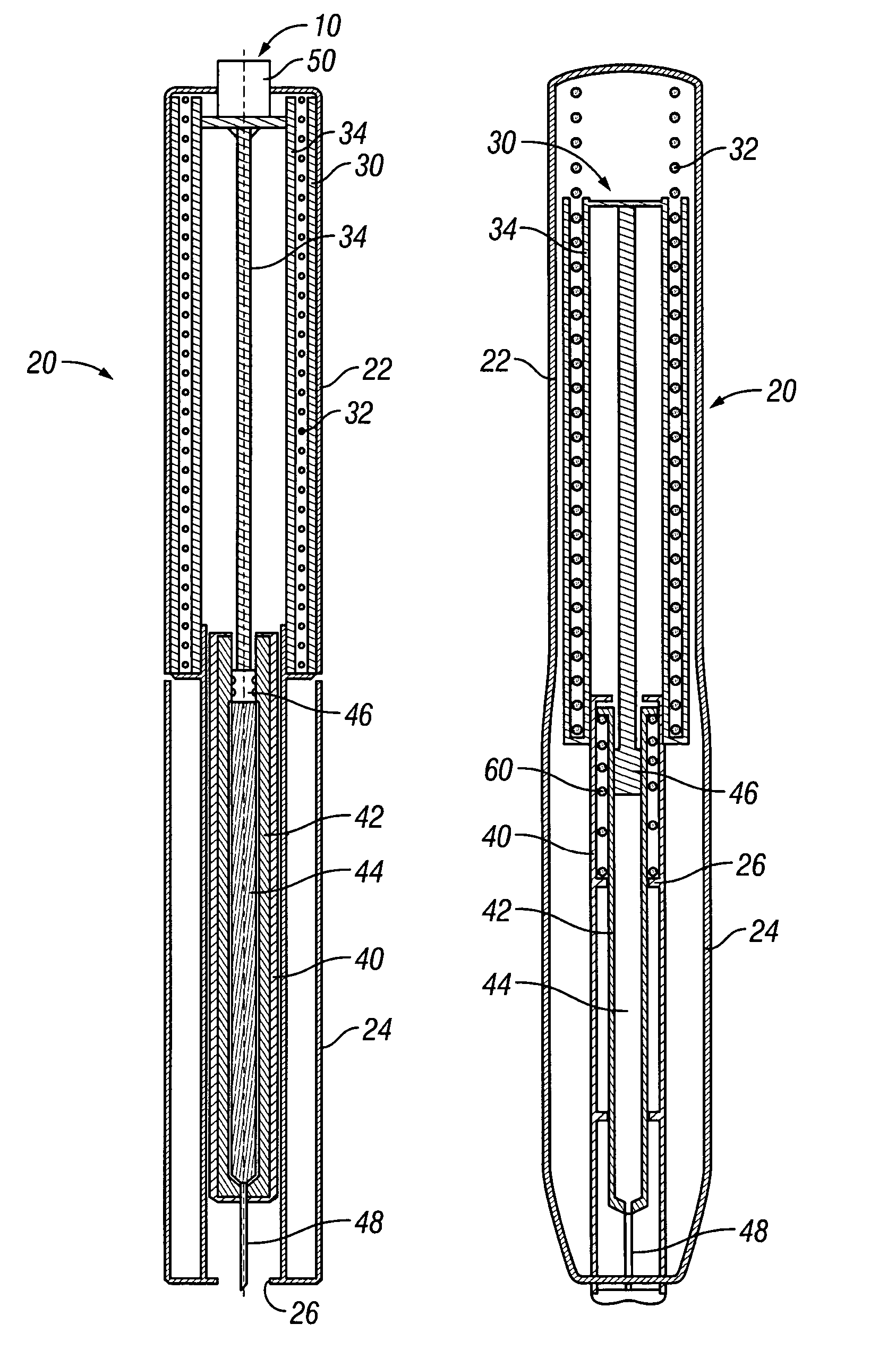

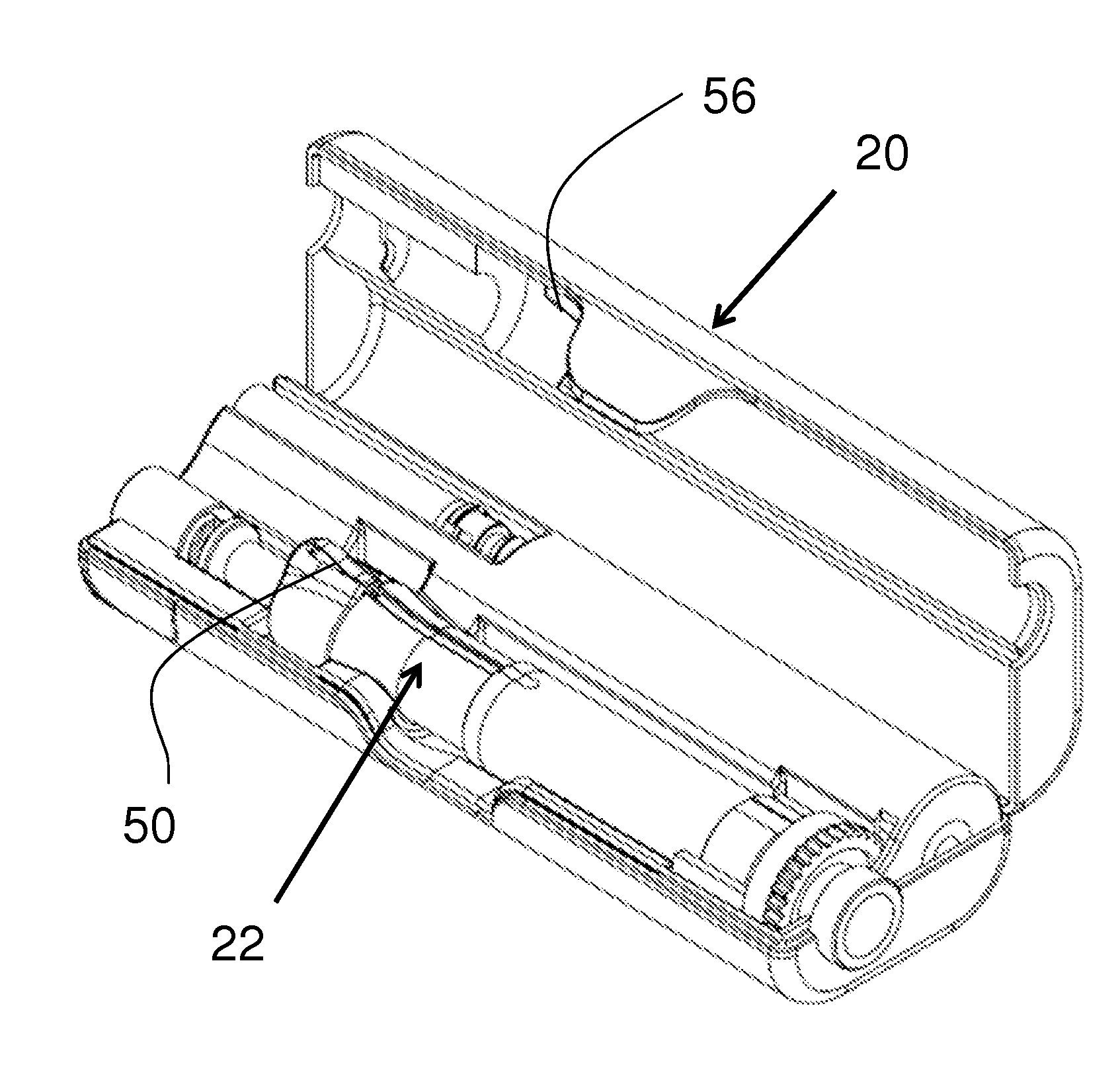

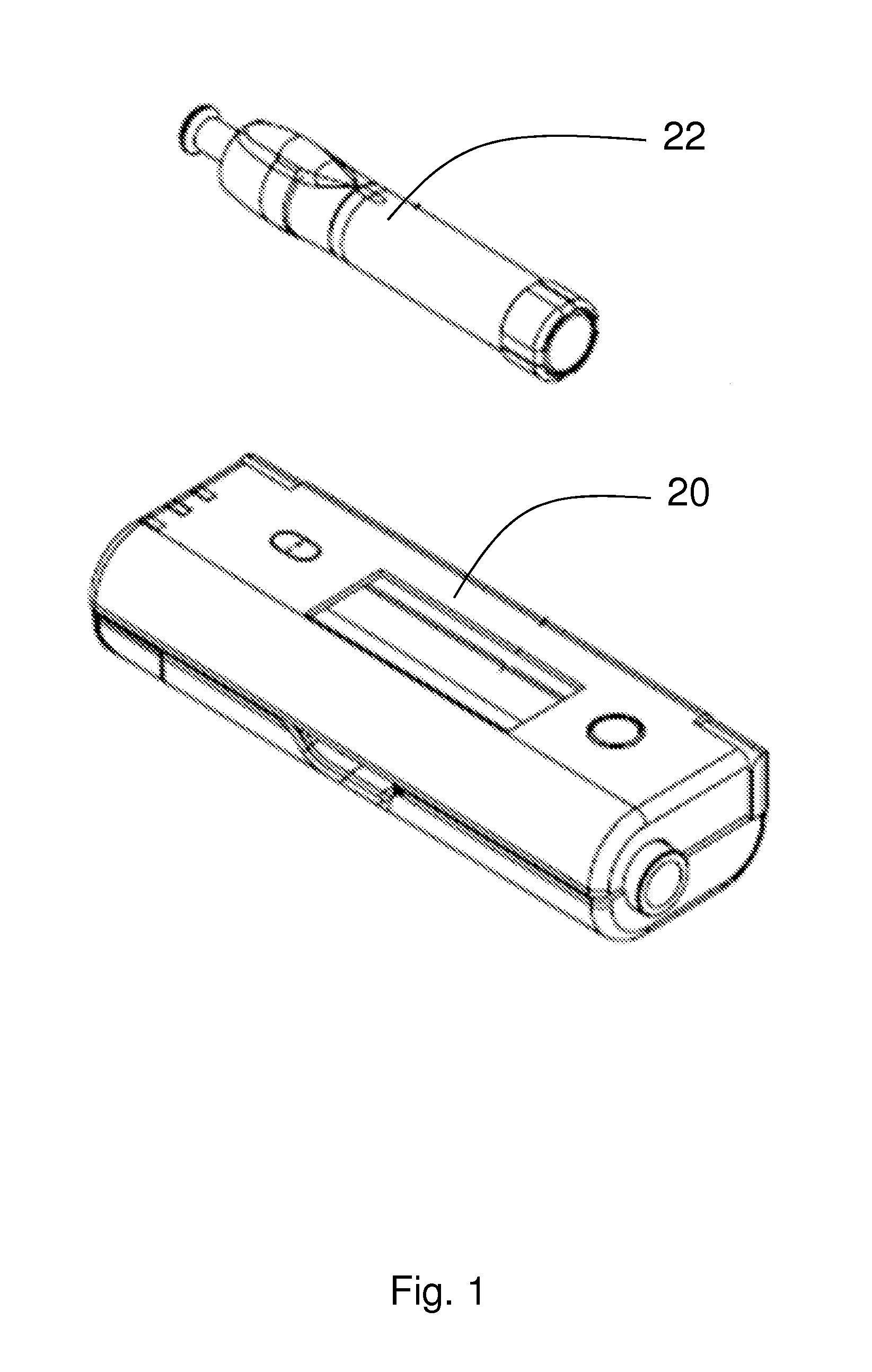

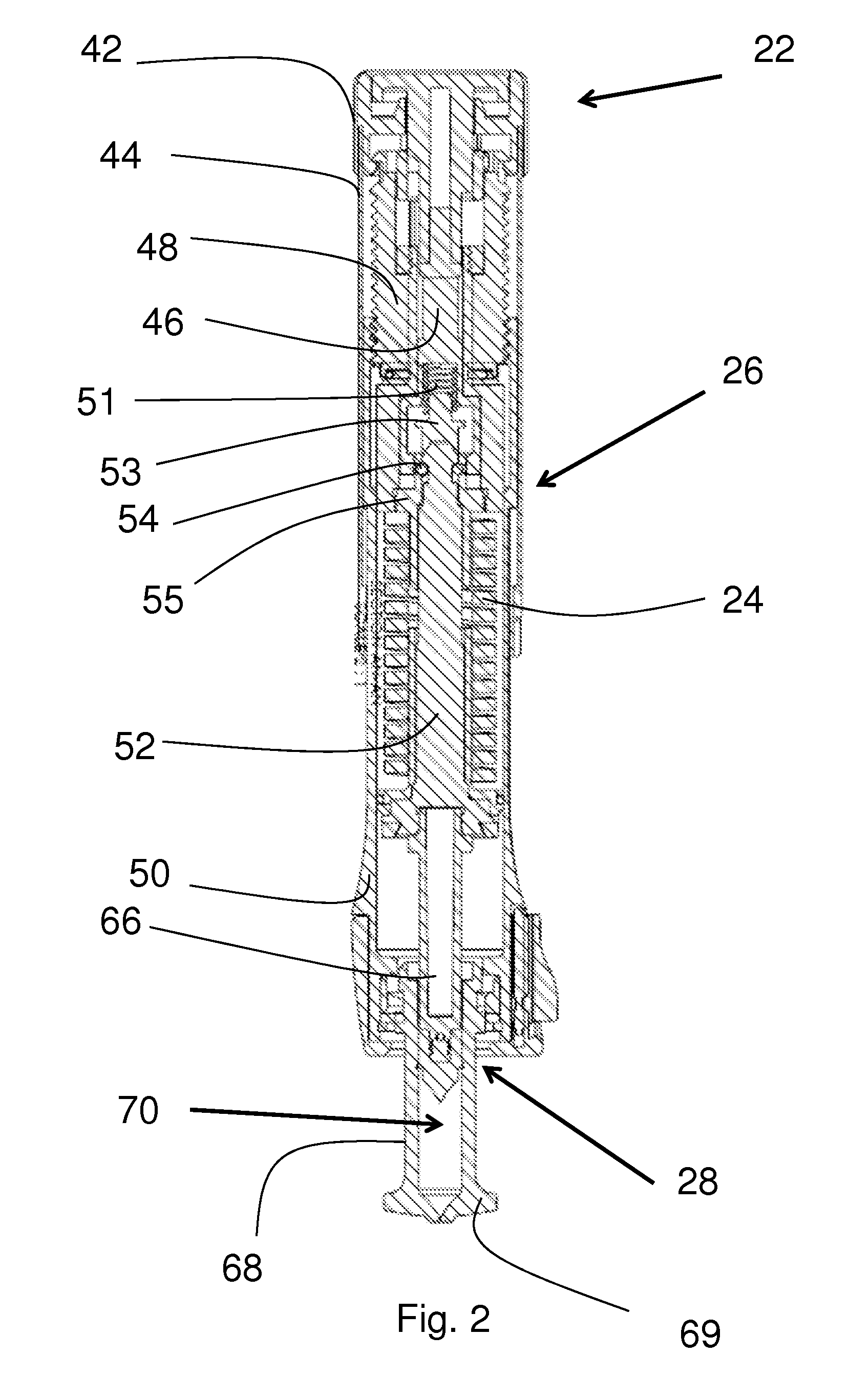

Reusable, spring driven autoinjector

The present invention provides a reusable spring driven autoinjector. The drive mechanism of the autoinjector of the present invention includes one or more drive springs formed of a shape memory alloy. Therefore, by alternating the shape memory alloy forming the one or more drive springs between austenite phase before an injection and a martensite phase after injection, the reusable autoinjector of the present invention is capable of providing an injection force that is higher than the compressive force required to cock the drive mechanism in preparation for a subsequent injection operation.

Owner:ALZA CORP

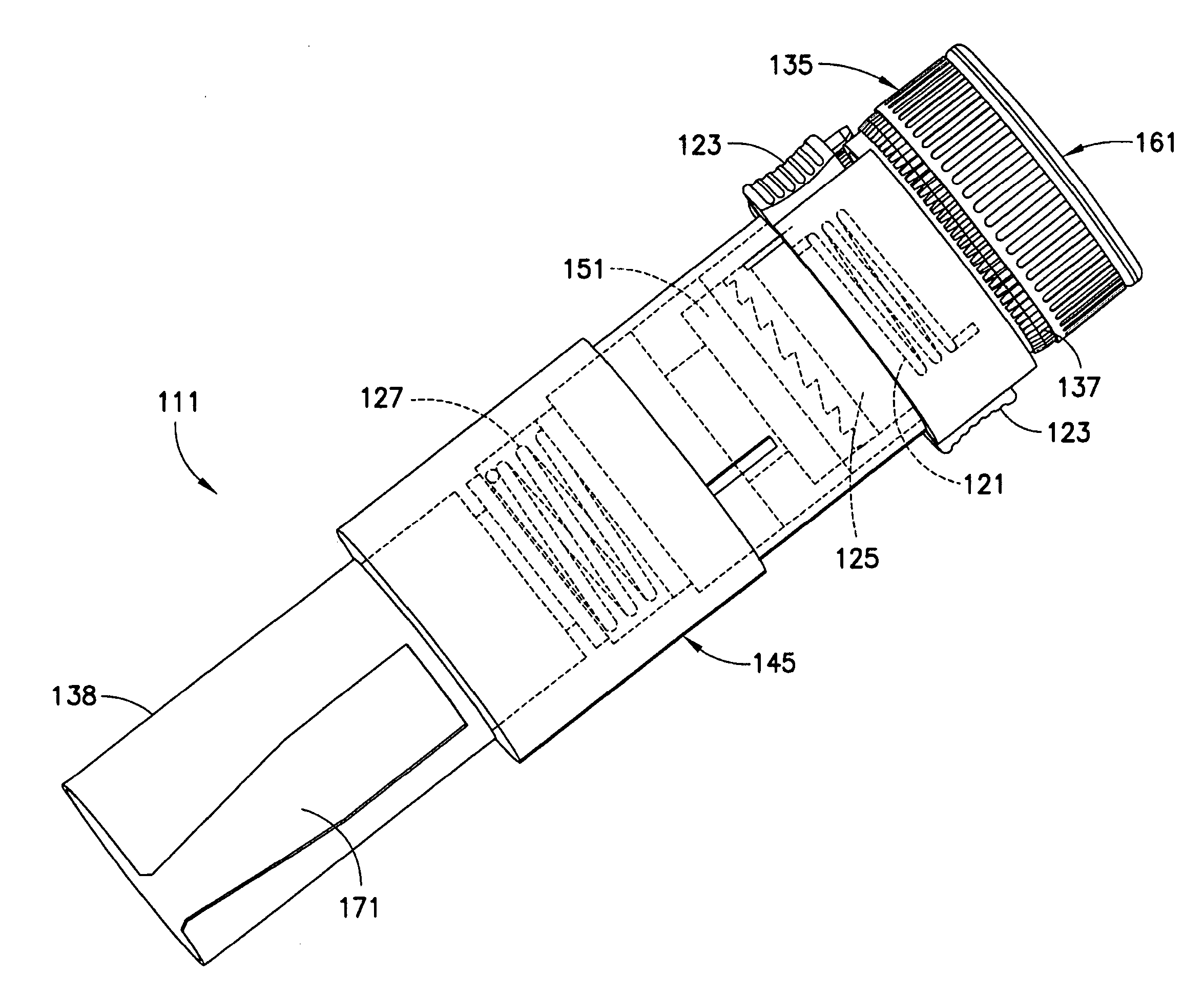

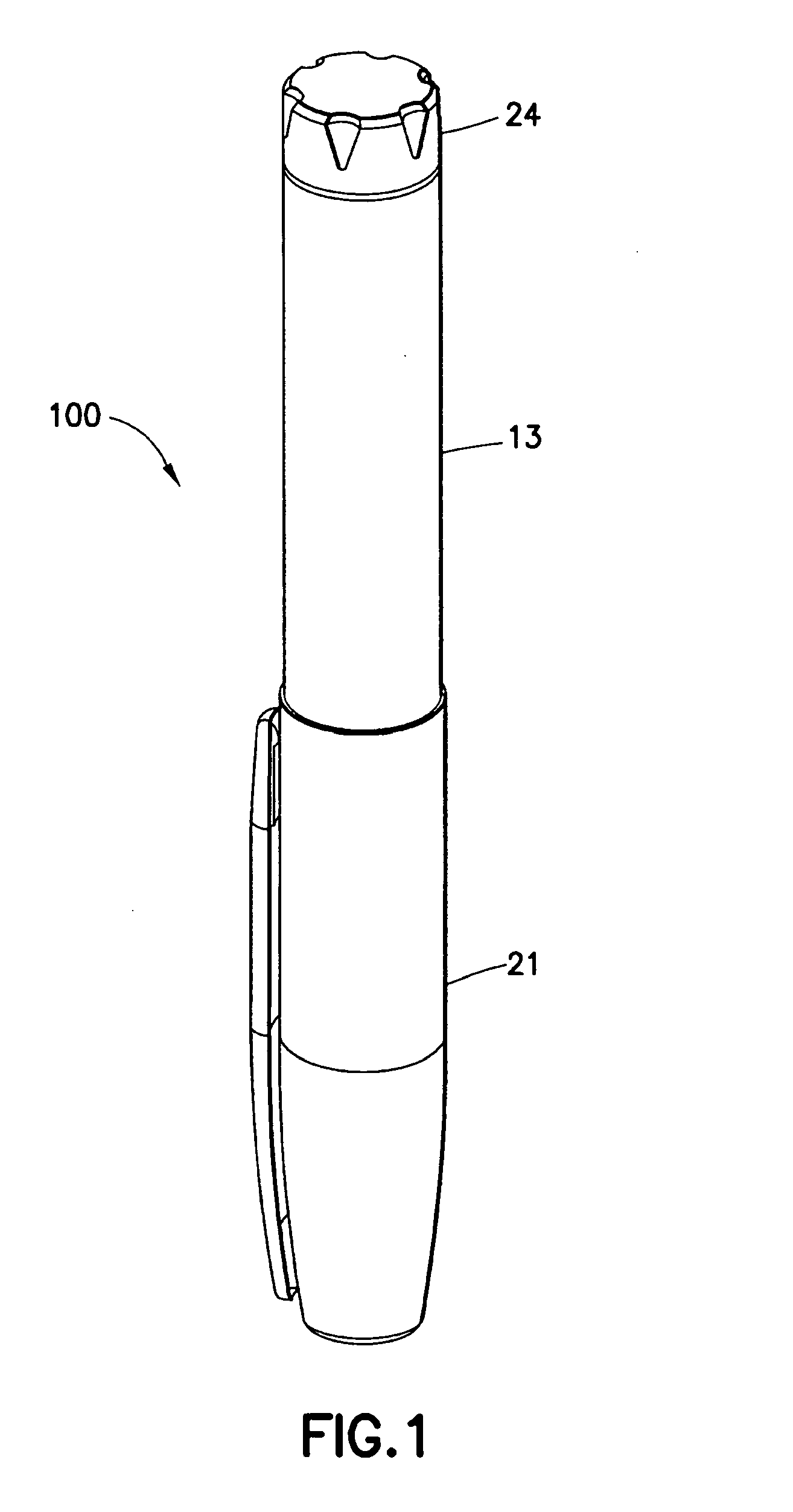

Additive Force Device For Drug Delivery Pen For Intradermal Medication Injection

ActiveUS20110257604A1Easy to optimizeFacilitating the intradermal medication injectionAmpoule syringesAutomatic syringesMedication injectionMechanical engineering

