Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Handling food" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basics for Handling Food Safely. Always wash hands with warm water and soap for 20 seconds before and after handling food. Don't cross-contaminate. Keep raw meat, poultry, fish, and their juices away from other food. After cutting raw meats, wash cutting board, utensils, and countertops with hot, soapy water.

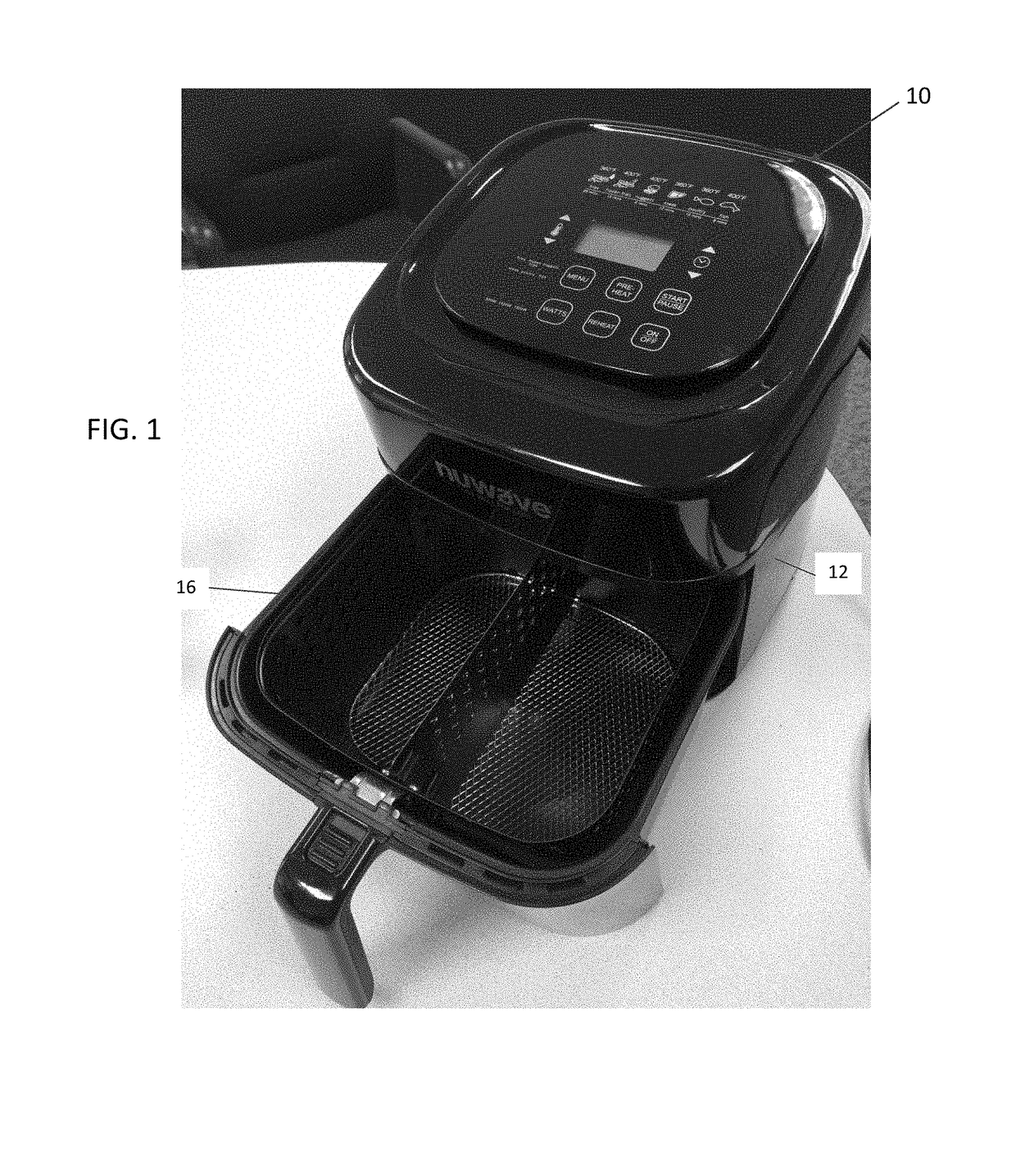

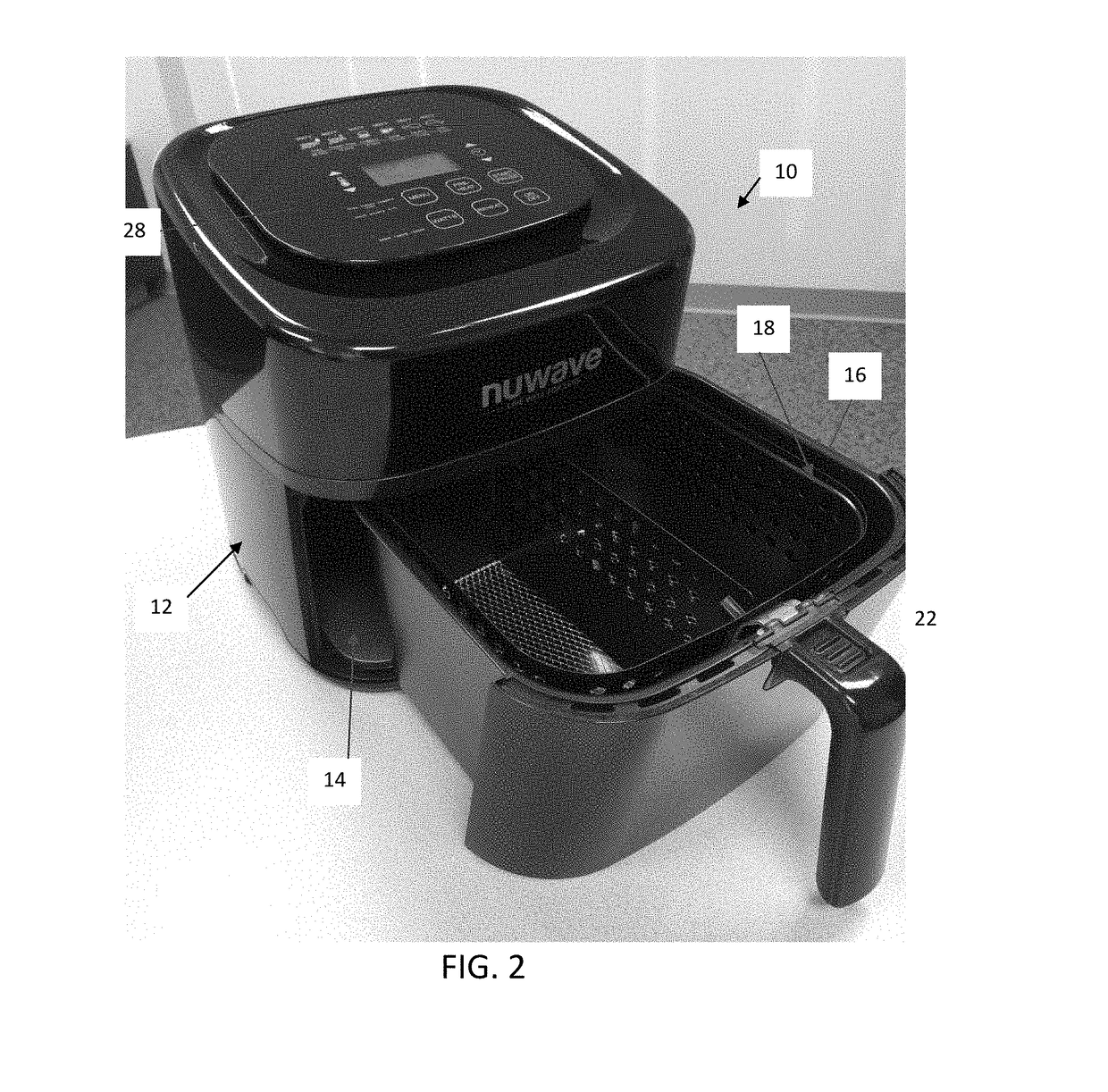

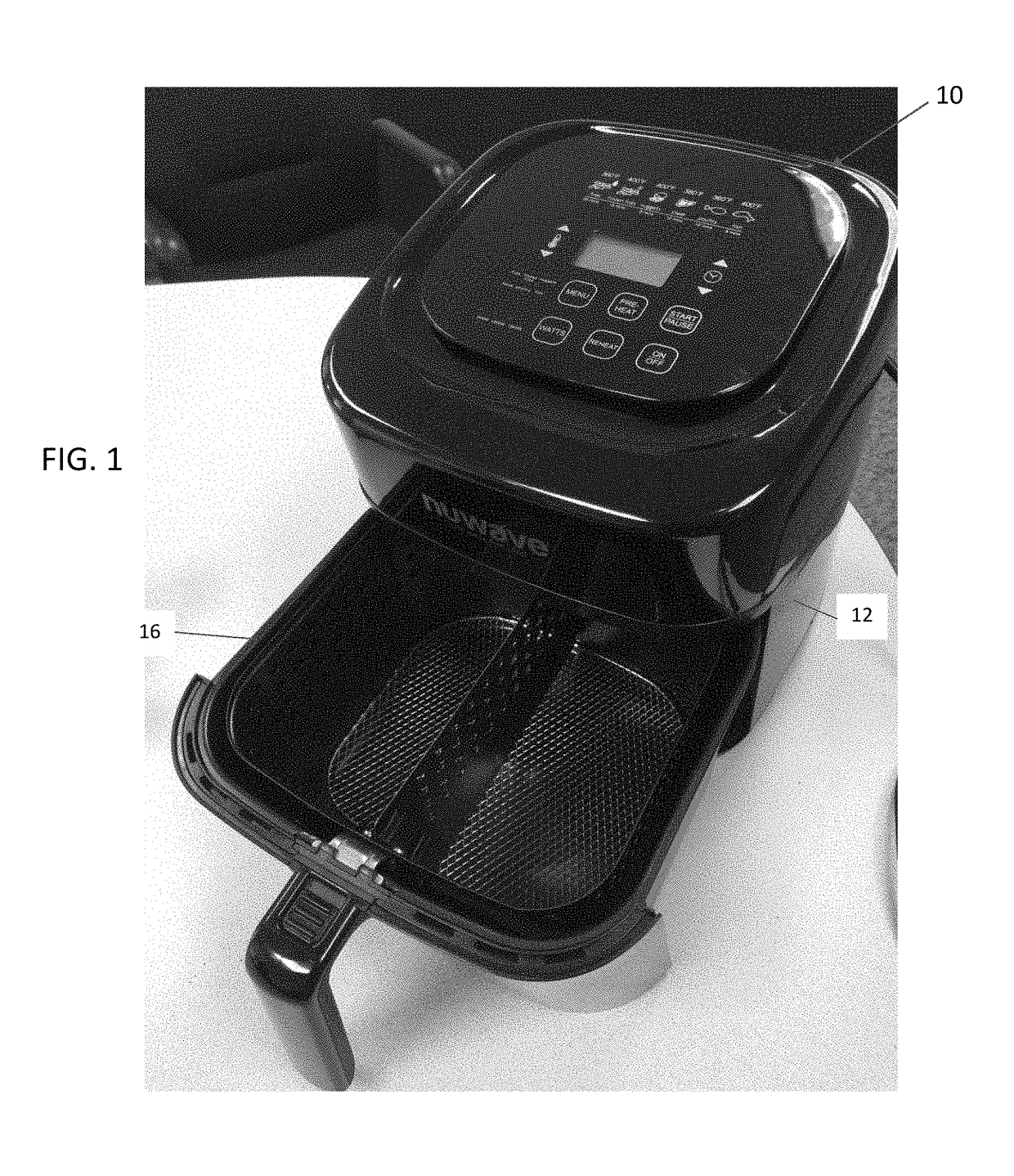

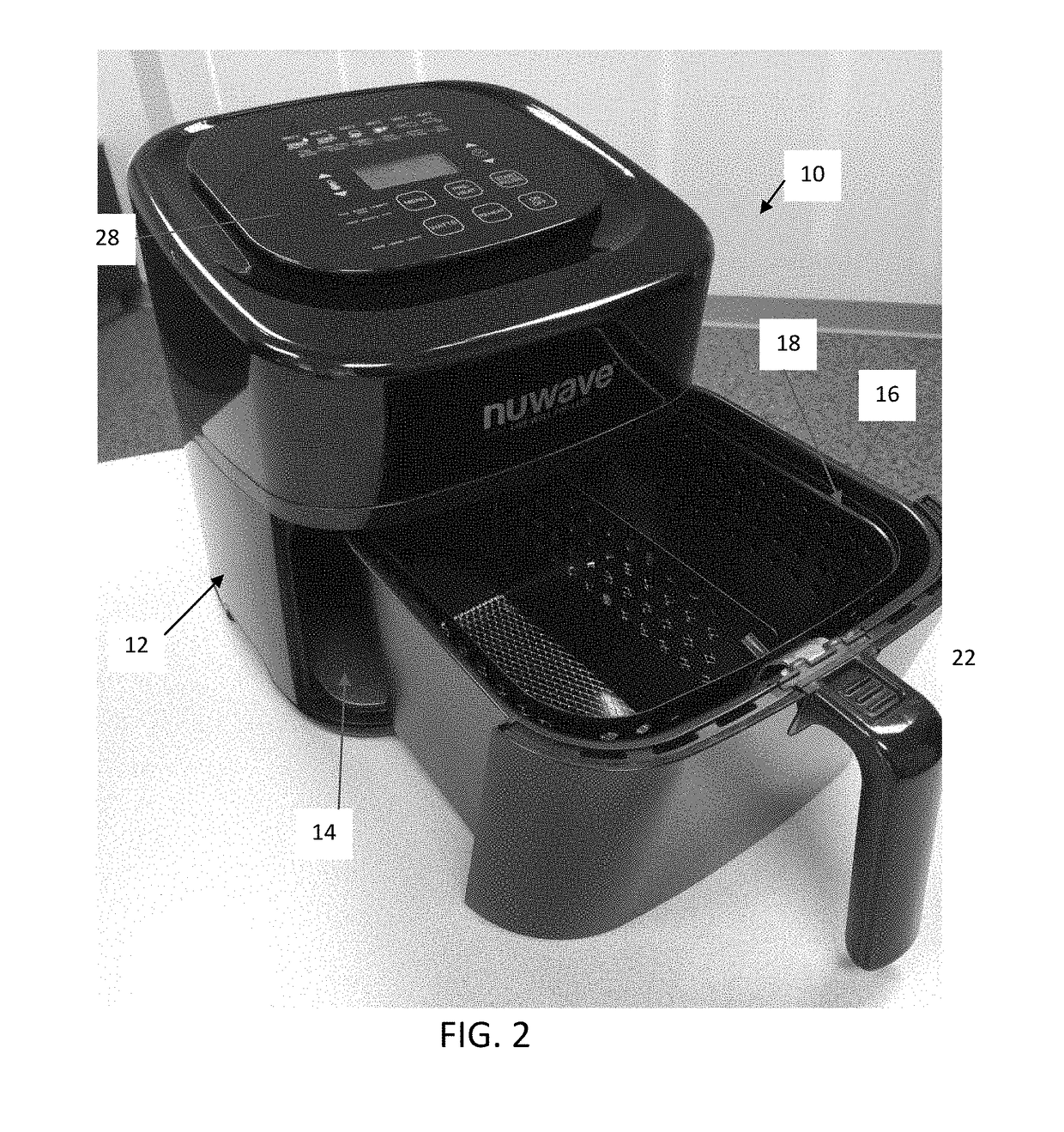

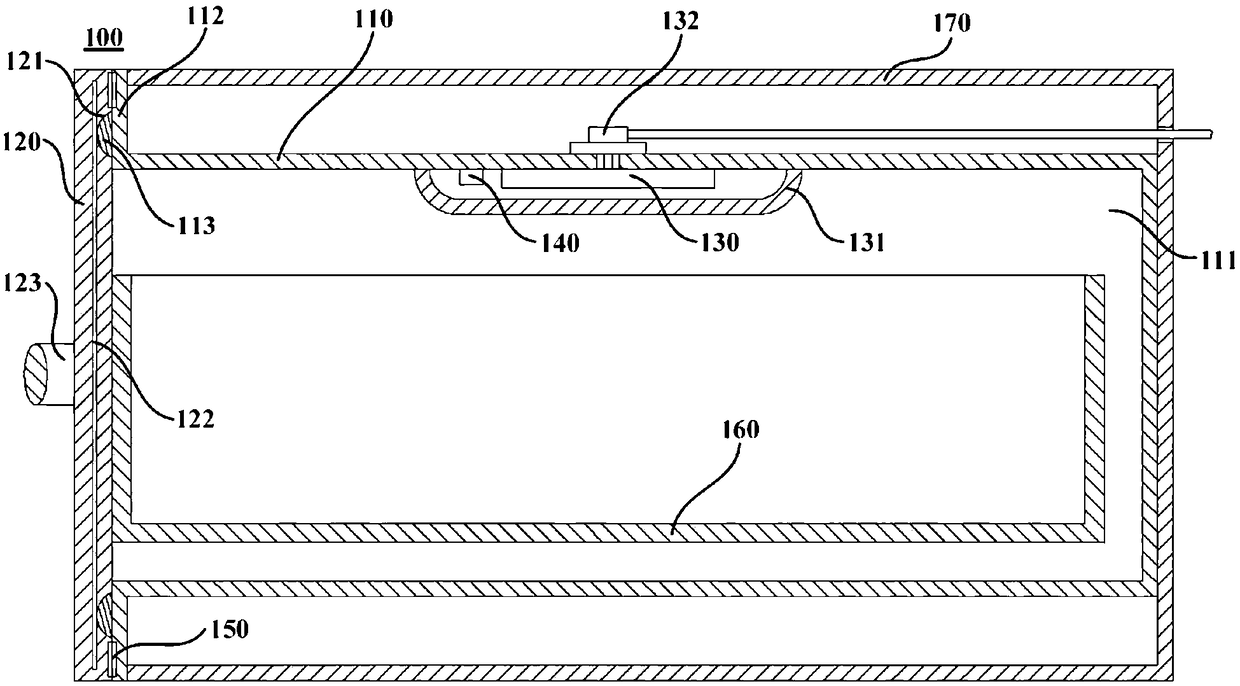

Air Fryer

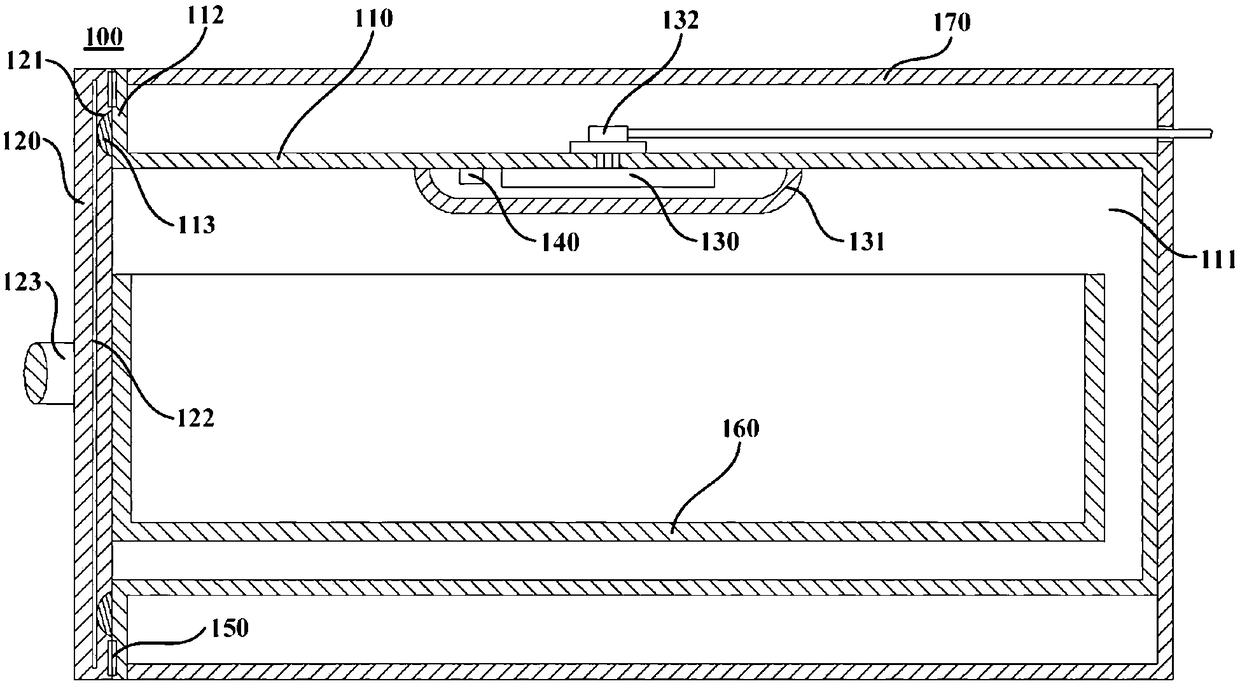

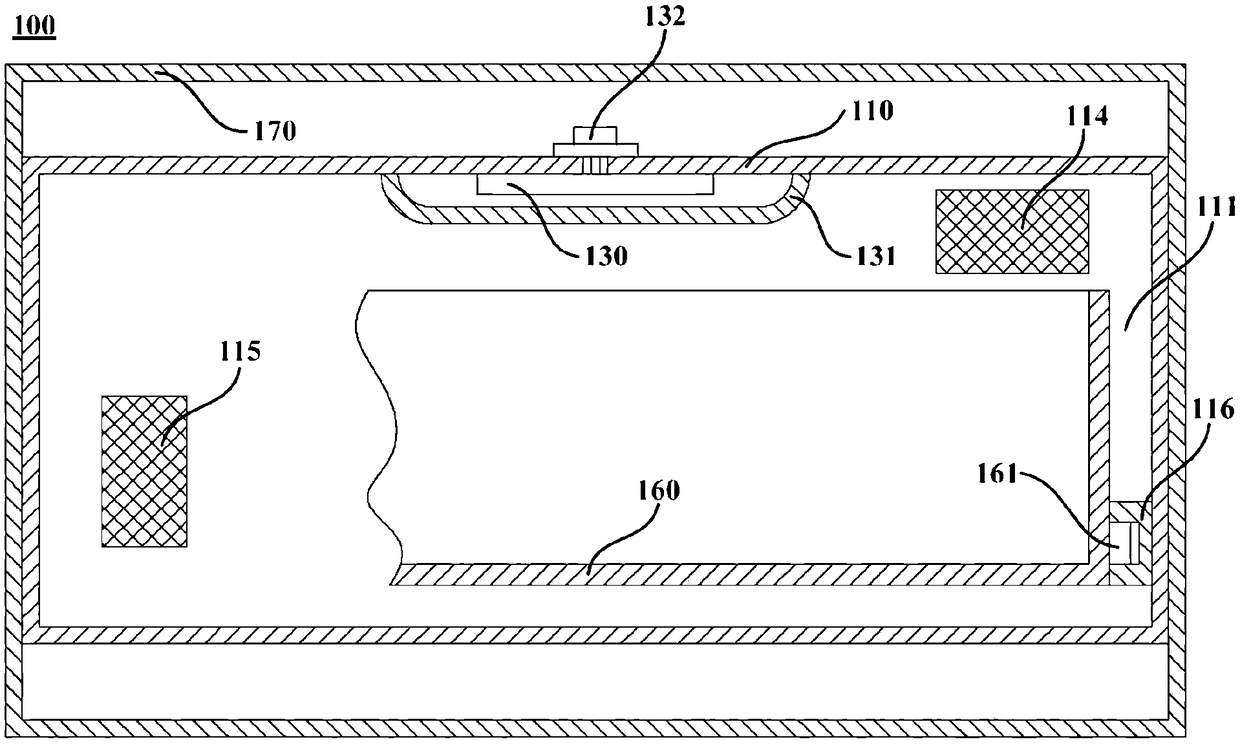

InactiveUS20170231430A1Simple structureAdditional operating advantageDeep fat fryersTemperature controlHandling food

An air fryer system is disclosed which comprises a base having a heating source and an air source located therein, both sources being supplied power for operation by an AC power cord. A cooking chamber is defined within the base and a cooking drawer fits securely within the cooking chamber to substantially seal the chamber against heat loss during use. A handled food basket which detachably secures to the cooking drawer is configured to facilitate even distribution of heated air within the cooking chamber. A digital, touch screen user interface attached to a surface of the base is electronically coupled to a controller for powering on the fryer system and setting cooking conditions. The preferred system also includes infrared heating, time and temperature controls, and an automatic safety shutoff mechanism.

Owner:NUWAVE

Air Fryer

InactiveUS20180255971A1Simple structureAdditional operating advantageCooking vesselsRoasters/grillsTemperature controlHandling food

An air fryer system is disclosed which comprises a base having a heating source and an air source located therein, both sources being supplied power for operation by an AC power cord. A cooking chamber is defined within the base and a cooking drawer fits securely within the cooking chamber to substantially seal the chamber against heat loss during use. A handled food basket which detachably secures to the cooking drawer is configured to facilitate even distribution of heated air within the cooking chamber. A digital, touch screen user interface attached to a surface of the base is electronically coupled to a controller for powering on the fryer system and setting cooking conditions. The preferred system also includes infrared heating, time and temperature controls, and an automatic safety shutoff mechanism.

