Interior static pressure injection device for measuring compressive strength of masonry mortar

A technology of compressive strength and masonry mortar, which is applied in the field of indoor static pressure penetration devices, to achieve the effects of simplifying the test process, improving accuracy and reliability, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

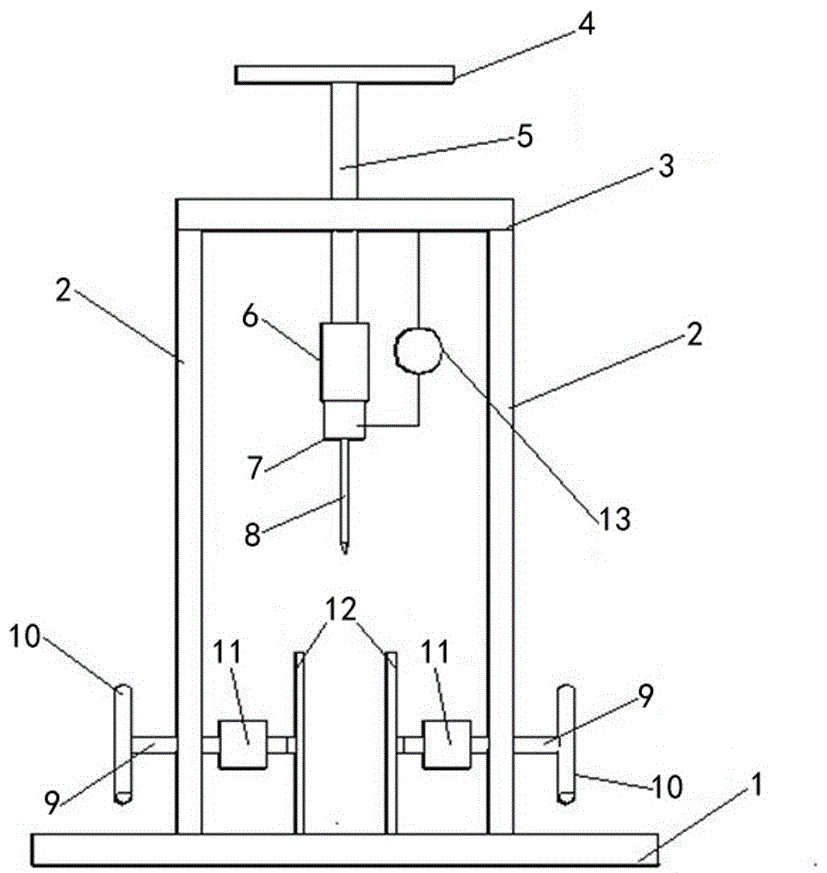

[0012] An indoor static pressure penetrating device for measuring the compressive strength of masonry mortar, comprising a bottom plate 1 fixed on a base, vertical and opposite side vertical plates 2 fixed on the bottom plate 1 in parallel, fixed on The cover plate 3 between the tops of the vertical plates 2 on both sides, the vertical screw rod 5 with the horizontal hand wheel 4 that vertically passes through the cover plate 3 and is screwed with the cover plate 3, is installed on the vertical screw rod 5 lower end of the vertical screw rod 5. To the pressure sensor 6, the clamp 7 installed at the lower end of the vertical pressure sensor 6 is fixed below the clamp 7 and the penetrating steel needle 8 whose cone head faces the bottom plate 1,

[0013] The lower part of each side vertical board 2 is respectively horizontally and vertically penetrated with a horizontal screw 9, and each horizontal screw 9 is threadably matched with the lateral vertical board 2, and each horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com