An additive force device (111) is connectible with a drug delivery device (100) to increase the amount of force exerted by a user on the dose setting knob (24) to facilitate injection. The additive force device (111) includes a first spring (121) and a loading barrel (135) connected to the first spring (121) for storing torque therein. A ratchet assembly (129) is connected to the loading barrel (135) and to the first spring (121). The ratchet assembly (129) has a first position in which torque is stored in the first spring (121) and a second position in which torque is released from the first spring (121). An inner barrel (133) is connected to the ratchet assembly and to the drug delivery device (100). The inner barrel (133) transmits the stored torque from the first spring (121) to the drug delivery device (100) to increase an injection force thereof.

Owner:BECTON DICKINSON & CO

Catheter injectable depot compositions and uses thereof

InactiveUS7829109B2Improved shear thinning behaviorReduce injection forcePowder deliverySenses disorderMedicineAromatic alcohol

Catheter injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions have substantially improved shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

Electrical needle-free injector system

InactiveUS20120302947A1Simplify the batching processReduce the possibilityJet injection syringesAutomatic syringesNeedle Free InjectionNeedle free

In one aspect of the invention, a system comprising a needle-free injector is disclosed. The system comprises a needle-free injector comprising a trigger assembly adapted to exert an injection force, the trigger assembly comprising a spring storing the injection force. The system also comprises a winding mechanism for priming the spring for the storing of the injection force, wherein the winding mechanism is electrically powered. According to another aspect of the present invention, an alternate needle-free injector system is disclosed. The system comprises a needle-free injector comprising a nozzle adapted to be loaded with an injectable. The system also comprises a dosing mechanism for loading the injectable into the nozzle, wherein the dosing mechanism is electrically powered.