Owner:NUWAVE

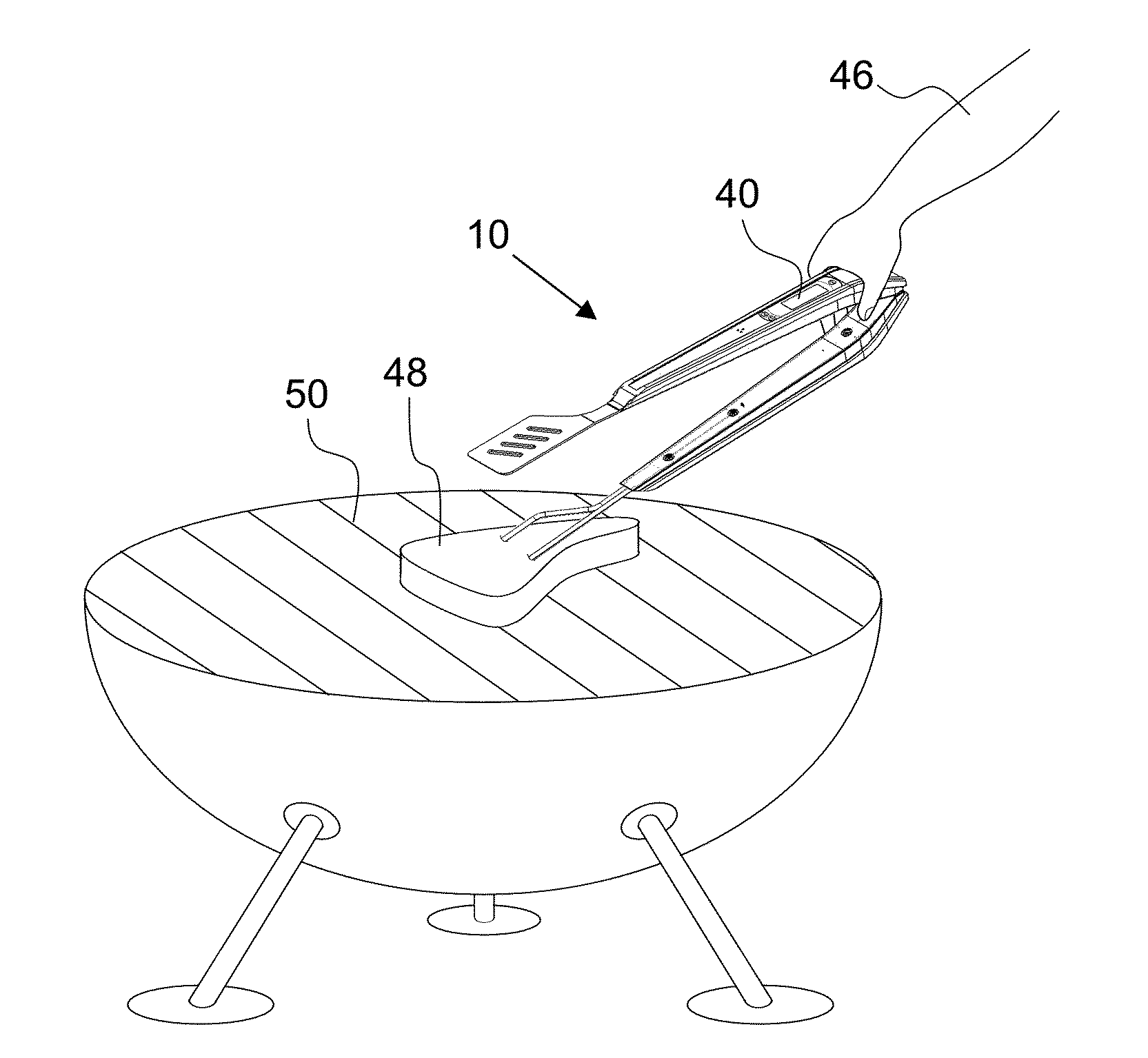

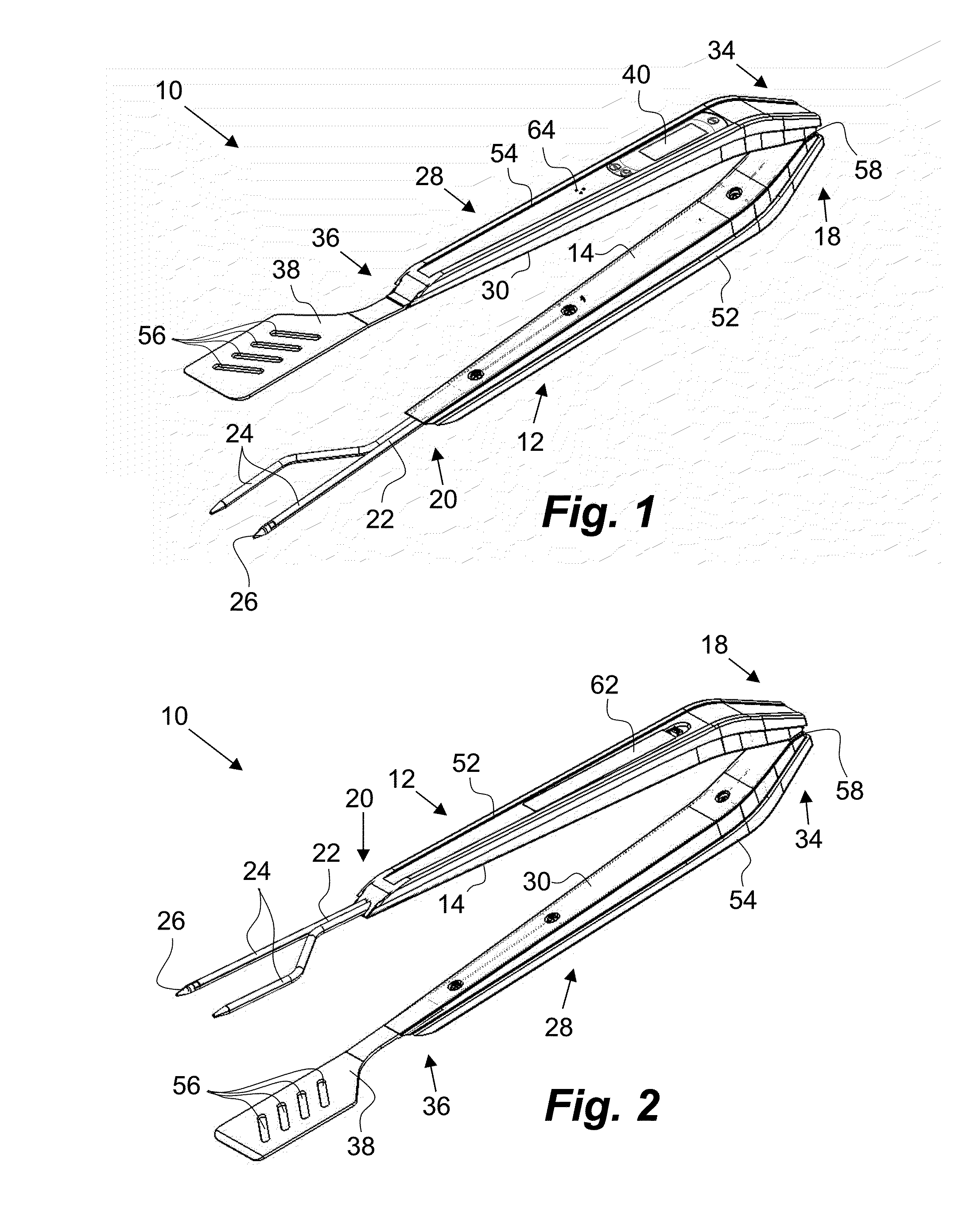

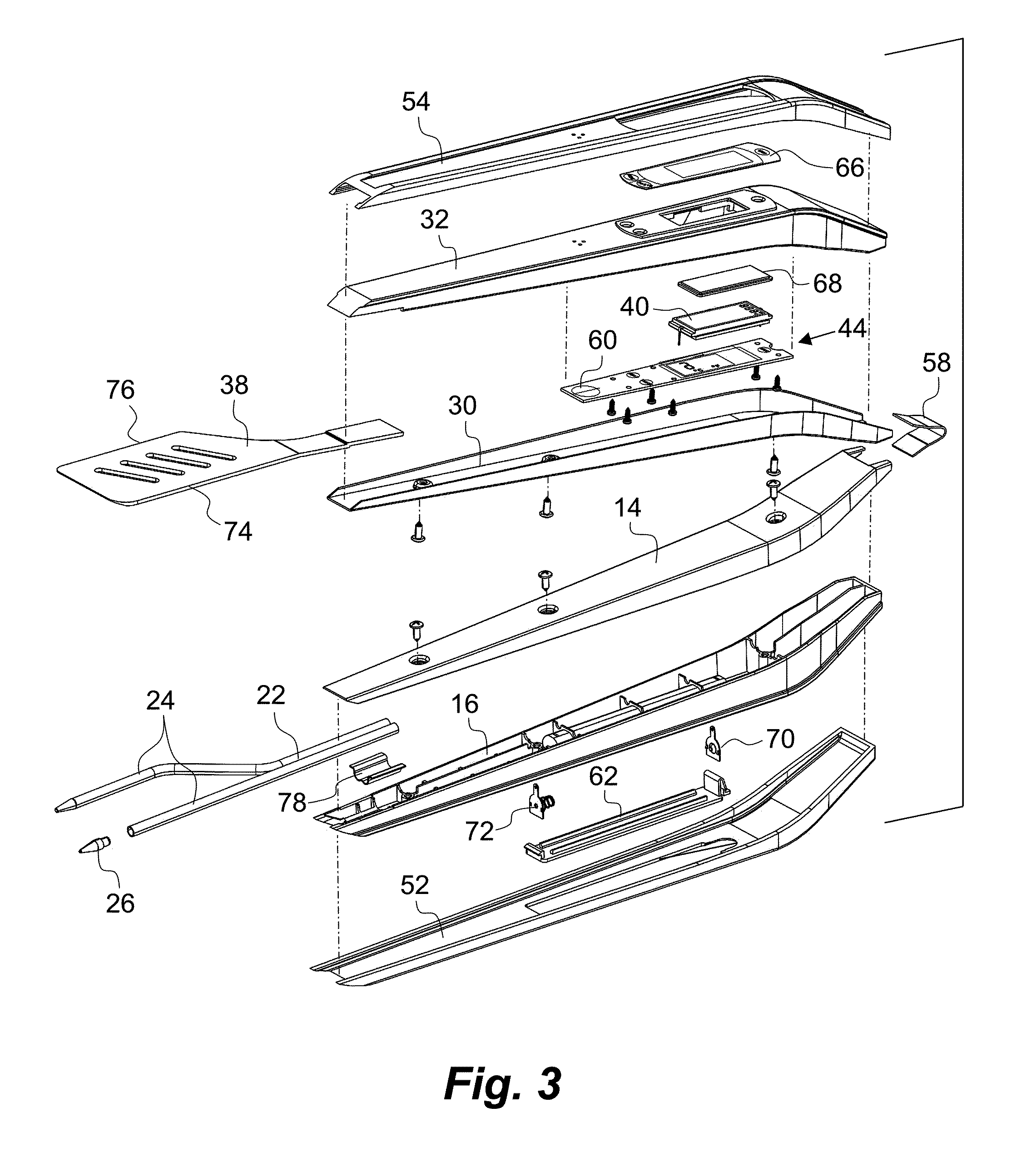

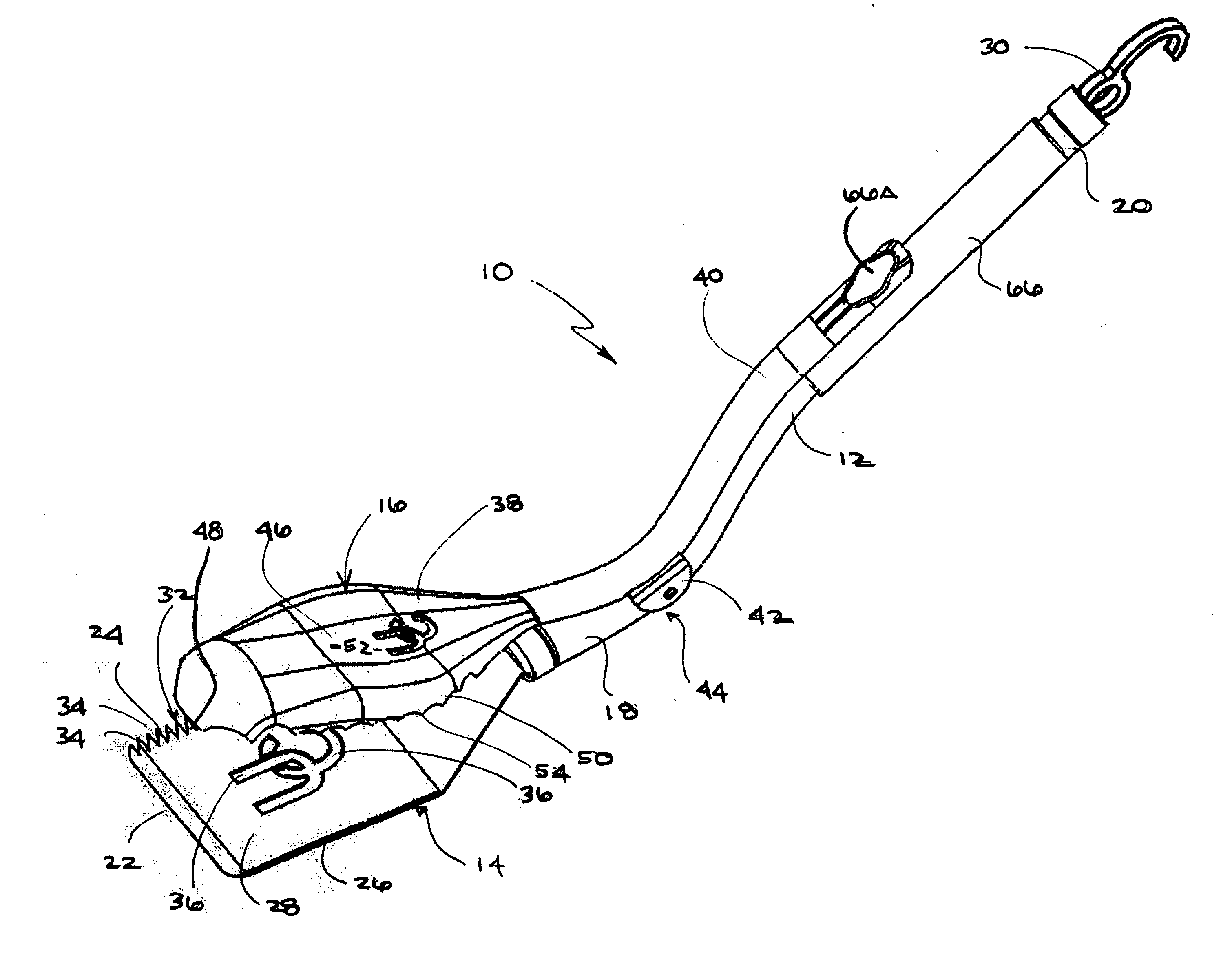

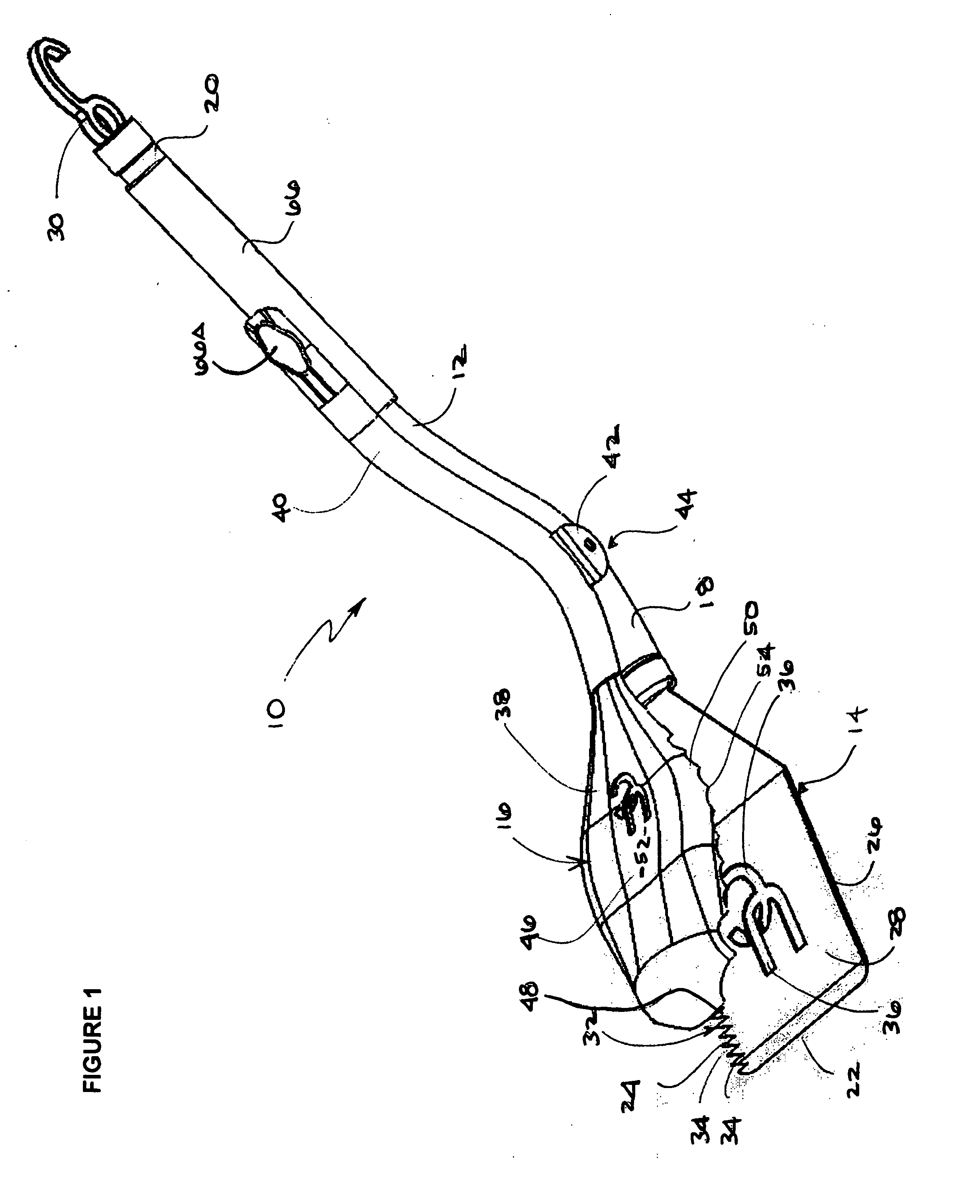

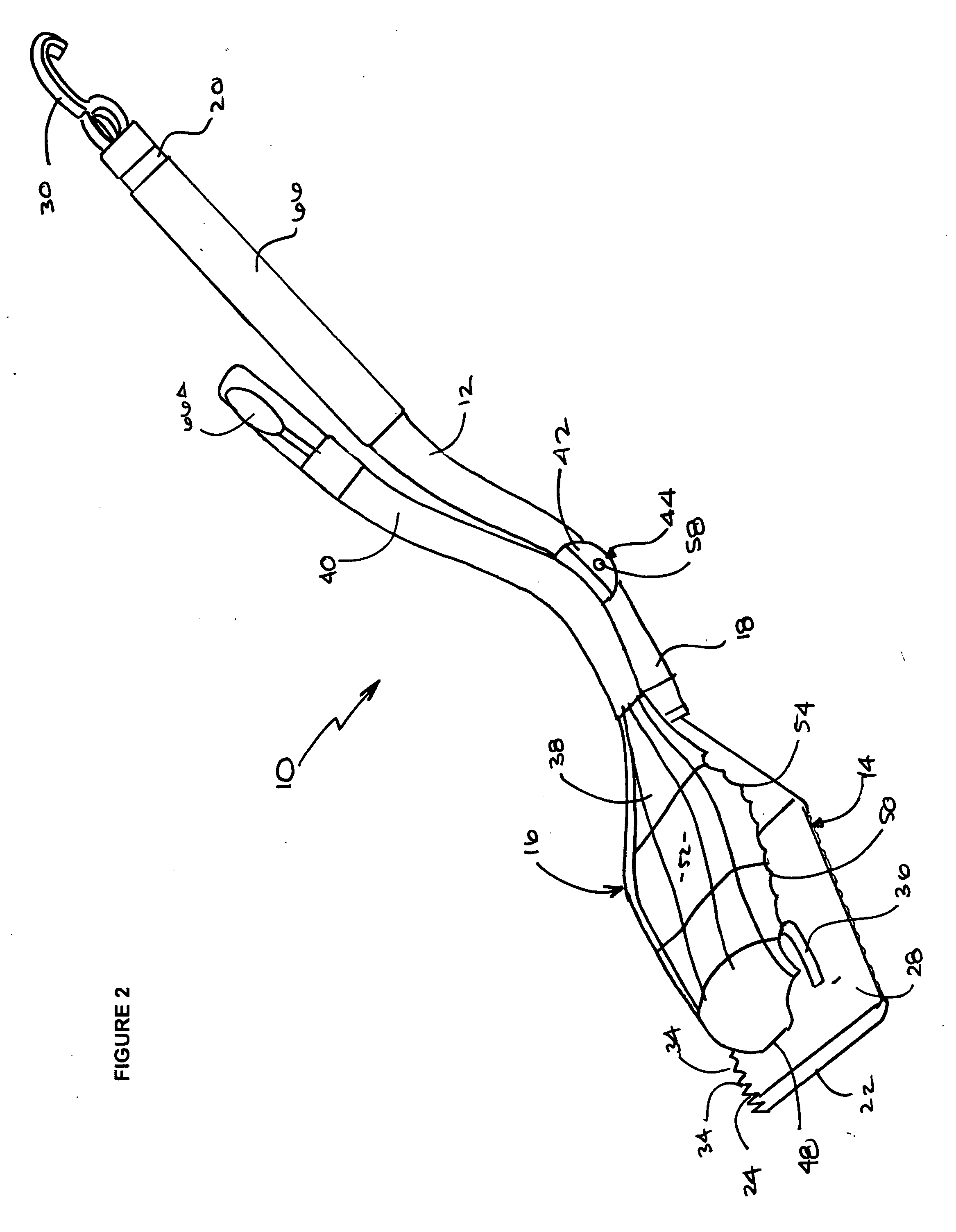

Barbecue Tongs With Temperature Sensor

InactiveUS20110044370A1Easy to viewThermometer detailsTemperature measurement in household appliancesHandling foodElectronic communication

A pair of cooking tongs is provided for use in manipulating and handling food items and displaying the temperature and degree of “doneness” of a meat during cooking. The invention comprises a pair of arms, one of which includes a fork at its end in which there is a temperature sensor. The other arm features a display which is in electronic communication with the temperature sensor. Some embodiments include a speaker which provides an audio signal indicating that the temperature of the meat has reached or passed a selected threshold. The invention allows a user to manipulate food using one hand while conveniently reading the temperature of any of a variety of meats to ensure they are cooked to a desired “doneness,” such as rare, medium rare, medium, and well done.

Owner:LEHR IP LLC

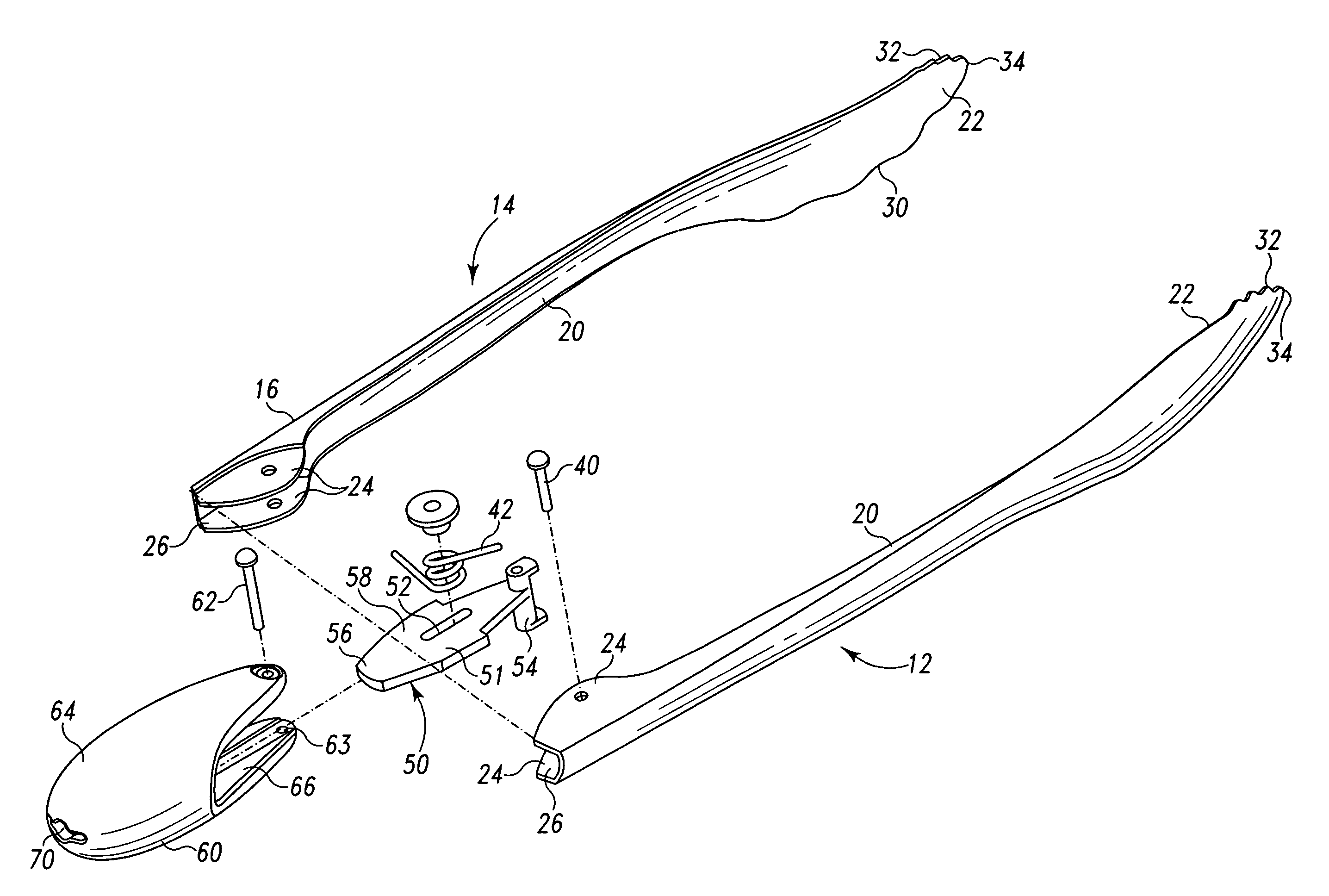

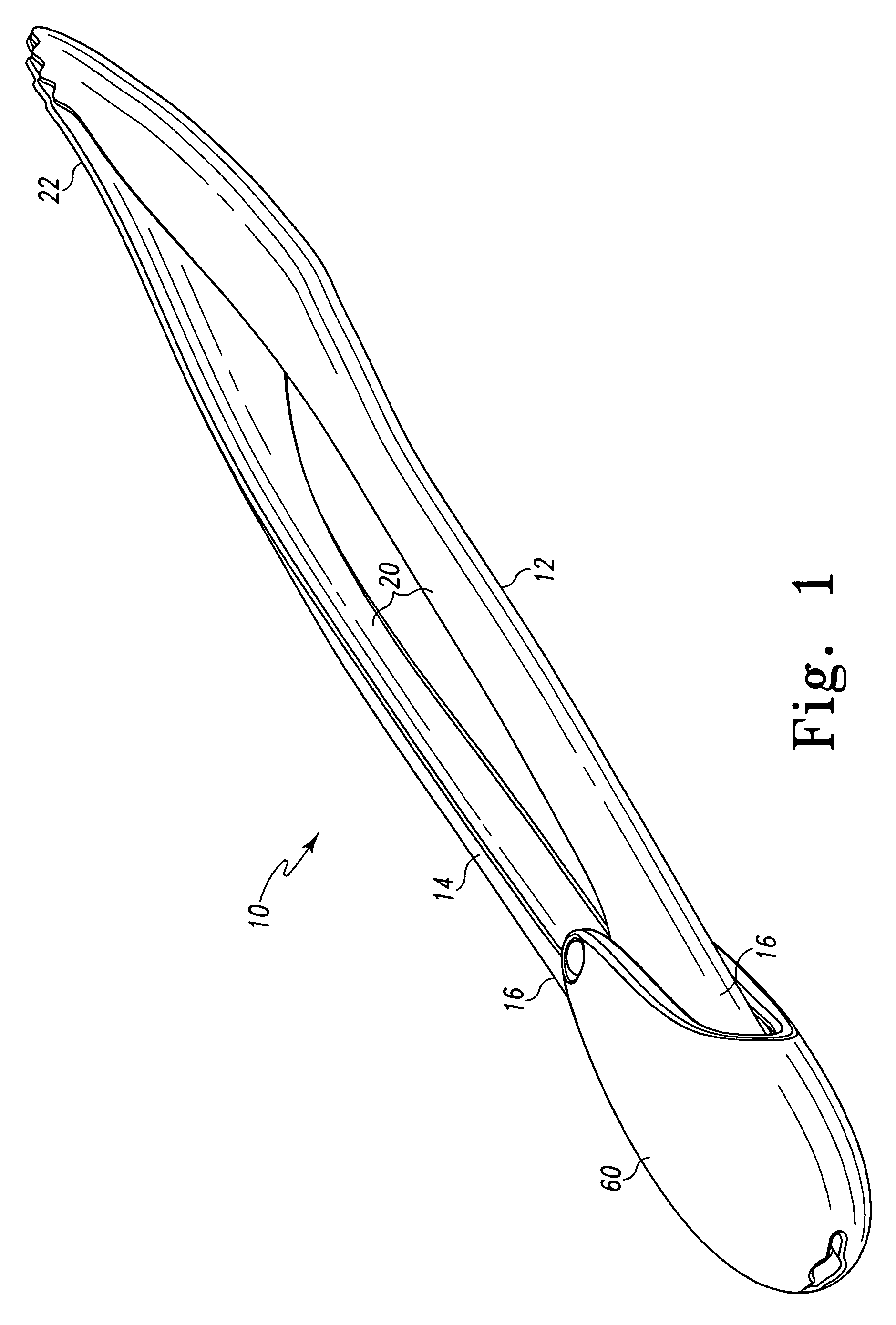

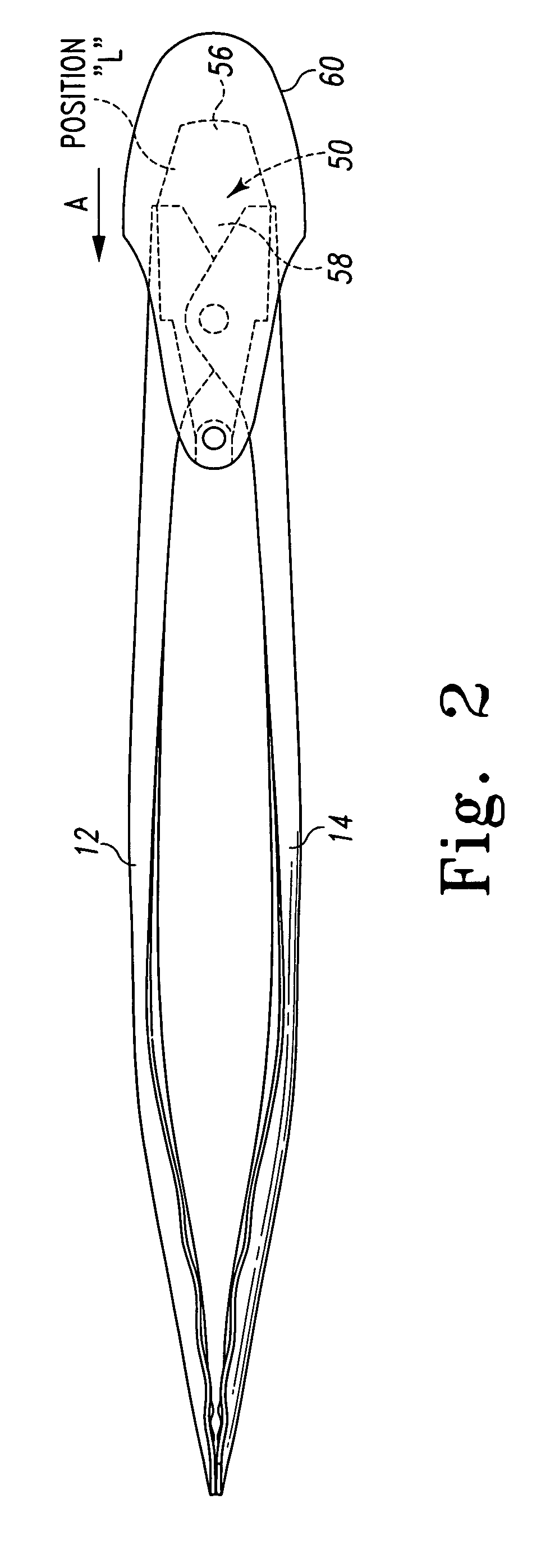

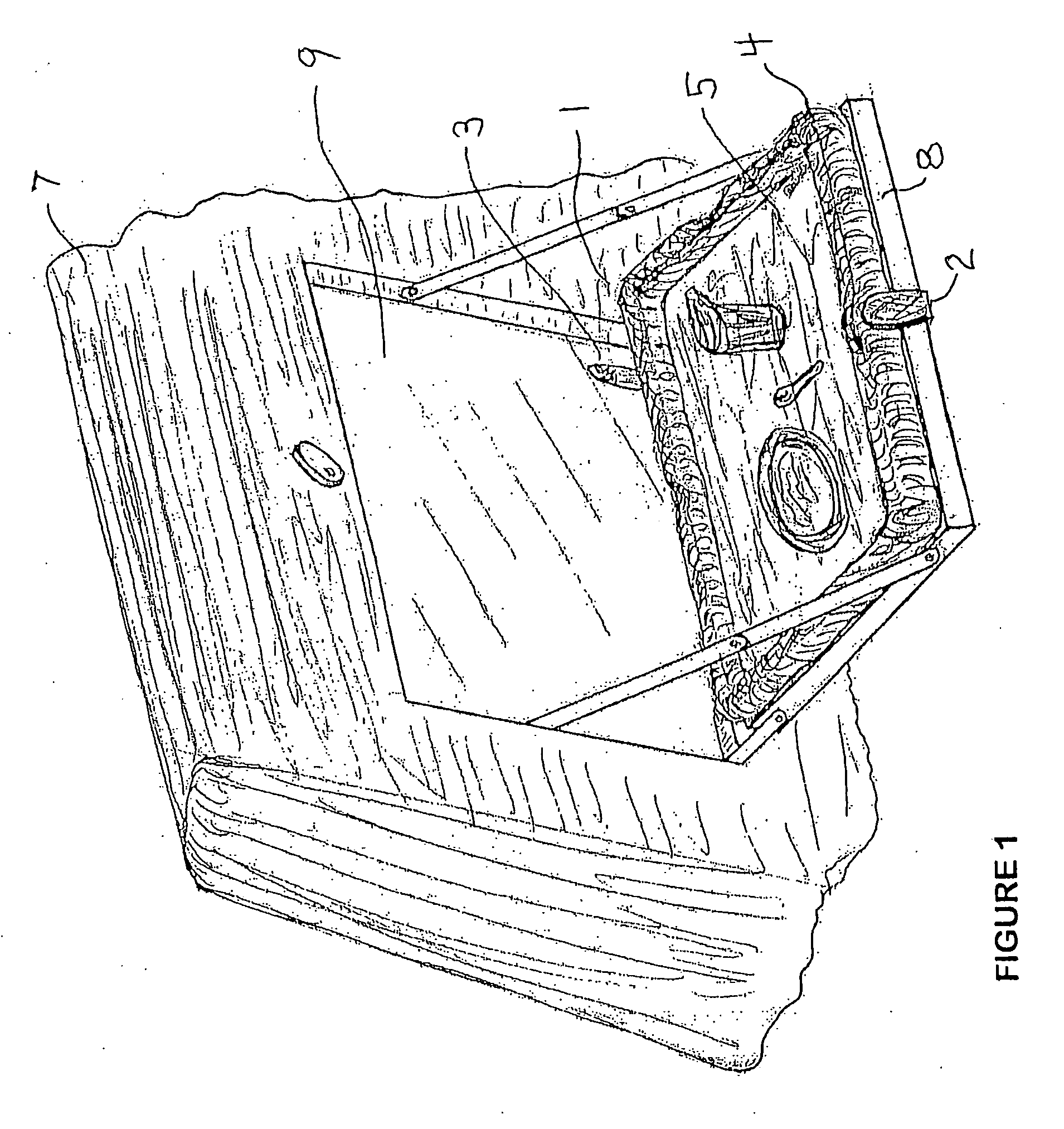

Tongs with encapsulated locking mechanism

A pair of locking kitchen tongs for use in handling food items and the like is disclosed. The tongs have a pair of rigid steel arms each having a workpiece engaging or grasping end, a body portion and a pivot end from which the arms are pivotally connected together. The grasping ends are preferably scalloped along one edge, for handling relatively large items, and serrated (i.e., fine-toothed) along another edge, for handling of smaller or fine items. A bulbous, tear-shaped body made from a rigid, non-metal material encapsulates the pivot ends of the two arms as they are pivotally connected together to permit movement between an open position and a closed position. Also within and coupled to the encapsulating body is a sliding locking plate. The locking plate has a body defining a slot which allows the locking plate to slide between a locked position, maintaining the arms in their closed position, and an unlocked position, allowing them free pivoting movement.