Owner:EURO PHARMA GRP

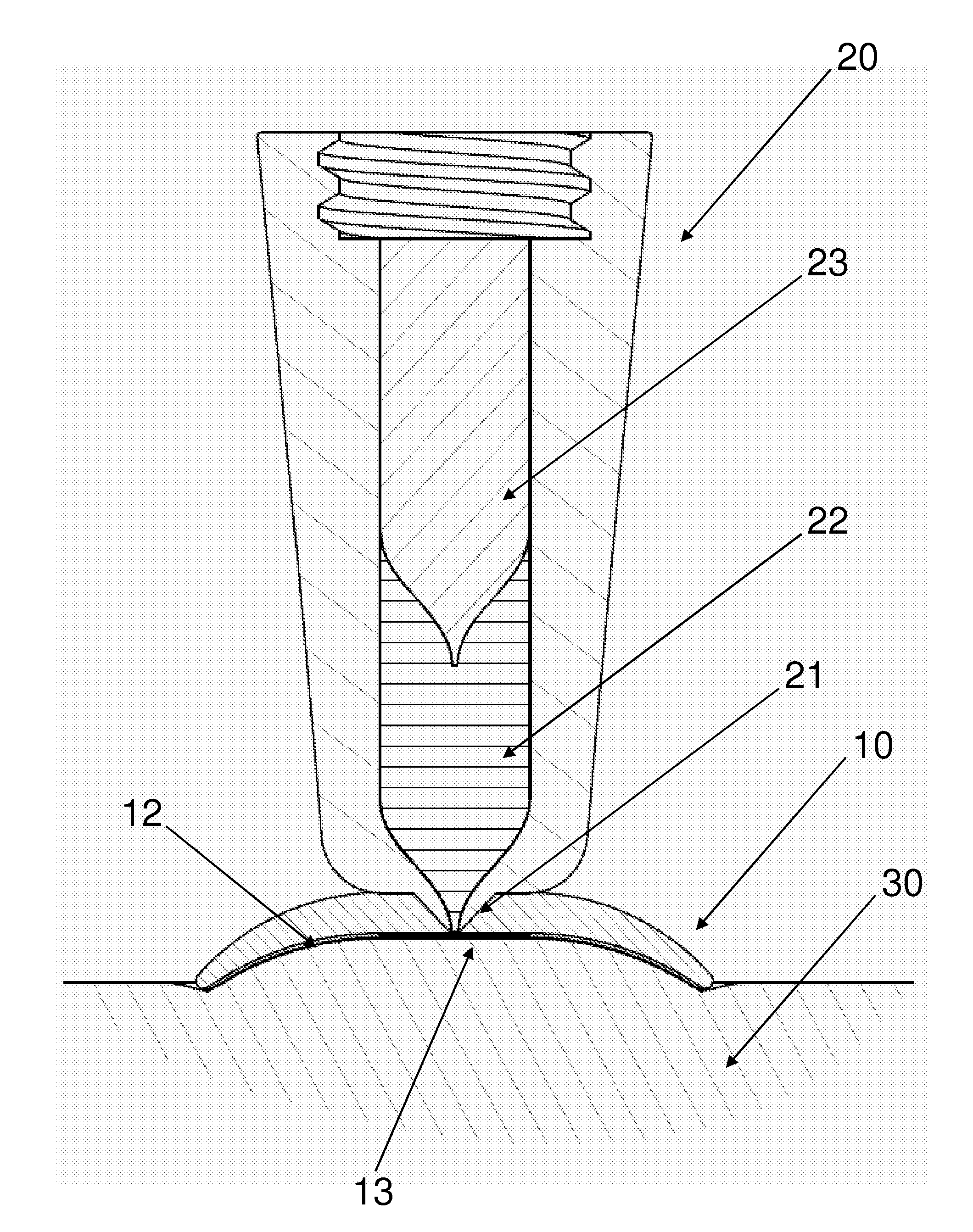

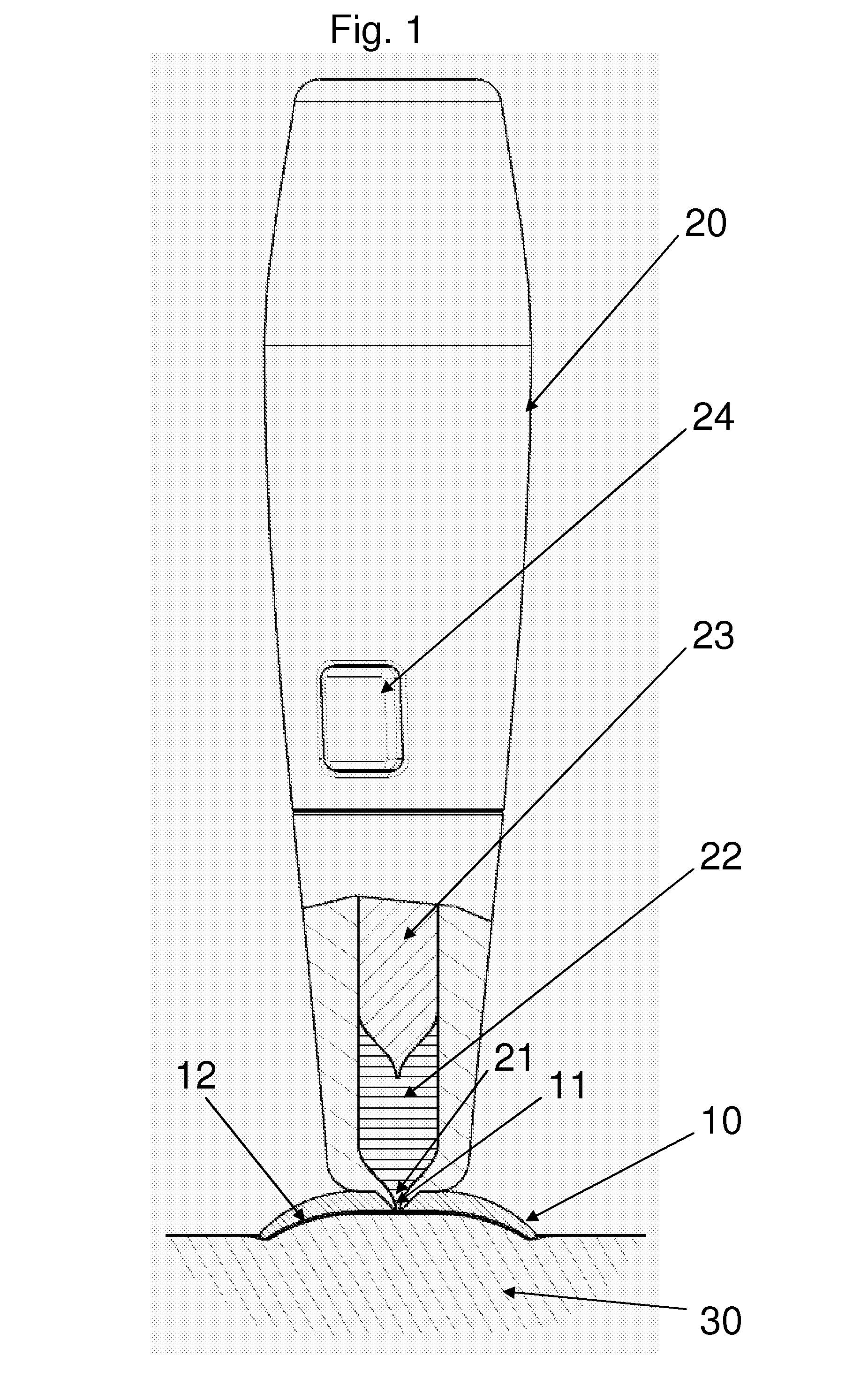

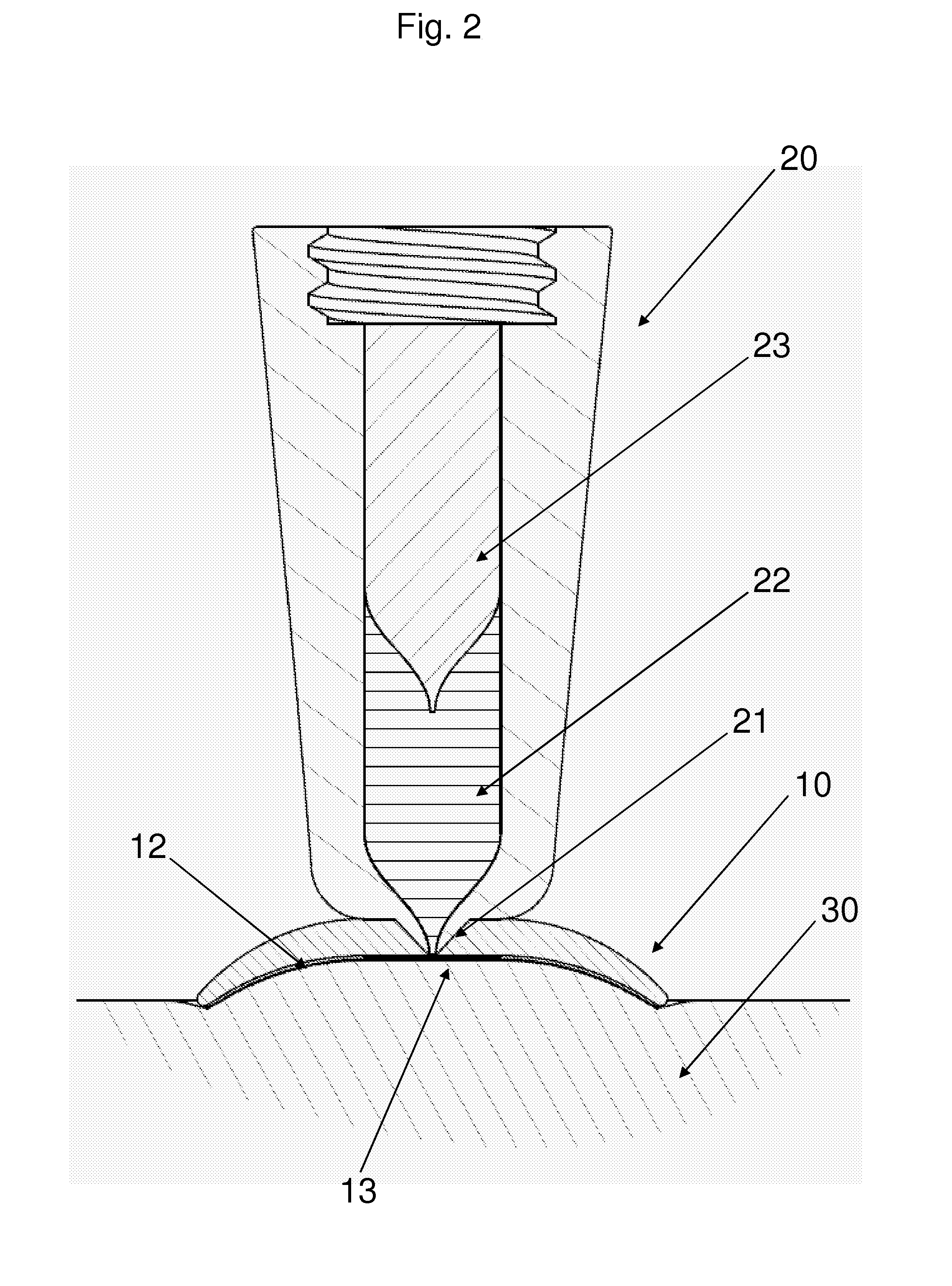

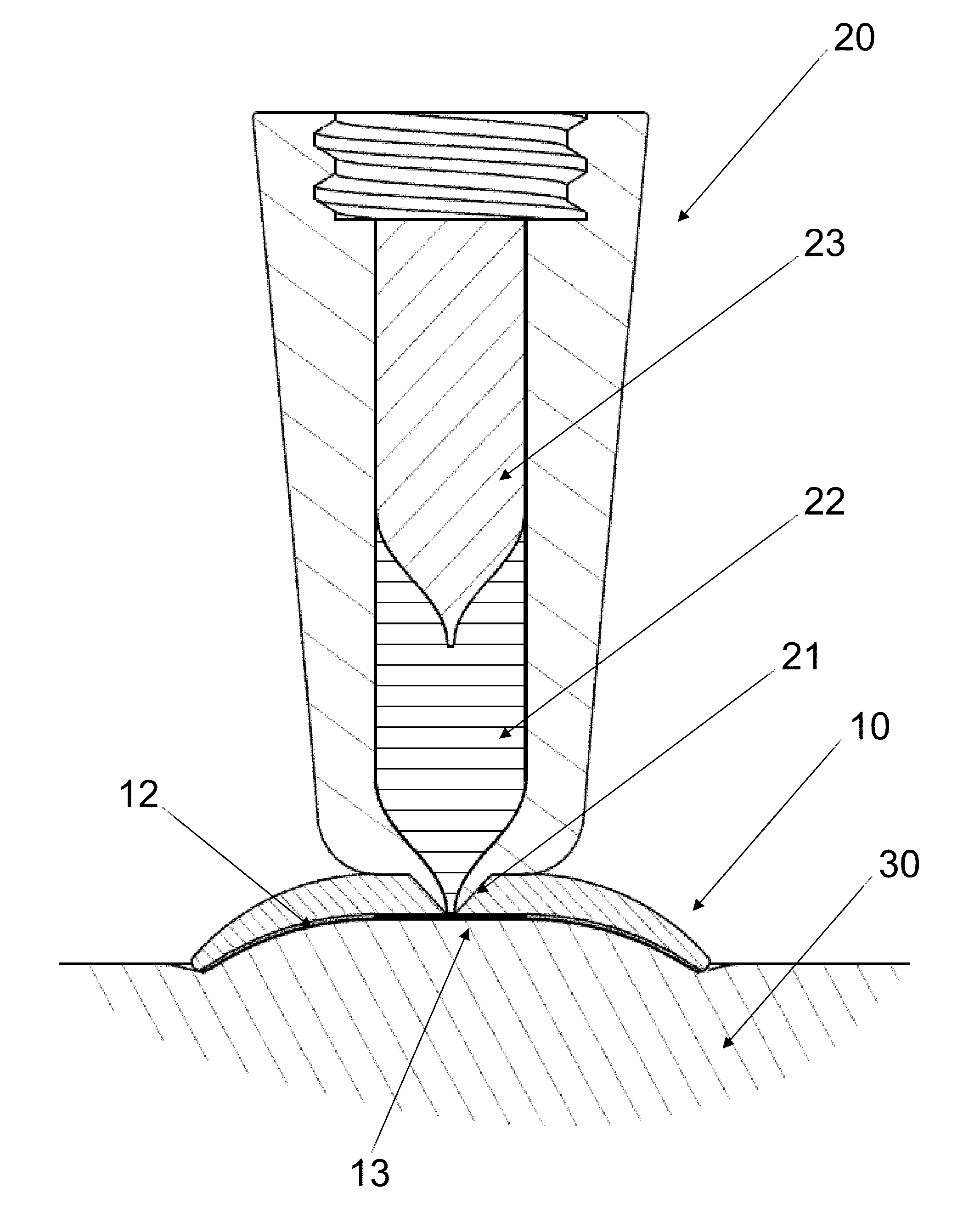

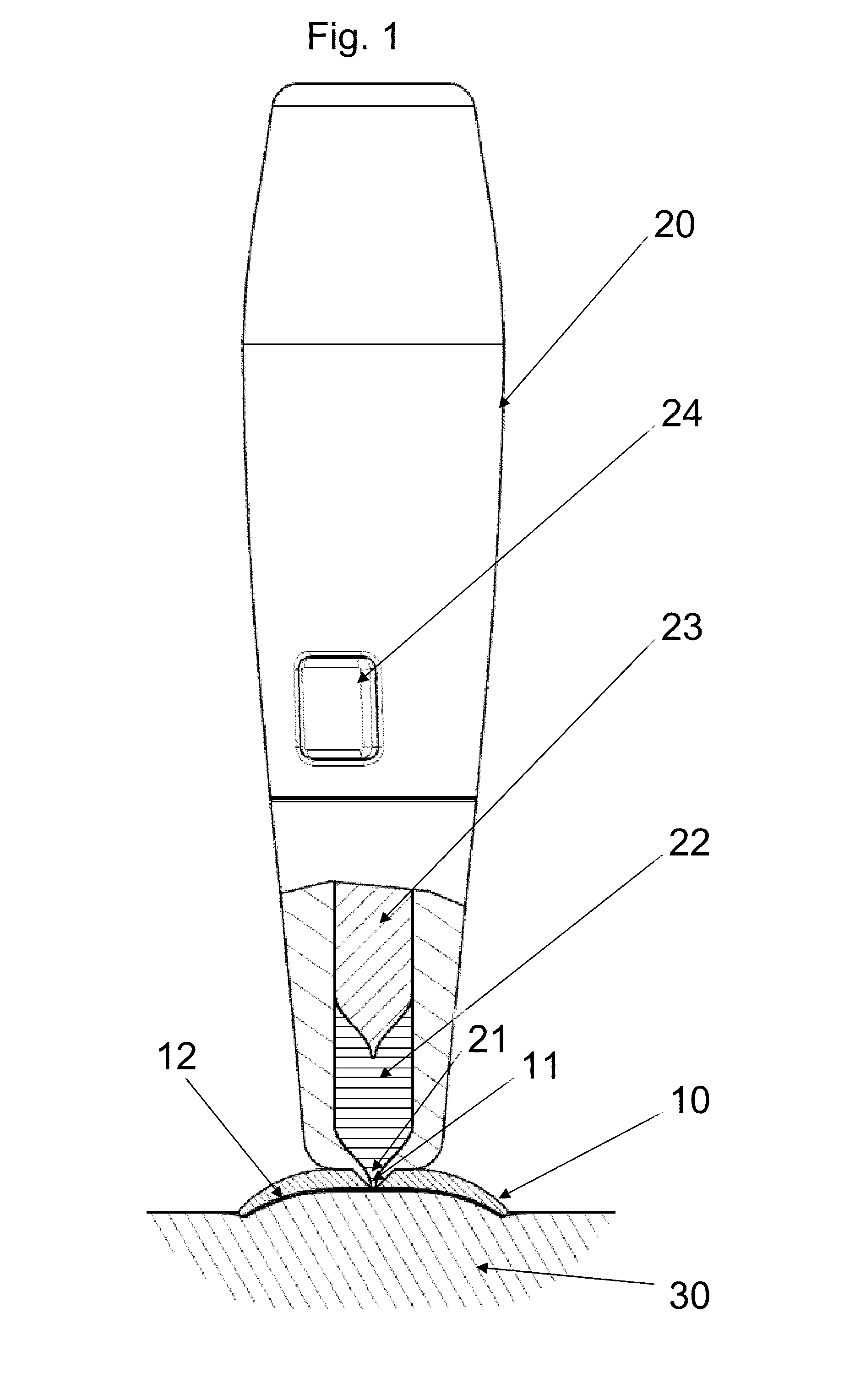

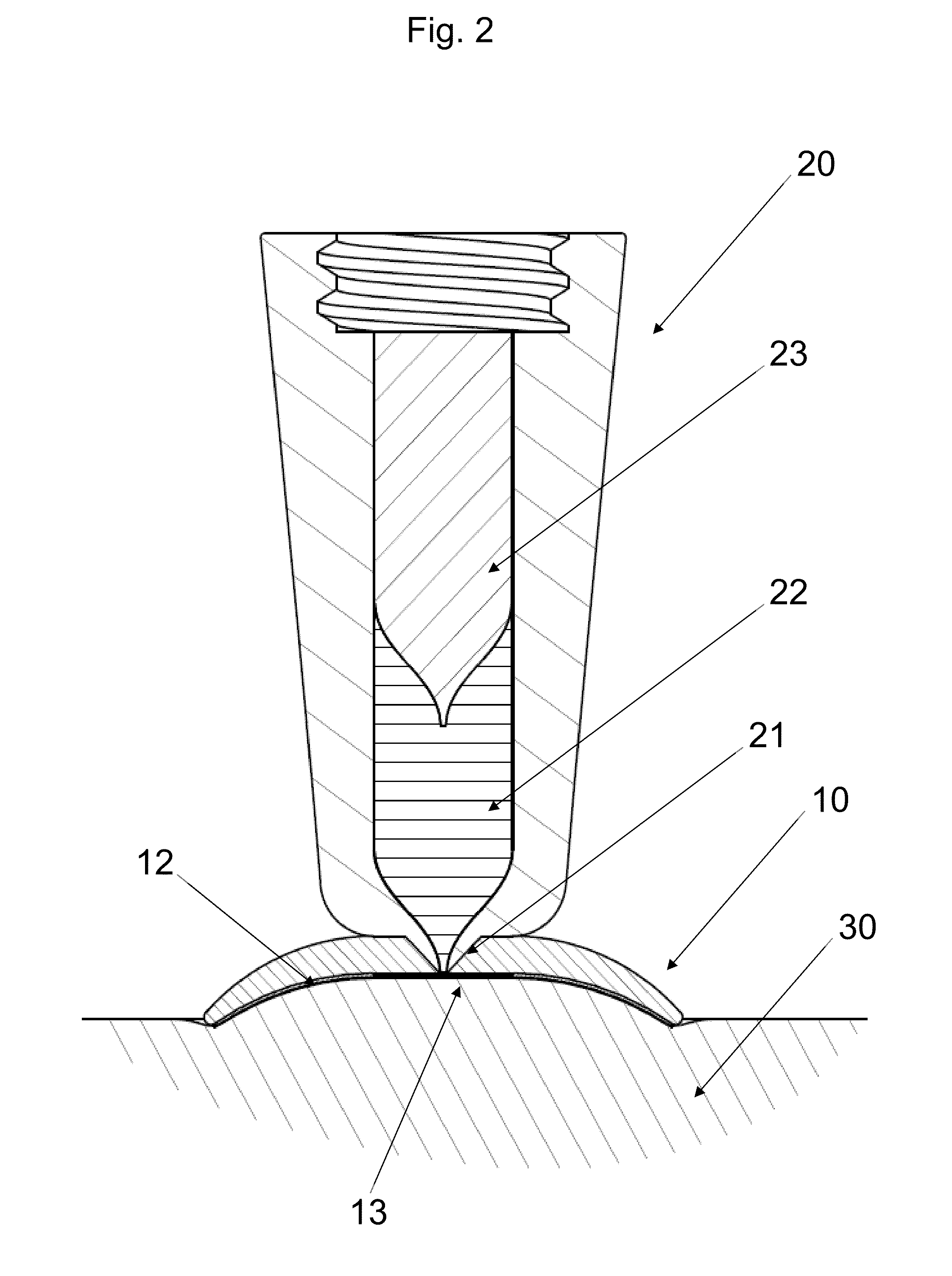

Skin Retention Device for a Medical Jet Injection Unit

InactiveUS20090227942A1Reduce the possibilityGreat degree of stretchJet injection syringesIntravenous devicesJet injectionInjection point

A skin retention device 10 for a medical jet-injection unit 20 comprises a contact face provided with adhesive 12 in the area surrounding and close to the injection opening(s) 11 of the nozzle 21 which ensures god contact between the nozzle 21 and the skin 30 of a subject in the area chosen for an injection. Consequently the injection force can be lowered dramatically. In case of two-stage jet-injections, the initial injection force can be lowered because the skin retention close to the injection point significantly reduces the energy consuming elastic expansion of the skin 30 in the injection area, and the second injection force can be lowered because of the high degree of fixed positioning of the injection opening of the nozzle 21 relative to the injection channel in the skin 30 made during the initial injection stage. Thus a high degree of injection safety is achieved, minimizing the risk of whet shots, while skin lift and lower injection force decreases the risk of damage of the underlying tissue.