Owner:HELEN OF TROY LIMITED

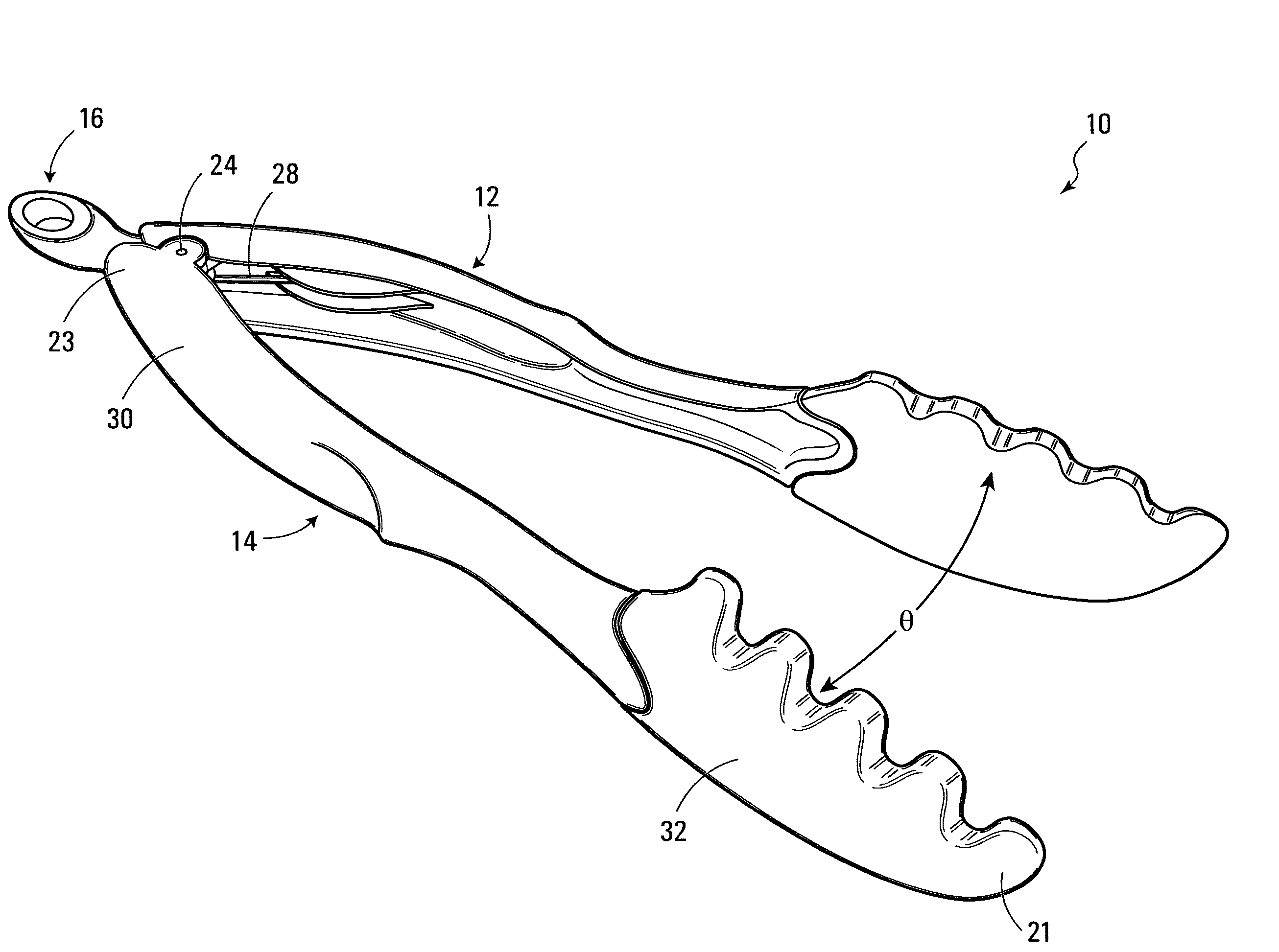

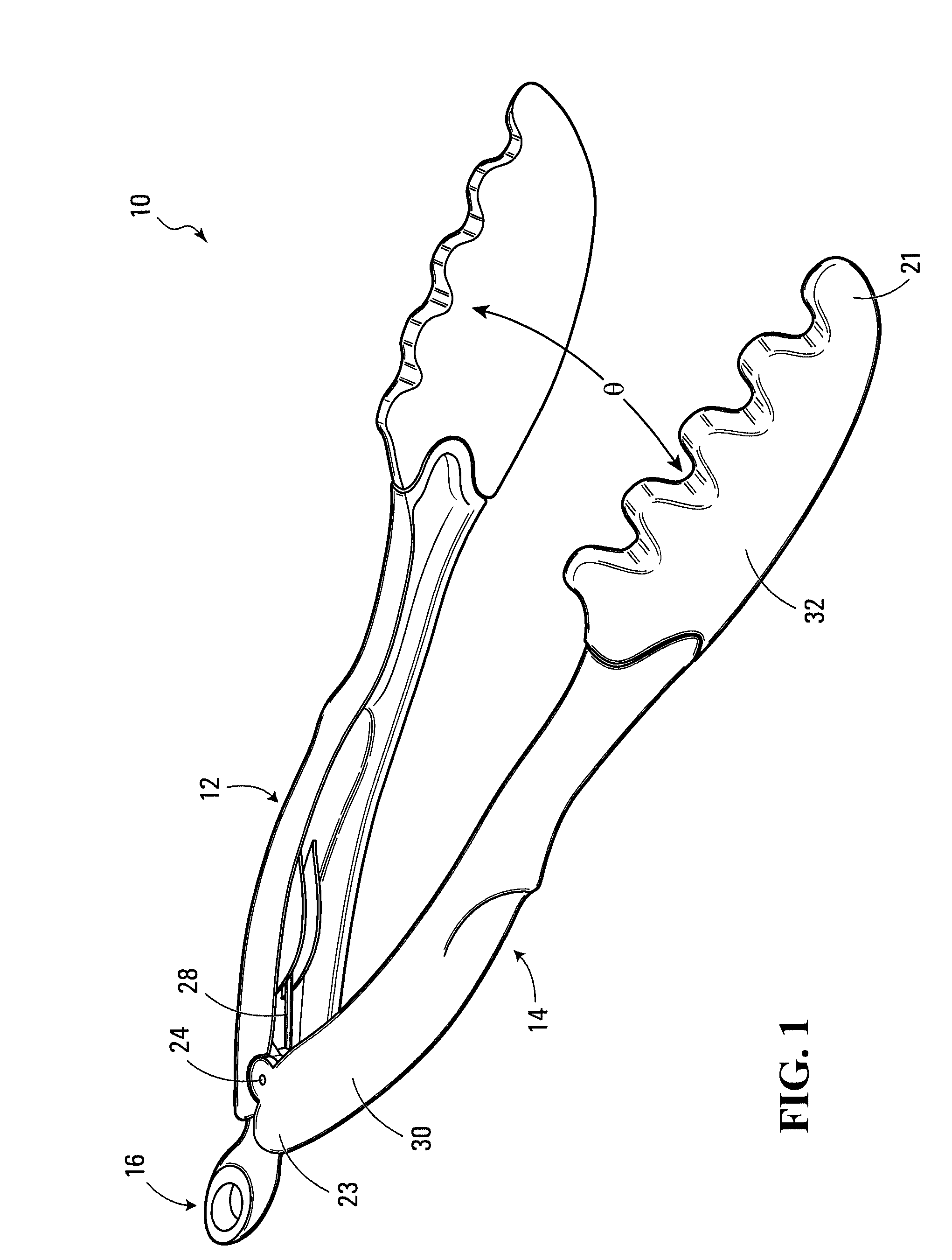

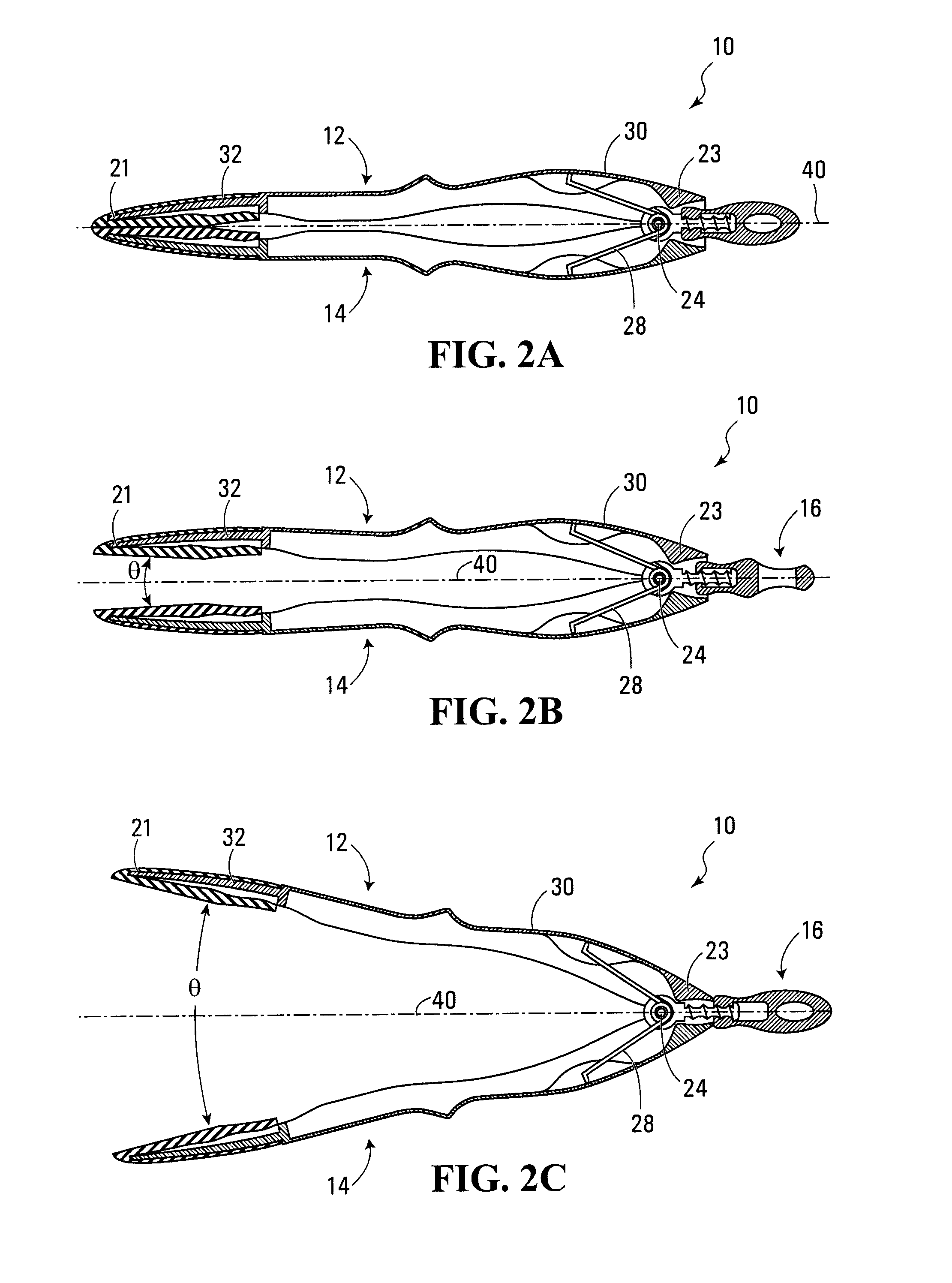

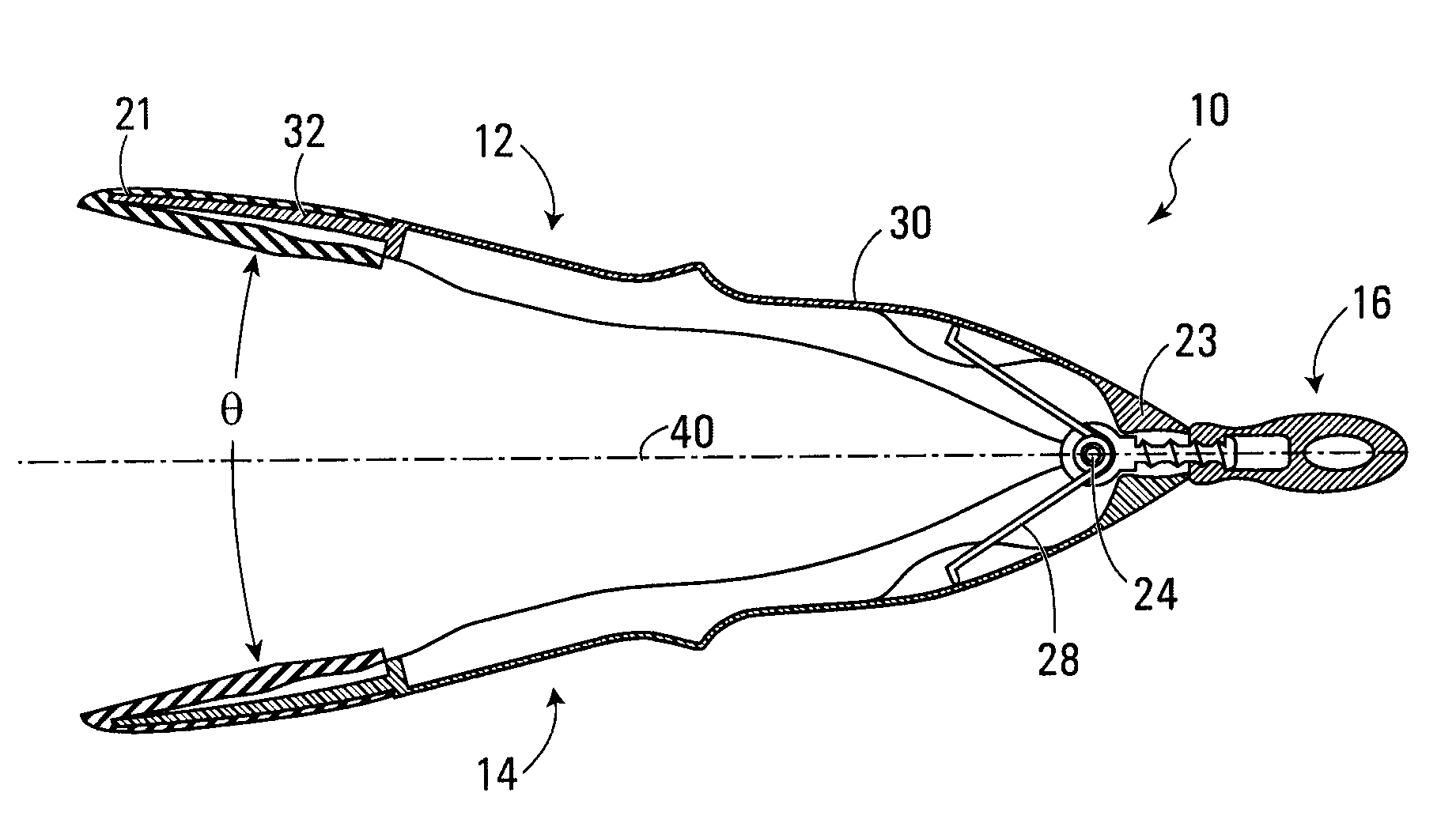

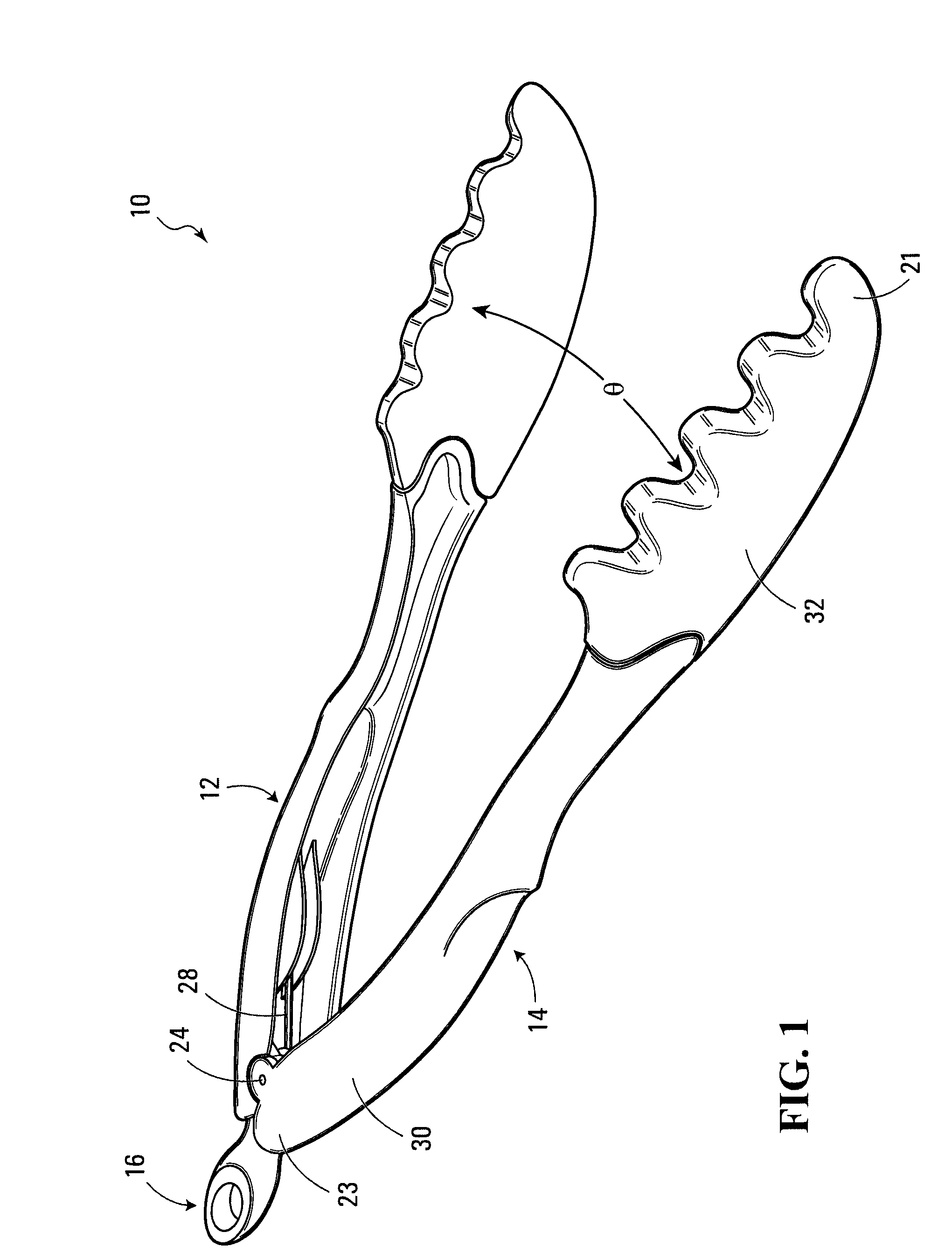

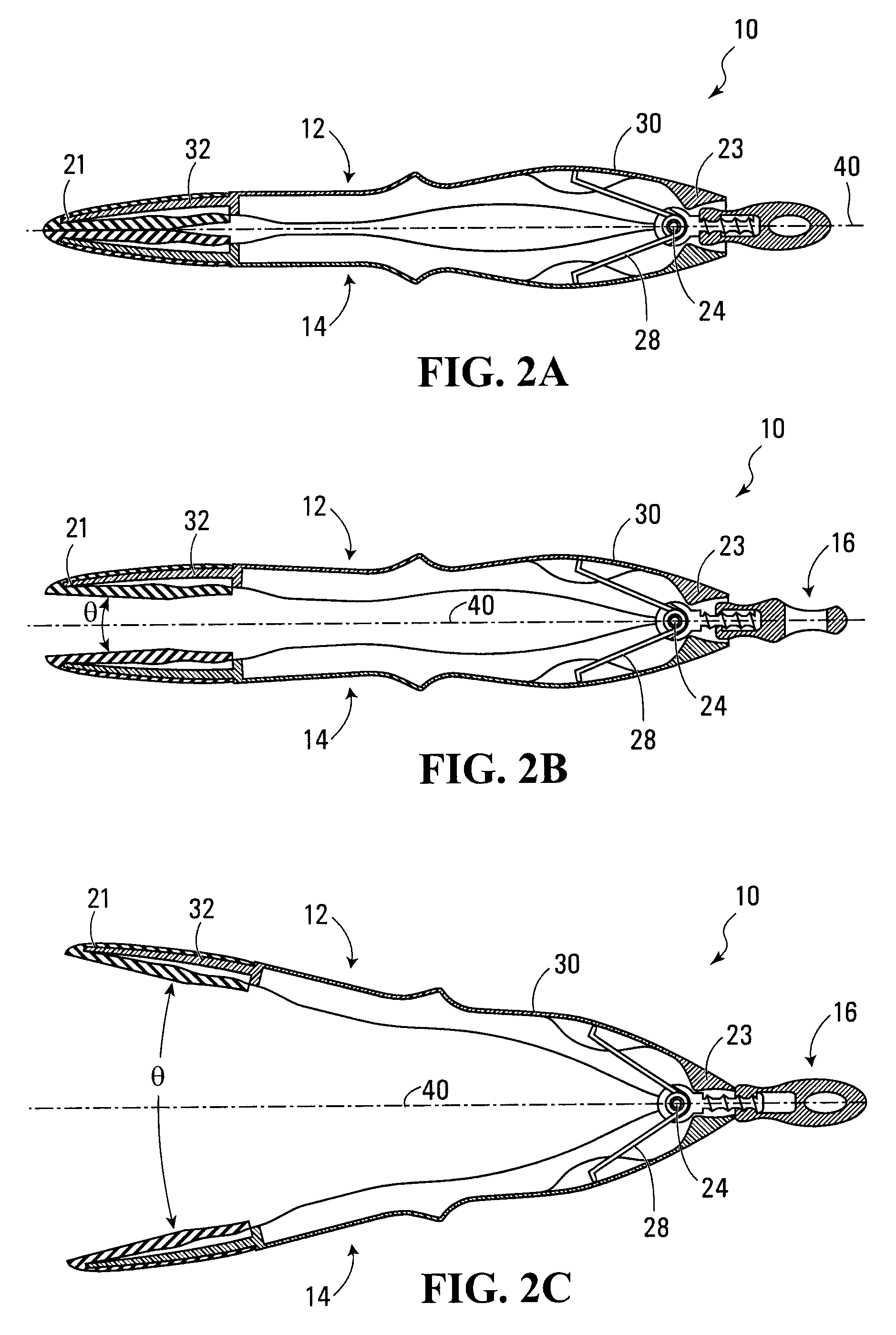

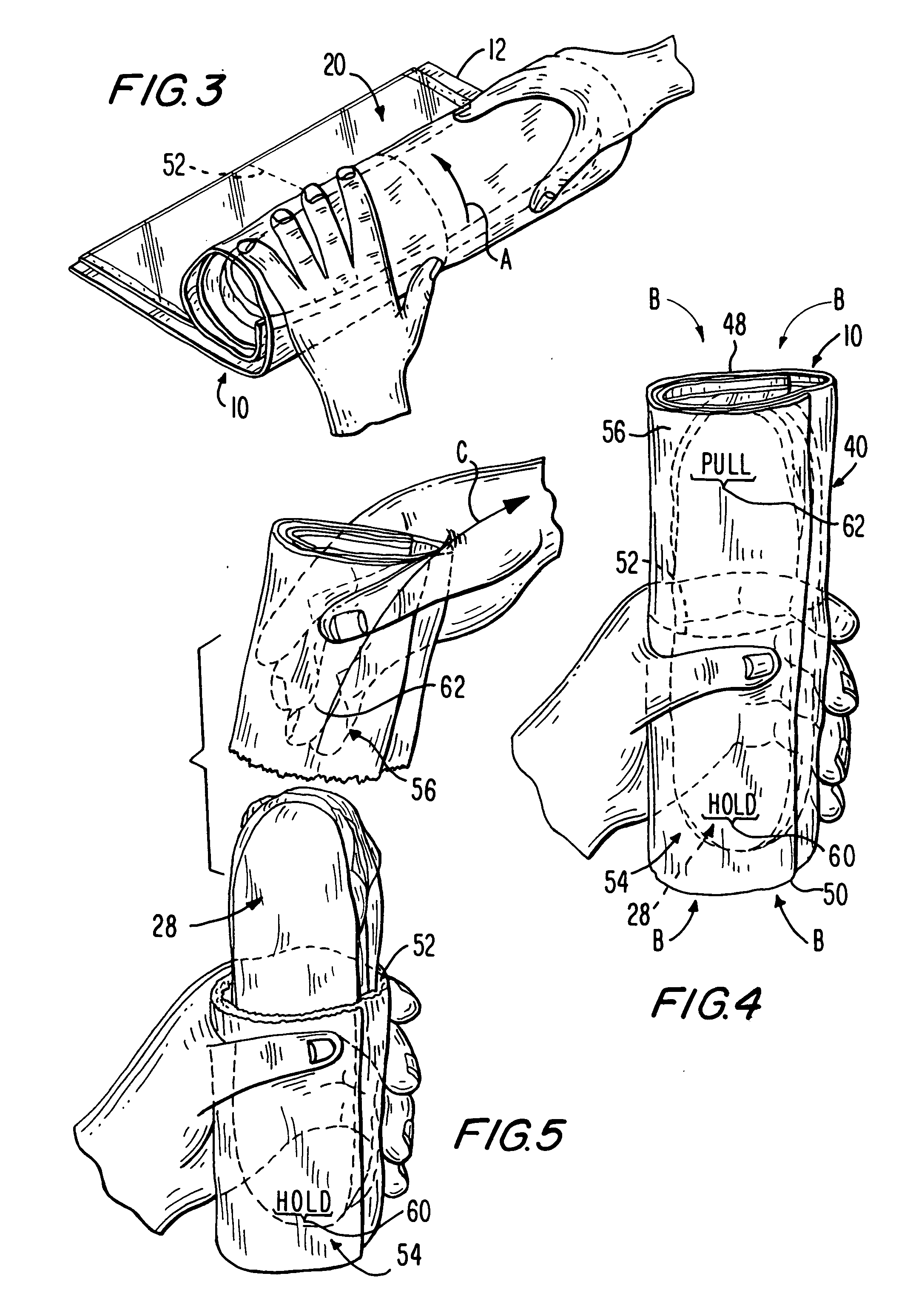

Tongs for Handling Food

InactiveUS20080179903A1Decrease opening angleIncrease opening anglePliersKitchen equipmentHandling foodActuator

Tongs for handling food. The tongs comprise a pair of tong members pivotally connected together and biased away from each other to define an opening angle therebetween. The tongs also comprise an adjustment mechanism for adjusting the opening angle to a desired opening angle in a range of opening angles. The adjustment mechanism may comprise a manually operable actuator rotatable about a longitudinal axis of the tongs for adjusting the opening angle to a desired opening angle in the range of opening angles. Each of the tong members comprises a handle portion and a food-handling portion. The food-handling portion of each of the tong members may have a removable element.

Owner:TRUDEAU 1889

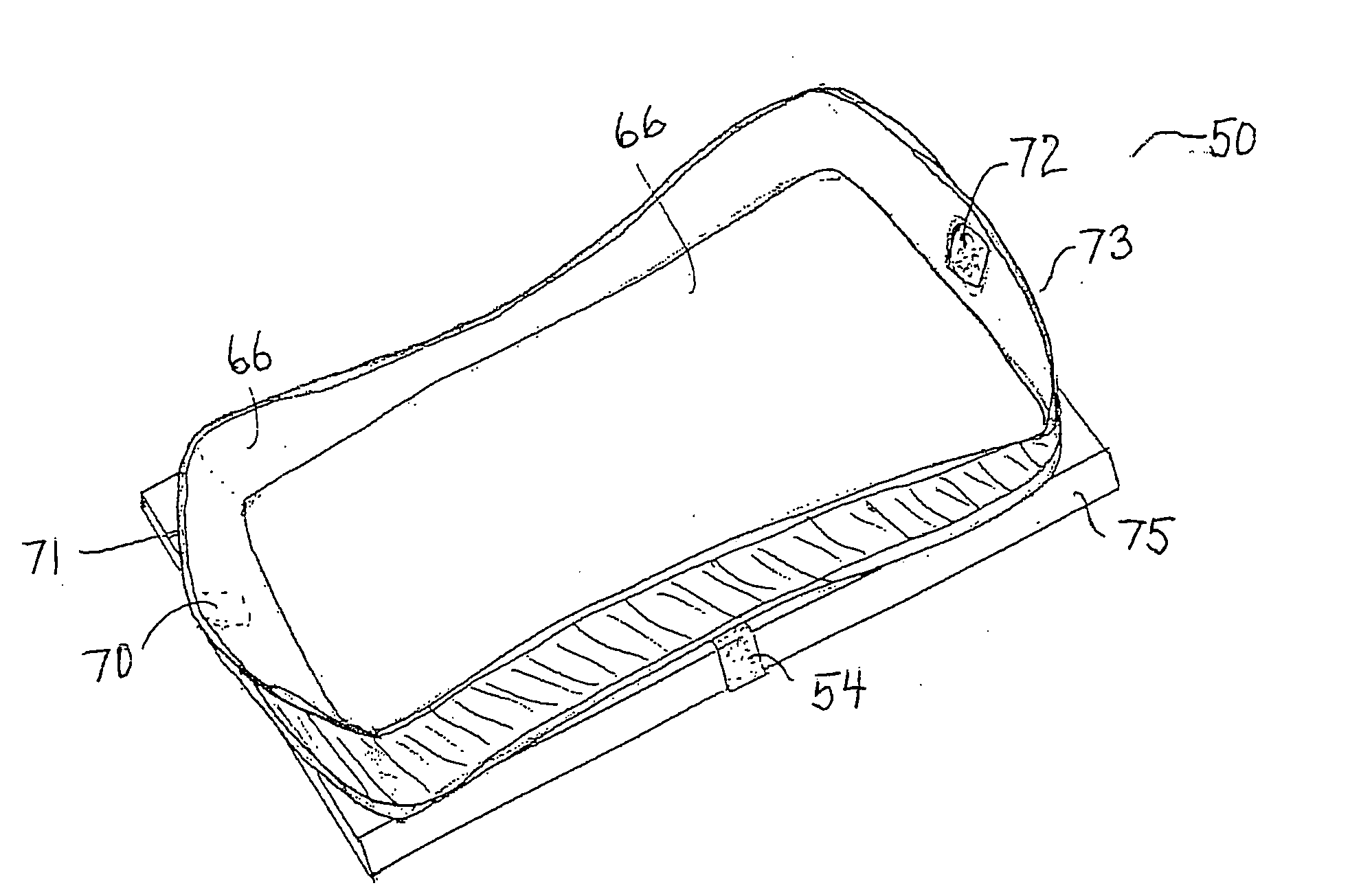

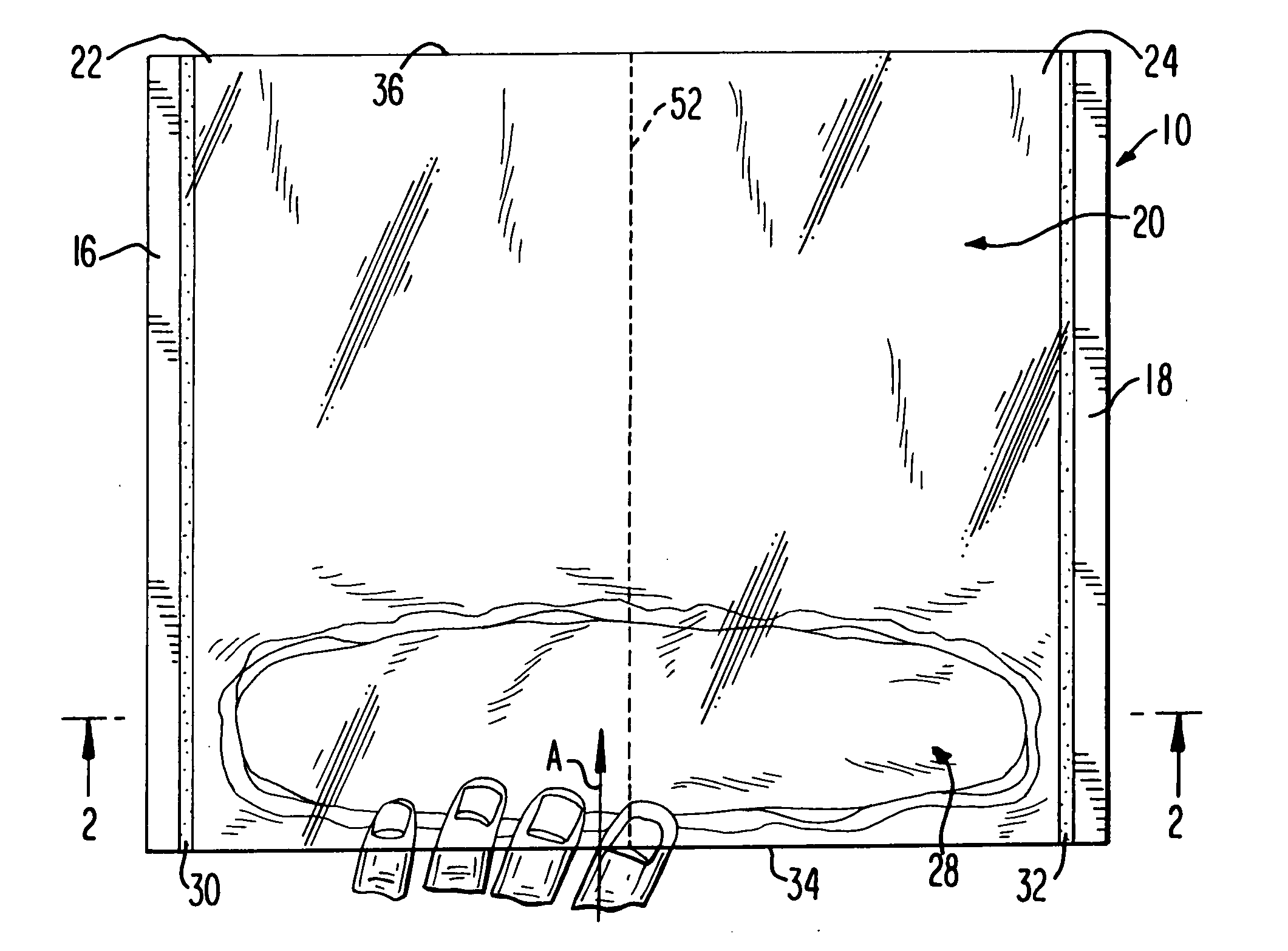

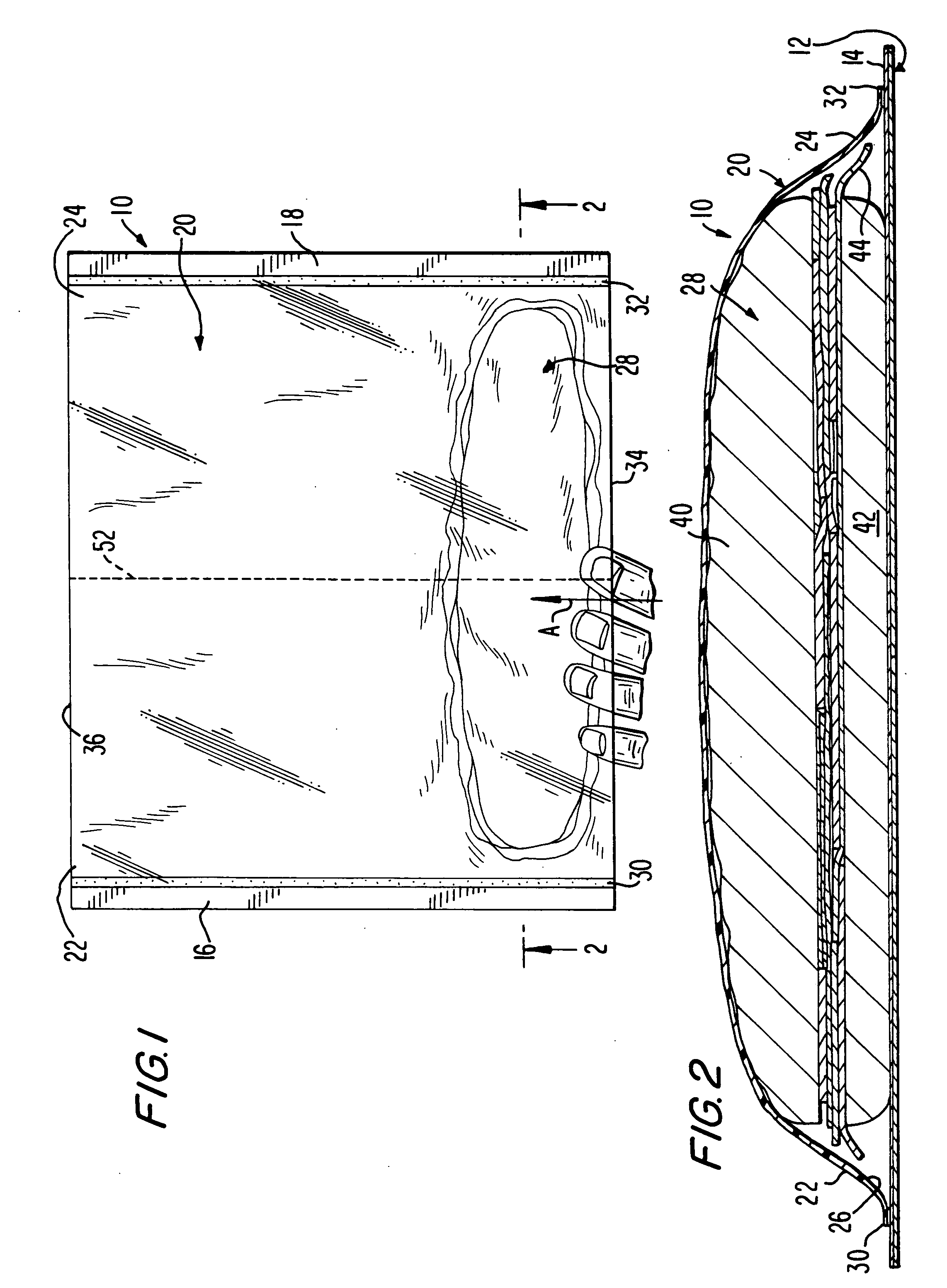

Travel tray liner

InactiveUS20090223418A1Easy to cleanEasy to useTravelling sacksVehicle arrangementsHandling foodCar seat

A tray liner of flexible construction relies on the rigid airline or railroad car seat tray underneath it to create a horizontal clean and sanitary surface useful for supporting food and drink utensils. While it is especially useful for handling food items for toddlers or small children during travel, the tray liner may also be used on a high chair in a restaurant. It may also be used by older children to provide a play area for toys with multiple parts that may easily fall off a tray. Adult use by the general public or by handicapped people also offers a more secure dining platform with spill protection during travel. It has soft semi-rigid edges which function to keep objects or fluids from falling off the supporting tray. It has a sturdy outer covering with an impervious interior surface which is impermeable to liquids and waterproof.

Owner:FERRARA MICHAEL

Tongs for Handling food

Tongs for handling food. The tongs comprise a pair of tong members pivotally connected together and biased away from each other to define an opening angle therebetween. The tongs also comprise an adjustment mechanism for adjusting the opening angle to a desired opening angle in a range of opening angles. The adjustment mechanism may comprise a manually operable actuator rotatable about a longitudinal axis of the tongs for adjusting the opening angle to a desired opening angle in the range of opening angles. Each of the tong members comprises a handle portion and a food-handling portion. The food-handling portion of each of the tong members may have a removable element.

Owner:TRUDEAU 1889

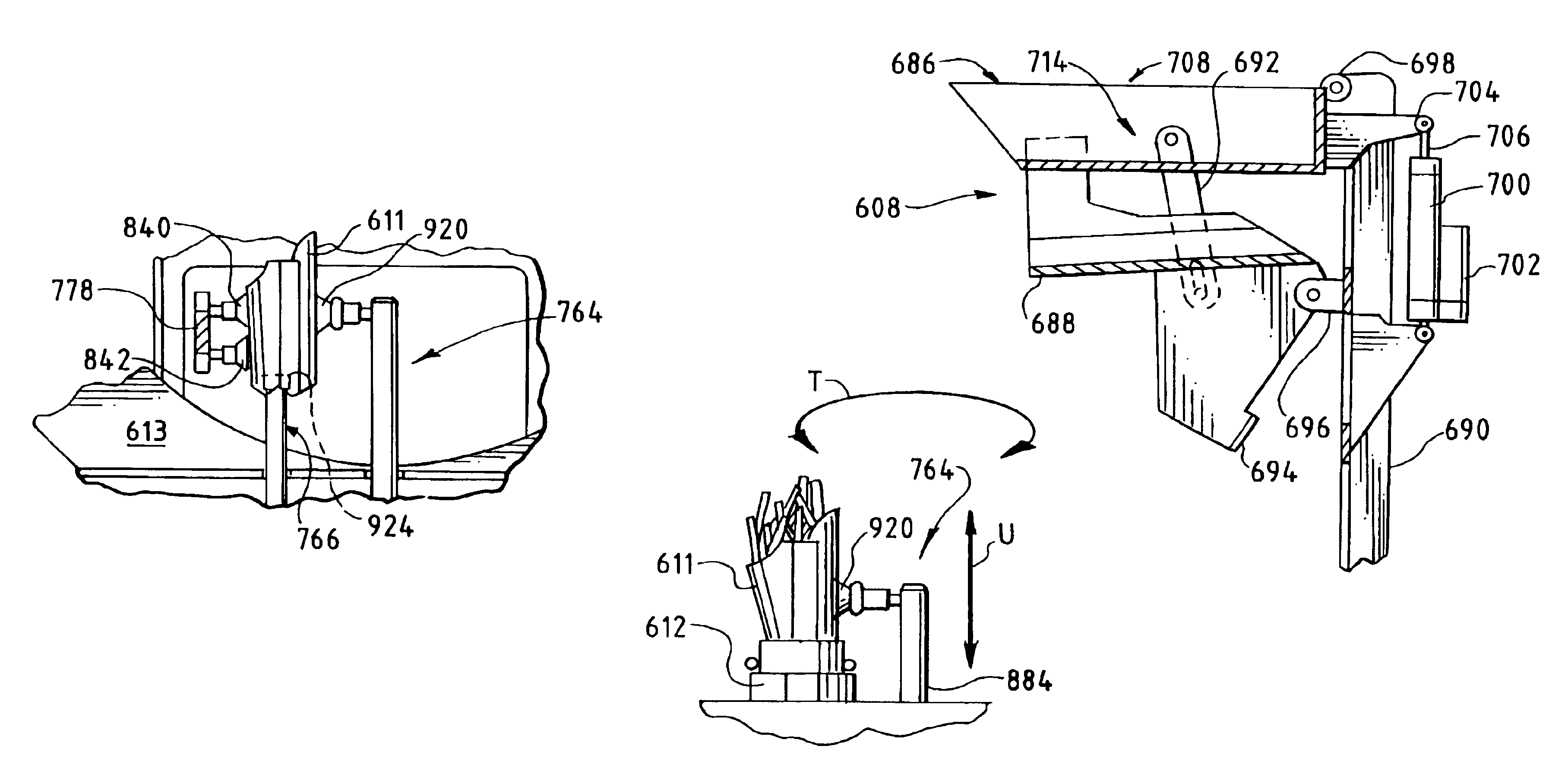

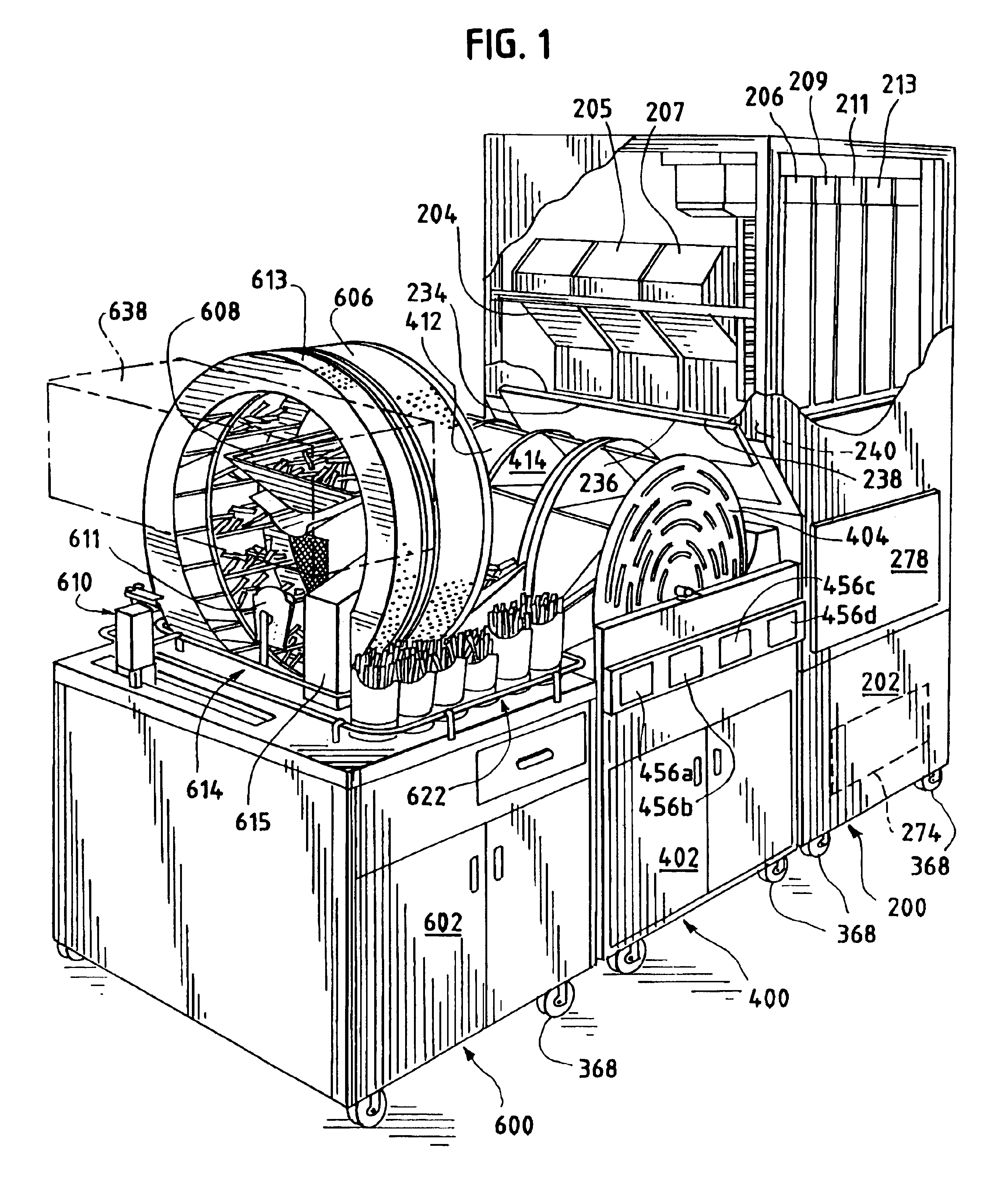

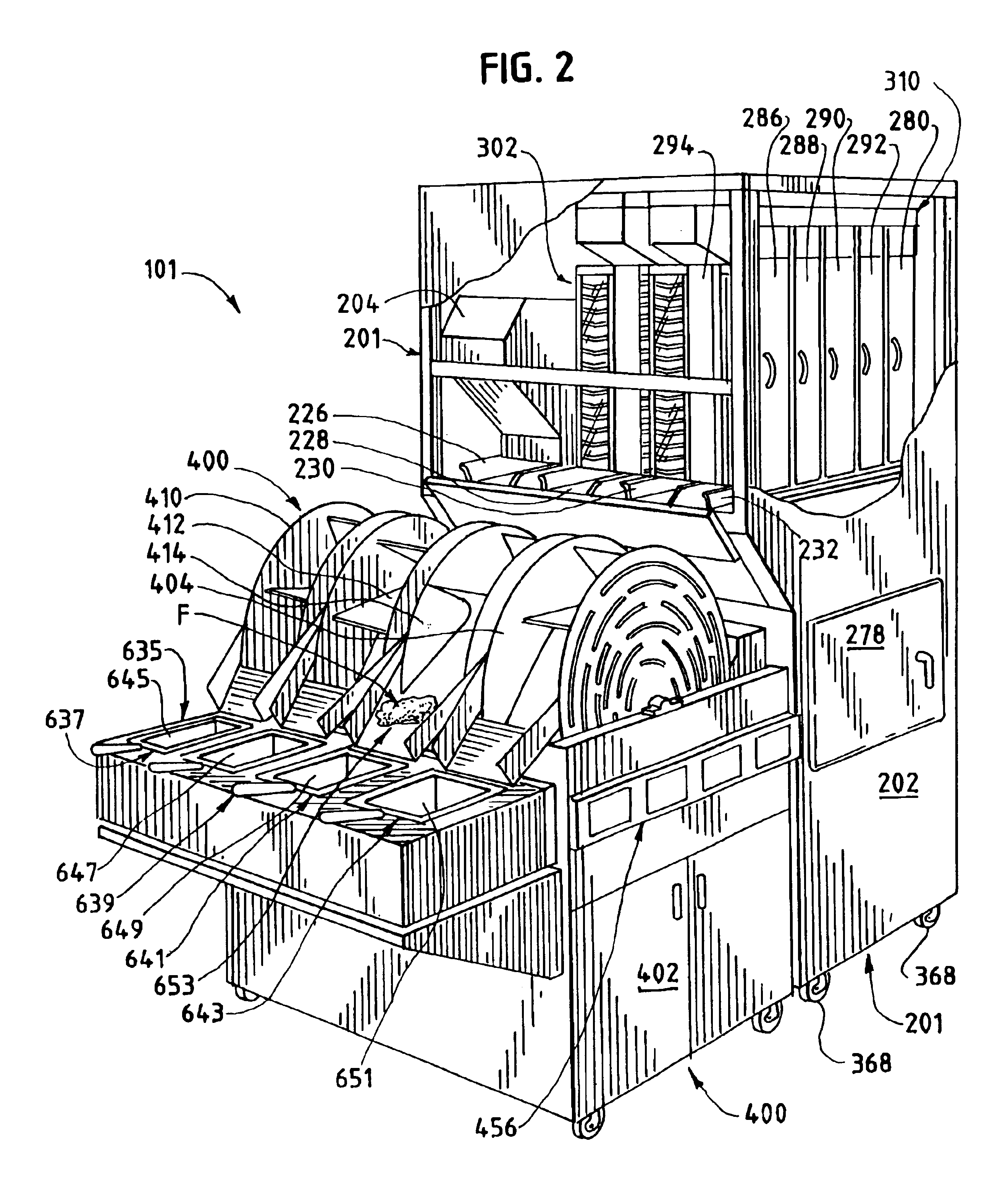

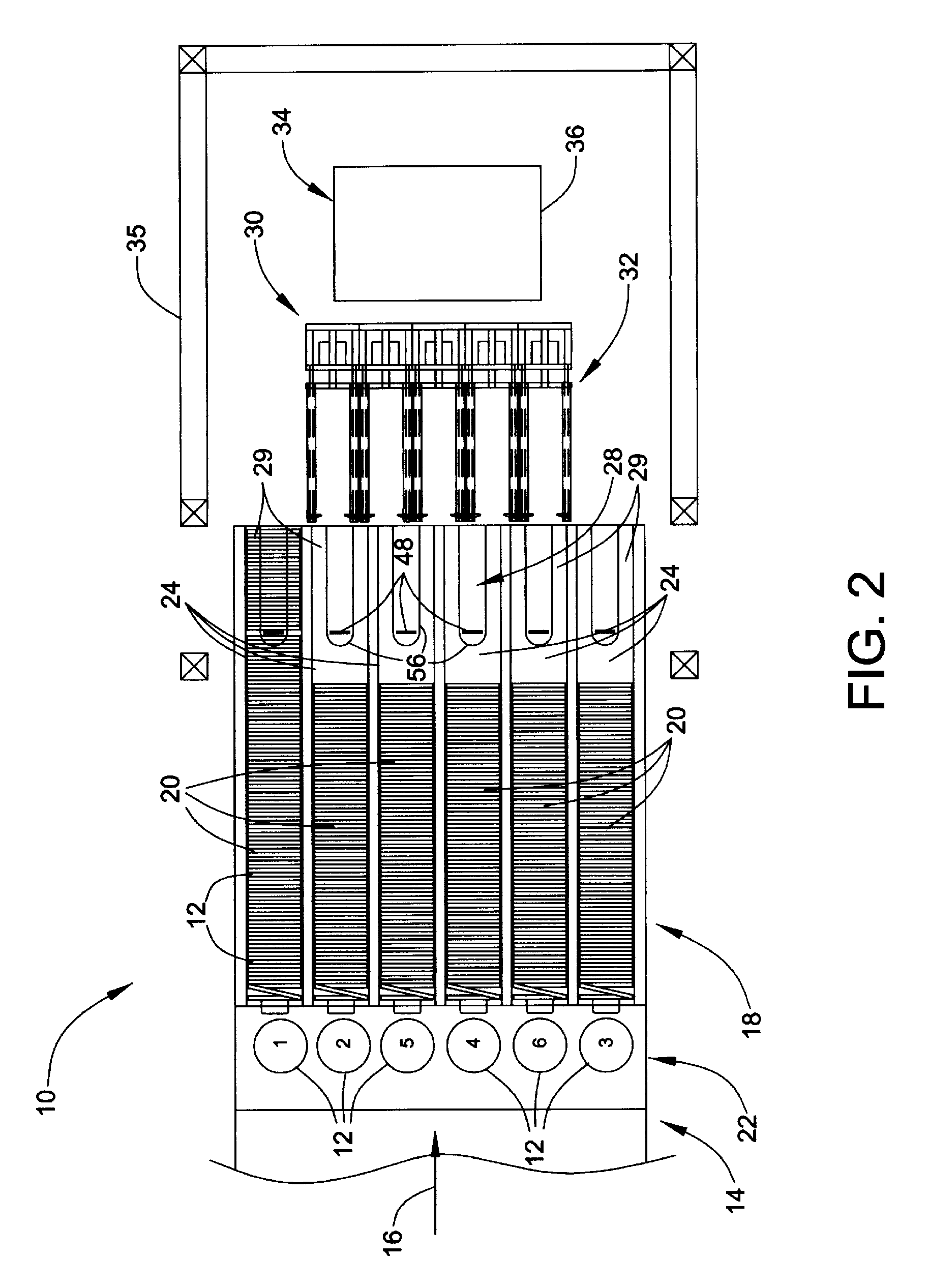

Automated system and method for handling food containers

An automated food processing system and method is provided that allows food to be dispensed, fried and packaged in a suitable container, which may be an individual portion-sized container. In one embodiment, the system includes separate automated modules for dispensing, frying and packaging the food. In one embodiment, an automated dispensing device dispenses a predetermined portion of food from a bulk storage container or food dispensing magazine. Food is dispensed from the automated dispensing device to an automated fry device that can include at least one circular fry wheel having a plurality of food containing compartments. After the food is fried it is dispensed from the fry device to an automated packaging device. The automated packaging device dispenses food to a container that may be an individual portion-sized container that is retrieved, erected and held into position for filling by an automated container handling system. After a food container is filled, a conveyor system transports the filled container to a suitable pick-up location.

Owner:RESTAURANT TECH

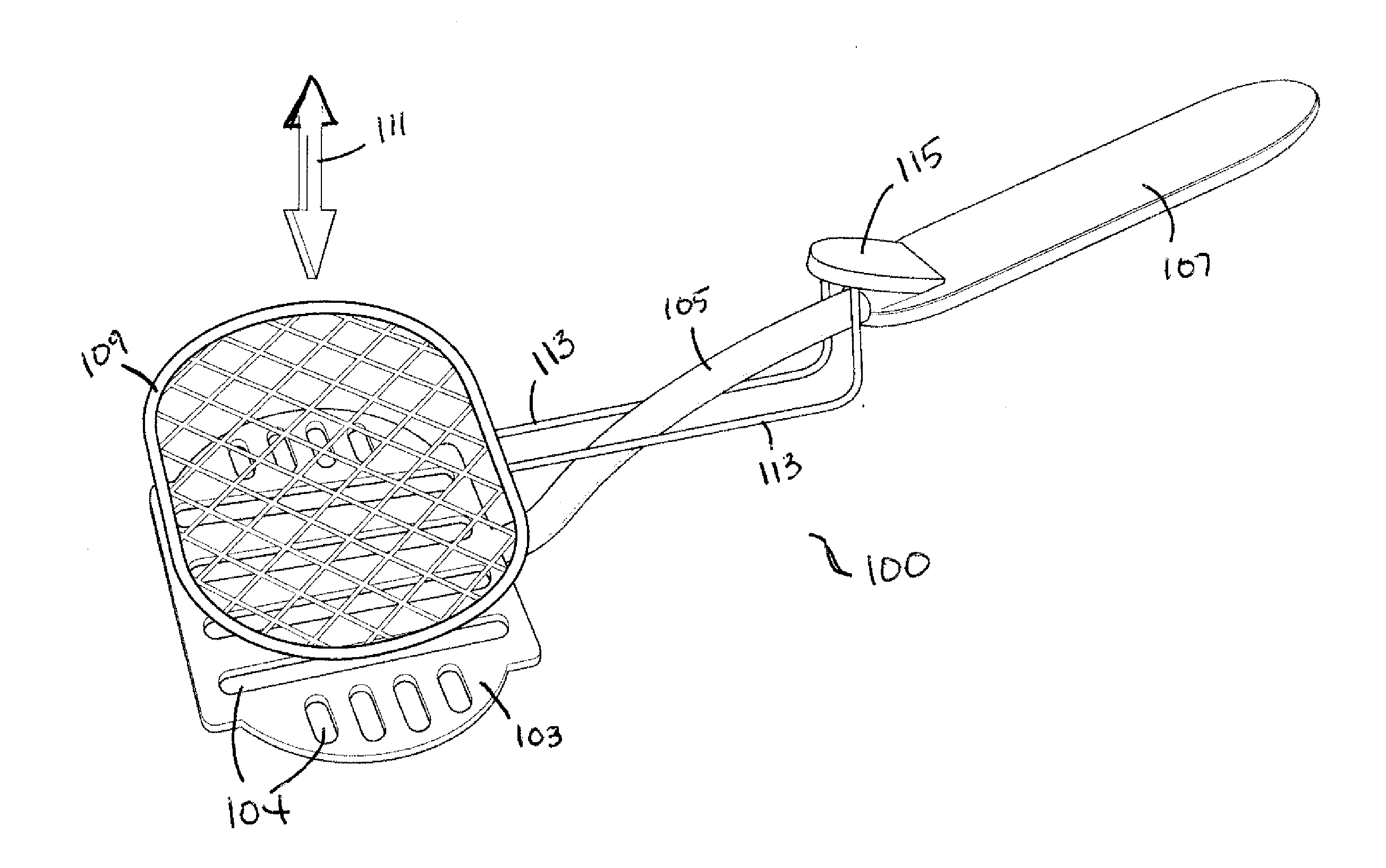

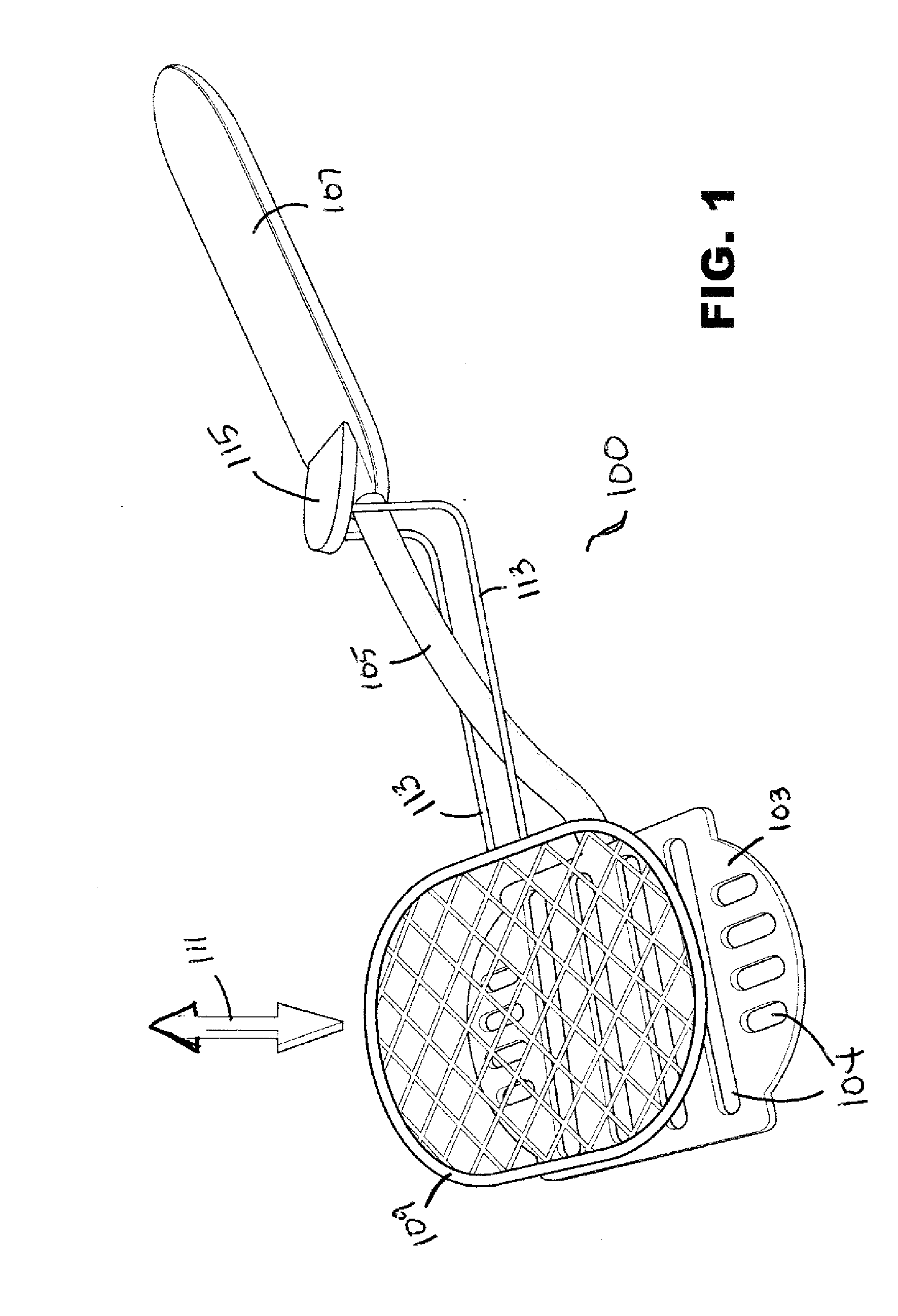

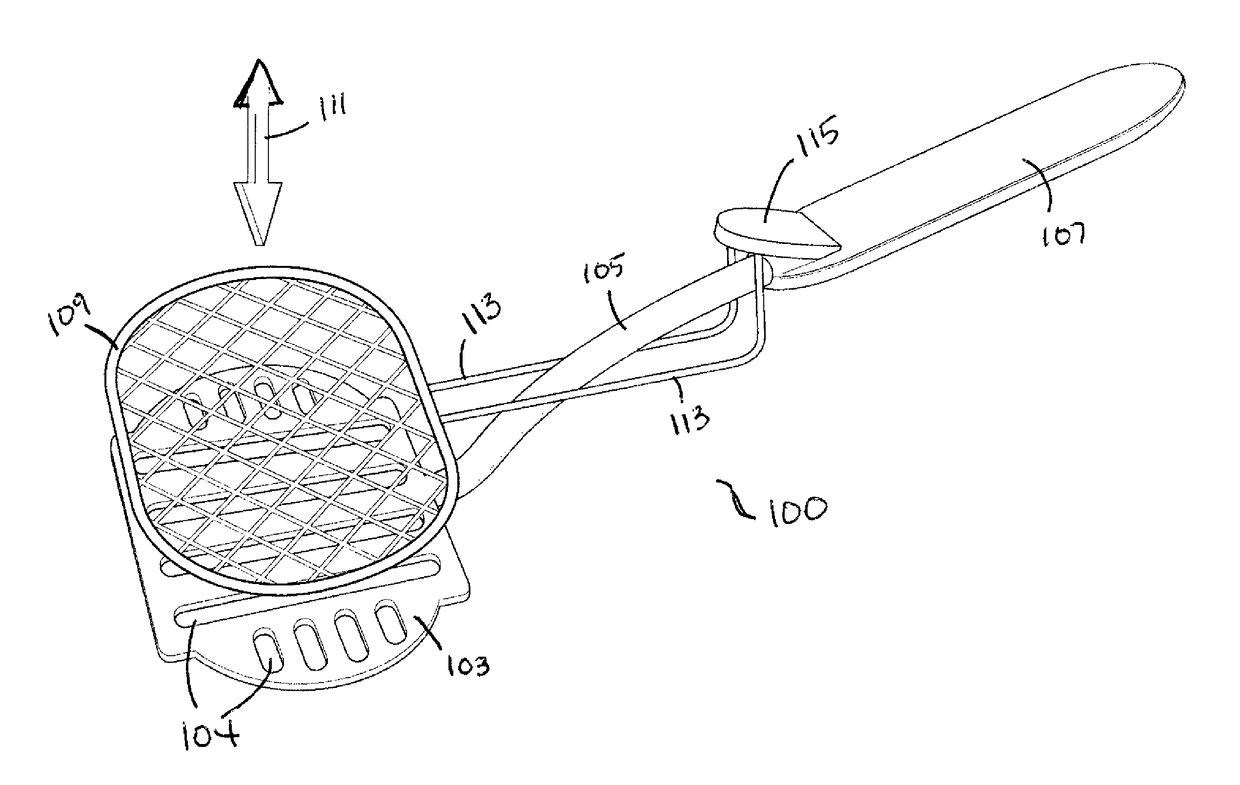

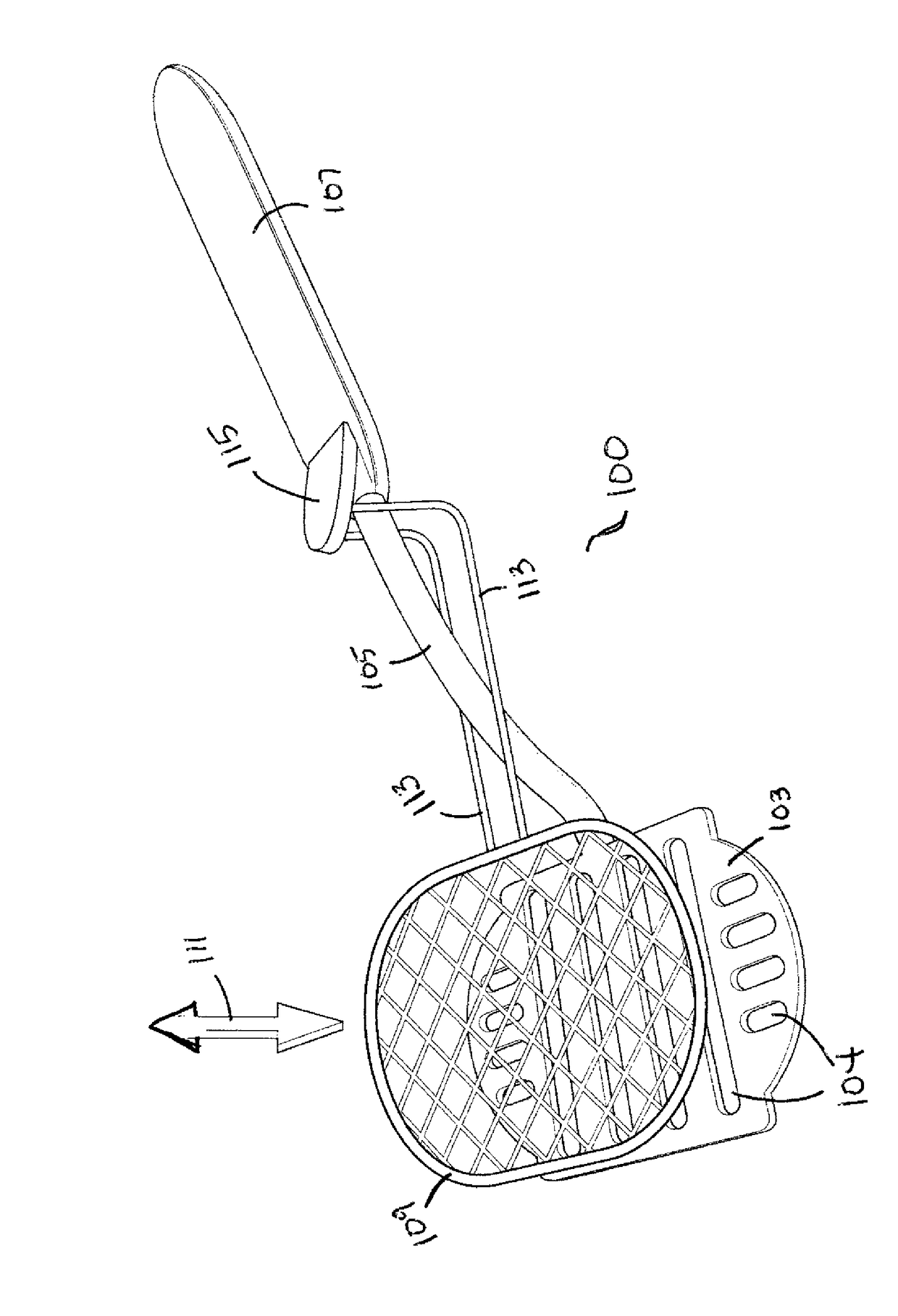

Combination spatula and tong device for handling food

A cooking utensil for handling food including an elongate handle member having a first end and an opposite second end, a generally flat spatula member provided on the second end of the elongate handle member, the spatula member having a first side edge generally opposed to a second side edge, wherein the first side edge having a tenderizing means, and a grasping member pivotally connected to the elongate handle member proximate to the second end, the grasping member adapted to bias toward the spatula for engaging and grasping the food.

Owner:DI PAOLO BRETT

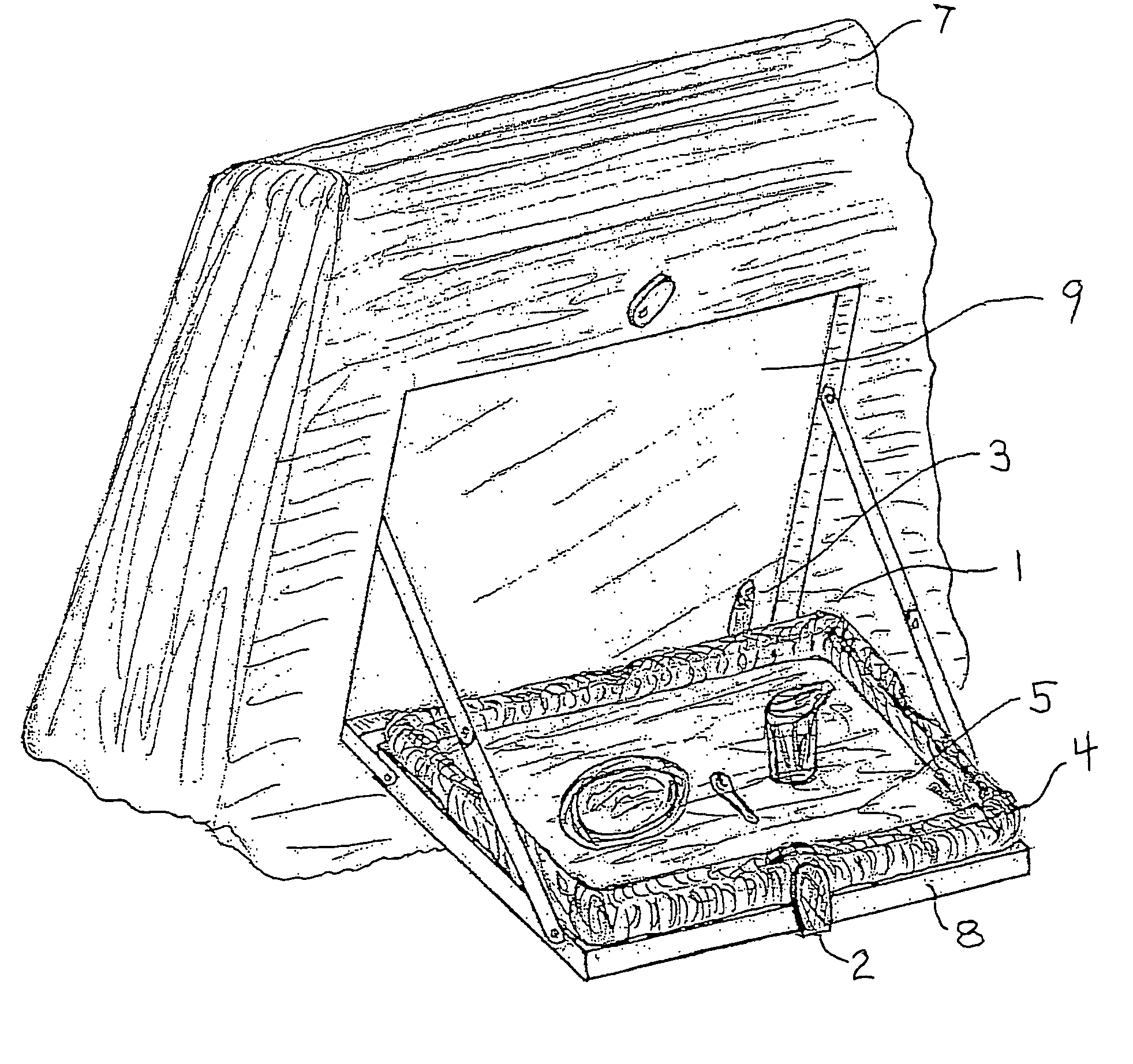

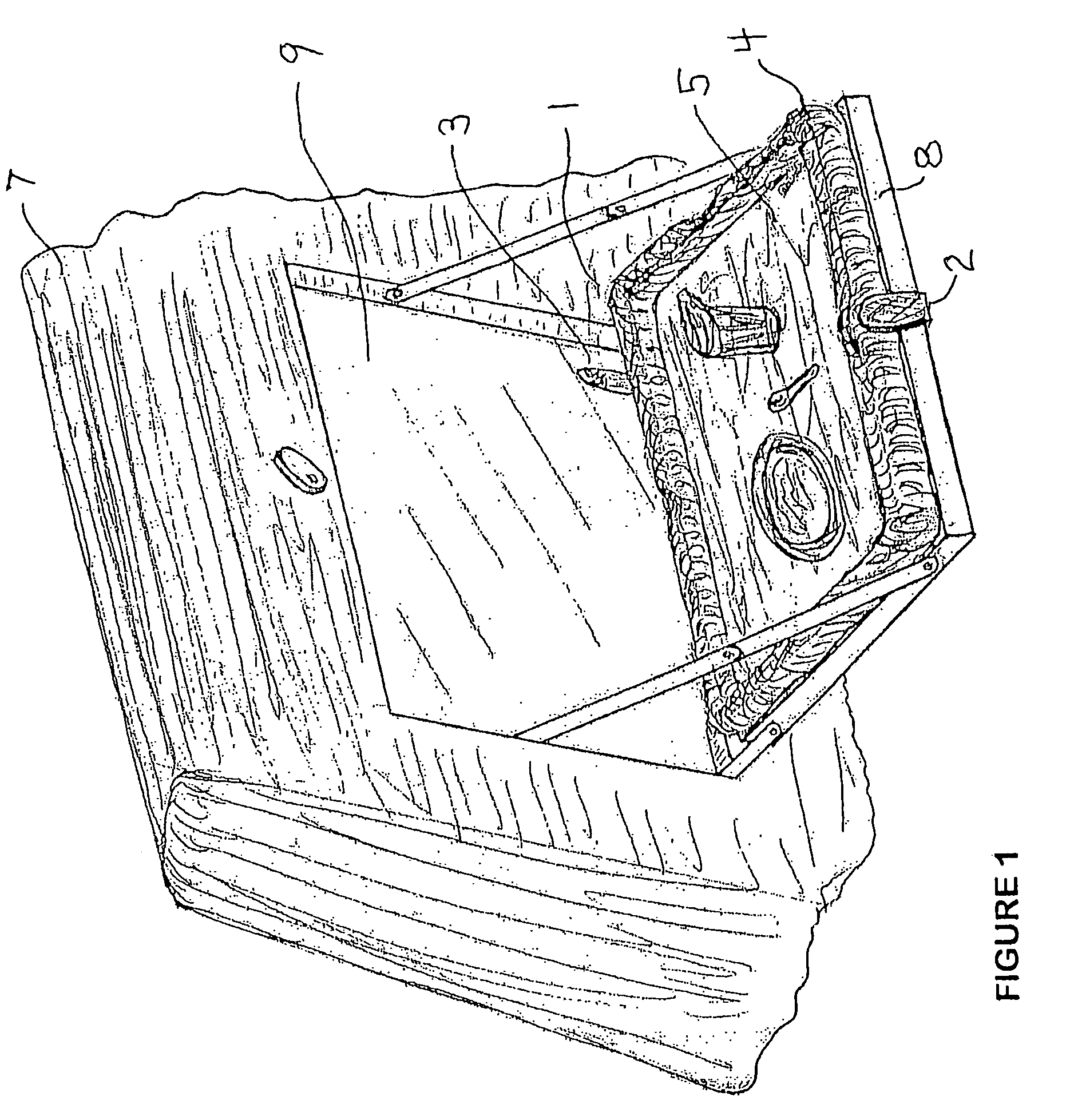

Travel tray liner

InactiveUS7976099B2Easy to cleanEasy to useTravelling sacksVehicle arrangementsCar seatHandling food

A tray liner of flexible construction relies on the rigid airline or railroad car seat tray underneath it to create a horizontal clean and sanitary surface useful for supporting food and drink utensils. While it is especially useful for handling food items for toddlers or small children during travel, the tray liner may also be used on a high chair in a restaurant. It may also be used by older children to provide a play area for toys with multiple parts that may easily fall off a tray. Adult use by the general public or by handicapped people also offers a more secure dining platform with spill protection during travel. It has soft semi-rigid edges which function to keep objects or fluids from falling off the supporting tray. It has a sturdy outer covering with an impervious interior surface which is impermeable to liquids and waterproof.