Owner:NOVO NORDISK AS

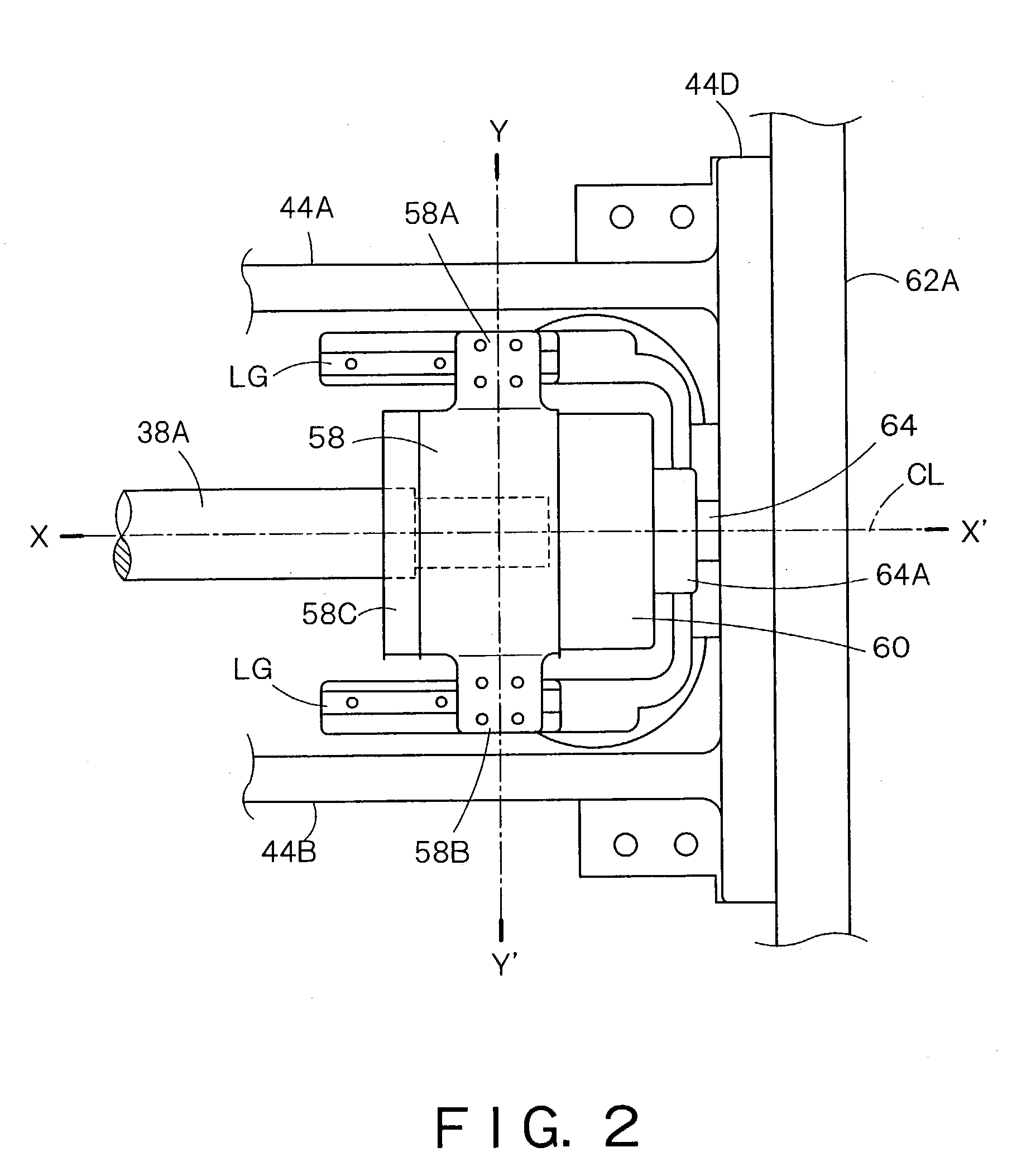

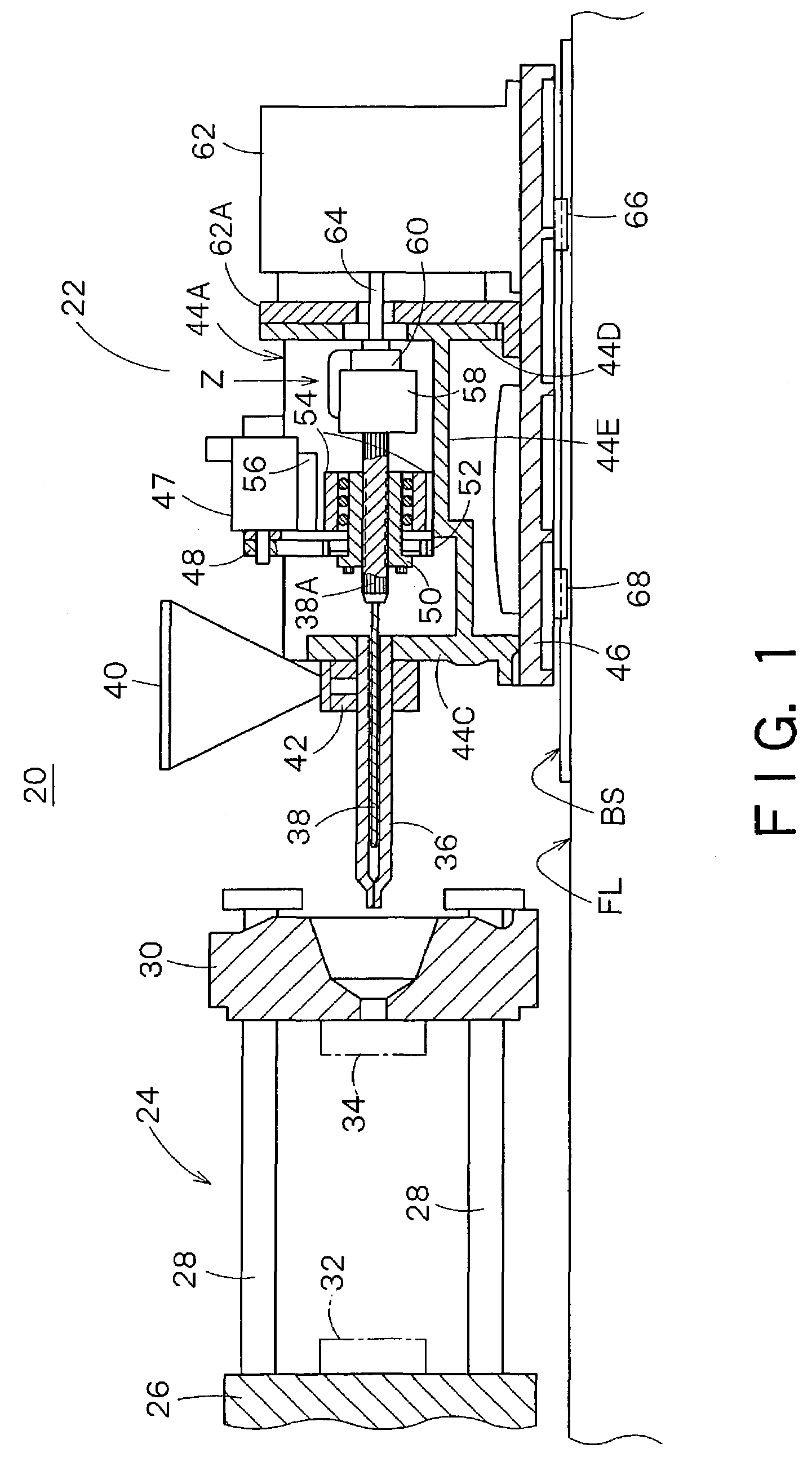

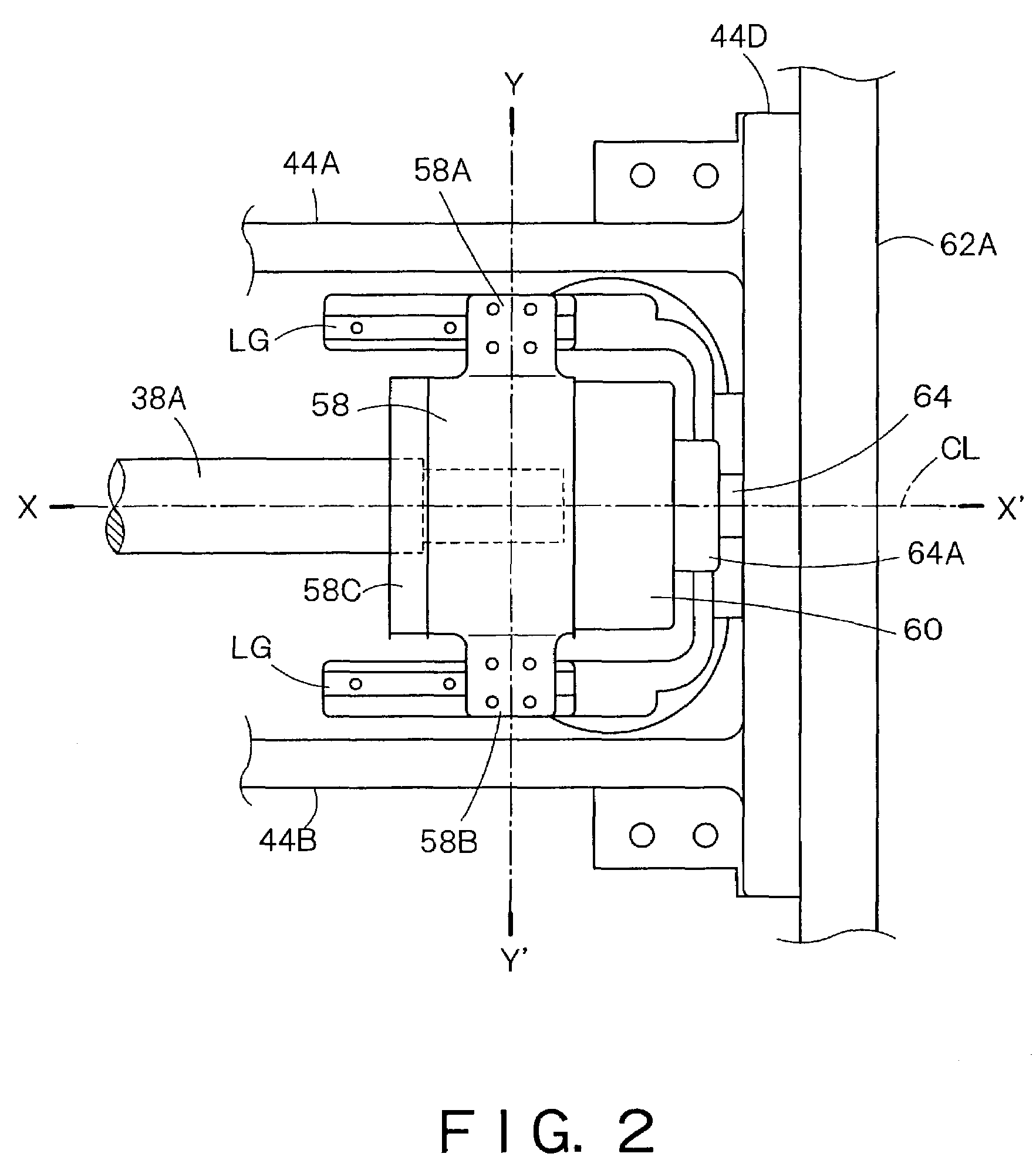

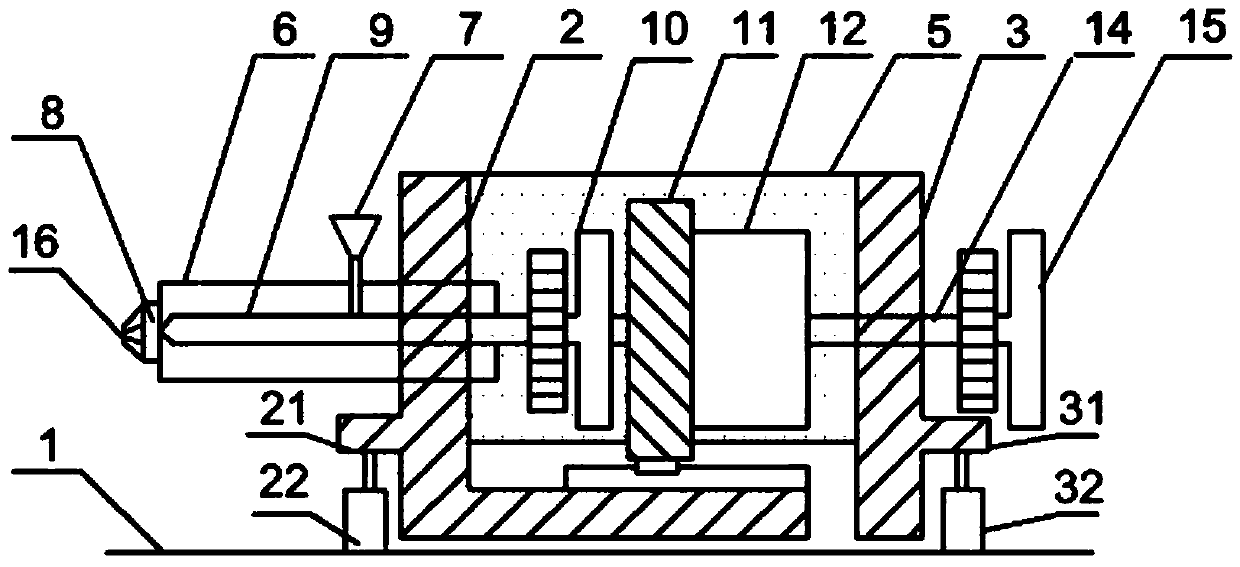

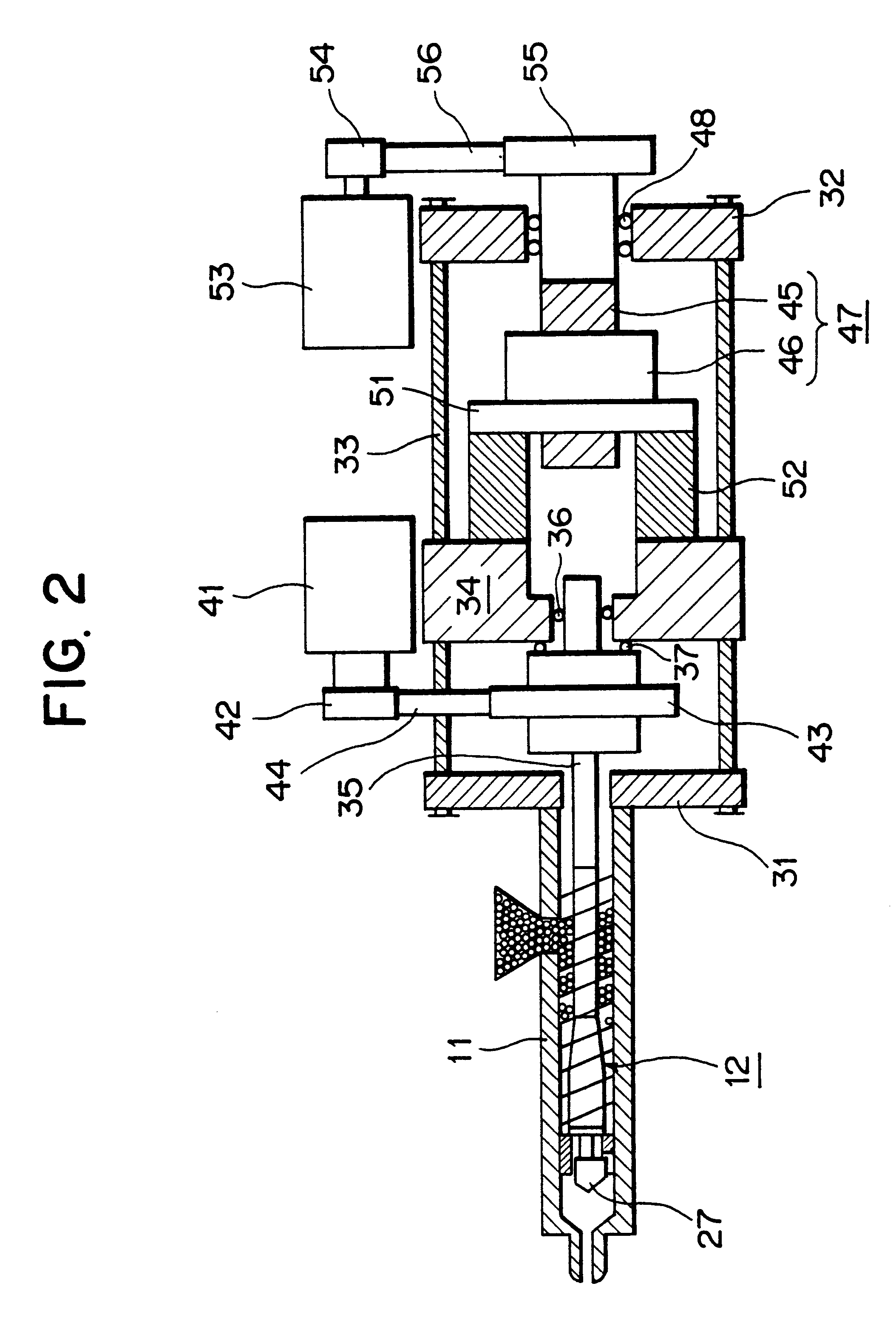

Injection molding machine

There is provided an injection molding machine provided with an injection mechanism that enables a high-speed injection. The injection molding machine includes: a heating barrel for melting and kneading a resin fed from a hopper, said barrel having an injection nozzle at its front end; a screw movably and rotatably inserted in the heating barrel; a screw drive shaft coupled at its one end to the rear end of the screw; charging means including a charging motor for rotationally driving the screw drive shaft to rotate the screw so as to melt the resin in the heating barrel while conveying the resin forward of the screw, and measure the volume of the molten resin, and torque transmission means for transmitting the driving torque of the charging motor to the screw drive shaft and permitting a displacement of the screw drive shaft in the axial direction; a body frame fixing and supporting the charging motor and the torque transmission means, said frame including a front plate fixing and supporting the base of the heating barrel; injection drive means including a linear-movement shaft coupled to the rear end of the screw drive shaft and movable in the axial direction, and an injection motor for advancing the screw and producing an injection force for injecting the molten resin in the heating barrel; and shaft coupling means for coupling the rear end of the screw drive shaft to the linear-movement shaft such that only a thrust in the axial direction is transmitted to the screw drive shaft.

Owner:TOSHIBA MASCH CO LTD

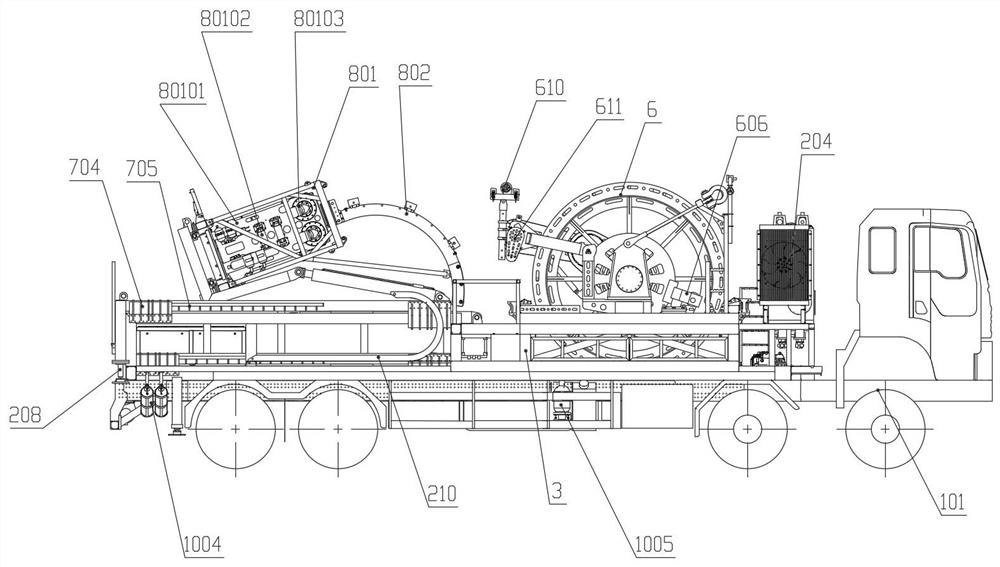

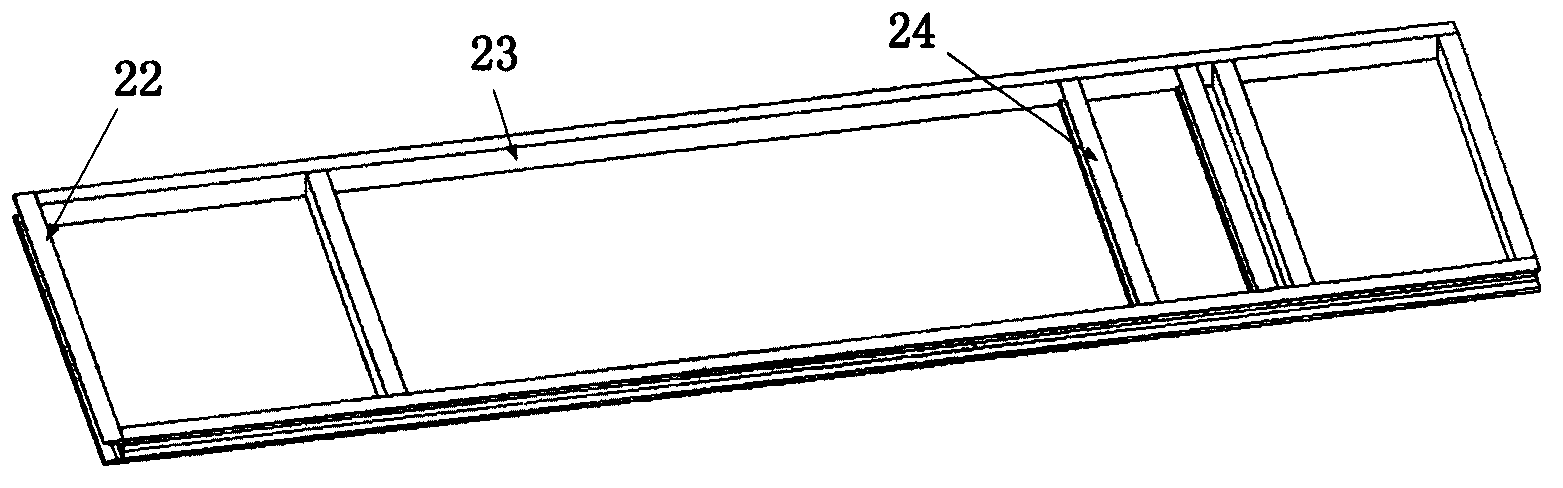

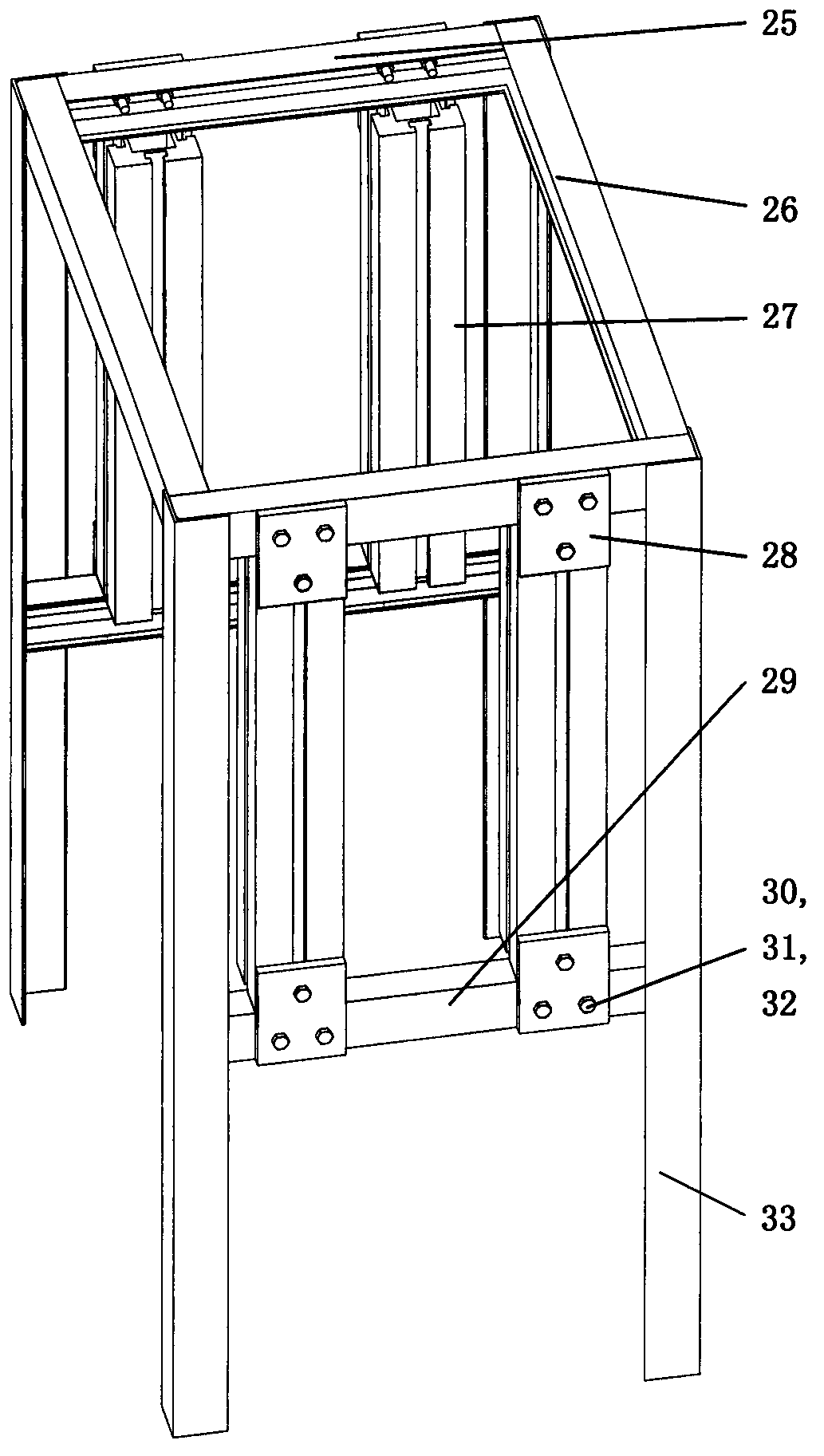

Continuous sucker rod operation vehicle and method

The invention relates to a continuous sucker rod operation vehicle and method, and belongs to the technical field of petroleum machinery. According to the technical scheme, the continuous sucker rod operation vehicle comprises a power system, a control system, an auxiliary frame beam, a side rear protector, a pipeline shield, a sucker rod roller, a sliding platform, a continuous sucker rod injection head assembly, a rod traction assembly, a matched accessory assembly and a continuous sucker rod. According to the continuous sucker rod operation vehicle, an operation vehicle type is adopted, thetrafficability of a cross-country type chassis vehicle is good, and the cross-country type chassis vehicle can adapt to various severe road conditions and well sites and is convenient to move and transport; a chassis vehicle engine power driving system is adopted for operation, so that the economy and stability are good; the operation vehicle has the advantages of the compact structure and complete function and can be operated independently; the sucker rod roller has two safety protection measures of speed reducer braking and hydraulic release type braking, so that accidents caused by hydraulic failure are avoided; the injection head has large lifting force and injection force, so that more complex underground conditions can be solved; and two wells can be operated at a time, so that theefficiency is improved, and economic benefits are obtained.

Owner:华信唐山石油装备有限公司

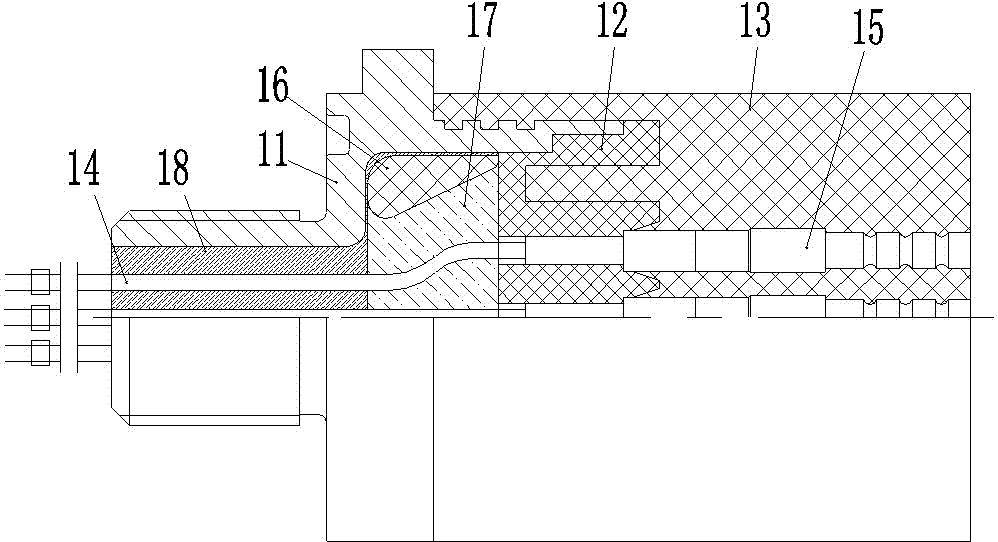

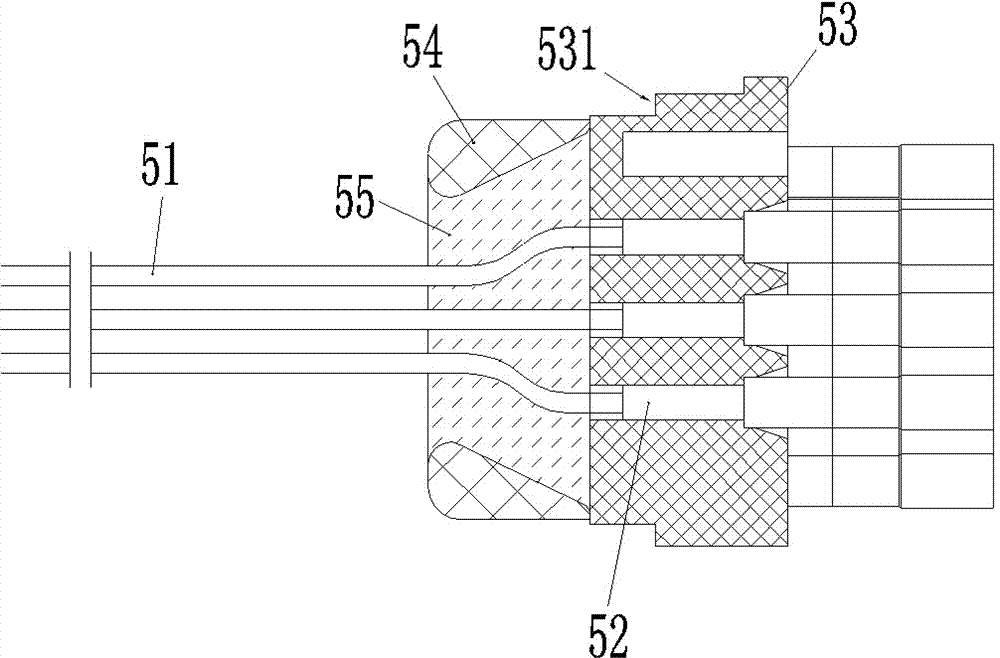

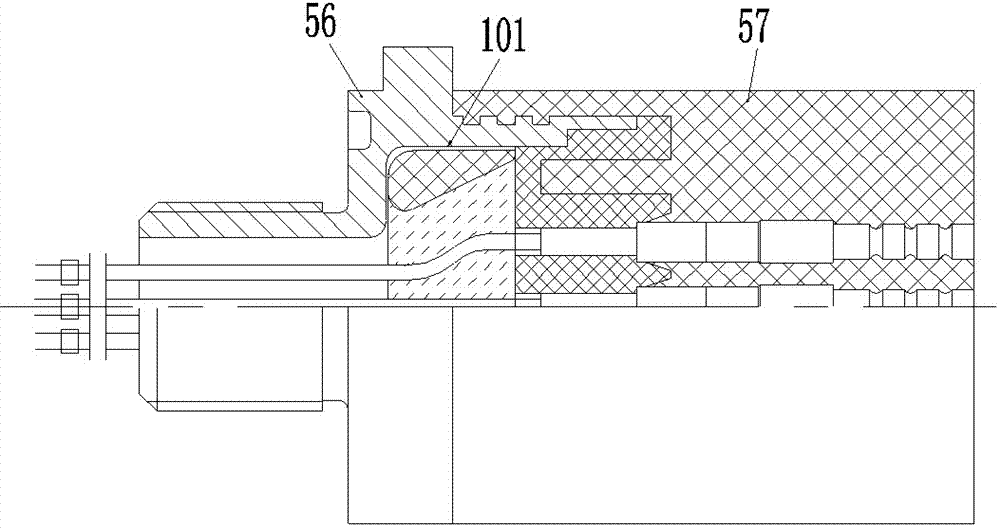

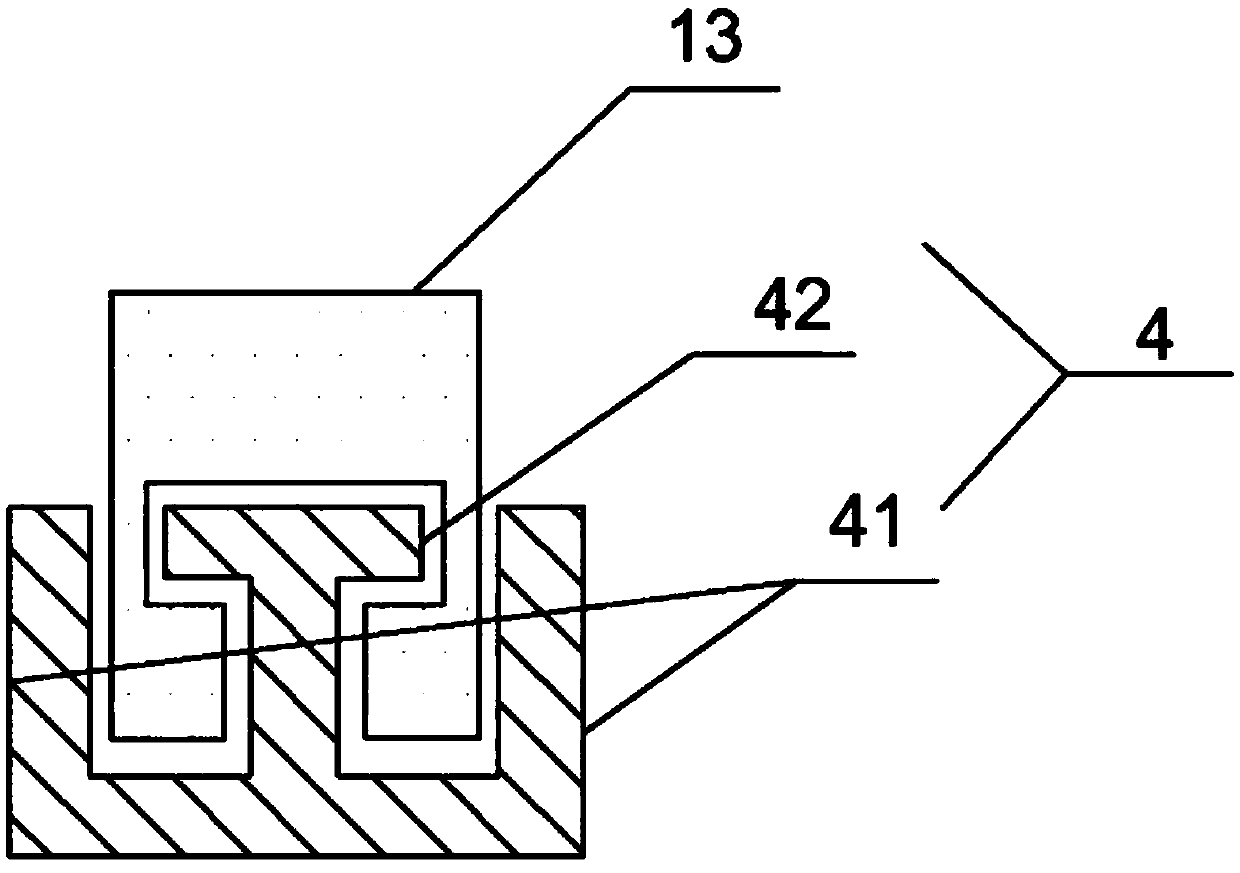

Underwater plug-pull connector and preparation method thereof

InactiveCN103036101ASolve the unreliable sealingStrong enoughContact member assembly/disassemblyCouplings bases/casesVulcanizationEngineering