Owner:FERRARA MICHAEL

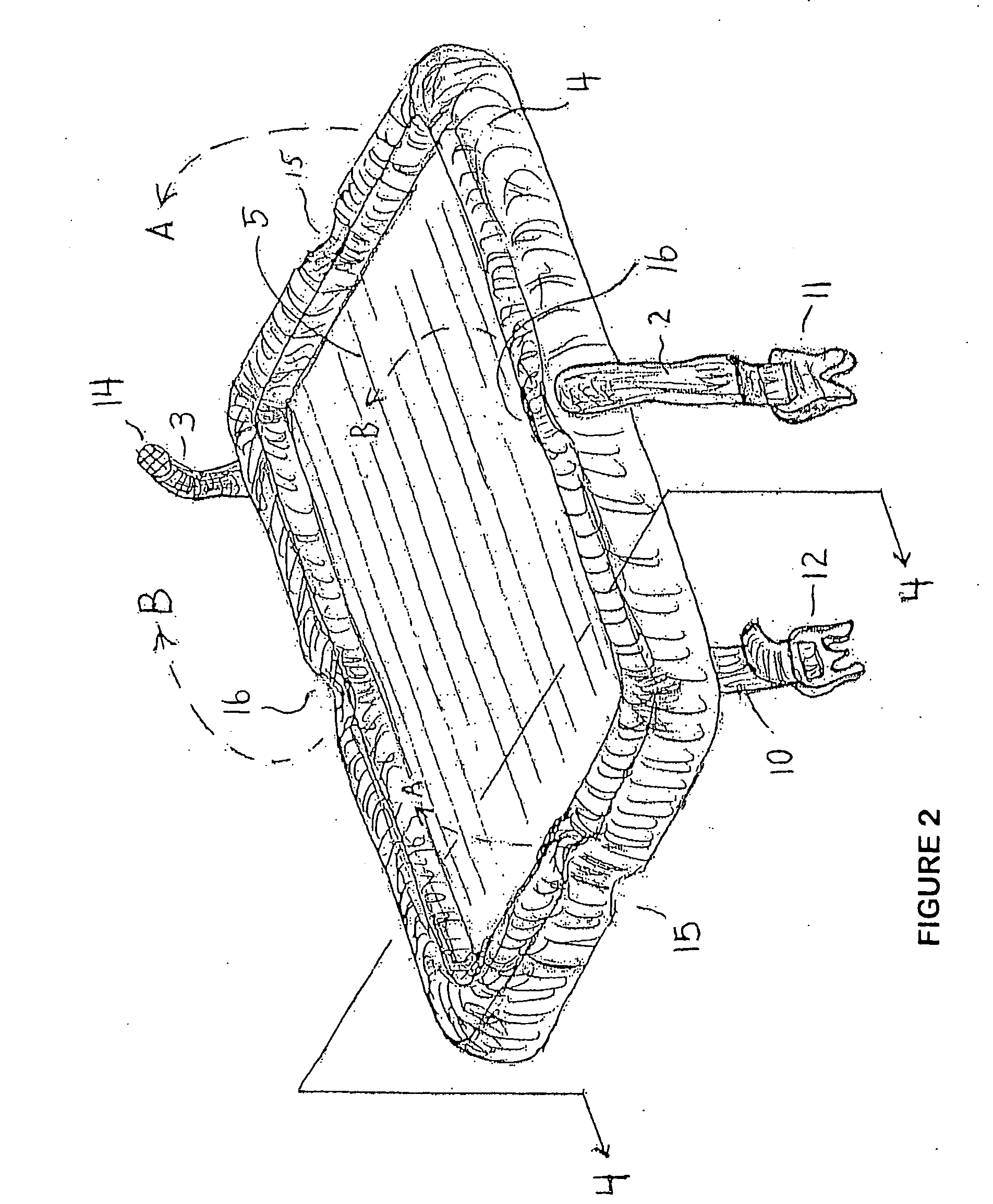

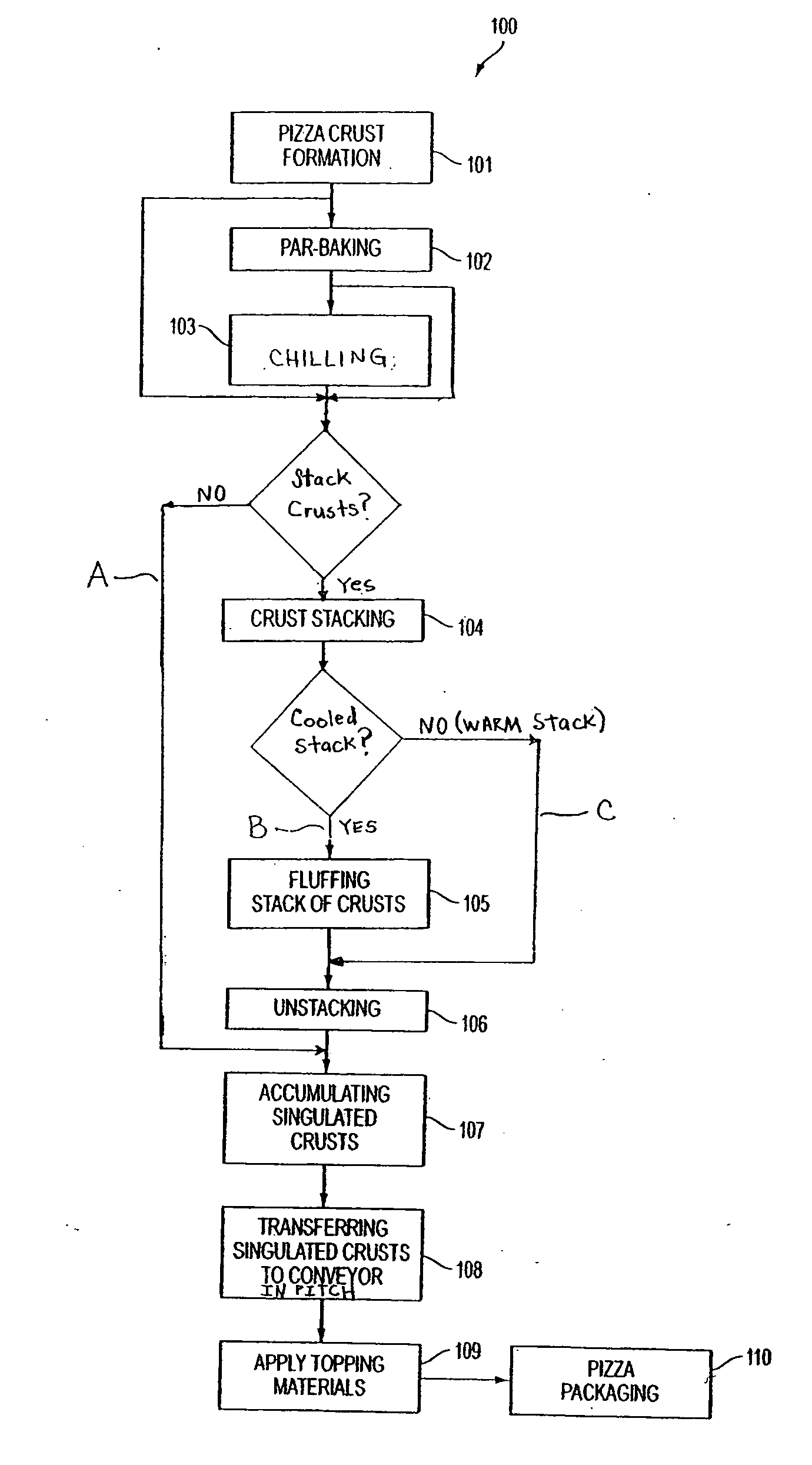

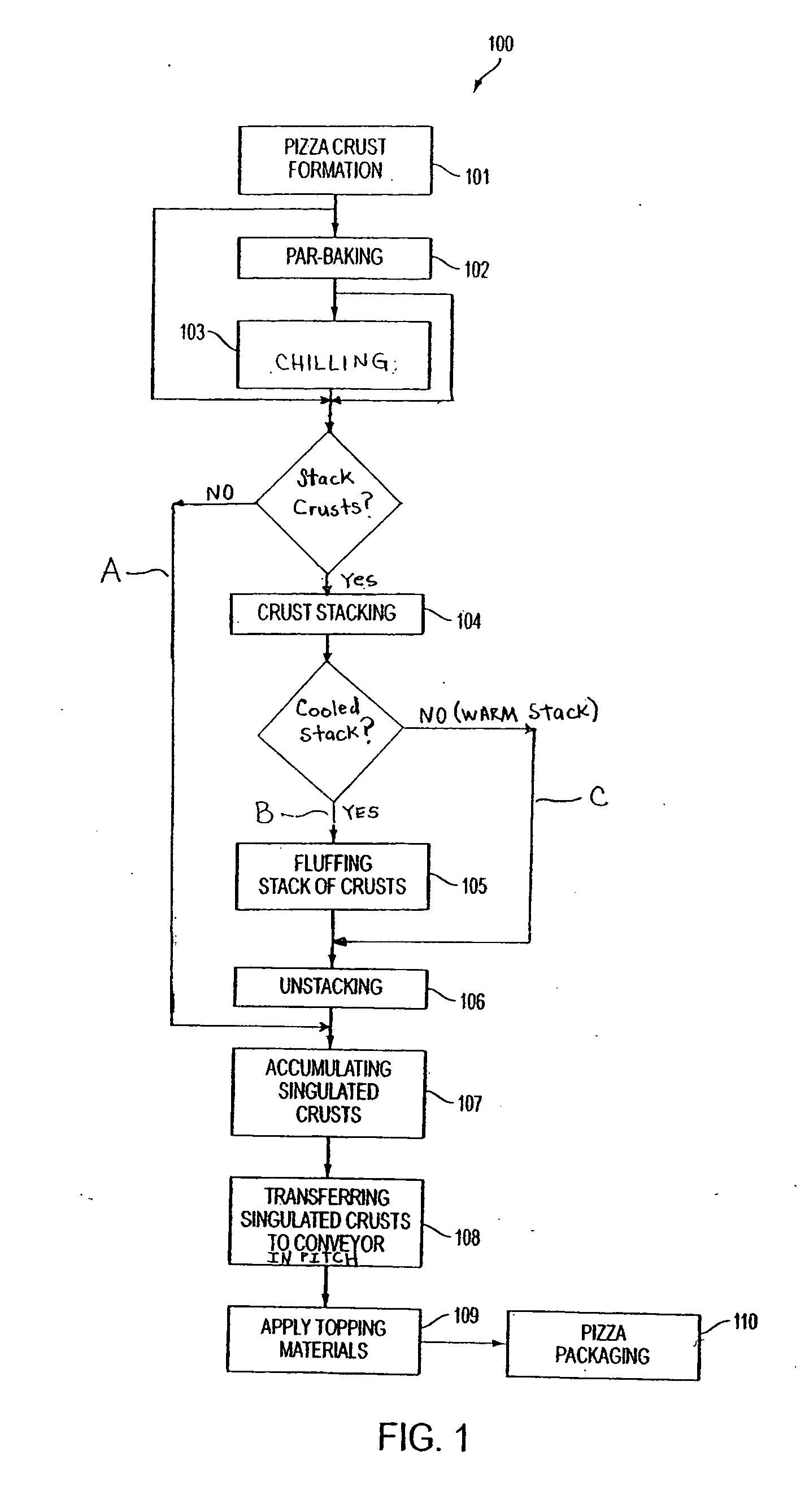

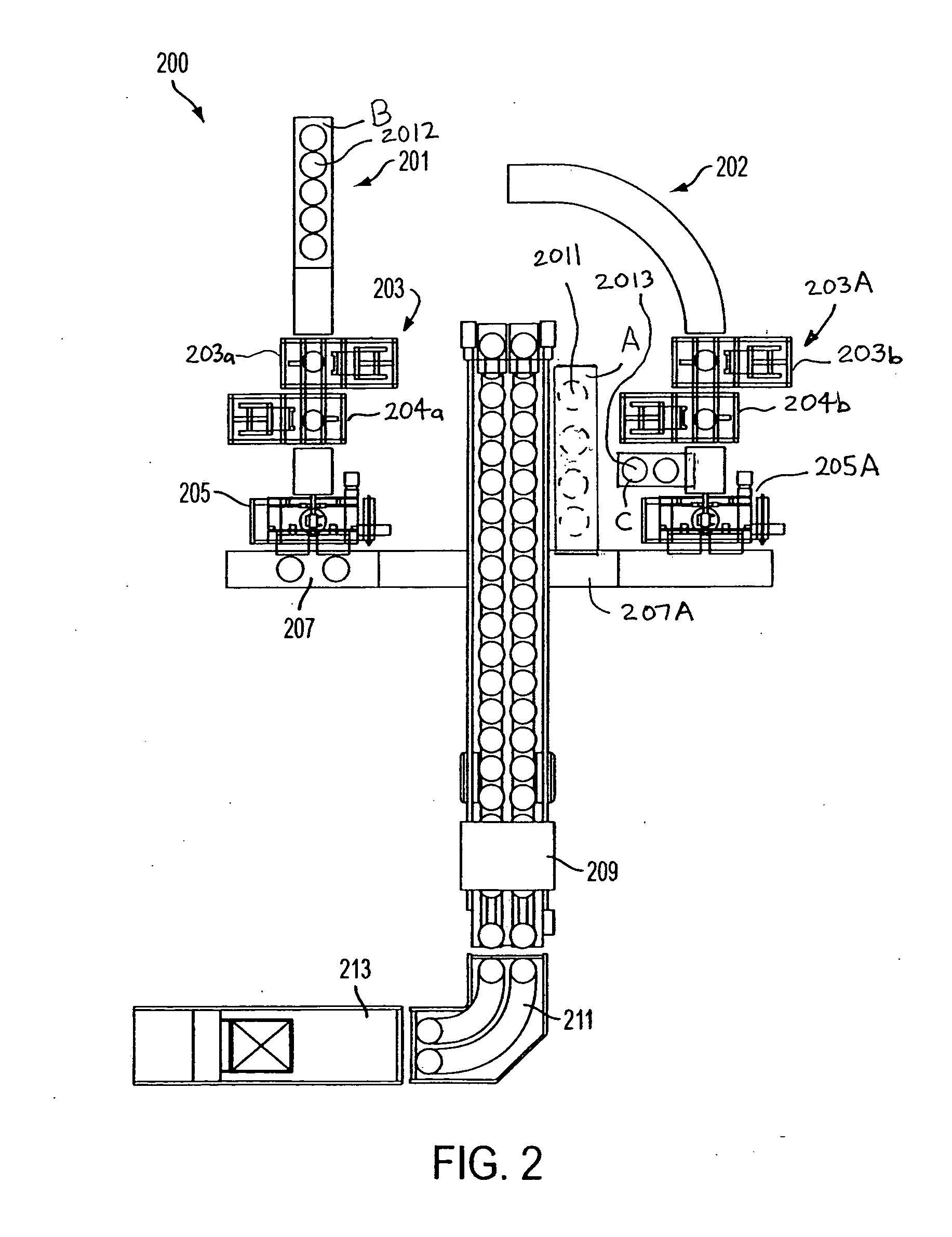

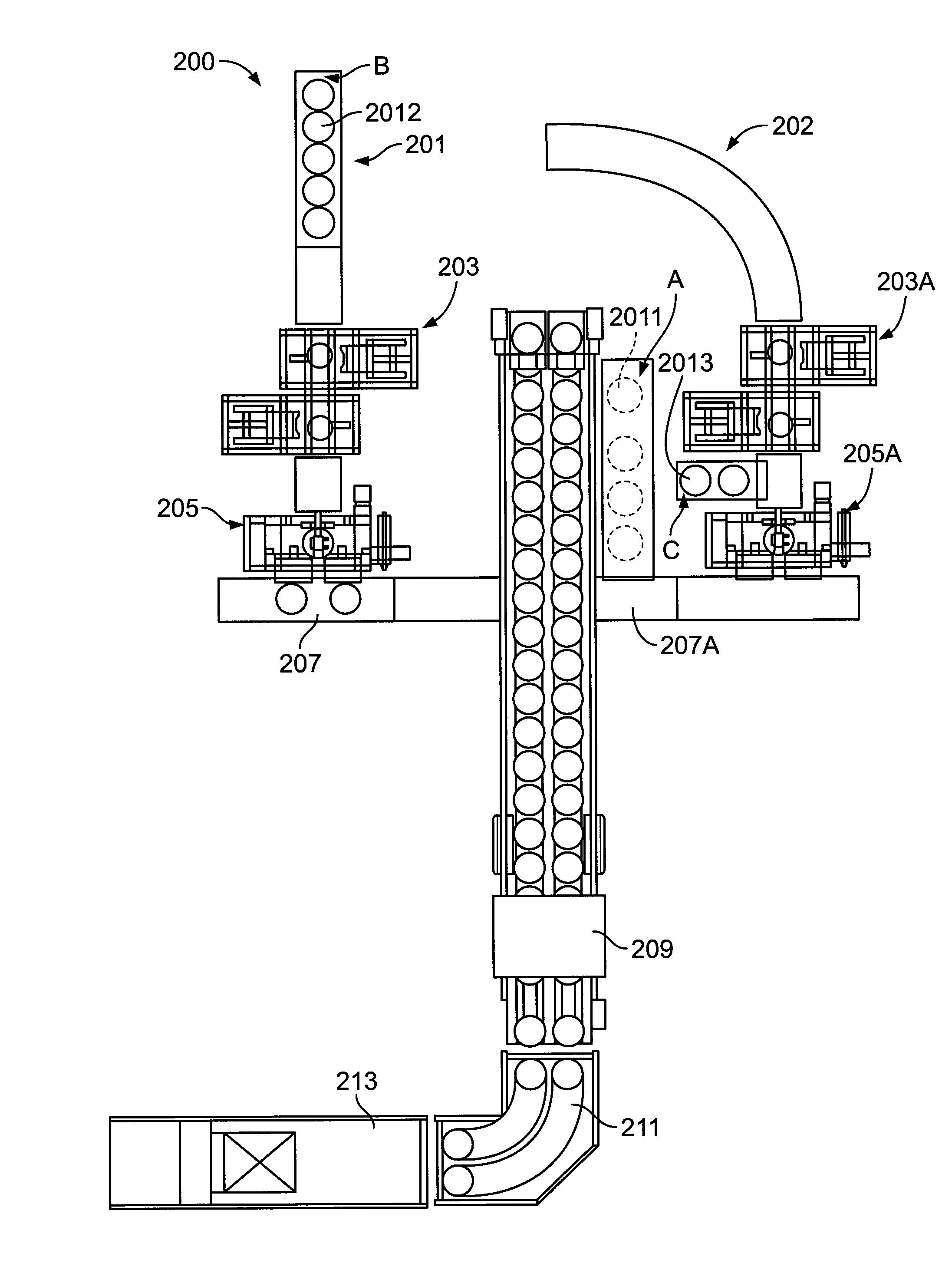

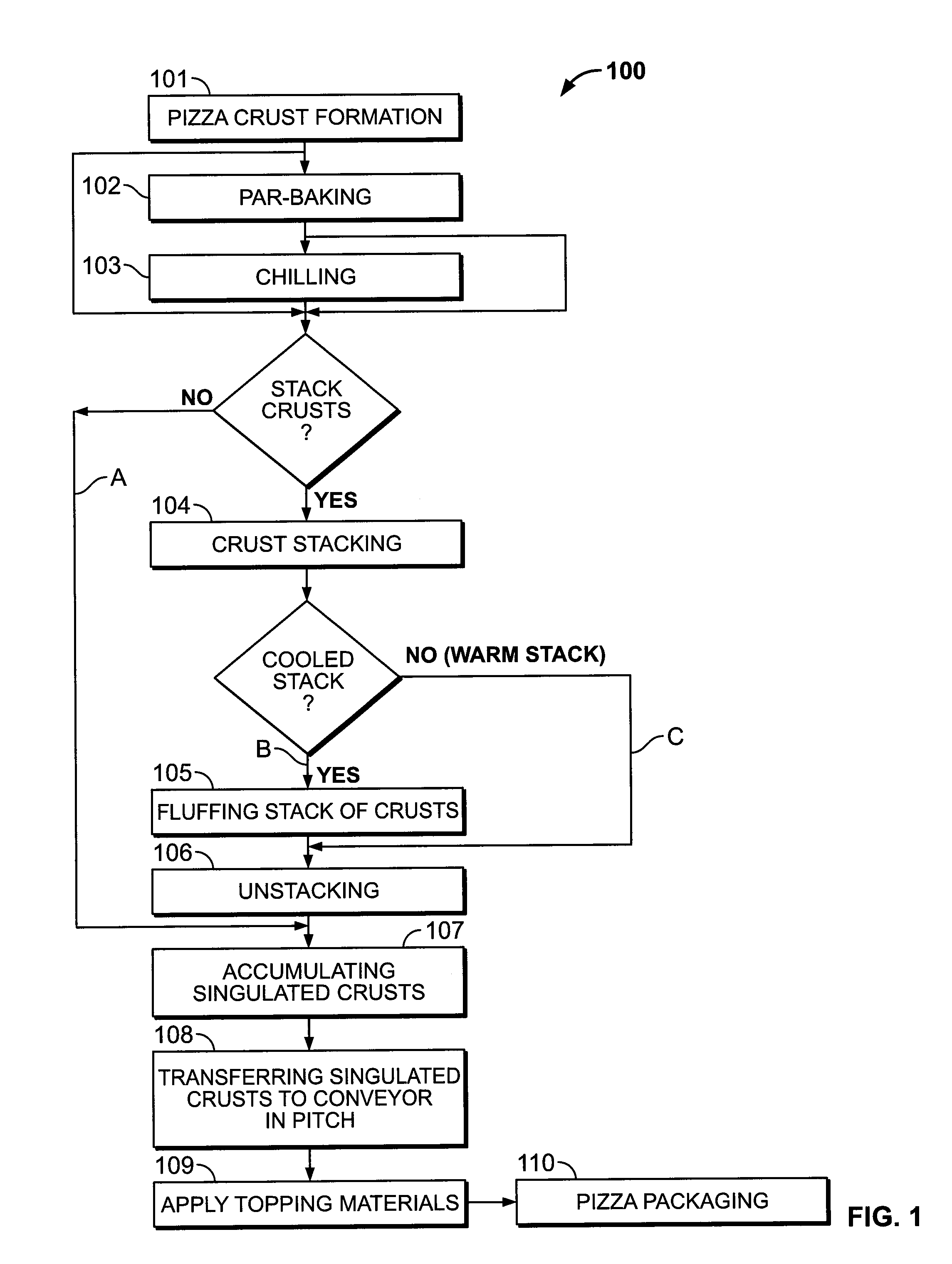

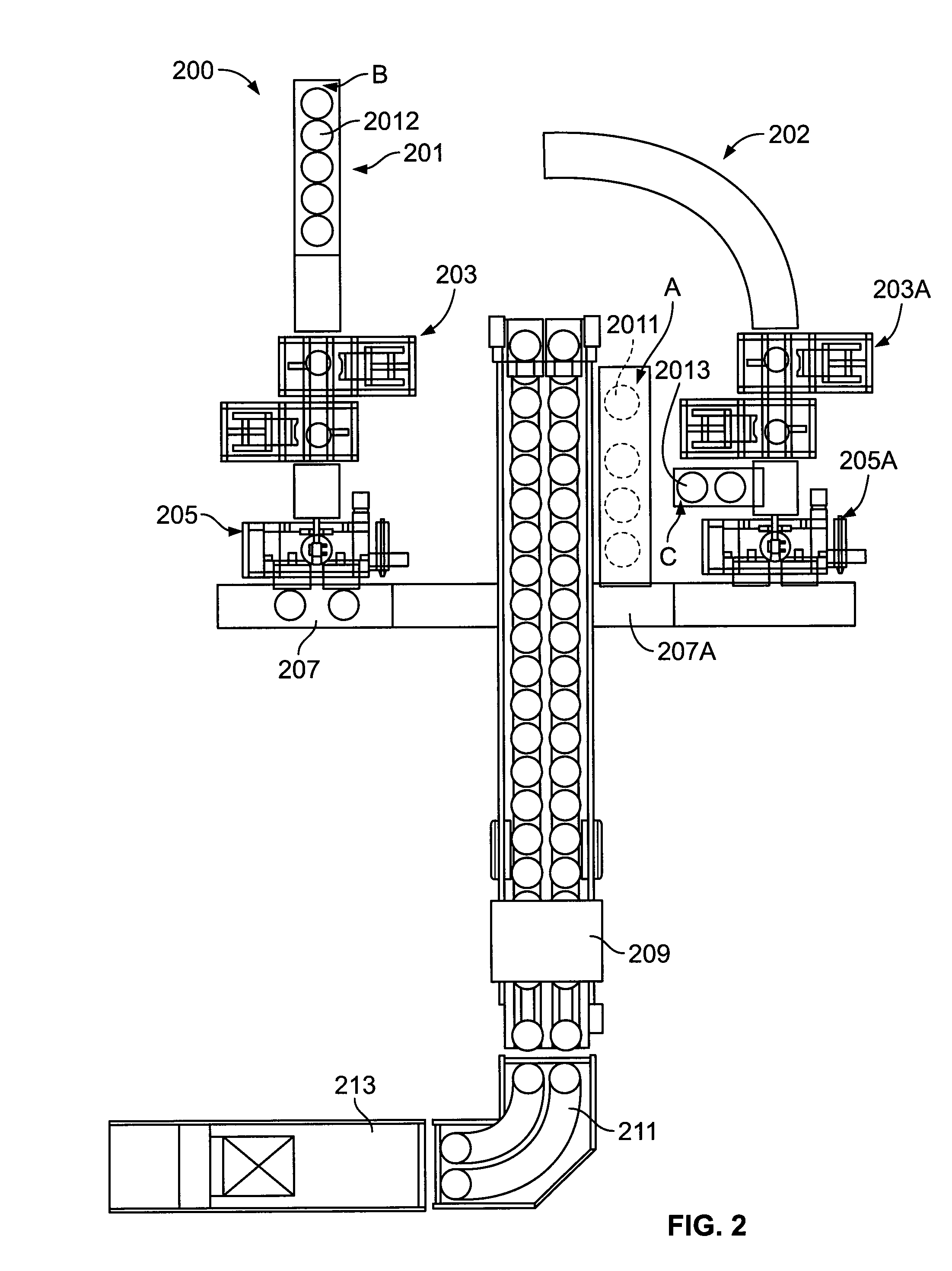

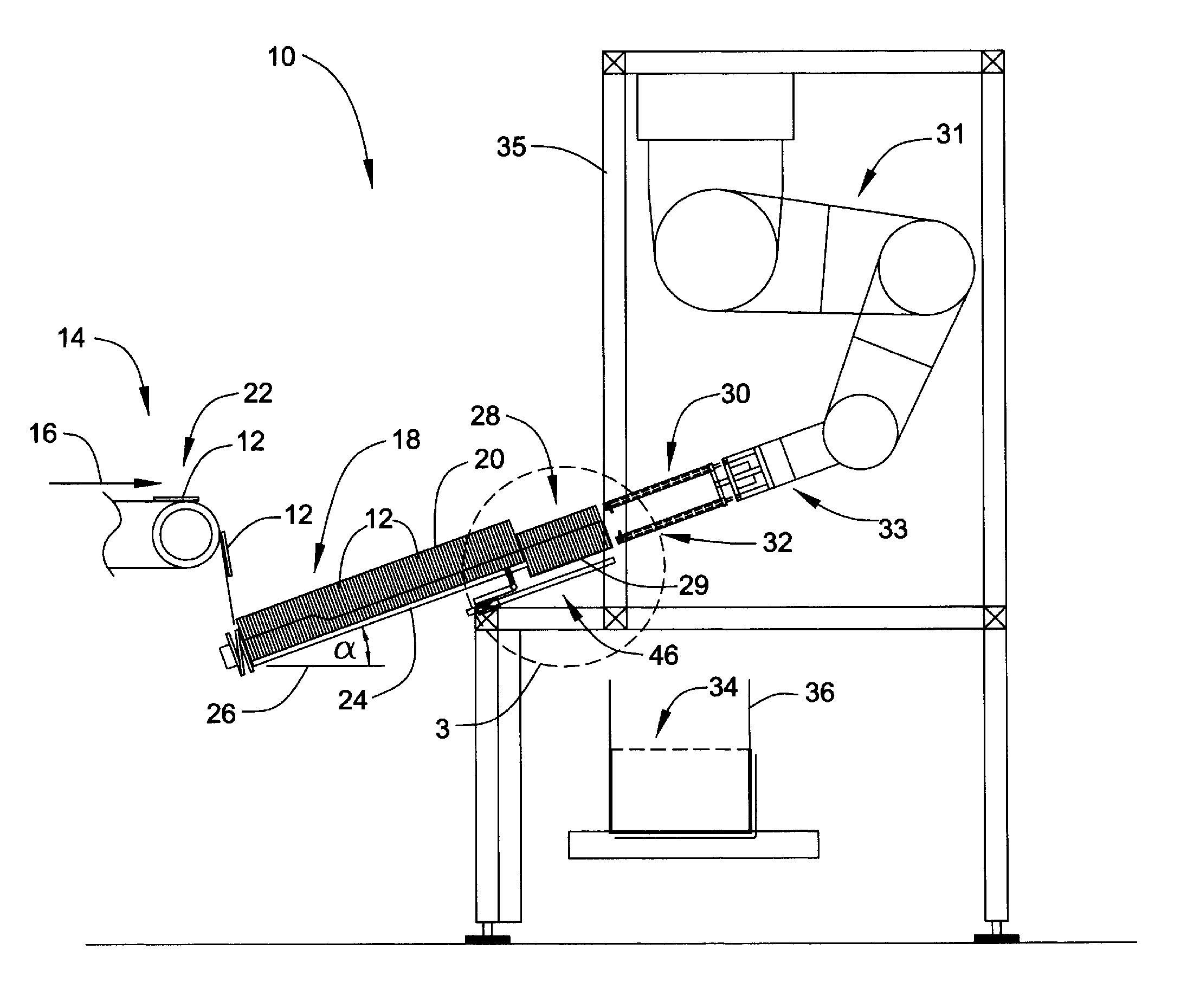

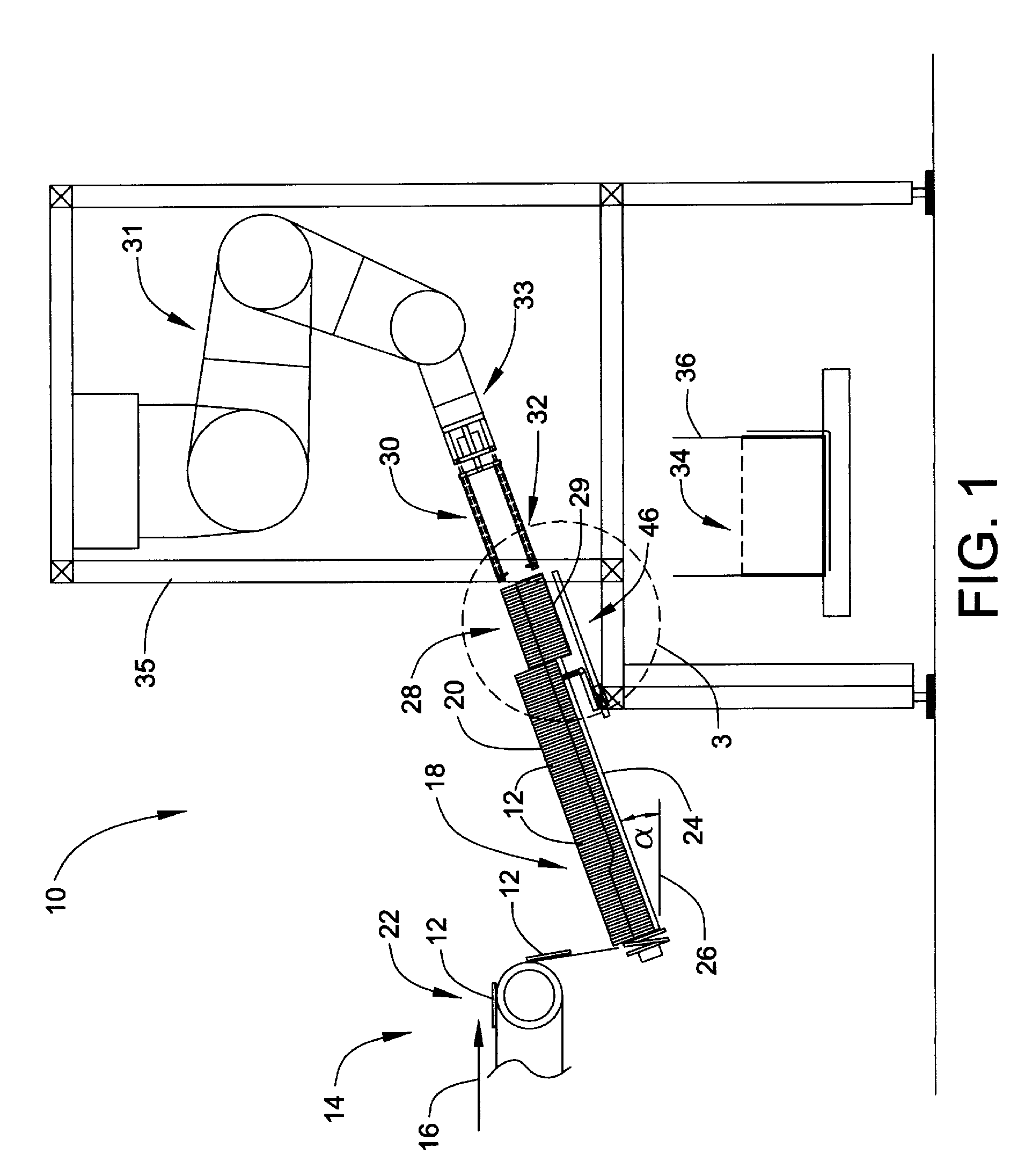

Automated system for handling food products

InactiveUS20060263181A1Widespread applicationBoiling over preventionArticle unpackingHandling foodEngineering

A system and method are provided for handling food products whereby stacked food products can be mechanically singulated or singulated product not on pitch can be dispensed individually at a regular pitch onto transport system carrying the food products to a subsequent process unit or units in an automated and essentially labor-free manner. The automated handling system may be used advantageously on stacks of pizza crusts, among other food product types.

Owner:SOC DES PROD NESTLE SA

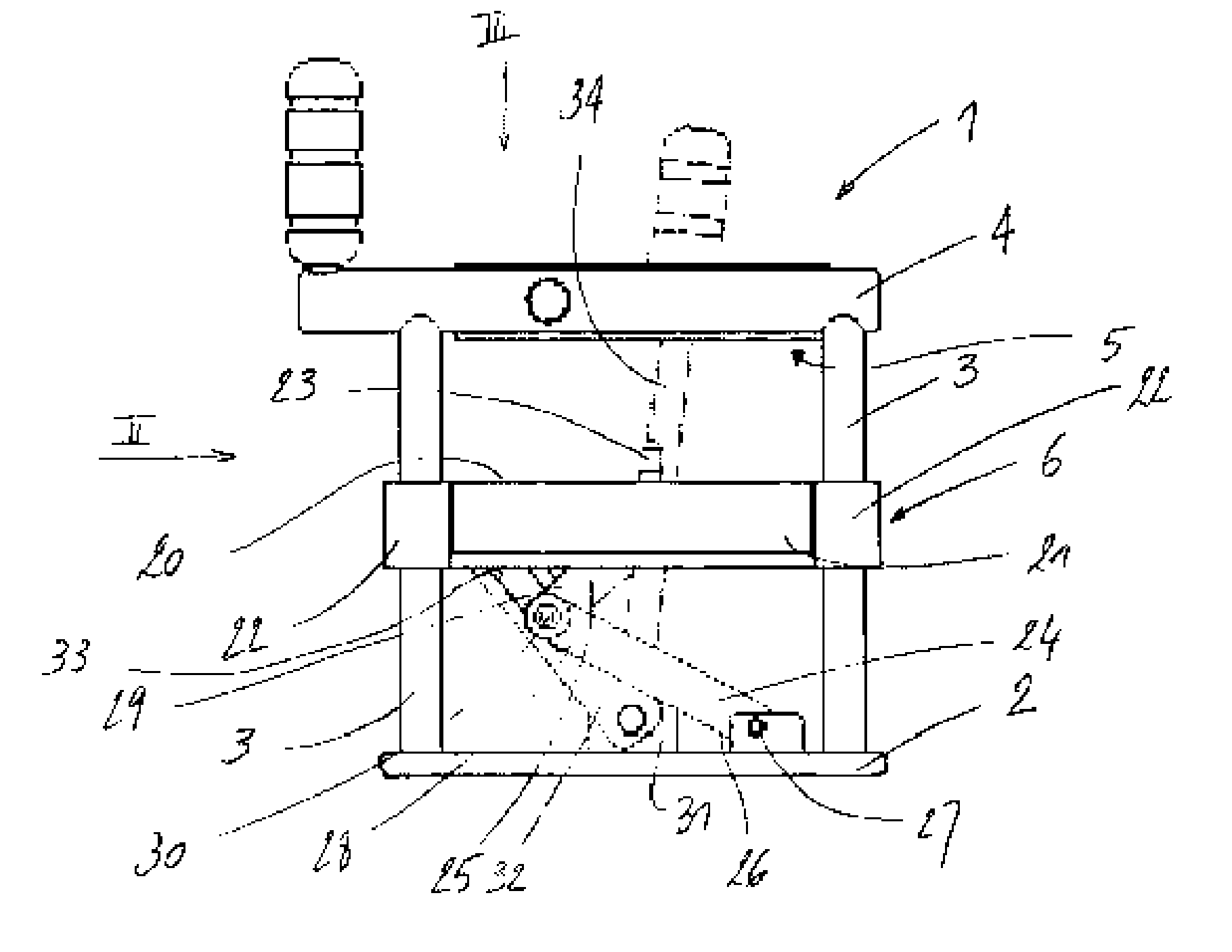

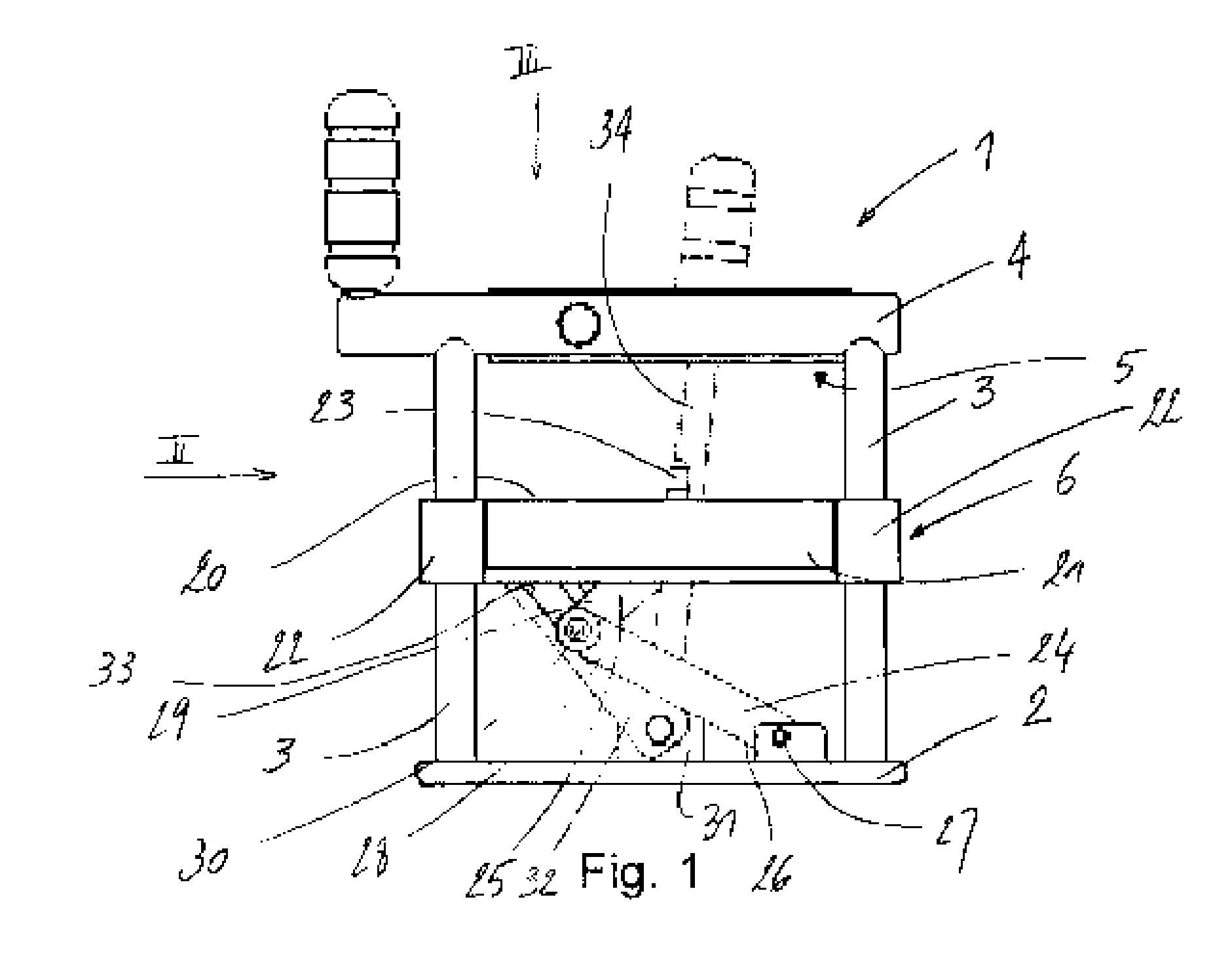

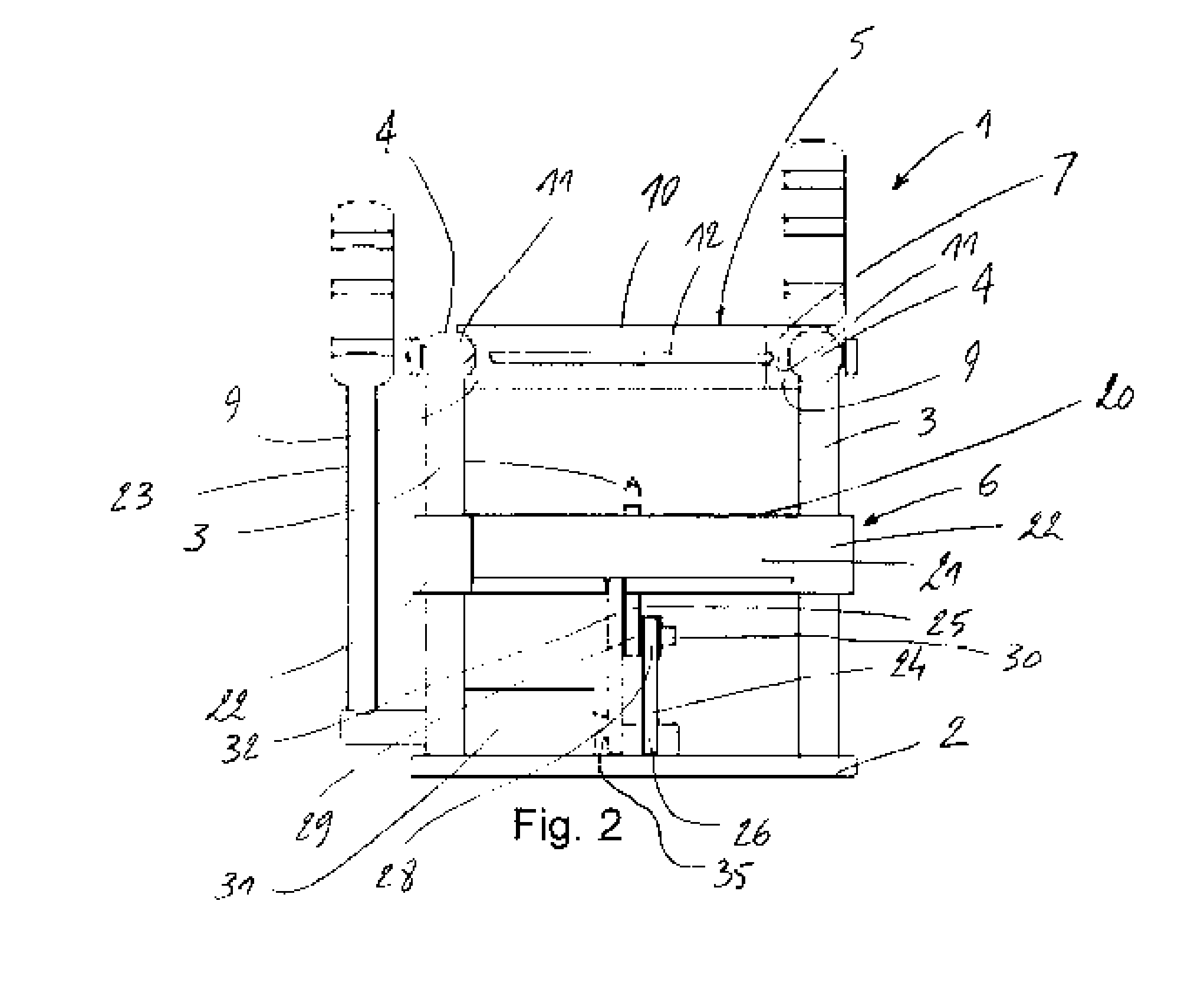

Device for handling food

Device for handling food, the device comprising a frame; a pressure unit; and a food handling unit, wherein the food handling unit is fixed to the frame, while the pressure unit is movably mounted on the frame, characterized in that pressure unit is movable along the frame in an upward direction towards the food handling unit.

Owner:ROES GUNTER ALFONS MATHILDE

Apparatus for Draining Excess Fluids from Food

An apparatus includes a spatula surface having a plurality of holes. The spatula surface is configured for handling food during a cooking process and for enabling fluids to drain through the holes. An arm supports the spatula surface during the cooking process. A handle is joined to an end of the arm. A drainer is positioned generally horizontally above a top surface of the spatula surface for contacting food positioned between the spatula surface and the drainer, and for enabling a pressure to be applied to the food to substantially remove excess fluids from the food. Attaching bars support the drainer and enable movement of the drainer relative to the spatula surface. A lever is joined to the attaching bars for enabling a user to impart a relative downward movement of the drainer to apply the pressure to the food, thereby enabling the user to substantially drain the excess fluids.

Owner:SARGENT III JIM WALLACE

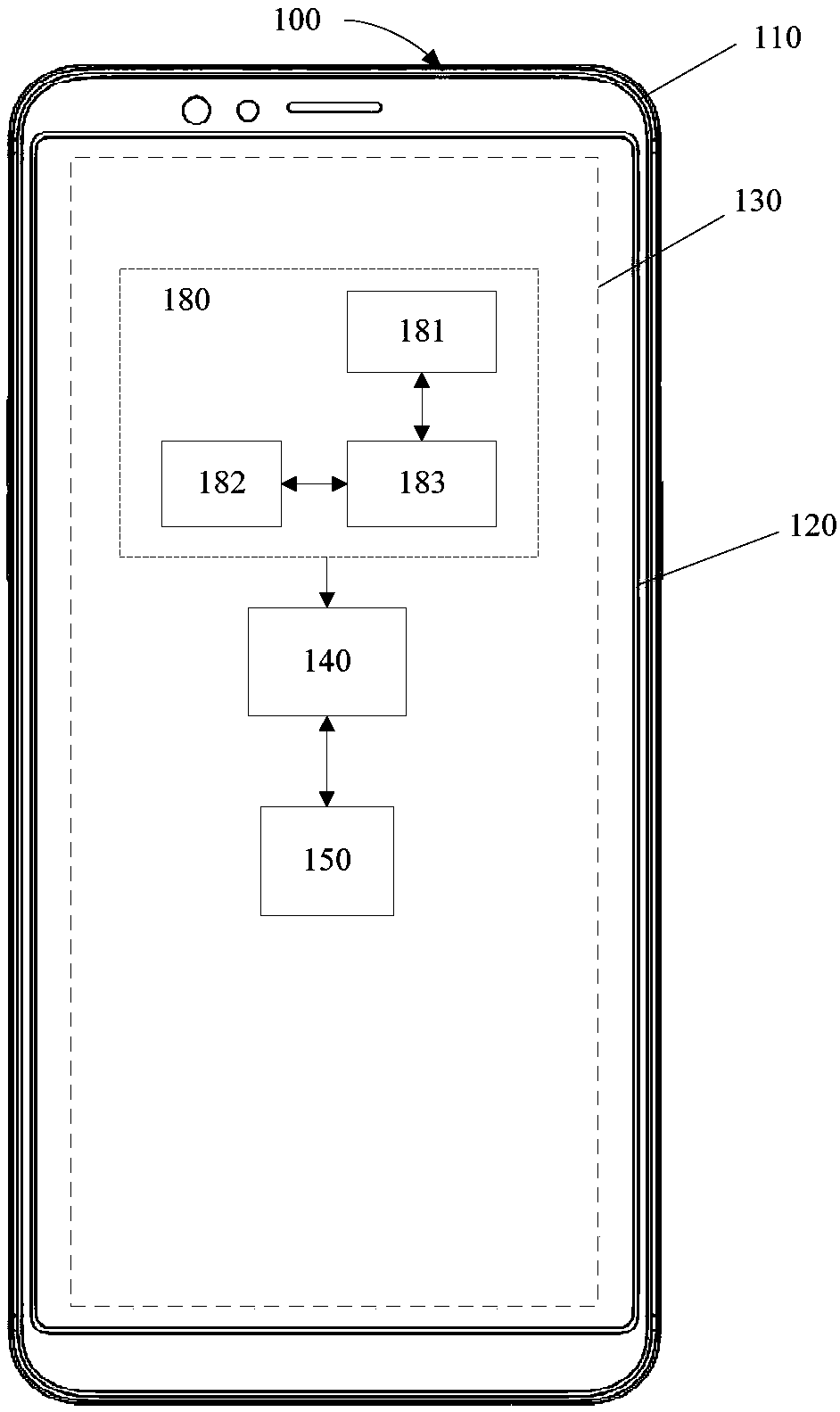

Electronic device, information pushing method, and related products

InactiveCN109618047AImprove securityImprove rationalityMaterial analysis by optical meansSubstation equipmentHandling foodHazardous substance

An embodiment of the application discloses an electronic device, an information pushing method, and related products. The method comprises the following steps: determining a target food by a camera ora substance sensor; detecting hazardous substance information of the target food by the substance sensor; and generating and outputting preset information according to the hazardous substance information. The embodiment of the application is beneficial to improving the convenience and rationality of the user in handling food.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Food wrapper and method of handling food

InactiveUS20060093711A1Facilitate speedImprove efficiencyReady-for-oven doughsContainers with multiple articlesHandling foodFood packaging

Owner:WORLD PACKAGING

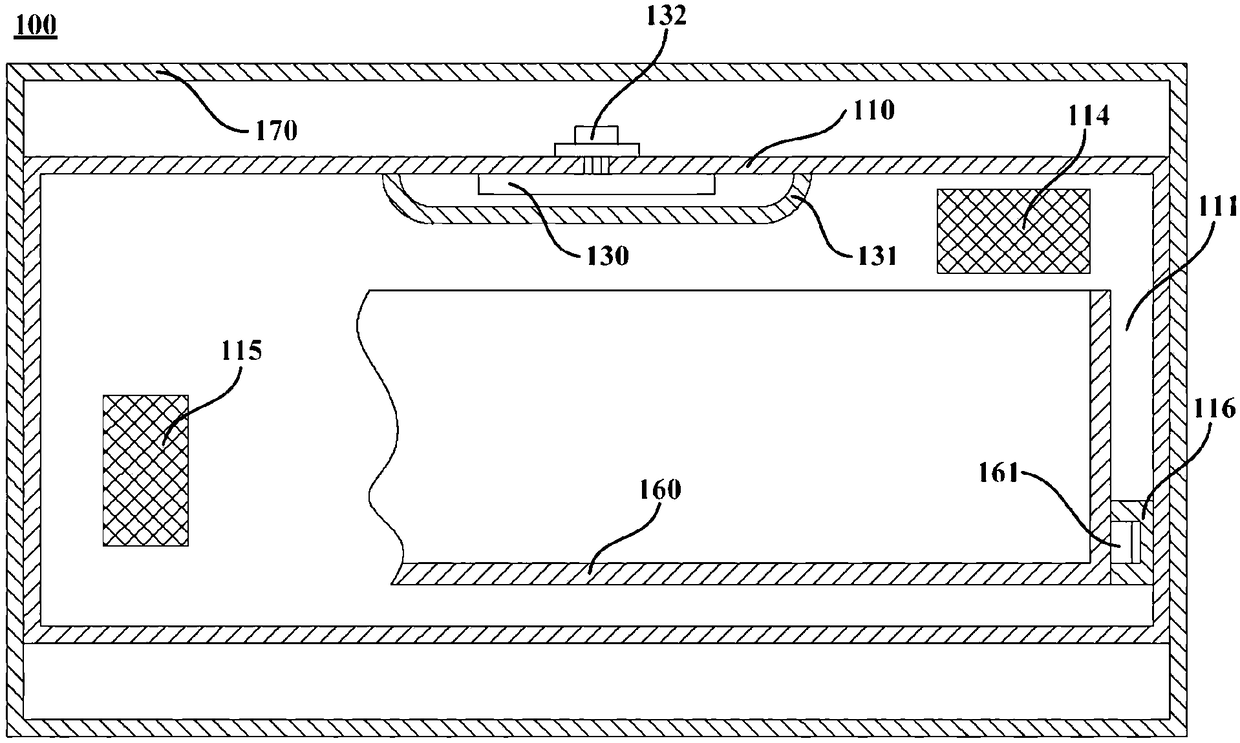

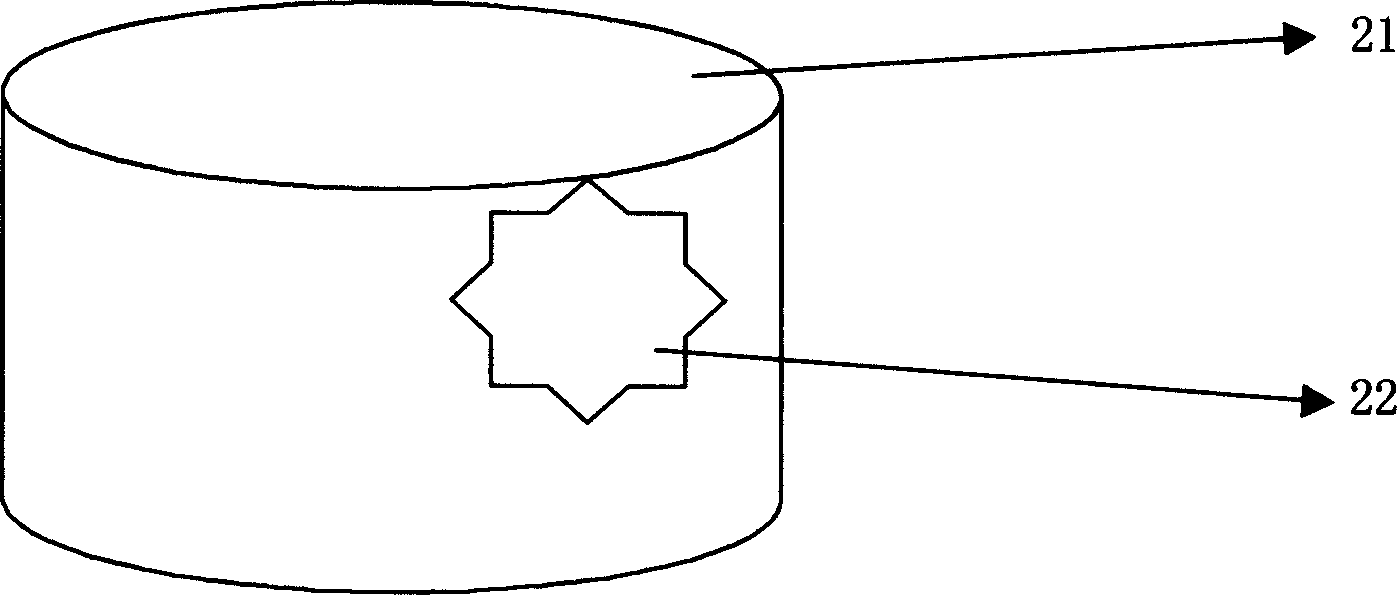

Control method used for thawing plant

PendingCN109323515ALow failure rateAvoid damageLighting and heating apparatusDielectric heating circuitsHandling foodStopped work

The invention provides a control method used for a thawing plant. The thawing plant comprises a cylinder, a plant door body, a radio frequency generating module and a radio frequency antenna, whereinthe cylinder defines a thawing chamber used for holding a to-be-handled food; the plant door body is arranged at a picking and placing opening position of the thawing chamber and is used for opening and closing the picking and placing opening of the thawing chamber; and the radio frequency antenna is arranged on the inner wall of the thawing chamber and is electrically connected with the radio frequency generating module. The control method comprises the following steps of judging whether the to-be-handled food is placed in the thawing chamber or not, if yes, the radio frequency generating module can work under control, and if not, the radio frequency generating module does not work. According to the control method provided by the invention, when there is no to-be-handled food (including that the to-be-handled food is too few) in the thawing chamber of the thawing plant, the radio frequency generating module stops working, so that dry burning phenomenon is avoided, i.e., the phenomenonthat radio frequency generating module is damaged due to long-term no-load operation is also avoided, and therefore, the fault rate of the thawing plant is reduced, and generation of undesirable energy consumption is avoided.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

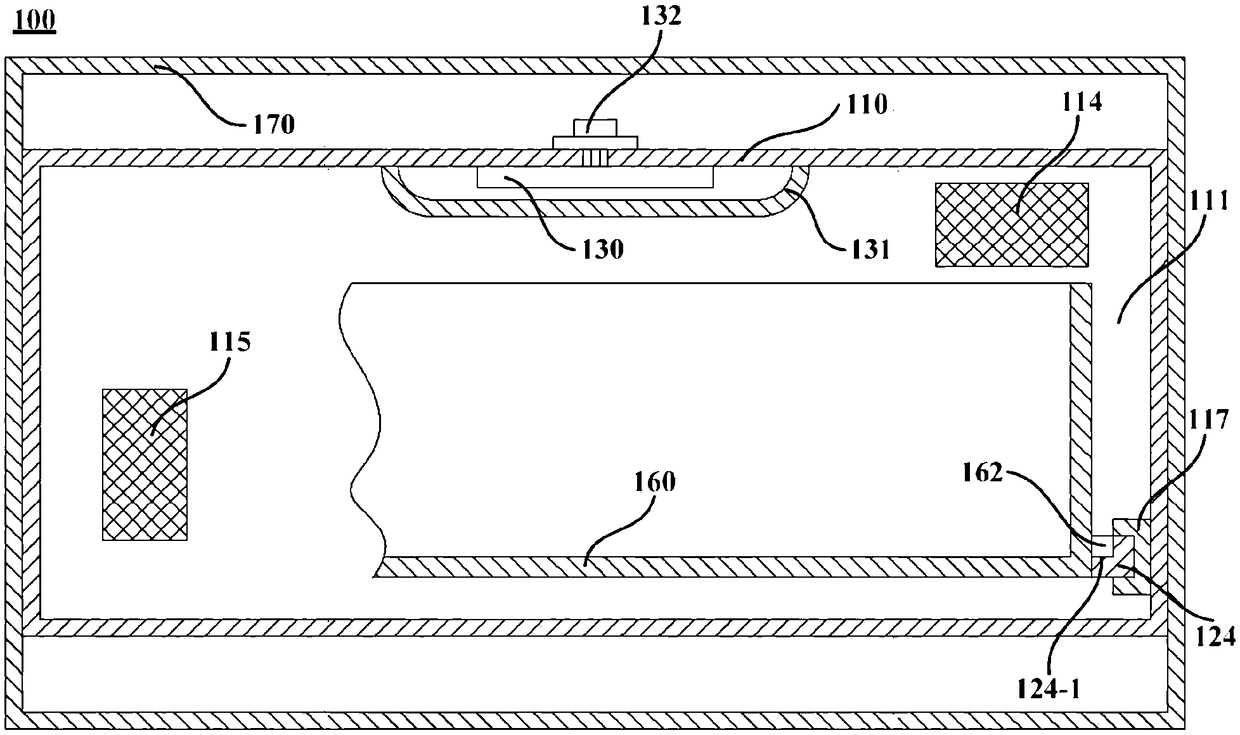

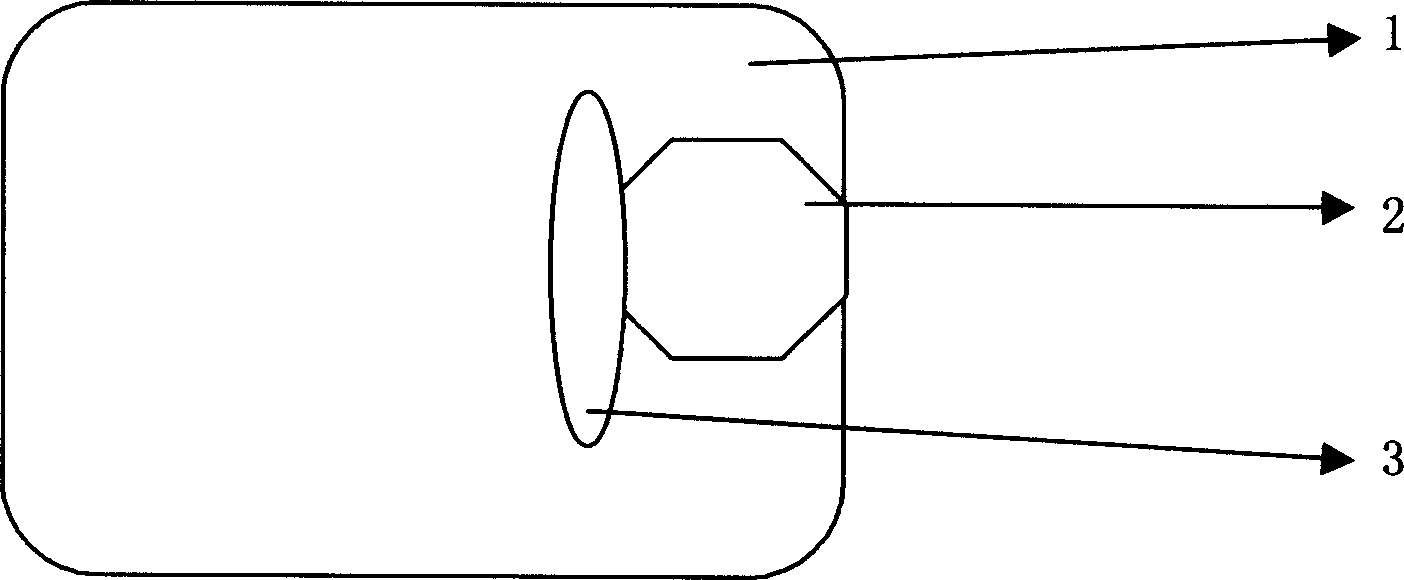

Thawing plant and refrigerator comprising same

PendingCN109323518AEasy accessImprove convenienceLighting and heating apparatusDomestic refrigeratorsHandling foodElectricity

The invention provides a thawing plant. The thawing plant comprises a cylinder, a plant door body, a radio frequency generating module and a radio frequency antenna, wherein the cylinder defines a thawing chamber provided with a front side opening; the plant door body is used for opening and closing the thawing chamber, and the radio frequency antenna is horizontally arranged on the top wall of the thawing chamber and is electrically connected with the radio frequency generating module; the radio frequency antenna is configured to generate a radio frequency wave of a corresponding frequency inthe thawing chamber according to a radio frequency signal and thaw a to-be-handled food in the thawing chamber; the thawing plant further comprises a drawer body unenclosed upwards, and the drawer body is used for bearing the to-be-handled food; and the drawer body is arranged to be capable of moving in front and rear directions of the thawing plant together with the plant door body. According tothe thawing plant provided by the invention, the drawer body unenclosed upwards is arranged specially, is used for bearing the to-be-handled food and is arranged to be capable of moving in the frontand rear directions of the thawing plant together with the plant door body, so that a user can conveniently pick and place the to-be-handled food placed at the rear side of the thawing chamber, and convenience of using the thawing plant by the user is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

Apparatus for draining excess fluids from food

An apparatus includes a spatula surface having a plurality of holes. The spatula surface is configured for handling food during a cooking process and for enabling fluids to drain through the holes. An arm supports the spatula surface during the cooking process. A handle is joined to an end of the arm. A drainer is positioned generally horizontally above a top surface of the spatula surface for contacting food positioned between the spatula surface and the drainer, and for enabling a pressure to be applied to the food to substantially remove excess fluids from the food. Attaching bars support the drainer and enable movement of the drainer relative to the spatula surface. A lever is joined to the attaching bars for enabling a user to impart a relative downward movement of the drainer to apply the pressure to the food, thereby enabling the user to substantially drain the excess fluids.

Owner:SARGENT III JIM WALLACE

Automatic valuation shopping appts

InactiveCN1601553ACan't solveSettle the priceCo-operative working arrangementsSpecial data processing applicationsHandling foodTotal price

Non touch IC card or wireless label can be added to products. Thus, price of product can be read out by reader / writer. But, customer can not caculate total price for all products in time and obtain detailed data of products. In the invention, reader / writer is added to dinner plate, shopping cart etc. so that customer can know price of product, total price, and detailed data of products etc. Non touch IC card or wireless label can be added container for placing food. The invention reduces waiting time, shopping time and number of time for handling food and updates data quickly.