The invention relates to the field of electric connectors, in particular to an underwater plug-pull connector and a preparation method thereof, wherein the underwater plug-pull connector can be applied to the seafloor and other deepwater environments. The front end of the connector serves as a plug end, the connector comprises a shell, an insulator, a sulfide body and a contact piece connected with a conducting wire, and the contact piece, the insulator and the shell are fixed together in a vulcanization mode through the sulfide body. A locating step surface facing the front is installed inside the shell, a matching step surface which is in check fit with the locating step surface is installed on the outer circumferential surface of the insulator, the contact piece is installed inside an installation hole of the insulator in a plug-in mode, the rear side of the insulator is fixedly connected with a supporting piece, and an air exhaust gap is formed between the supporting piece and the inner wall surface of the shell. The fact that the insulator has enough strength to bear vulcanization injection force can be guaranteed through the supporting piece, and meanwhile, the air exhaust gap is formed between the supporting piece and the inner wall surface of the shell, so that during a vulcanization process, air inside the shell can be exhausted from the rear end of the shell through the air exhaust gap, and therefore, the problem that seal of an existing underwater plug-pull connector is not reliable is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Manufacturing process of novel embedded metal tube die-casting cooling cavity

The invention relates to a manufacturing process of a novel embedded metal tube die-casting cooling cavity. The manufacturing cost comprises the following steps of S1, tube selecting, wherein the thicknesses of selected metal tubes are within the range of 1-4 mm, and burrs at end openings are removed; S2, bent forming, wherein heated parts of the metal tubes are placed on a bend-forming die or a bender and are bent according to a machining drawing, and the heated parts are cooled to be at the normal temperature; S3, water nozzle welding; S4, placing and locating the metal tubes and the water nozzles in a die-casting die; S5, die closing and die-casting, wherein after the die-casting die is closed, aluminum alloy solution is poured to a melting cup of a die-casting machine and is injected to the die through injection force of the die-casting machine, and the metal tubes are wrapped by the aluminum alloy solution; S6, die-casting pieces are taken out after the die is opened; S7, washing, drying, deburring, and local CNC machining, wherein finished products are finally obtained. The manufacturing process has the advantages that the die-casting piece and the metal tube are integrally formed in one time, raw material cost is low, machining cost is low, machining cycle is short, the production process is simple, and the cooling effect is improved.

Owner:CHENGDU TIGER MICROWAVE TECH

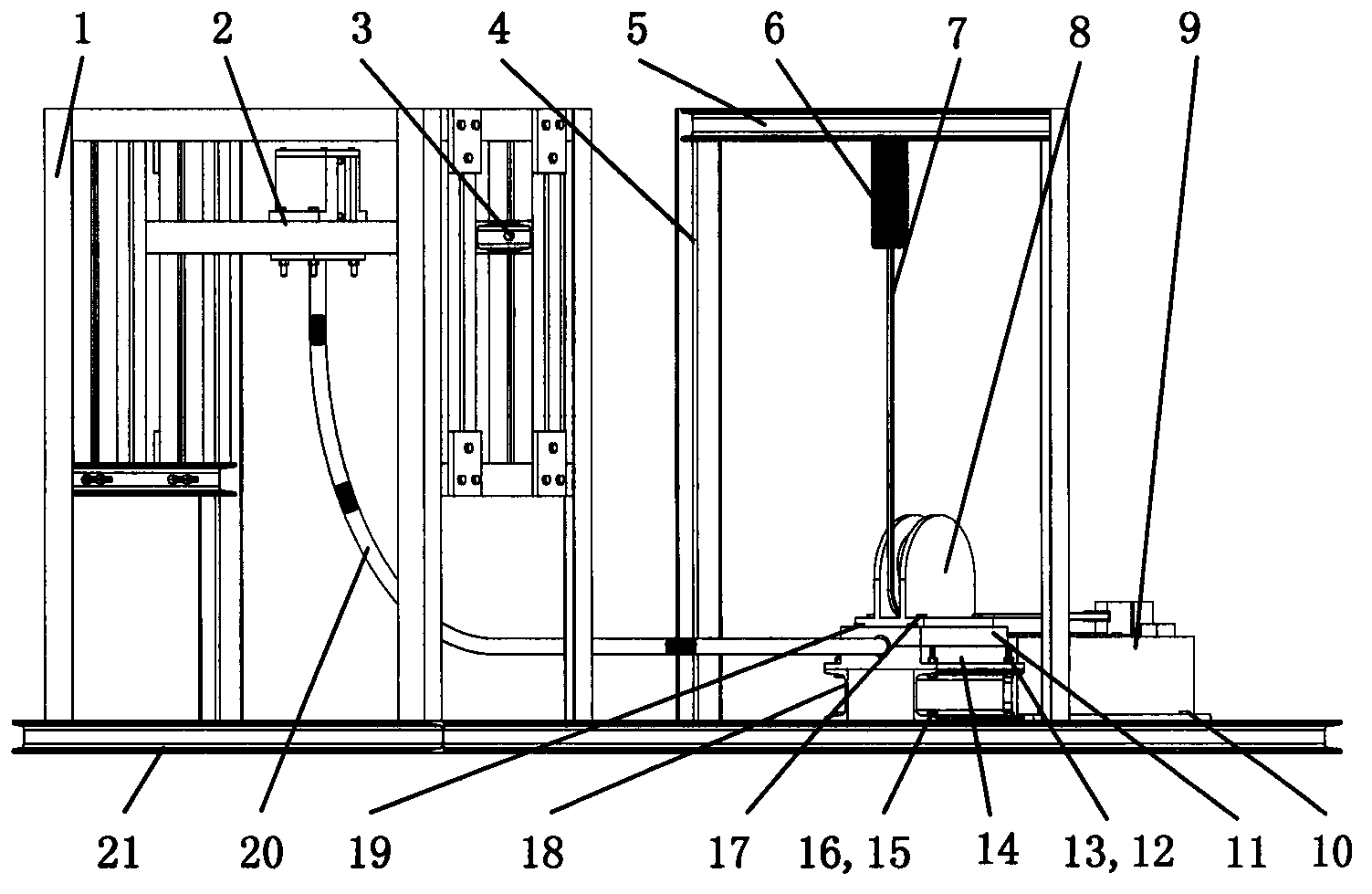

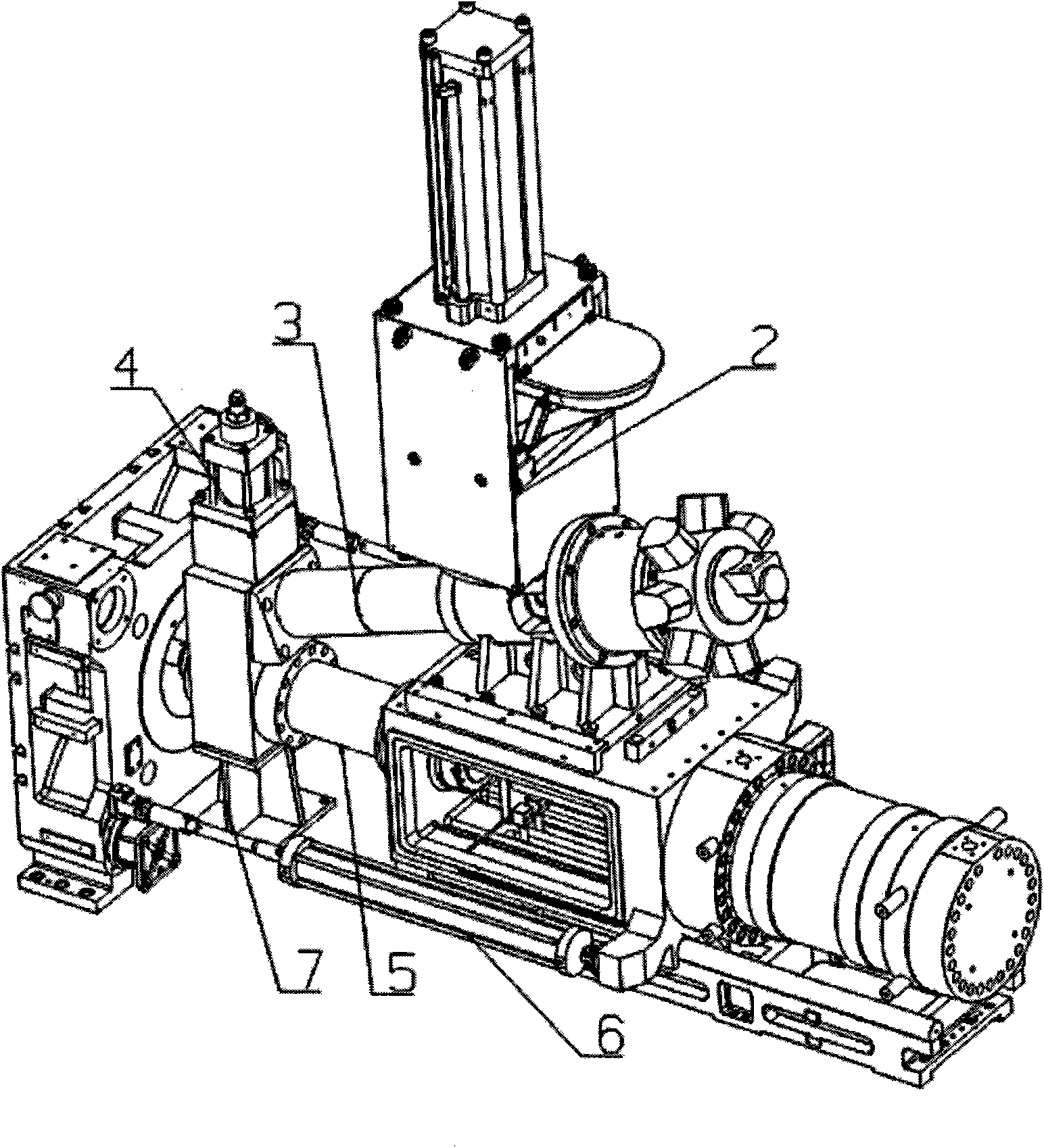

Deep-sea pipe-in-pipe mechanical transfer characteristic analysis experiment device

The invention relates to a deep-sea pipe-in-pipe mechanical transfer characteristic analysis experiment device, in particular to a device for analyzing mechanical transfer characteristics in the process of coiled tubing tripping into a deep-sea riser. When in experiment, a chain hoist 6 is opened, and an injection test assembly 9 clamps simulated coiled tubing to perform injection operation under the traction effect of a steel wire rope 7. The injection force of the simulated coiled tubing can be obtained by reading parameters of a tension compression sensor on the injection test assembly 9 in the injection process, the injection depth of the simulated coiled tubing can be obtained by reading parameters of a displacement sensor on the injection test assembly 9, the stress of the end of the simulated coiled tubing can be obtained by reading parameters of a pressure sensor inside a pipe end fixing test assembly 2, and the stress of a simulated riser can be obtained by reading parameters of a strain gauge on a pipe-in-pipe system 20. Finally obtained results can be used for analyzing mechanical characteristics of the coiled tubing tripping into the marine riser.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

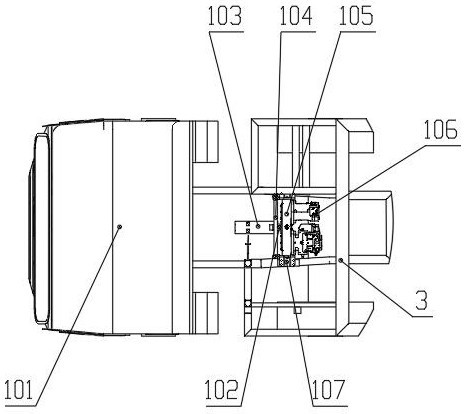

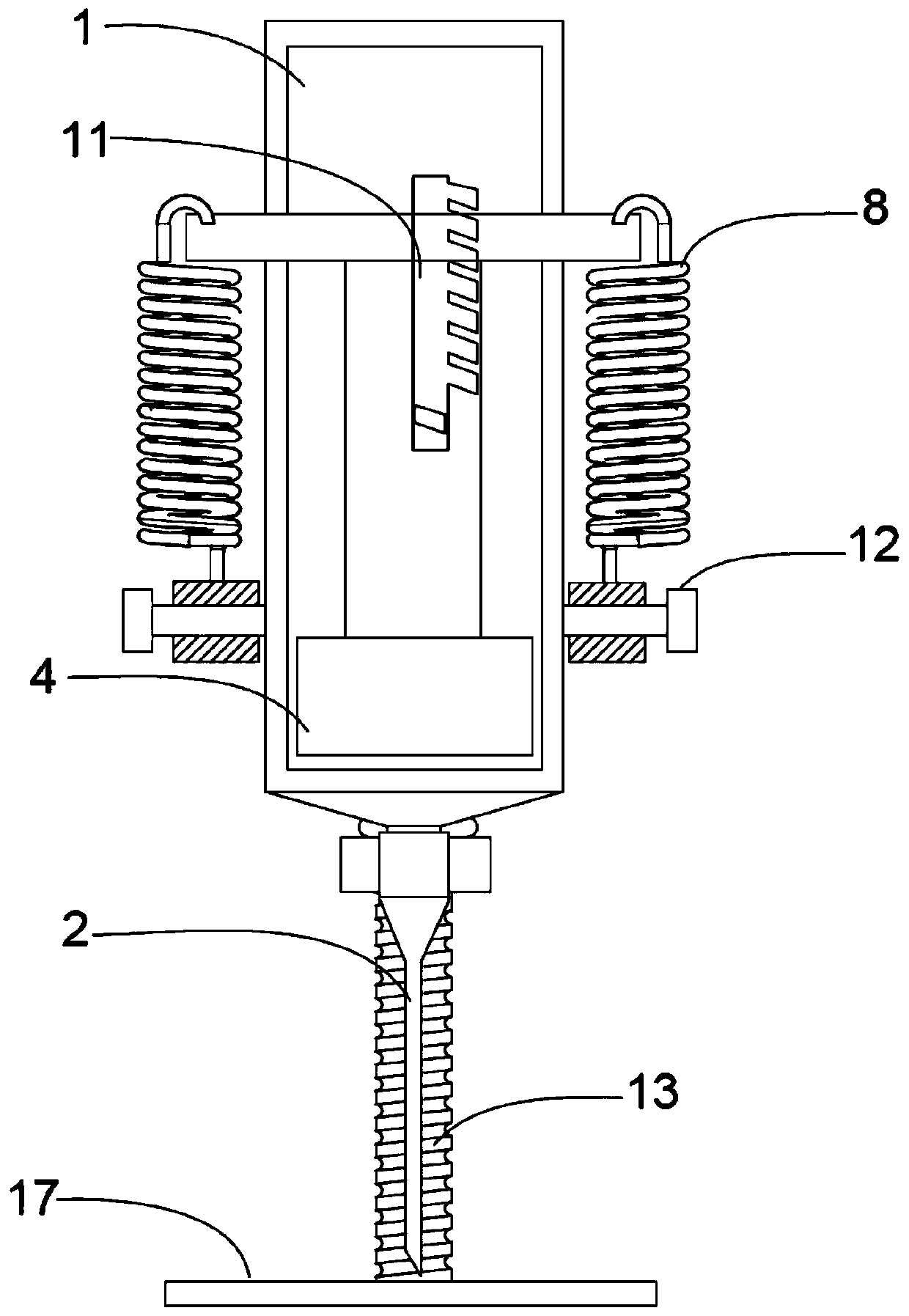

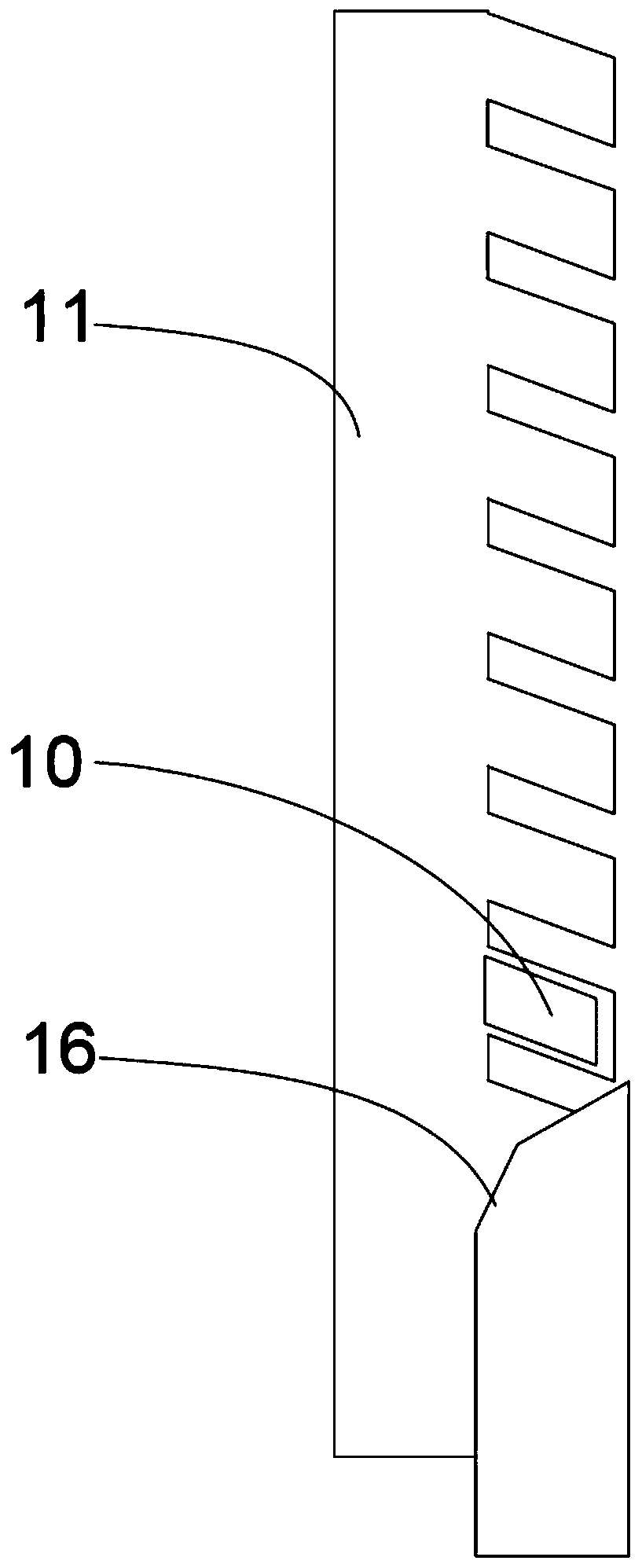

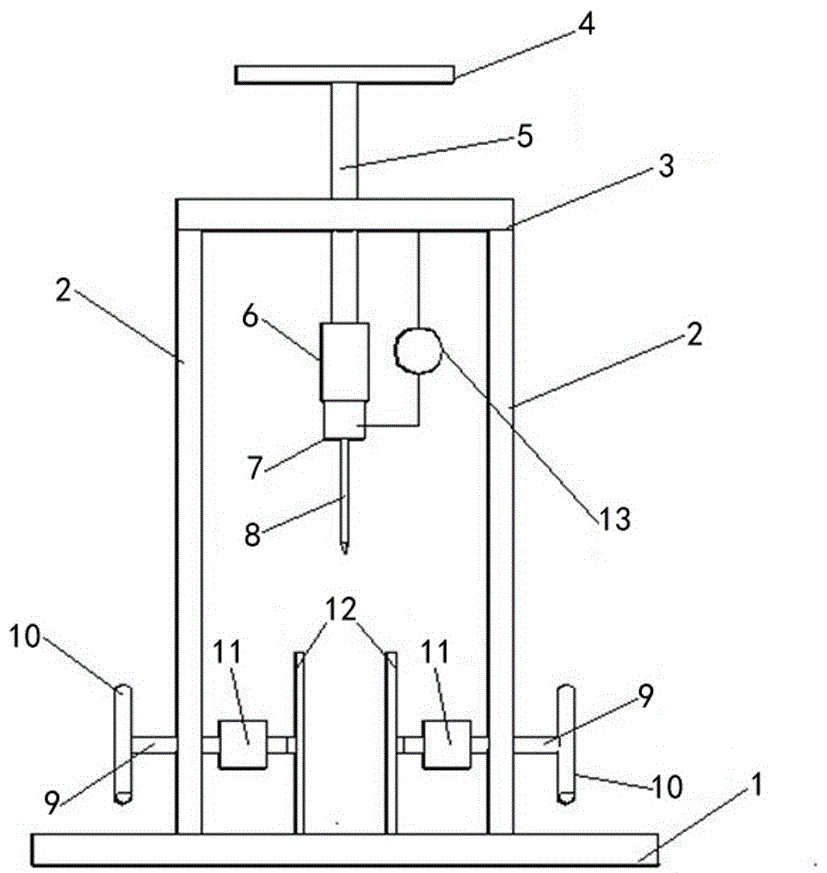

Automatic injection injector with adjustable puncture depth

ActiveCN110354340AAffect absorbencyAffect the efficacy of the drugAutomatic syringesIntravenous devicesEngineeringInjection force