Owner:SHANGHAI ZHONGCE IND & TRADING +1

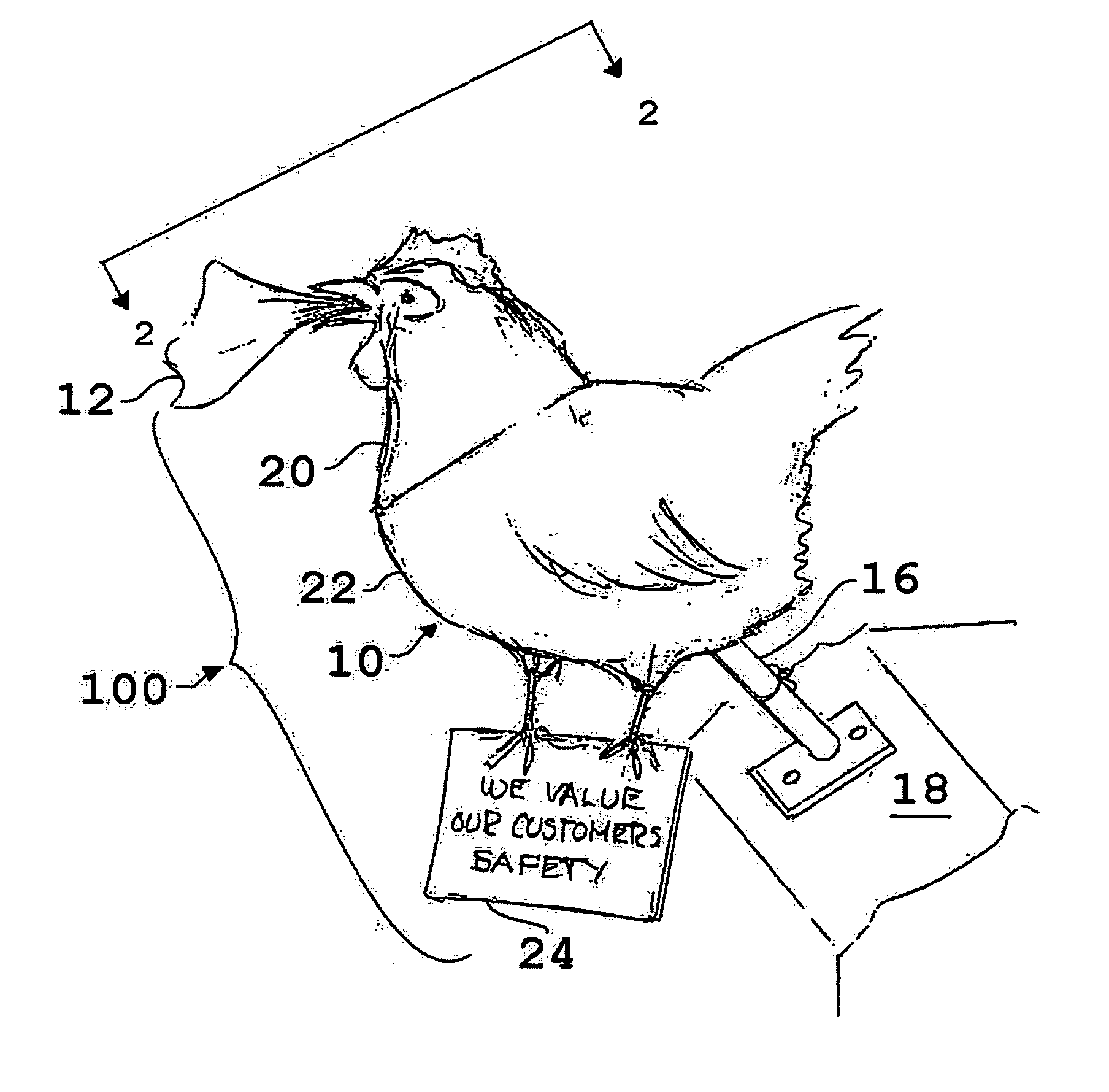

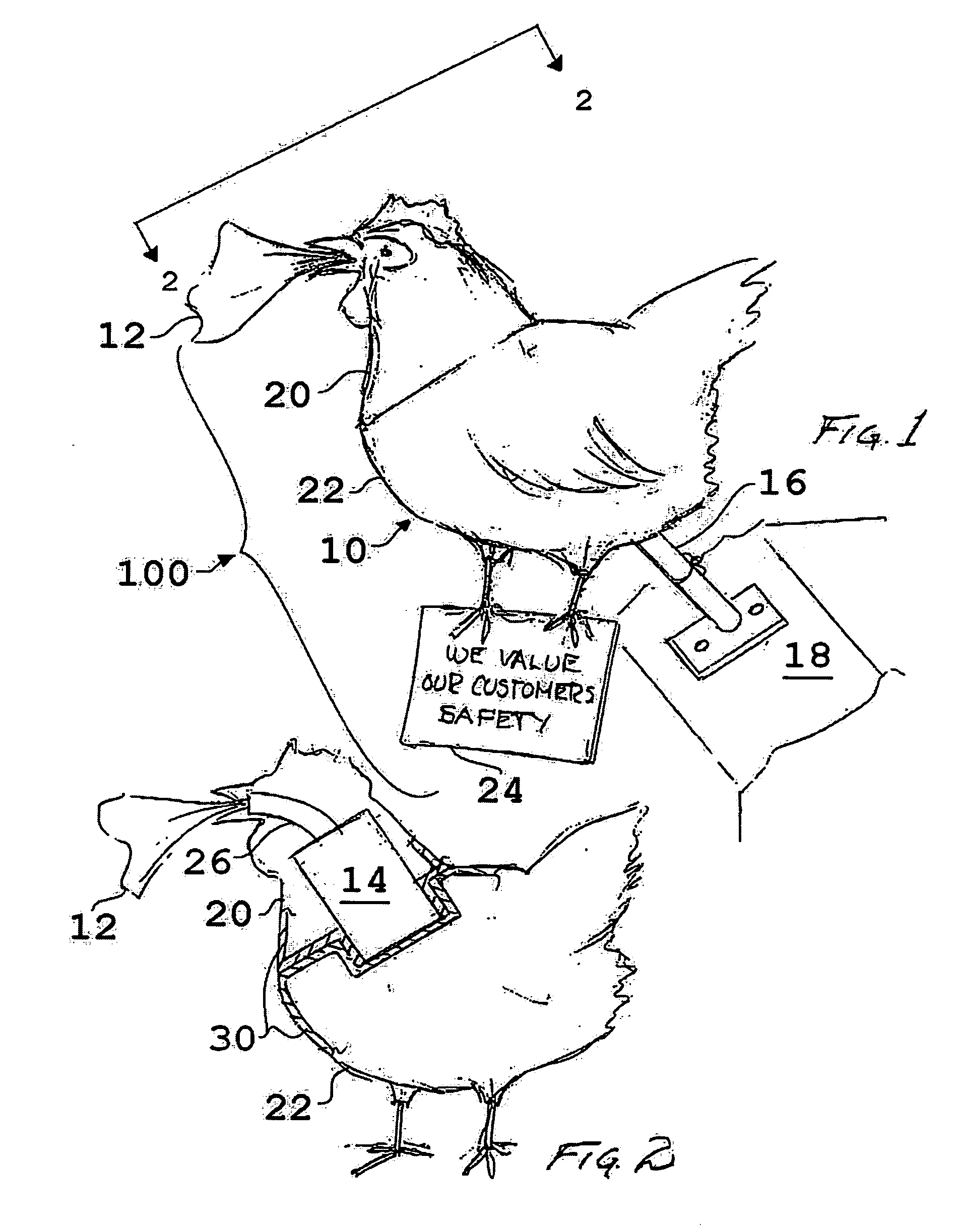

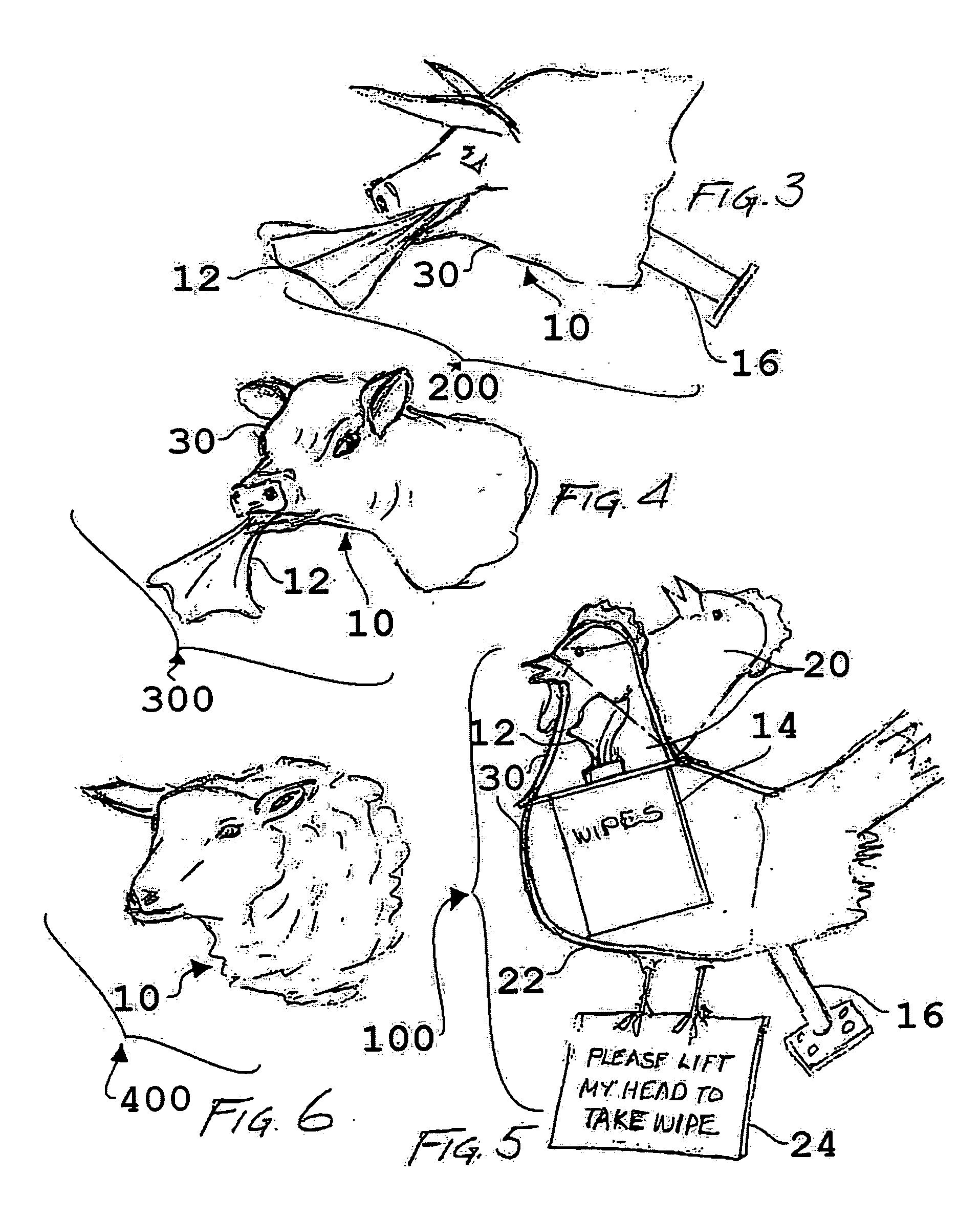

Devices for safe handling of food and methods therefor

InactiveUS20050274640A1Operational securityAdd deviceOther accessoriesContainer/bottle contructionHandling foodAnimals food

A device for safe handling of food comprises a dispenser assembly having an animal-shaped configuration. The dispenser assembly is provided with a plurality of antimicrobial wipes and at least a portion of the dispenser assembly is adapted to be located in a food handling area. The plurality of antimicrobial wipes of the dispenser assembly both facilitate and permit hygienic handling of an animal food product of the type represented by the animal-shaped configuration of the dispenser assembly by using at least one of the plurality of wipes that is retrieved from the dispenser assembly. The animal-shaped configuration of the dispenser assembly is at least one of a chicken, a turkey, a pig, a cow, a lamb and a fish. A safety message is coupled to a portion of the dispenser assembly, thereby inviting a person to practice hygiene after handling the animal food product.

Owner:PELLEGRINO JOHN

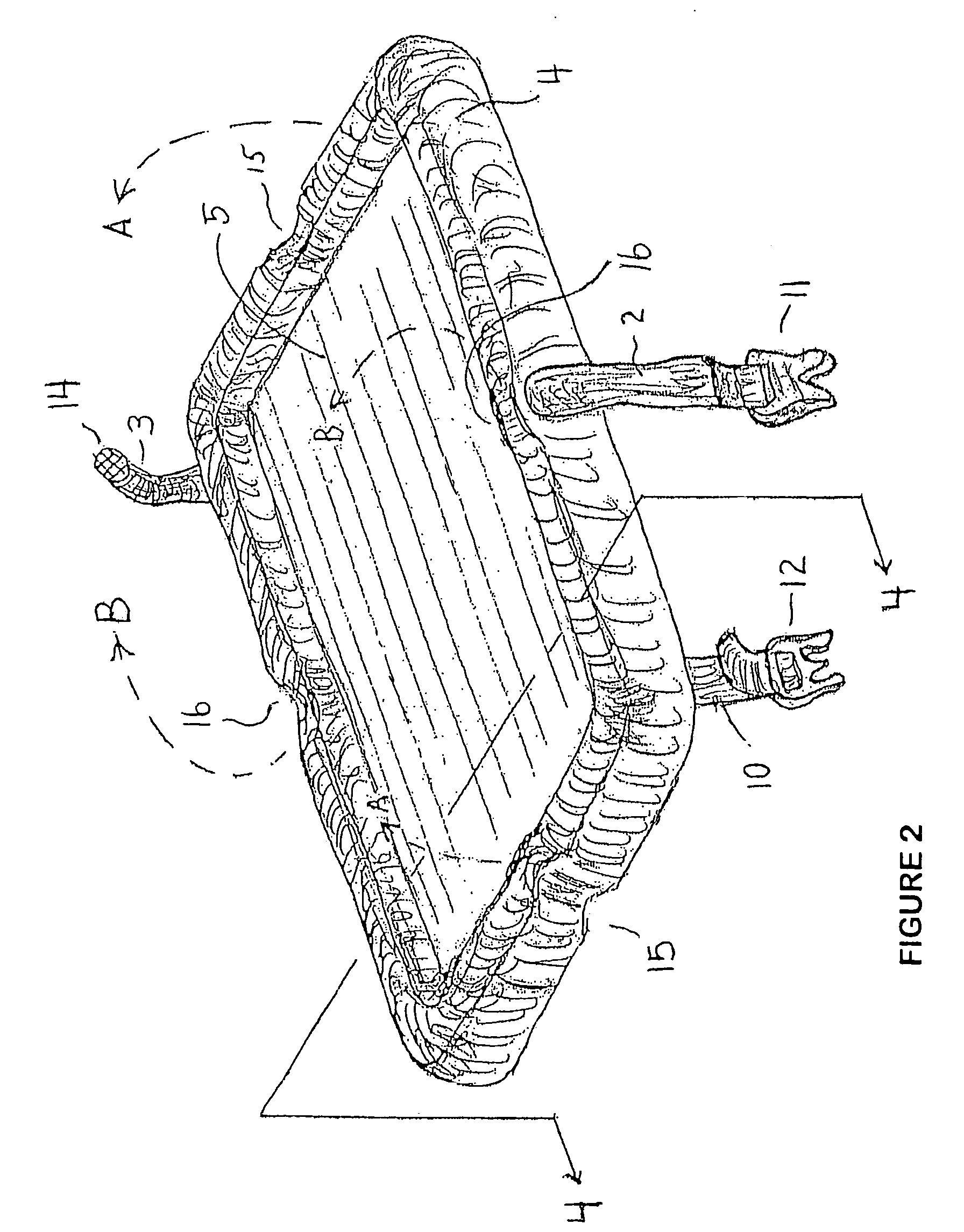

Automated system for handling food products

A system and method are provided for handling food products whereby stacked food products can be mechanically singulated or singulated product not on pitch can be dispensed individually at a regular pitch onto transport system carrying the food products to a subsequent process unit or units in an automated and essentially labor-free manner. The automated handling system may be used advantageously on stacks of pizza crusts, among other food product types.

Owner:SOC DES PROD NESTLE SA

Systems and methods for processing stackable articles

ActiveUS9540191B2Facilitate and accelerate safe and efficient handlingPackaging meatPile receiversHandling foodRobot hand

Systems and methods for processing stackable articles, such as, frozen hamburgers or compact disks, are provided. The systems include mechanisms for determining the number of articles in a stack of articles, a transfer device adapted to transfer the articles when the number of articles equals a predetermined number of articles, a gripping device adapted to receive the stacks of articles from the transfer device, an automated manipulator adapted to transfer the gripping device with the stacks of articles, and a mechanism for discharging the stacks of articles from the gripping device to, for example, a container. The systems and methods may also provide staging areas adapted to receive the stack of articles and then transfer the stack of articles to the gripping device. Though aspects of the invention may be uniquely adapted to handle food items, aspects of the invention may also be used for non-food items.

Owner:RMF STEEL PRODS

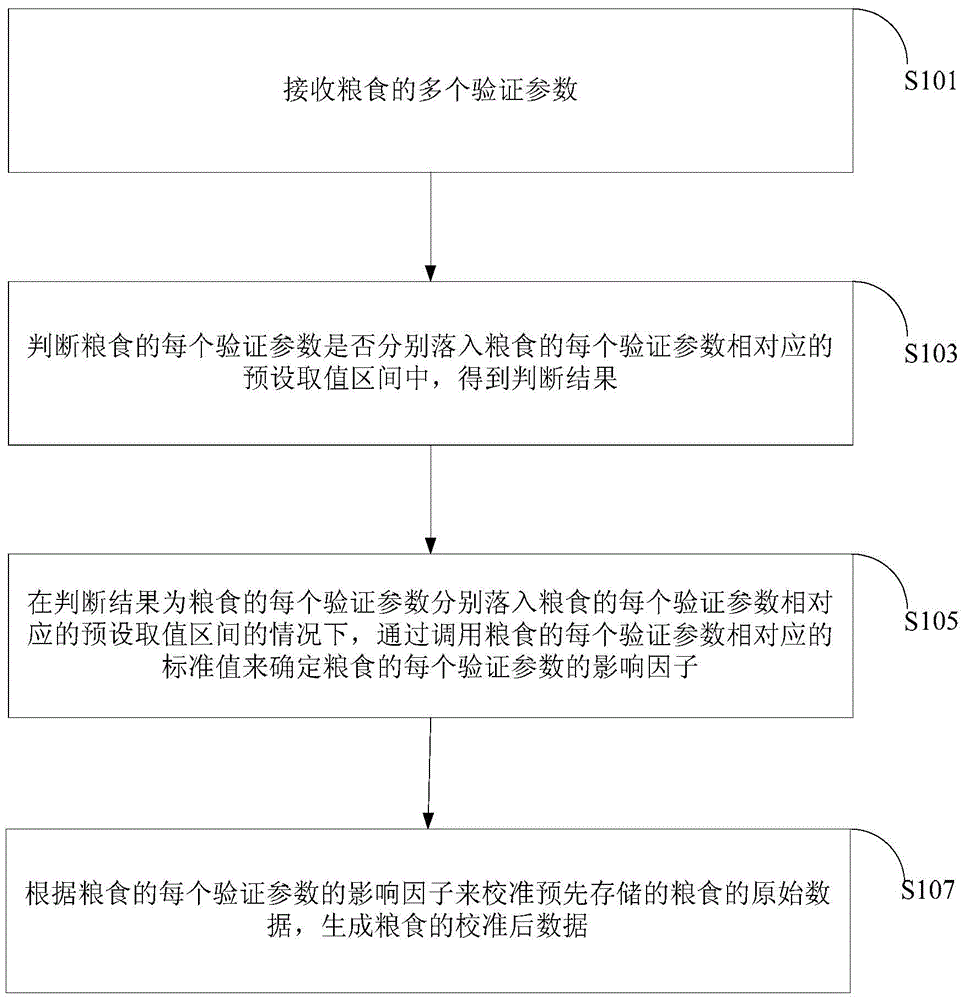

Food data processing method and system

InactiveCN105809498AProcessing scienceSolve the problem of standardized processing of grain dataBilling/invoicingBuying/selling/leasing transactionsHandling foodComputer science

The invention discloses a grain data processing method and system. The method includes: receiving a plurality of verification parameters of the grain, judging whether each verification parameter of the grain falls into a preset value interval corresponding to each verification parameter of the grain, obtaining a judgment result, and determining whether each verification parameter of the grain is When the verification parameters fall into the preset value range corresponding to each verification parameter of the grain, the influence factor of each verification parameter of the grain is determined by calling the standard value corresponding to each verification parameter of the grain, according to The impact factor of each verification parameter of the grain is used to calibrate the raw data of the grain stored in advance to generate the calibrated data of the grain. The invention solves the problem of how to standardize the processing of grain data in the prior art.