The invention discloses an automatic injection injector with the adjustable puncture depth. The injector comprises an injector body, the injector body comprises a needle tubing, and the needle tubingmovably sleeves a syringe; a piston is movably installed in the syringe, a press block is fixedly installed on a core rod and movably installed in a press block slide channel in the syringe, and a pushing block is further fixedly installed on the core rod and movably installed in a sawtooth-shaped slide channel in the syringe; fastening rotary knobs are installed on fixing bases, the fixing basesmovably sleeve extrusion rods, and thread adjustment rotary knobs are movably installed on the extrusion rods; stirring rods are further fixedly installed on the extrusion rods and movably connected with the pushing block. According to the automatic injection injector, the injection depth can be adjusted, medicine pushing and injection are automatically conducted after pricking is conducted, the situation is avoided that medical personnel inject a medicine solution too deeply or too shallowly, the injection force is stable, the operation difficulty of medical personnel is lowered, and the painof patients is relieved.

Owner:奉节县妇幼保健院(奉节县妇幼保健计划生育服务中心)

Injectable multimodal polymer depot compositions and uses thereof

InactiveUS8501215B2Effective distributionLow loading ratePowder deliveryAerosol deliverySolventCompatibilization

Injectable depot compositions are provided that include a polymer matrix having a plurality of bioerodible, biocompatible polymers wherein each polymer of the plurality of polymers has a specified average molecular weight, and the polymer matrix has a broad molecular weight distribution of the plurality of polymers; a solvent having a miscibility in water of less than or equal to 7 wt % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith; and a beneficial agent. The compositions have substantially improved shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

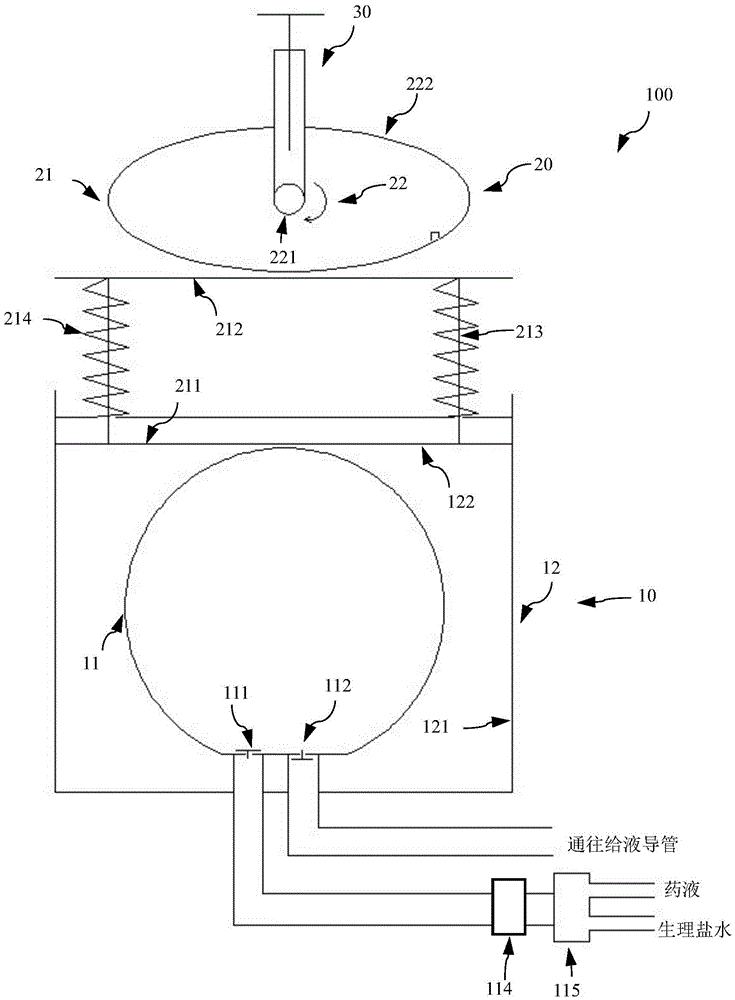

Pulse transfusion micropump

The invention provides a pulse transfusion micropump which is used for delivering medical solution or normal saline pulse to a solution catheter which is disposed in a vessel. The pulse transfusion micropump is characterized by including the following: a medicine solution cavity unit for accommodating medicine solution, the medicine solution cavity provided with a solution inlet and a solution outlet thereon, the solution inlet provided with a one-way valve thereon for defining one way entrance of the medicine solution, the solution outlet provided with a one-way valve thereon for defining one way exit of the medicine solution; a pulse excruciating unit which is communicated with the medicine solution cavity and is used for excruciating the medicine cavity and includes a reciprocating piece and a power source, the reciprocating piece being communicated with the medicine solution, the power source providing power to the reciprocating piece. The pulse transfusion micropump has a large injection force in terms of the medicine solution, can perform solution washing and solution discharging, which greatly facilitates medicine feeding of medical staff. The medicine solution cavity of the pulse transfusion micropump has no moving pieces, no wearing, and does not introduce material pollution.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

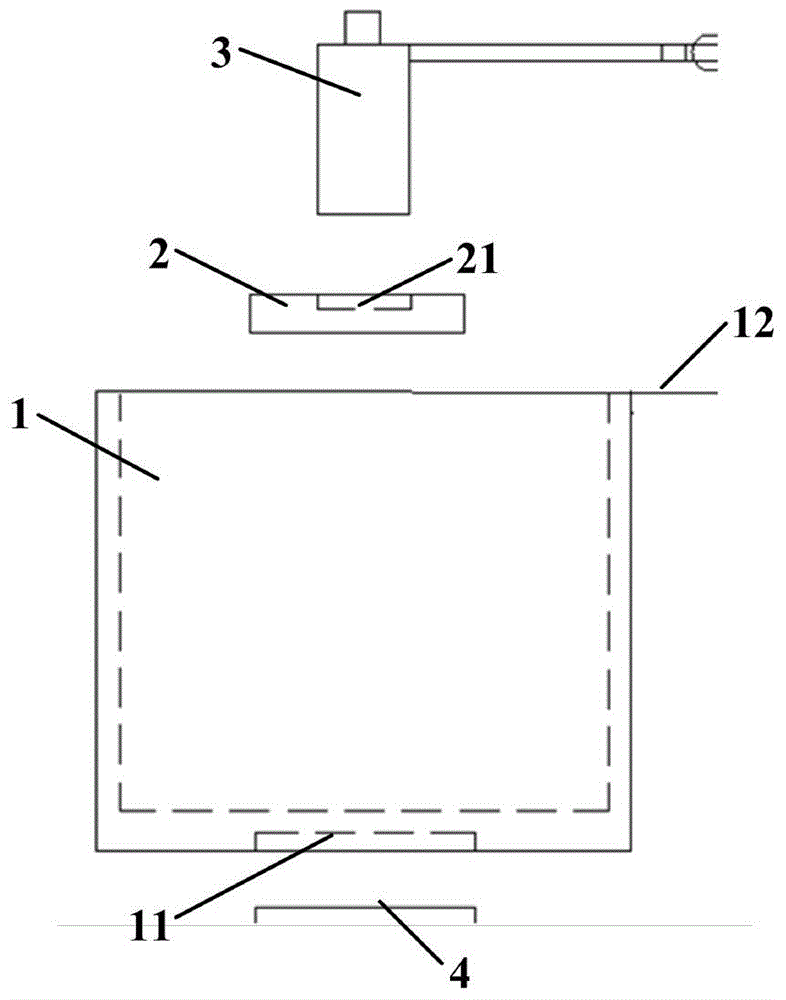

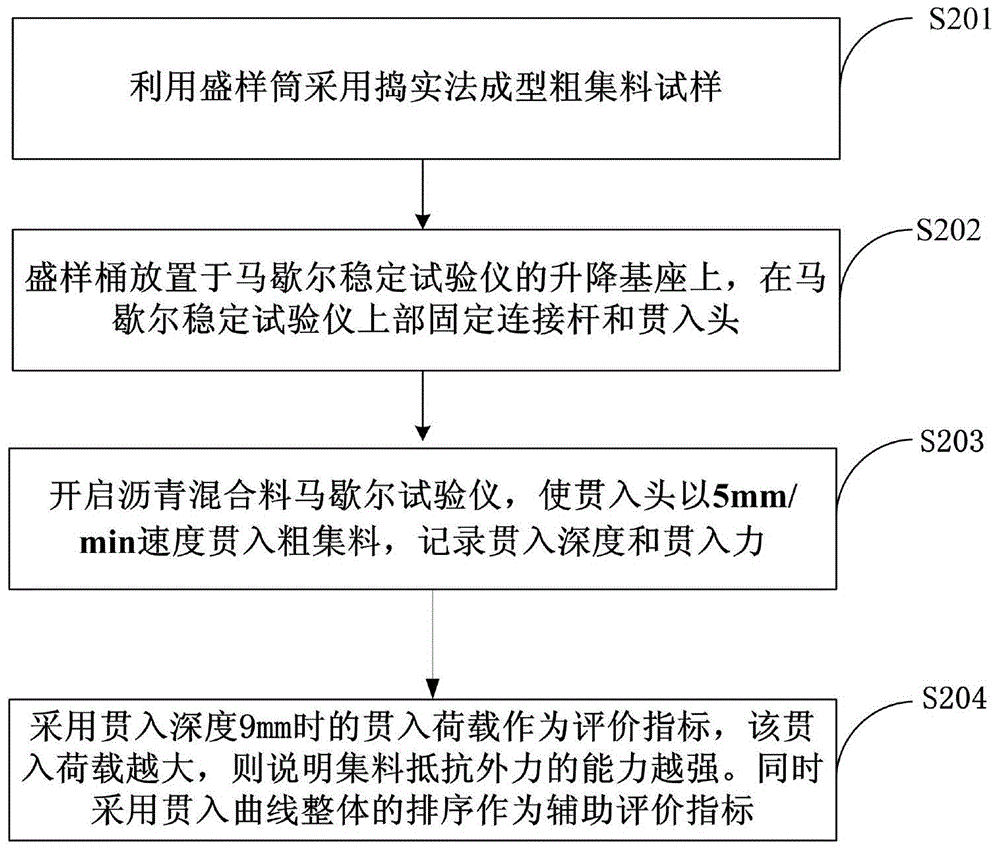

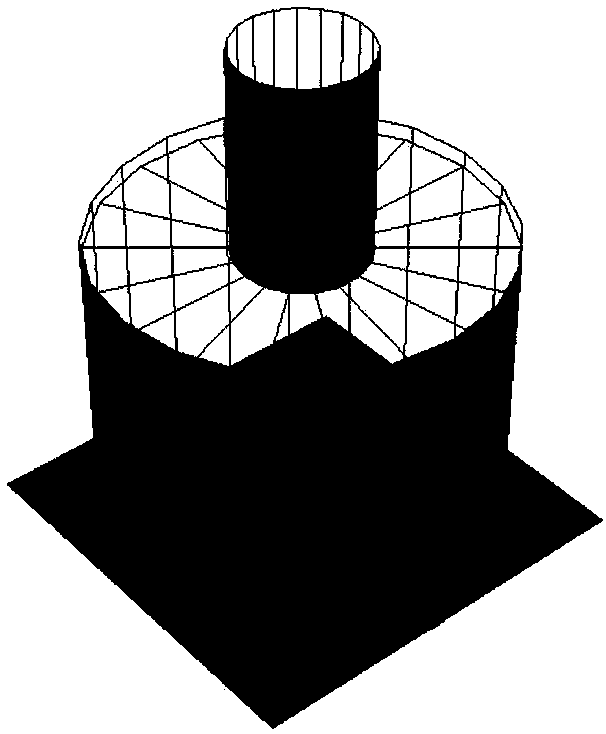

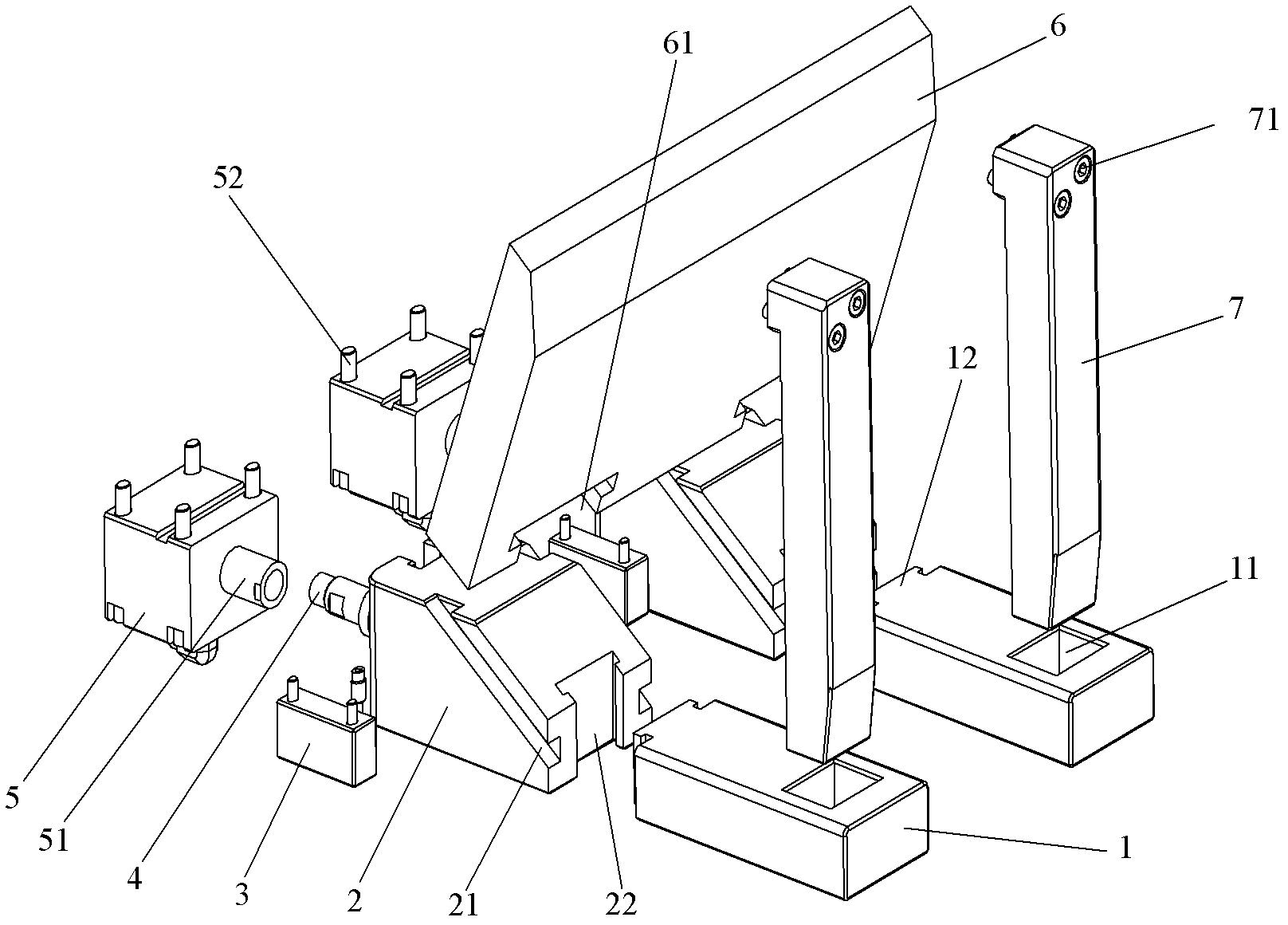

Coarse aggregate injection test device and coarse aggregate injection test method based on asphalt mixture tester

InactiveCN104090092AImproves rutting resistanceImprove effectivenessMaterial testing goodsUltimate tensile strengthAsphalt

The invention discloses a coarse aggregate injection test device and a coarse aggregate injection test method based on an asphalt mixture tester. A coarse aggregate sample is formed through a sample containing barrel by a tamping method; the sample containing barrel is arranged on a lifting base of an asphalt mixture Marshall tester; a connecting rod and an injection head are fixed on the upper part of the asphalt mixture Marshall tester; with a fixed displacement sensor and the turned-on asphalt mixture Marshall tester, the injection head injects aggregate at a speed of 5mm / min, the instrument automatically records the injection depth and injection force, and the injection load at the injection depth of 9mm is used as an evaluation index for the coarse aggregate skeleton strength. According to the device and the method disclosed by the invention, the bearing performance of coarse aggregate can be evaluated and a basis is provided for the optimal design of coarse aggregate grading, so that the high-temperature rutting resistance of the asphalt mixture can be estimated; moreover, the effectiveness of the mixture grading design can be improved while the rutting resistance of the asphalt mixture is enhanced; the device and the method have relatively high popularization and application values.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Grading gravel CBR numerical experiment method based on three-dimensional state

ActiveCN108256248AFast and accurate CBR valueReveal the micro-mechanical propertiesDesign optimisation/simulationSpecial data processing applicationsEngineeringInjection force

The invention discloses a grading gravel CBR numerical experiment method based on the three-dimensional state. The method comprises the steps that firstly, a value is assigned to microscopic parameters of a simulation test piece, then, the CBR experiment loading process is simulated, a relation curve of injection force and pressing head injection amount can be obtained, and then, the injection force corresponding to the injection amount being 2.5 mm in the model result can be inverted into a CBR value through a CBR reduction formula. According to the method, the CBR experiment of grading gravels under the three-dimensional state can be truly represented, the defect that a two-dimensional model cannot describe gravel interlocking or spatial distribution is overcome, the grading gravel CBR value can be rapidly and accurately obtained, and the mesomechanics performance change rules of grading gravel particles in the CBR experiment process can be tracked in real time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Injectable depot compositions and uses thereof

InactiveUS8252303B2Effective distributionBeneficial agent loading rateOrganic active ingredientsPowder deliveryAromatic alcoholAromatic ketones

Injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having a miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions have substantially improved the shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

Injection molding machine

There is provided an injection molding machine provided with an injection mechanism that enables a high-speed injection.The injection molding machine includes: a heating barrel for melting and kneading a resin fed from a hopper, said barrel having an injection nozzle at its front end; a screw movably and rotatably inserted in the heating barrel; a screw drive shaft coupled at its one end to the rear end of the screw; charging means including a charging motor for rotationally driving the screw drive shaft to rotate the screw so as to melt the resin in the heating barrel while conveying the resin forward of the screw, and measure the volume of the molten resin, and torque transmission means for transmitting the driving torque of the charging motor to the screw drive shaft and permitting a displacement of the screw drive shaft in the axial direction; a body frame fixing and supporting the charging motor and the torque transmission means, said frame including a front plate fixing and supporting the base of the heating barrel; injection drive means including a linear-movement shaft coupled to the rear end of the screw drive shaft and movable in the axial direction, and an injection motor for advancing the screw and producing an injection force for injecting the molten resin in the heating barrel; and shaft coupling means for coupling the rear end of the screw drive shaft to the linear-movement shaft such that only a thrust in the axial direction is transmitted to the screw drive shaft.

Owner:TOSHIBA MASCH CO LTD

Catheter injectable depot compositions and uses thereof

InactiveUS20110046606A1Effective distributionOrganic active ingredientsPowder deliveryMedicineAromatic alcohol

Catheter injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions are have substantially improved the shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

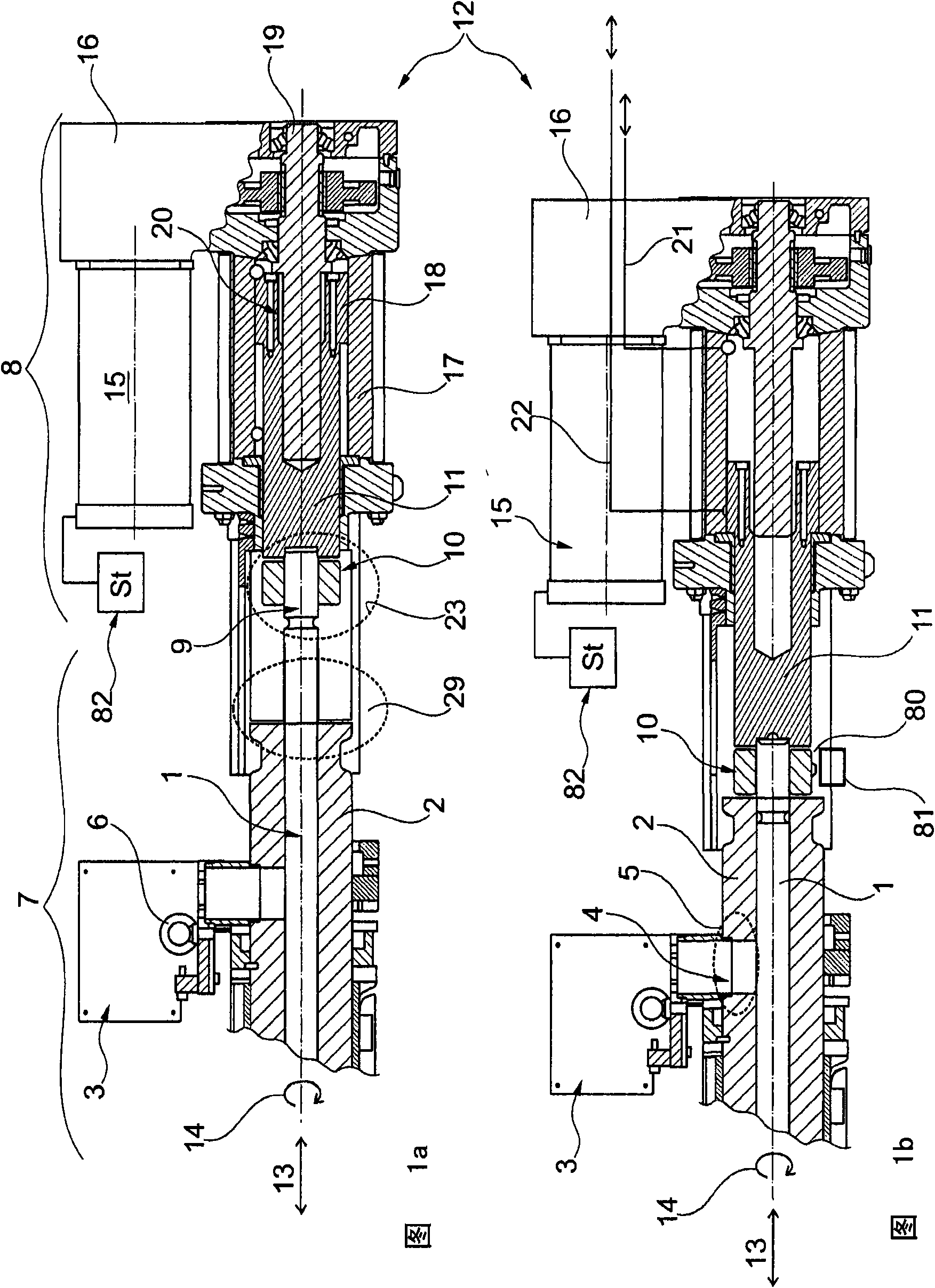

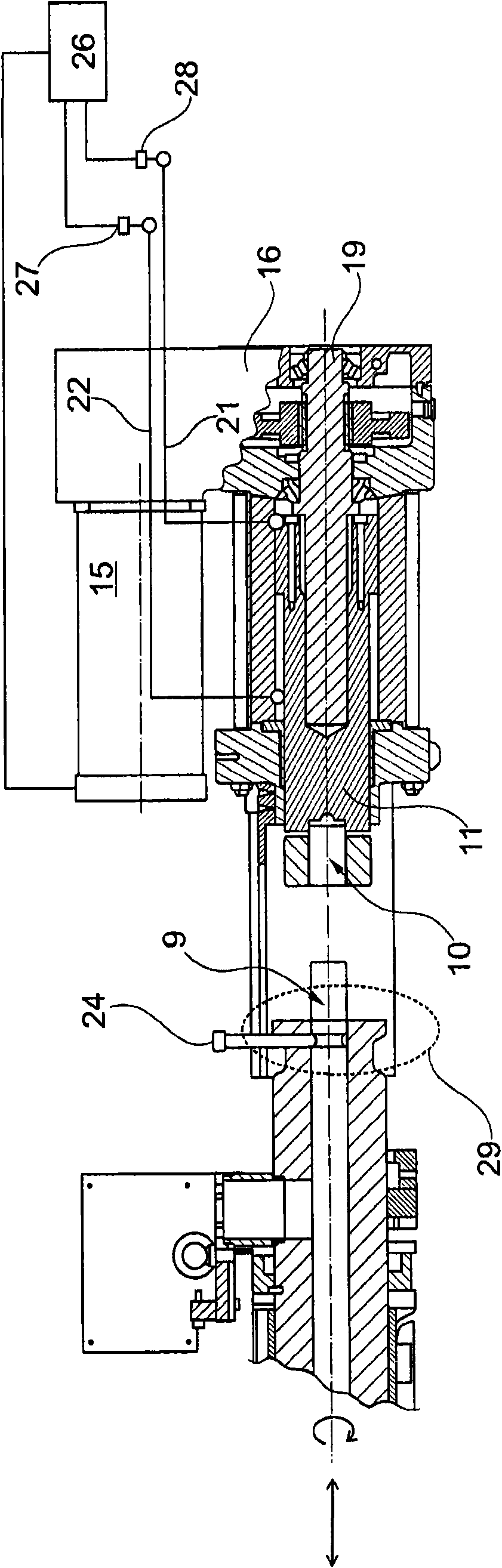

Method and device for the assembly and disassembly of a preplasticizing spindle

The invention relates to a method and a device for the assembly and disassembly of the preplasticizing spindle (1) of a ram or drive end (11) of a worm drive system of an injection molding machine by means of a clamp coupling (10). The worm drive system is designed for a controlled linear and rotary movement of the preplasticizing spindle (1). The coupling occurs by means of clamping agents which are preferably in the form of mechanical clamp coupling (10), wherein the rotary driving power and the worm return force are transferred via frictional engagement, and the axial injection force is transferred via an end stop. The assembly and disassembly procedure is supported by being controlled by the worm drive system. The preplasticizing spindle (1) can also be developed and coupled or decoupled as a heat-shrinkage connection or as a hydraulic tension system (23), wherein the preplasticizing spindle (1) is introduced during coupling to the end stop.

Owner:NETABTAL MASCHEN

Injection mold

The invention provides an injection mold, which comprises a fixed mold and a moving mold. A core-pulling mechanism is disposed on the moving mold, a locking part is arranged on the outer side of the fixed mold, and a locking part fixing seat is disposed on the moving mold and connected with the core-pulling mechanism. One end of the locking part is connected with the fixed mold, and the other end of the locking part is movably connected with the locking part fixing seat. In addition, when the injection mold is in a state of mold closing, the locking part and the locking part fixing seat are in a state of connection so as to prevent the core-pulling mechanism from being beaten back due to overlarge injection force during an injection process. Due to the fact that the locking part is arranged on the outer side of the fixed mold, the arrangement of the locking part is not limited by space inside the mold, the problem that a locking mechanism is difficult to connect due to limit of space arrangement is resolved, and meanwhile the space inside the mold can be saved.

Owner:QINGDAO HAIER MOLDS

Compound insulator processing technology for extruding irregular sheath

The invention discloses a compound insulator processing technology for extruding an irregular sheath. An extruder non-uniformly extrudes during wrapping refined silicone rubber compound on a mandril; an irregularly shaped sheath is formed on the surface of the vulcanized mandril; the vulcanized and molded mandril is put into an injection die; and an injector is used for injecting an outer umbrella skirt of a compound insulator to vulcanize and mold the compound insulator. In the compound insulator processing technology, by adopting the extruder for extrusion, the irregularly shaped sheath is formed on the surface of the mandril; as the shape of the sheath is irregular, the vulcanizing process of the subsequent umbrella skirt is easier and more convenient; and problems of bubbles, low adhering property and the like in the vulcanizing process can be solved; furthermore, by adopting the technology, the situation that the mandril is eccentric to the sheath due to the unidirectional injection force during injection can be avoided, and damages, such as hurting, whitening and the like which are caused by mechanical positioning, to the surface of the mantril at high temperature can be prevented.

Owner:SUZHOU YINGSILEIDI ELECTRIC

Injection moulding method of composite material mainly containing stone and injection moulding equipment

InactiveCN101830028AImprove pass rateEasy to produceCeramic shaping apparatusThermoplasticHeat resistance

The invention relates to injection moulding method and equipment of composite material mainly containing stone. The injection moulding method comprises the following steps of: a. putting used raw materials in a charging device, and then pushing the raw materials into a preplasticizing machine barrel of a preplasticizing device by a material compacting component in the charging device; b. under the condition of keeping the temperature to be 15-55 DEG C, compacting the raw materials along with the rotation of a preplasticizing screw rod and conveying to an injection machine barrel; c. under the condition that material injection force is 50-180MPa, injecting the raw materials in the injection machine barrel into a mould by a mould sprue; d. under the condition of keeping the temperature of the mould to be 140-200 DEG C, curing for 40-300 seconds; and e. opening mould to take out products. The invention has the advantages of simple production process, high yield of the produced products, high production efficiency and low production cost. The products have the advantages of good mechanical strength, fire resistance, heat resistance, corrosion resistance, good electrical property, low cost and the like and can replace most of thermosetting plastics and thermoplastic plastics, thereby reducing the application amount of plastic products and providing powerful support and guarantee for creating resource-saving and environmental-friendly industries.

Owner:HAITIAN PLASTICS MACHINERY GRP

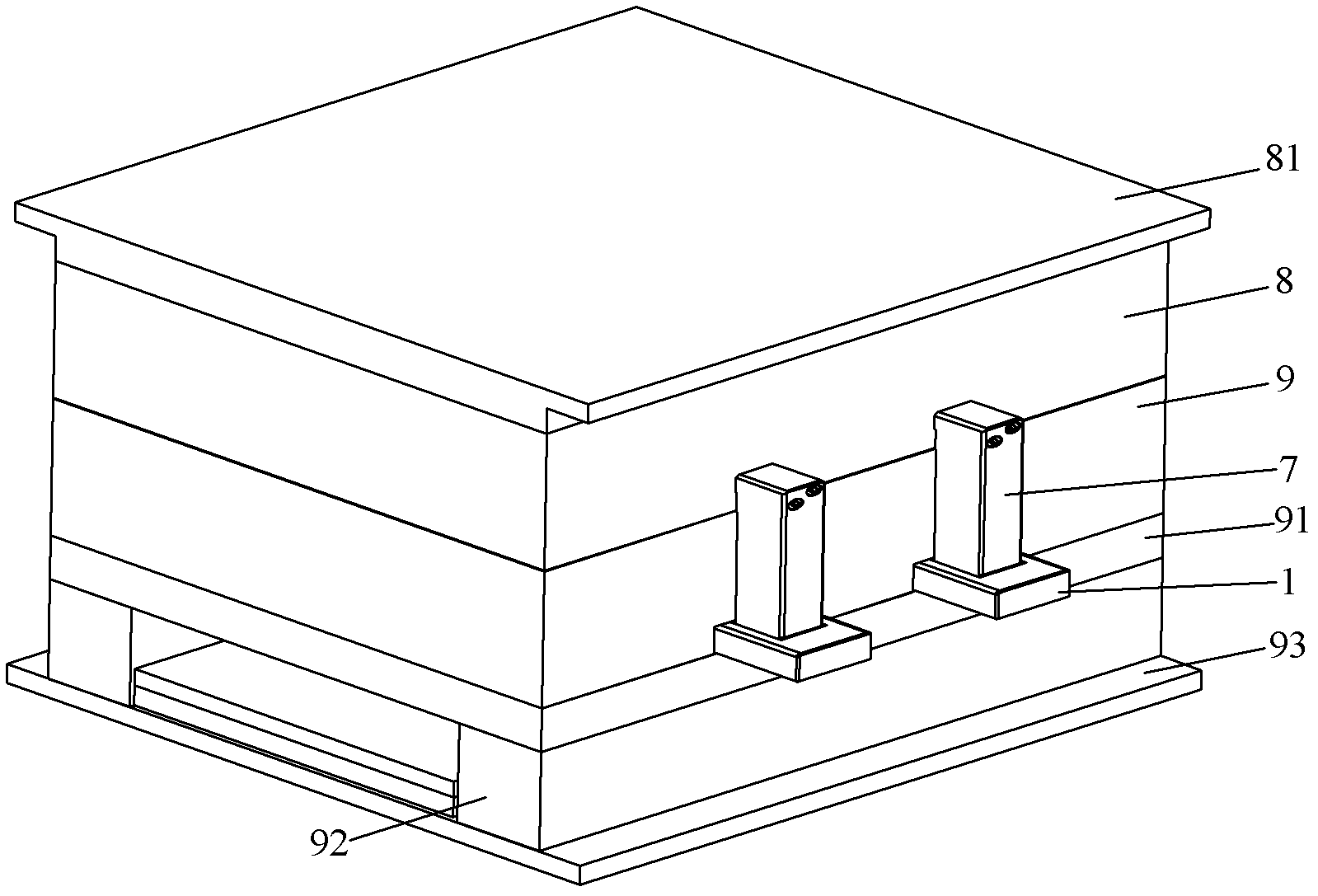

Interior static pressure injection device for measuring compressive strength of masonry mortar

InactiveCN106769445AHigh precisionImprove reliabilityMaterial strength using tensile/compressive forcesAxial pressureLimit value

The invention relates to the field of measuring the compressive strength of mortar in mortar joints of masonry, and particularly relates to an interior static pressure injection device for measuring the compressive strength of masonry mortar. The interior static pressure injection device comprises a bottom plate, two lateral vertical plates, a cover plate, a vertical screw, a vertical pressure sensor, a clamp and an injection steel needle, wherein the bottom plate is fixedly arranged on a base, the two lateral vertical plates are vertical and are oppositely fixed on the bottom plate in parallel, the cover plate is fixedly arranged between the top ends of the two lateral vertical plates, the vertical screw vertically and perpendicularly penetrates through the cover plate, is in threaded fit with the cover plate and is provided with a horizontal hand wheel, the vertical pressure sensor is arranged at the lower end of the vertical screw, the clamp is arranged at the lower end of the vertical pressure sensor, the injection steel needle is fixedly arranged below the clamp, and the conical head of the injection steel needle faces towards the bottom plate. Compared with the prior art, the interior static pressure injection device has the beneficial effects that the simultaneous measurement on axial pressure, injection force limit value and injection depth in the same device can be realized, so that the testing precision and reliability can be increased.

Owner:TAIYUAN UNIV OF TECH

Skin Retention Device for a Medical Jet Injection Kit

InactiveUS20110270217A1Risk minimizationLow pressureJet injection syringesMedical devicesJet injectionInjection point

A skin retention device 10 for a medical jet-injection unit 20 comprises a contact face provided with adhesive 12 in the area surrounding and close to the injection opening(s) 11 of the nozzle 21 which ensures god contact between the nozzle 21 and the skin 30 of a subject in the area chosen for an injection. Consequently the injection force can be lowered dramatically. In case of two-stage jet-injections, the initial injection force can be lowered because the skin retention close to the injection point significantly reduces the energy consuming elastic expansion of the skin 30 in the injection area, and the second injection force can be lowered because of the high degree of fixed positioning of the injection opening of the nozzle 21 relative to the injection channel in the skin 30 made during the initial injection stage. Thus a high degree of injection safety is achieved, minimizing the risk of whet shots, while skin lift and lower injection force decreases the risk of damage of the underlying tissue.

Owner:NOVO NORDISK AS

Injection molding machine used for producing plastic products

ActiveCN105500598ASmooth and orderly reciprocating motionAvoid offsetEngineeringInjection molding machine

The invention discloses an injection molding machine used for producing plastic products, comprising an injection part and a die assembly part, wherein the injection part comprises a base, L-shaped front panel and rear panel, a pair of connecting boards, a charging barrel, a moving board and a second screw; a hopper is arranged at the upper part of the charging barrel, one end of the charging barrel is provided with a nozzle, the other end is sealed, and a first screw is coaxially arranged in the charging barrel; the moving board is provided with a pressure sensor and a nut; a circular-truncated-cone-shaped gum guide body with a sliding block axis of a tenon structure is arranged on the lower surface of the moving board; the bottom surface with relatively small diameter of the gum guide body faces a die; a plurality of notches are formed in the side face of the gum guide body, so as to form a plurality of passages for molten plastics to flow; and the nozzle is of a cylindrical structure, and one end, far away from the hopper, of the nozzle, is detachably provided with a circular-truncated-cone-shaped gum guide body which is coaxial with the nozzle. By adopting the injection molding machine, dislocation and offset caused by injection force or die replacement during injection of a front plate and a rear plate can be avoided, the charging barrel cannot contact with the screws, discharge speed is high, and the nozzle cannot be damaged.

Owner:重庆力标汽车部件有限公司

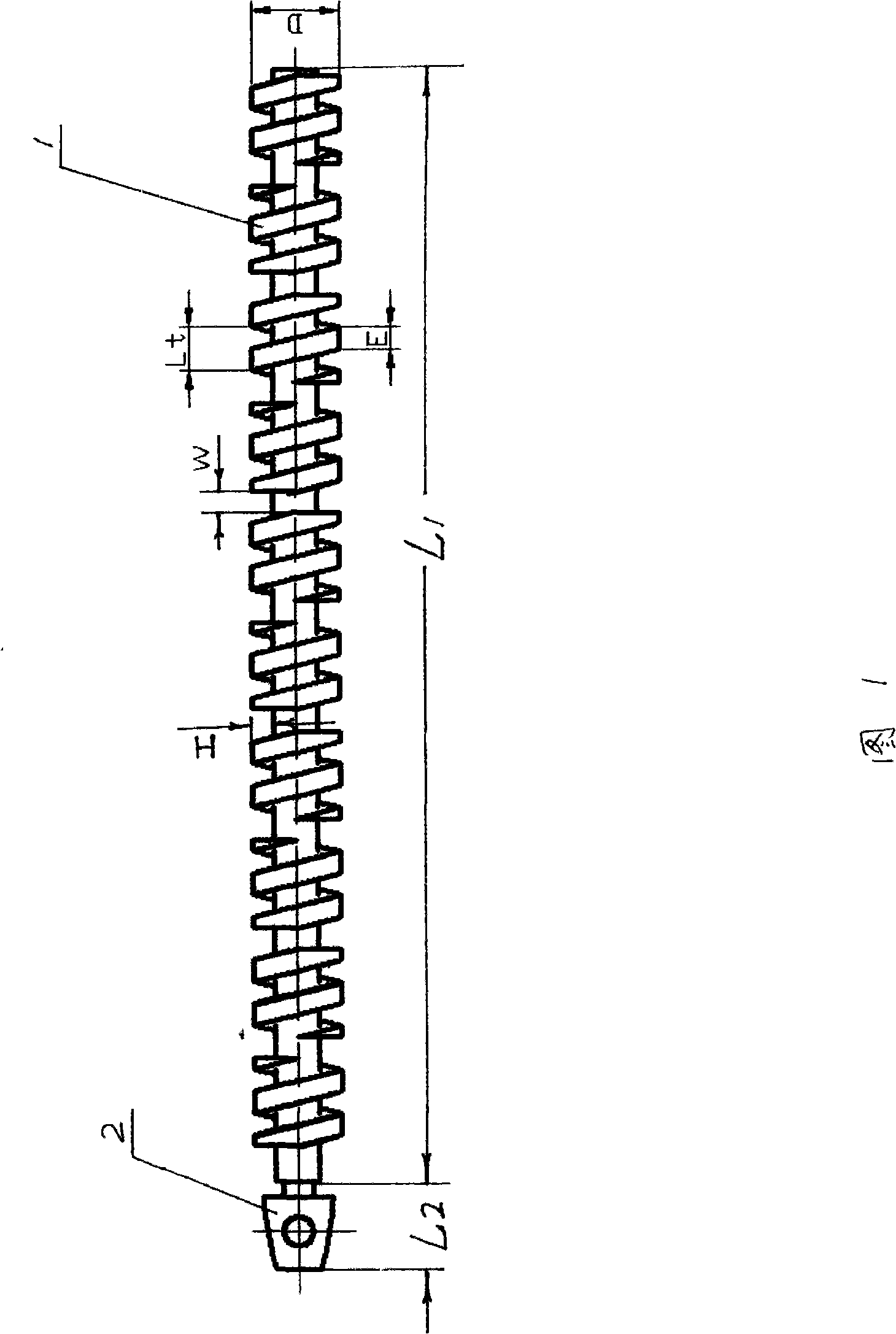

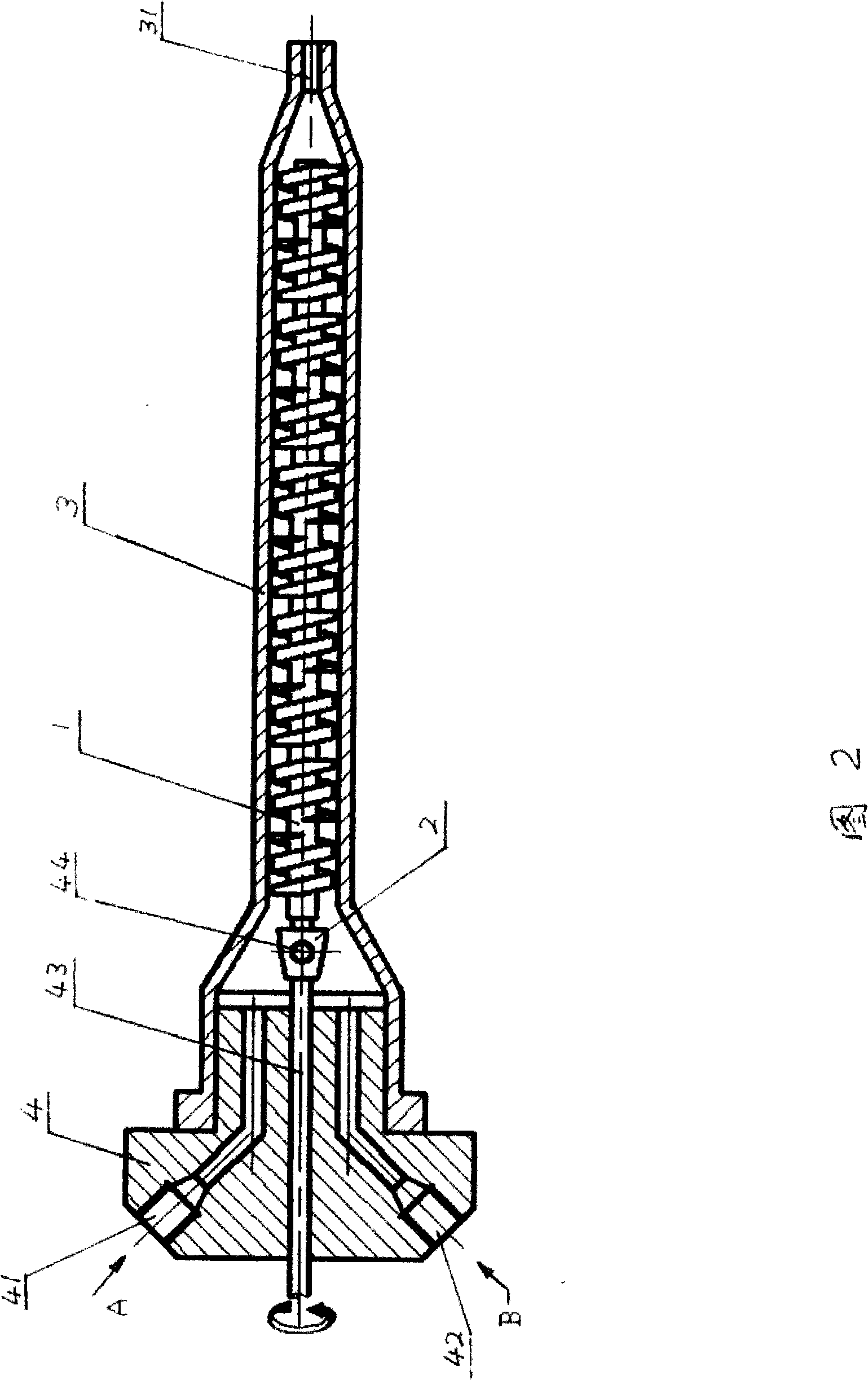

Intermittent screw thread type reaction injection mixing element

An injection mixing element of a discontinuous thread type reaction consists of a discontinuous thread type working section (1) and a drive connection section (2); wherein, the discontinuous thread type working section (1) is a rectangle thread section lathed and is manufactured by a metal material; the structure parameters of the discontinuous thread type working section (1) are that the length is L1, the diameter is D, the thread pitch is Lt, the width of the thread ridge is E and the depth of the thread slot is H; besides, a discontinuous slot with discontinuous width of W is processed by being spaced by every two thread pitches; the depth of the discontinuous slot is also the depth of the thread slot which is H; a connection structure matched with a drive shaft of the mixing element is manufactured on the drive connection section (2). The invention can build a larger injection force; the surface quality of a product is good; the structure is simple; the cost is low; besides, the invention is simple and easy to be used, maintained and repaired.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

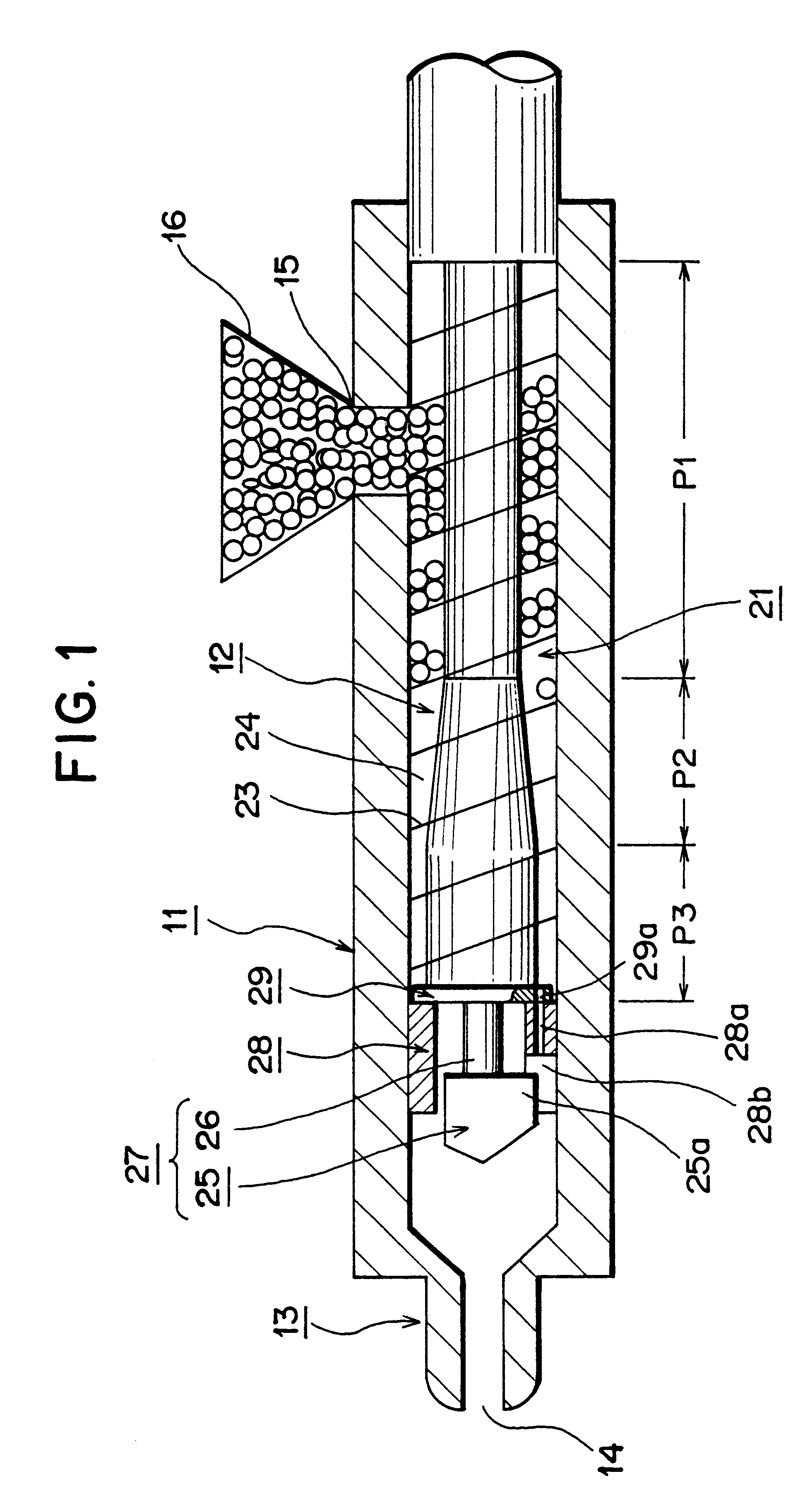

Injection apparatus and method of controlling the same

InactiveUS6321940B1Increase injection pressureReduce frictional resistanceLarge containersLiquid transferring devicesInjection pressureReciprocating motion

An injection apparatus which can reduce frictional resistance which acts on resin during an injection step to thereby prevent variation in a reference position and improve quality of molded products. The injection apparatus comprises a heating cylinder; a screw disposed within the heating cylinder to be rotatable and reciprocatable, the screw having a flight portion in which a flight is formed on an outer circumference of a screw body, and a screw head disposed at a front end of the flight portion; a first drive unit for rotating the screw; a second drive unit for advancing and retracting the screw; a screw-advancement control unit for driving the second drive unit in an injection step in order to advance the screw at a predetermined screw speed; and a flight speed control unit for driving the first drive unit in the injection step in order to advance the flight at a flight speed that is apparently lower than the screw speed. Since the frictional resistance acting on resin in the vicinity of the inner circumferential surface of the heating cylinder can be reduced, during the injection step, the injection force can be made to correspond to the injection pressure, so that a sufficiently large injection pressure can be generated.

Owner:SUMITOMO HEAVY IND LTD

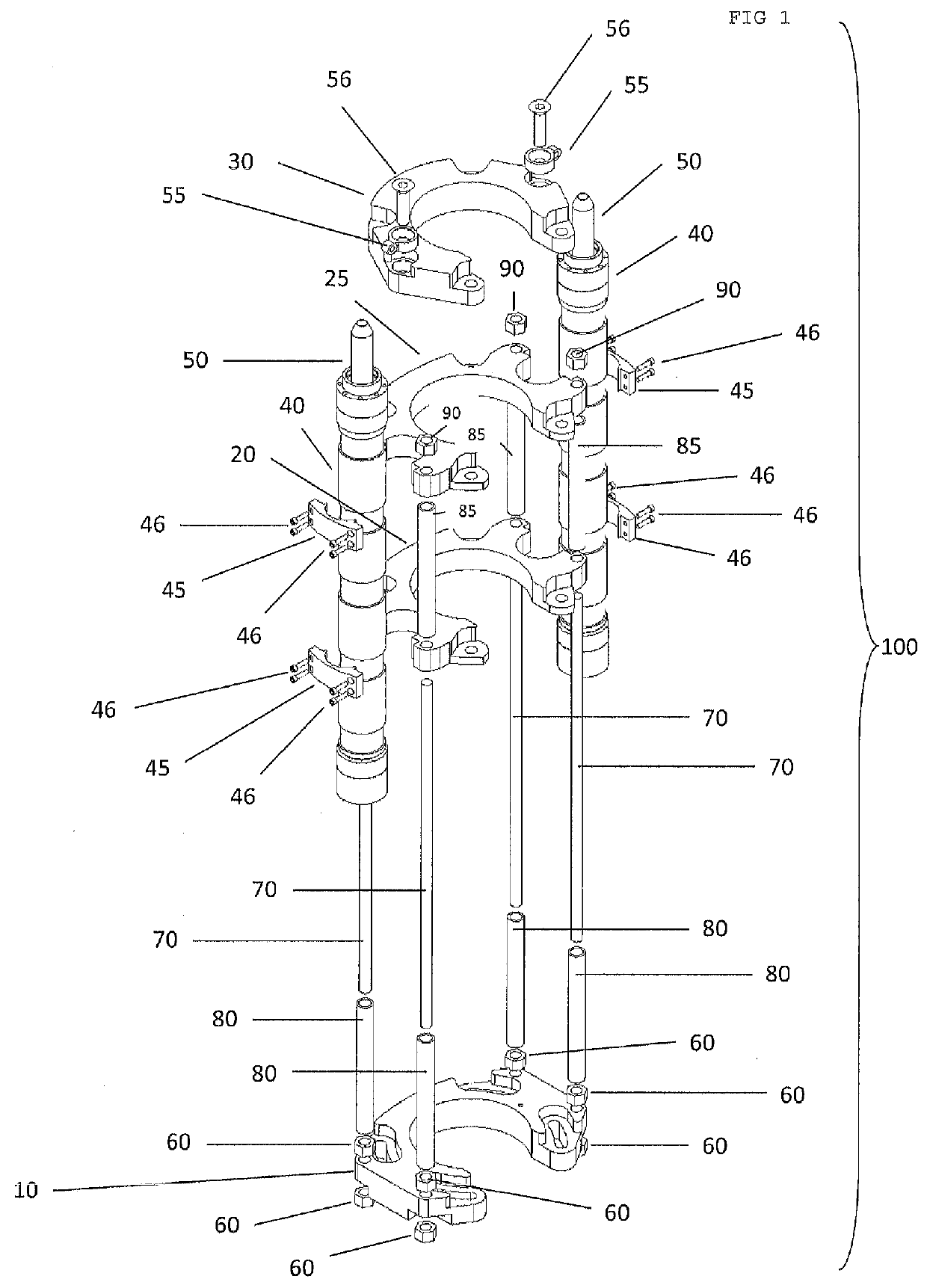

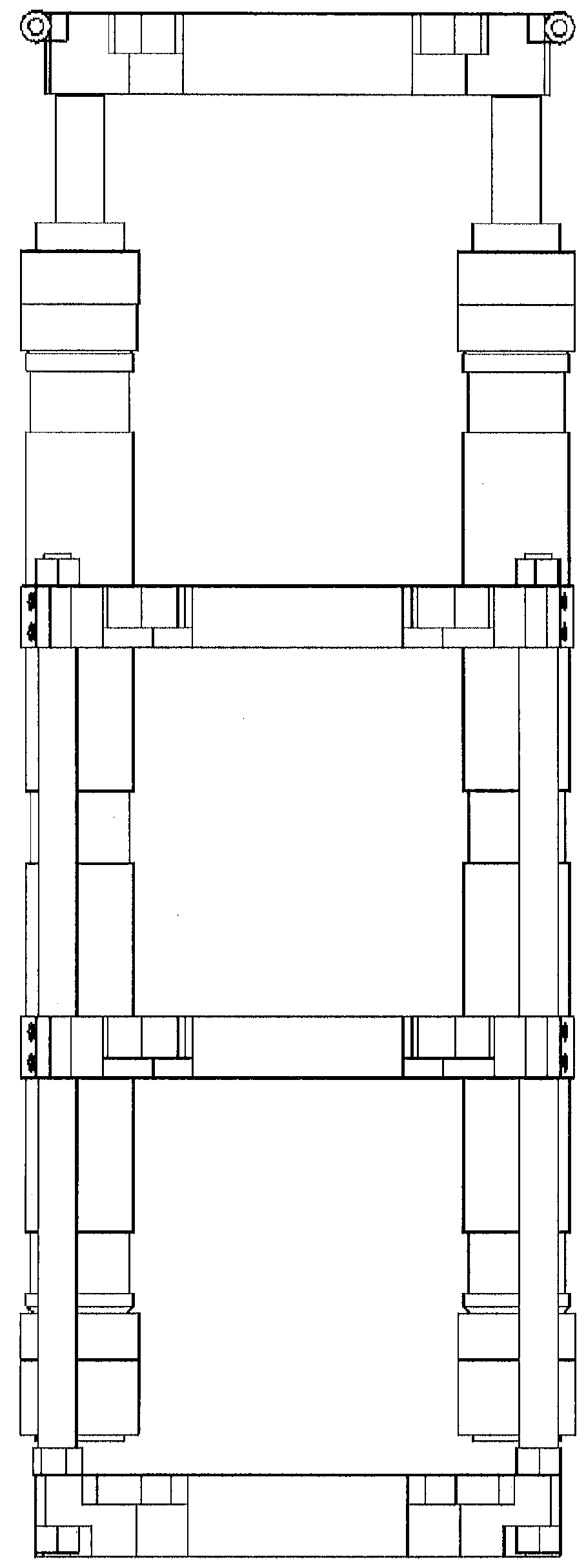

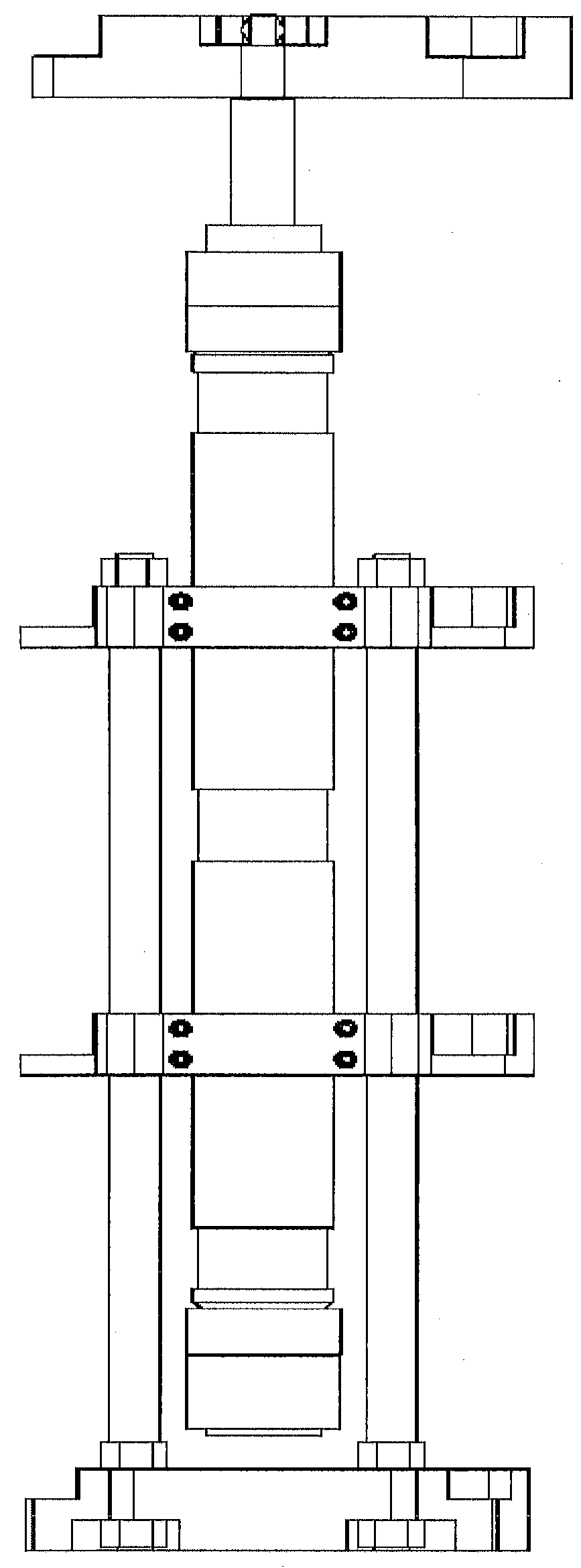

Horseshoe jack for drilling, work-overs and completions

ActiveUS20160032667A1Simple control mechanismImprove powerDrilling rodsConstructionsInjection forceBiomedical engineering

A jack and push / pull apparatus is provided by attaching to a wellhead an extendable / contractible horseshoe-shaped jack assembly of sufficient diameter to surround and act upon the tubing or casing to be manipulated in the well, the linear action of the assembly being powered between an extended and a retracted position, the assembly having at least one tube-gripping mechanism at the end of the assembly away from the wellhead attachment. Tubing is inserted into the well bore through the assembly and the wellhead, and when injection forces are desired tube-gripping means grip the tubing being injected and the apparatus is powered to a retracted position, forcing the grasped tubing into the well. The operation may be reversed to pull tubing or casing. The assembly can be simply added to the rig while tubing is present on and above the rig's floor.

Owner:1440072 ALBERTA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com