Owner:航天信息软件技术有限公司

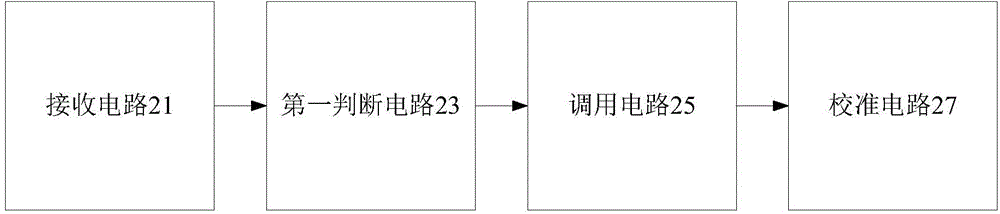

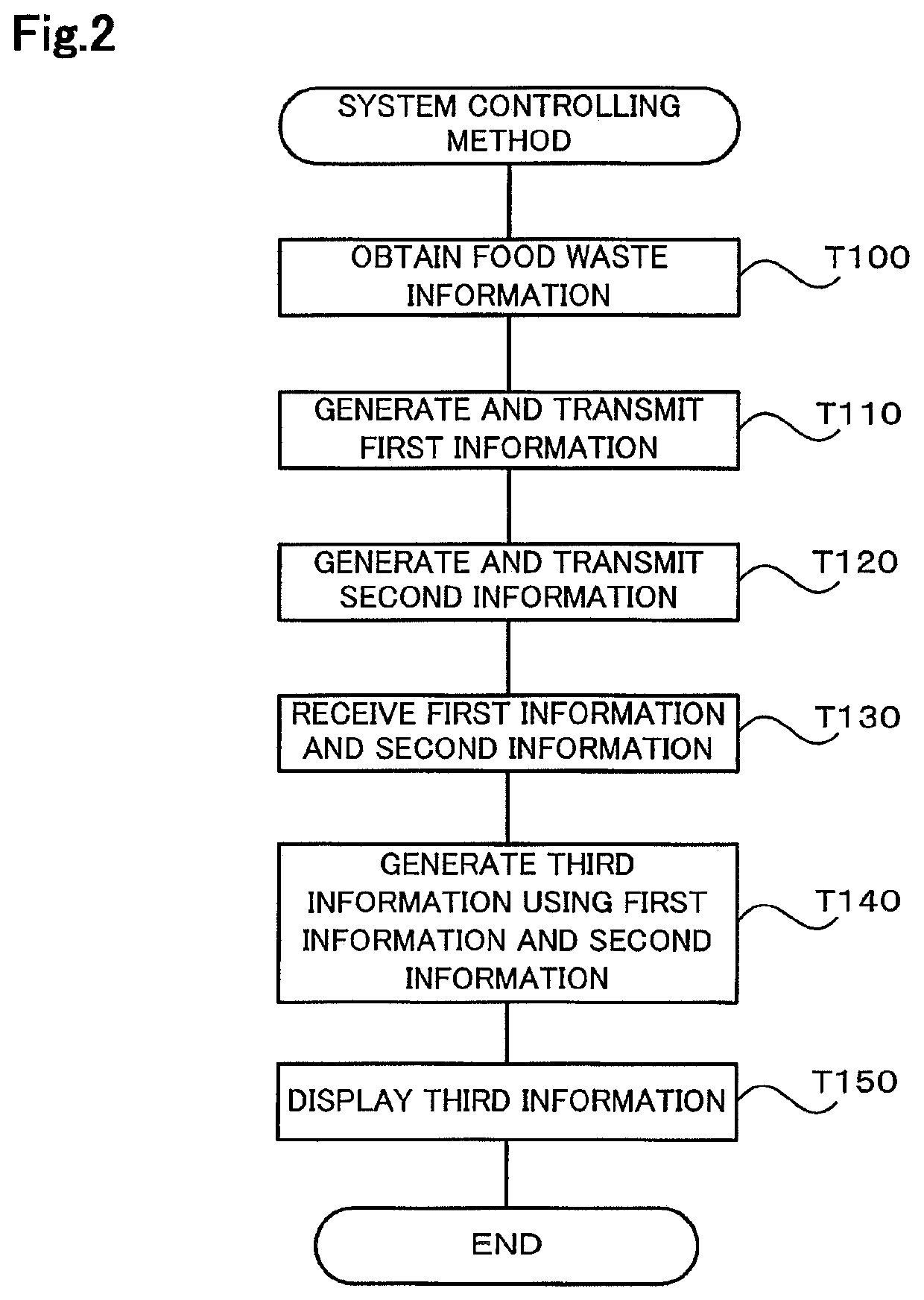

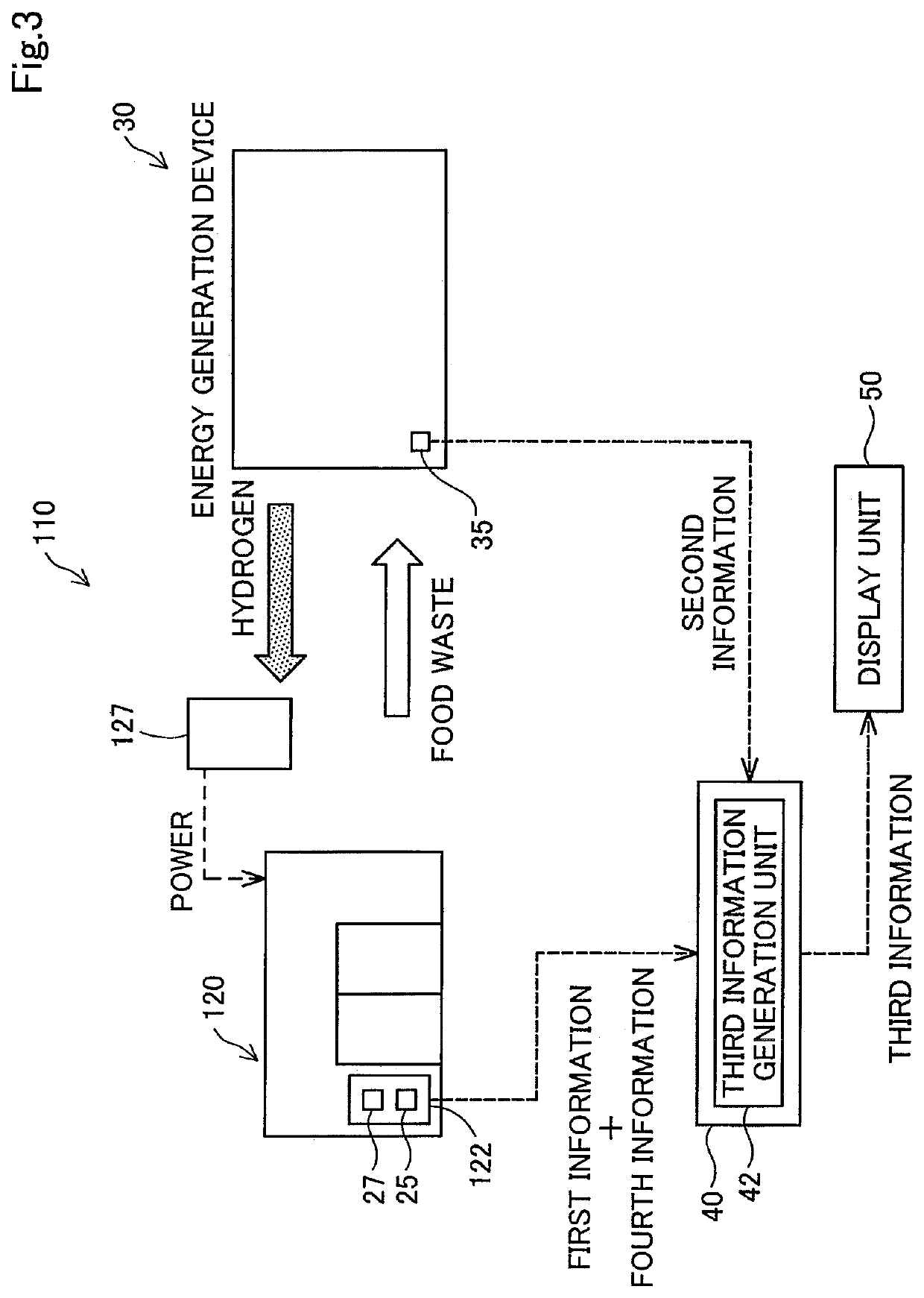

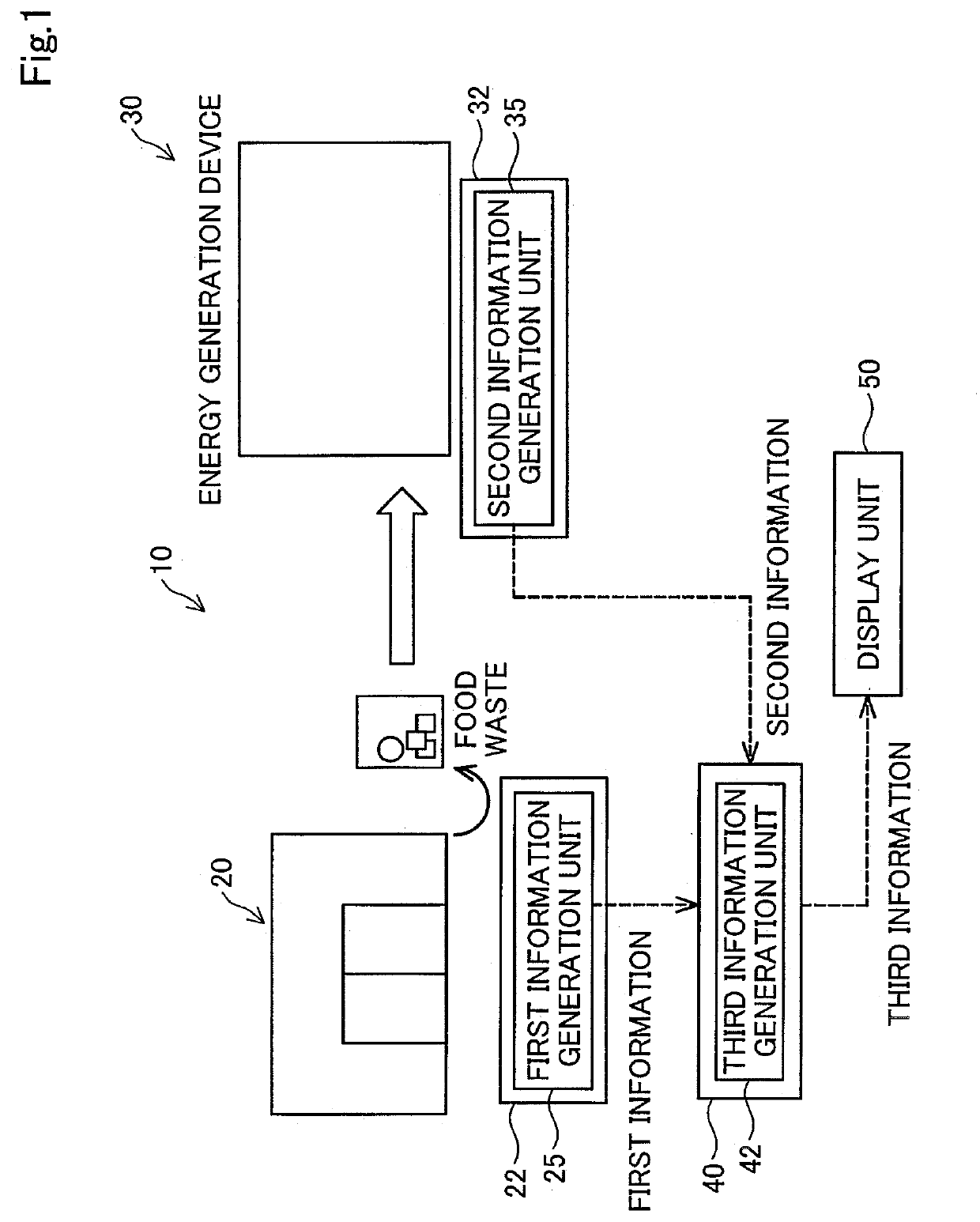

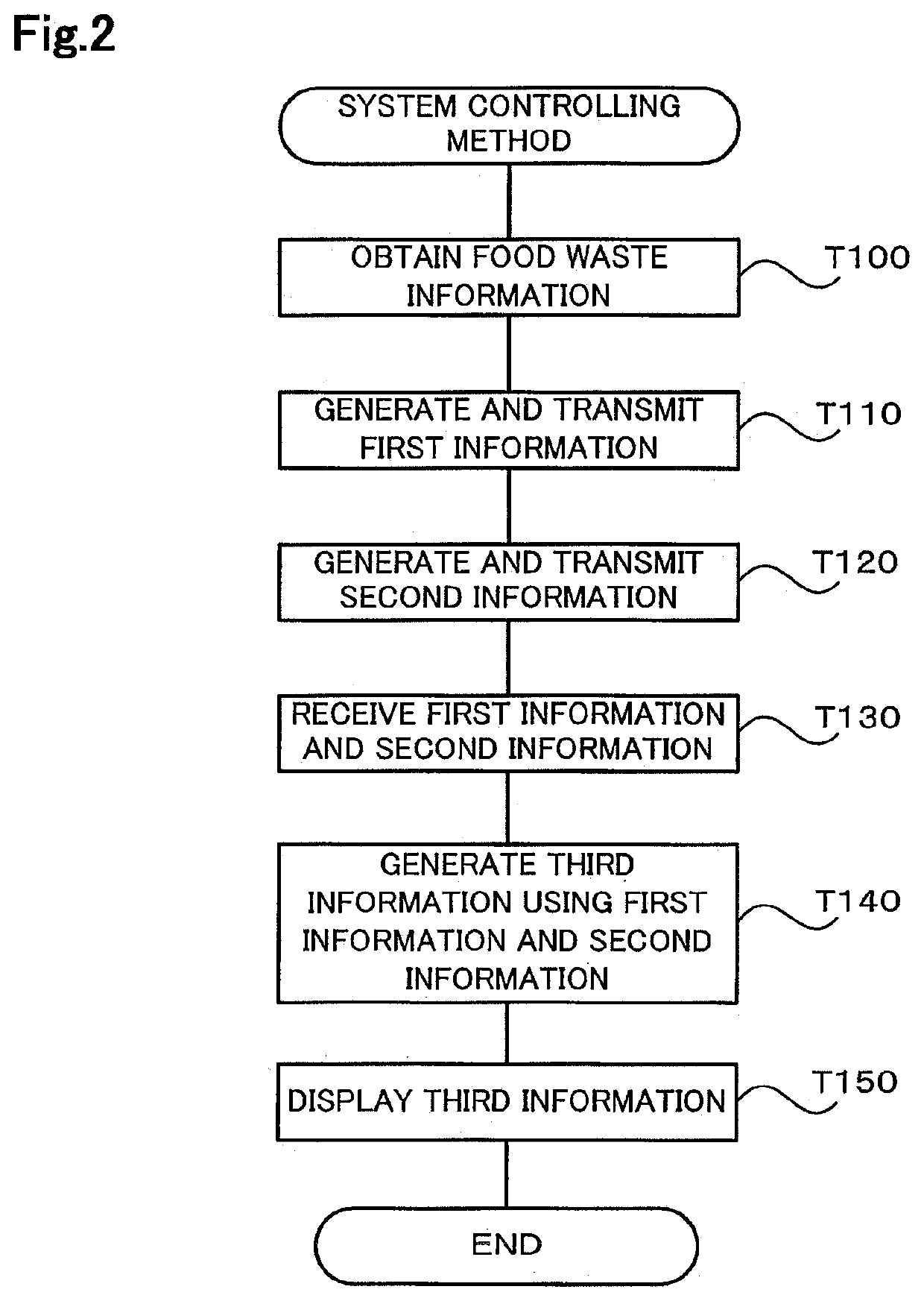

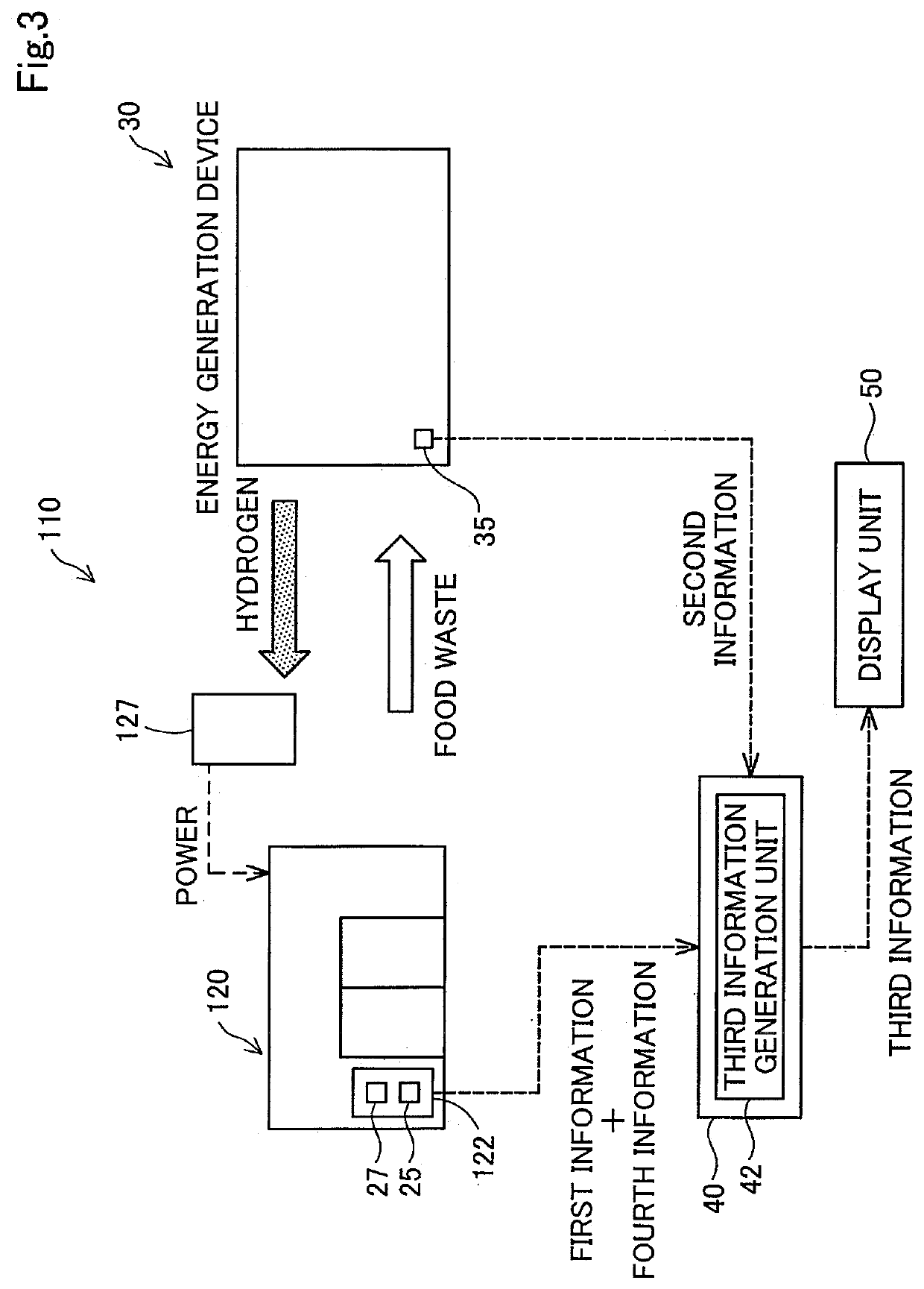

Energy generation system using biomass and method of controlling the same

An energy generation system using biomass includes a first information generation unit that generates the first information indicating that a distributor handling food has disposed of food waste biomass, an energy generation device that generates energy and the like using biomass collected from the distributor, a second information generation unit that generates the second information indicating that energy and the like have been generated using biomass collected from the distributor, a third information generation unit that obtains the first information and the second information and generates the third information indicating generation of at least one of energy and energy sources by collecting biomass disposed by the distributor, and a display unit that displays the third information generated by the third information generation unit.

Owner:TOYOTA JIDOSHA KK

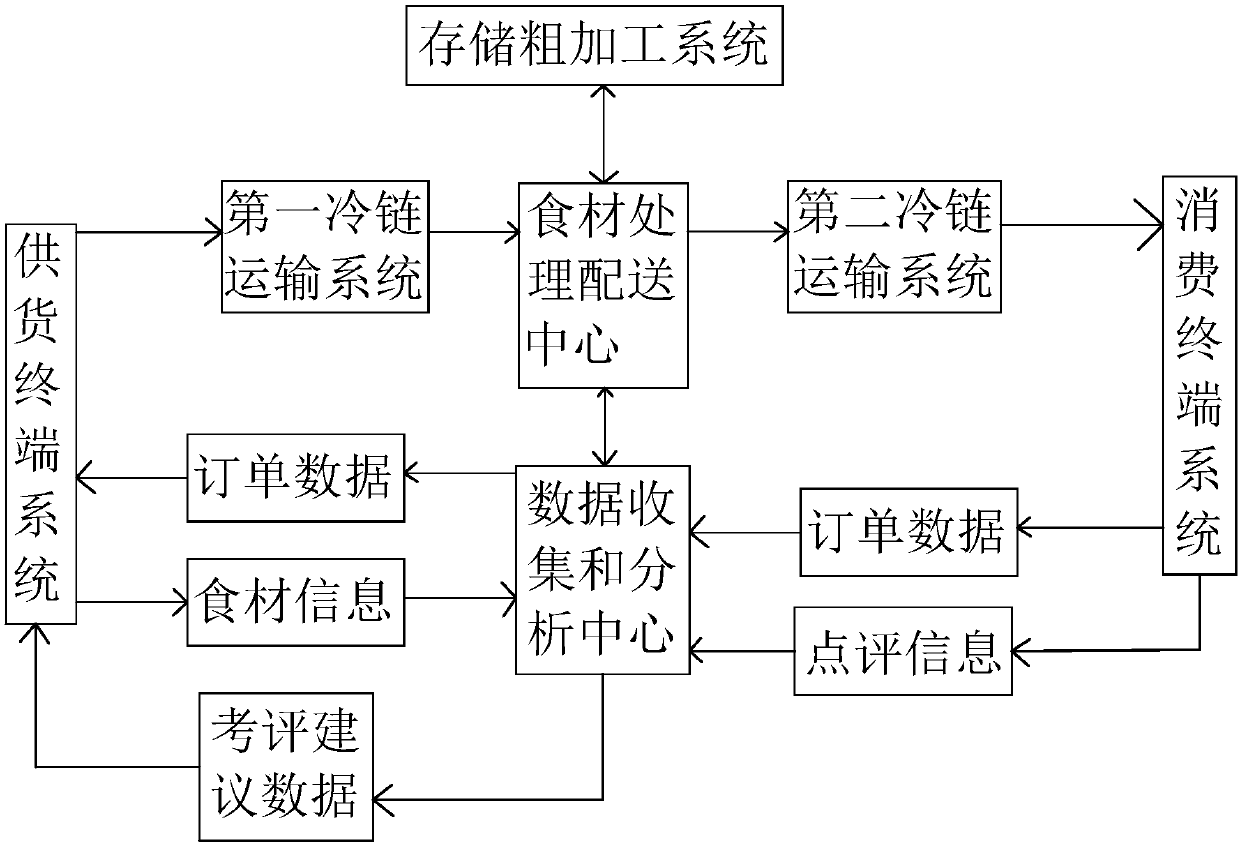

Food material circulation system based on Internet-plus IT technology

InactiveCN107665413AProtect interestsIncrease production capacityLogisticsMarket data gatheringCold chainData connection

The invention discloses a food material circulation system with Internet plus IT technology, which includes a data collection and analysis center, a first cold chain transportation system, a second cold chain transportation system and a food material processing and distribution center. The data collection and analysis center and the consumption terminal The data connection between the system and the supply terminal system, the consumer sends the order data to the data collection and analysis center through the consumption terminal system, the data collection and analysis center sends the order data to the supply terminal system after analysis and processing, and the farmers pass the The terminal system sends the food information to the data collection and analysis center, the data collection and analysis center will select the best farmers to purchase, the best farmers will transport the food to the food processing and distribution center, and the food processing and distribution center will transport the food to consumers; beneficial Effect: Provide farmers with more and more convenient sales channels, and the market is relatively transparent, thus providing certain protection for consumers.

Owner:娄宗华

Energy generation system using biomass and method of controlling the same

An energy generation system using biomass includes a first information generation unit that generates the first information indicating that a distributor handling food has disposed of food waste biomass, an energy generation device that generates energy and the like using biomass collected from the distributor, a second information generation unit that generates the second information indicating that energy and the like have been generated using biomass collected from the distributor, a third information generation unit that obtains the first information and the second information and generates the third information indicating generation of at least one of energy and energy sources by collecting biomass disposed by the distributor, and a display unit that displays the third information generated by the third information generation unit.

Owner:TOYOTA JIDOSHA KK

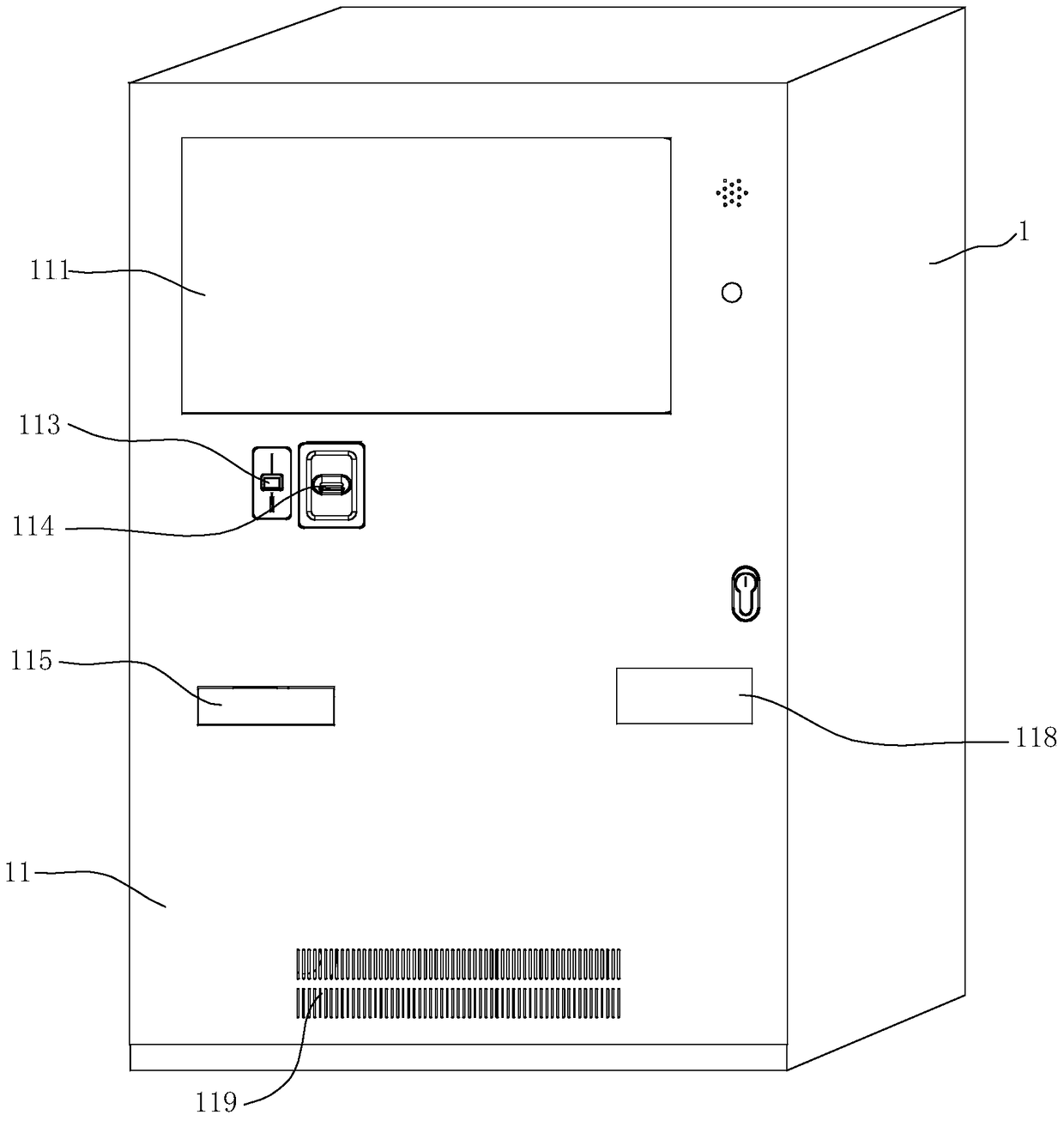

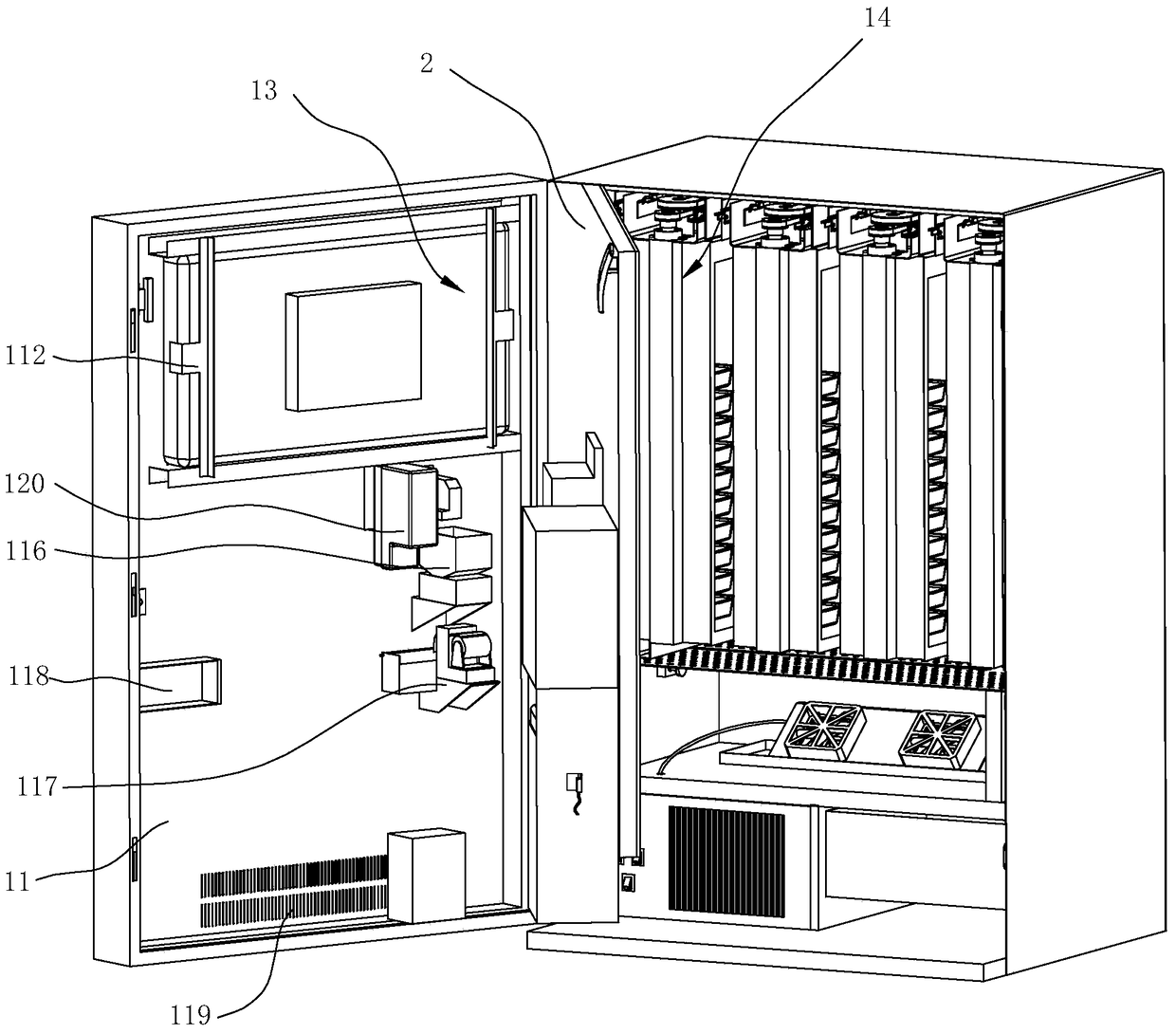

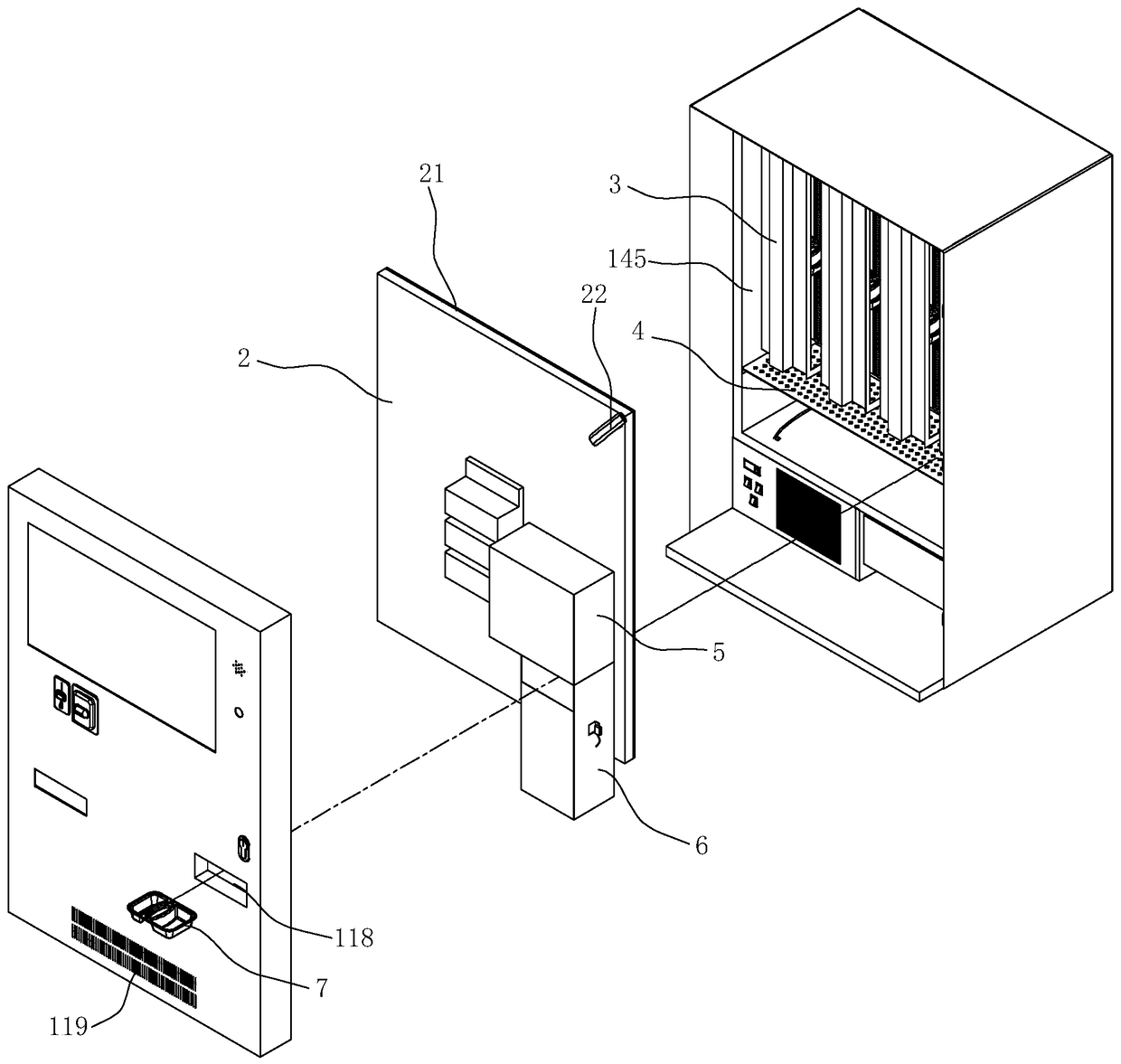

A delivery mechanism for an automatic meal vending machine

InactiveCN105118156BPromote increaseEasy to fixCoin-freed apparatus detailsApparatus for dispensing discrete articlesHandling foodFood vending machines

The invention discloses a delivery mechanism of an automatic meal vending machine, which includes a container and a heating device adjacent to the container, and is characterized in that: the container includes at least one food storage cabinet and a meal pushing mechanism; , the hanging cabinet is provided with at least one meal storage cavity with an opening at the bottom, and a plurality of upper and lower lunch boxes are stored in the meal storage cavity. The meal delivery mechanism that moves the meal box downwards; the meal pusher mechanism is arranged under the meal storage cabinet, and the meal pusher mechanism includes a horizontally arranged meal push table, which is used to move the meal box that falls on the table pusher horizontally from the table pusher The first side pushes the horizontal dining mechanism to the second side, and the vertical dining mechanism for pushing the lunch box longitudinally forward on the dining table; The lunch box is sent into the heating device, and the heated lunch box is sent to the meal delivery mechanism at the corresponding position of the meal outlet of the automatic meal vending machine.

Owner:宁波市晶睿医疗科技有限公司

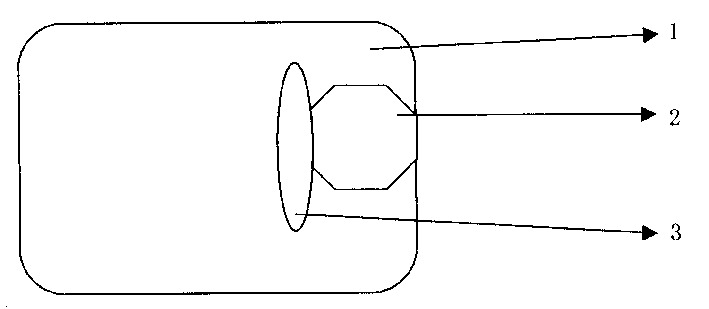

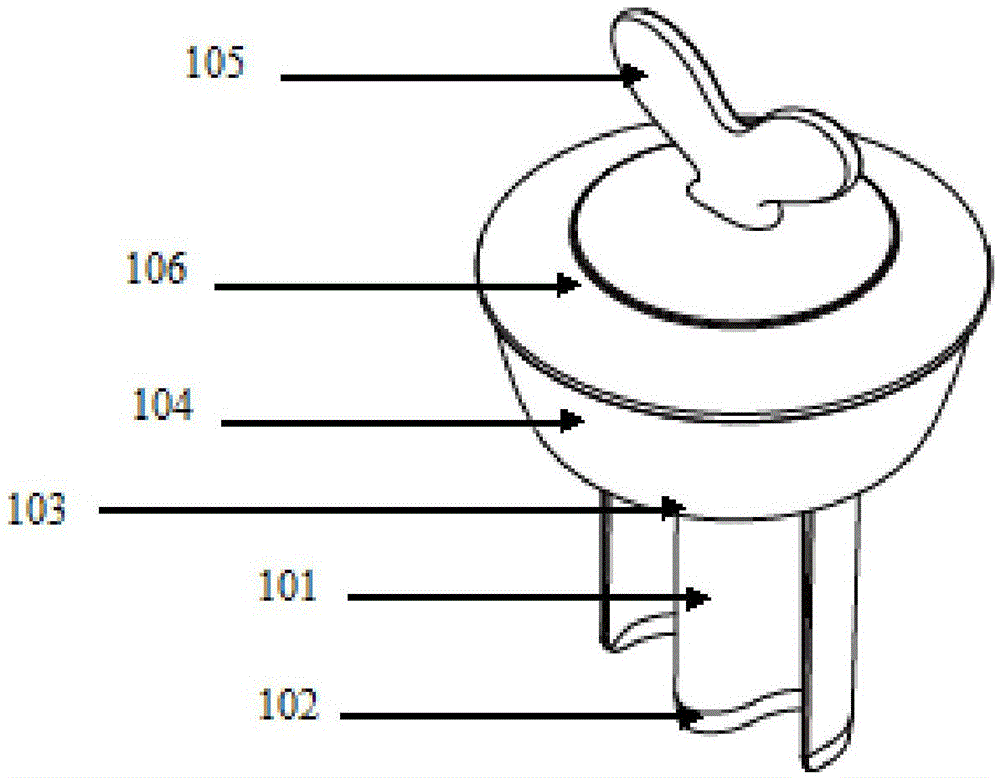

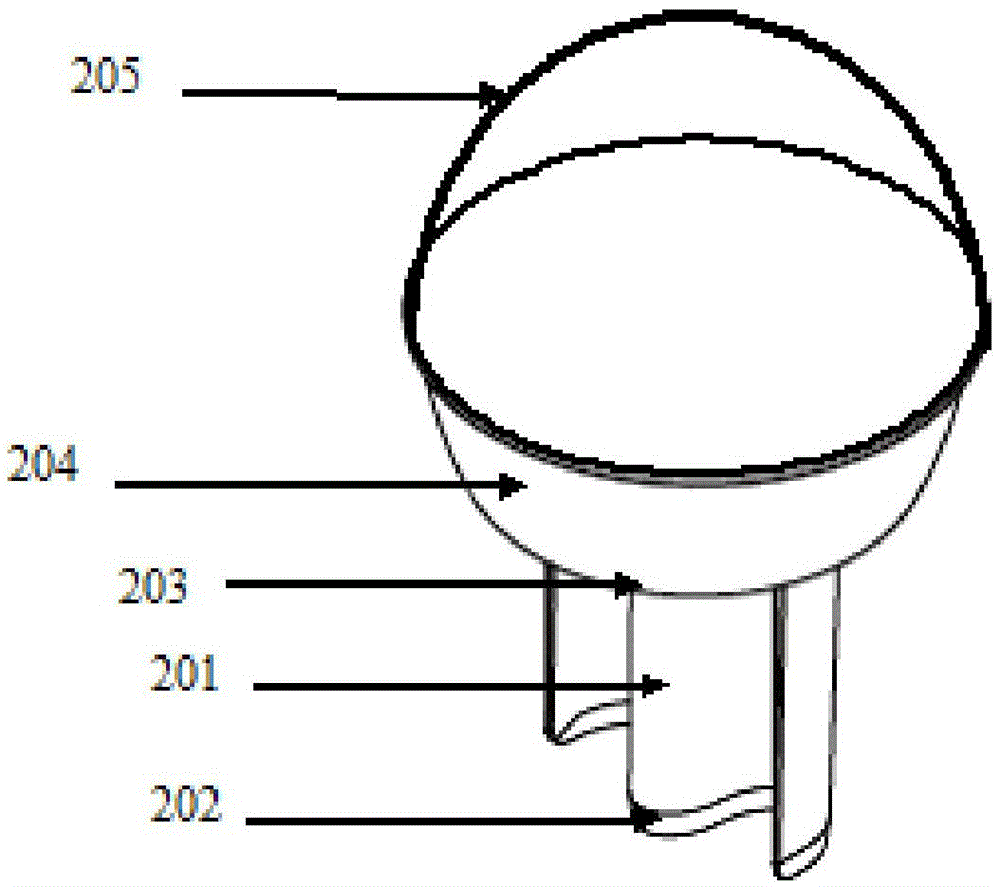

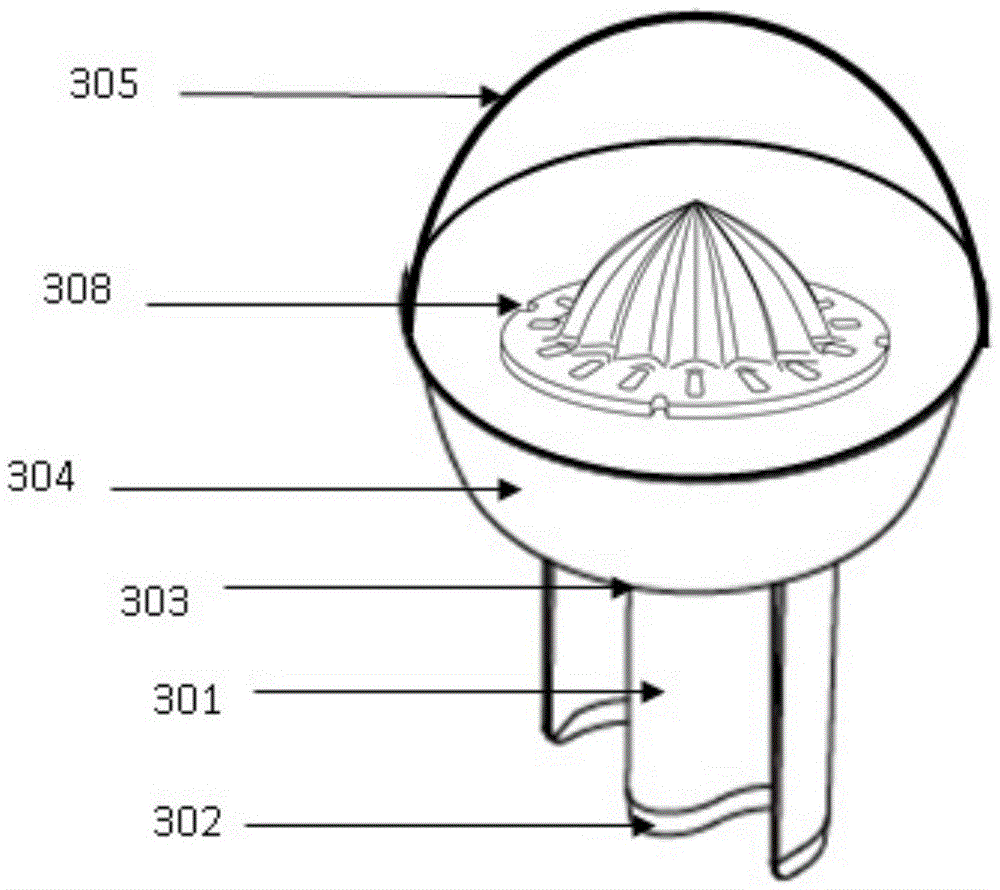

a food processor

InactiveCN104095560BLess chance of chewingChewing encouragementKitchen equipmentHandling foodFresh food

The invention relates to a food processor, comprising a container for placing food, a cutting member and a handle; the container includes an open end and a closed end; the cutting member includes a blade; The closed end is connected; the handle is connected to the container. The present invention can conveniently put the granular food into the bite food supplementary device, and increases the chance of the baby chewing. Therefore, fresh food can be chopped into granules with a simple principle, and the shape of the small potted plant is interesting and attractive, and it can be used as a small decoration when there is no need to handle food.

Owner:DONGGUAN KIDSME IND LTD

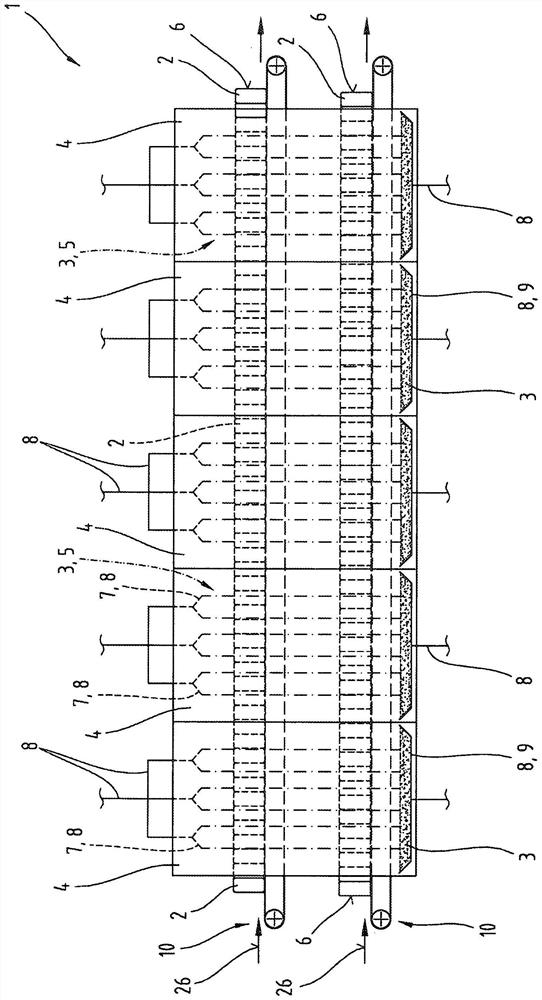

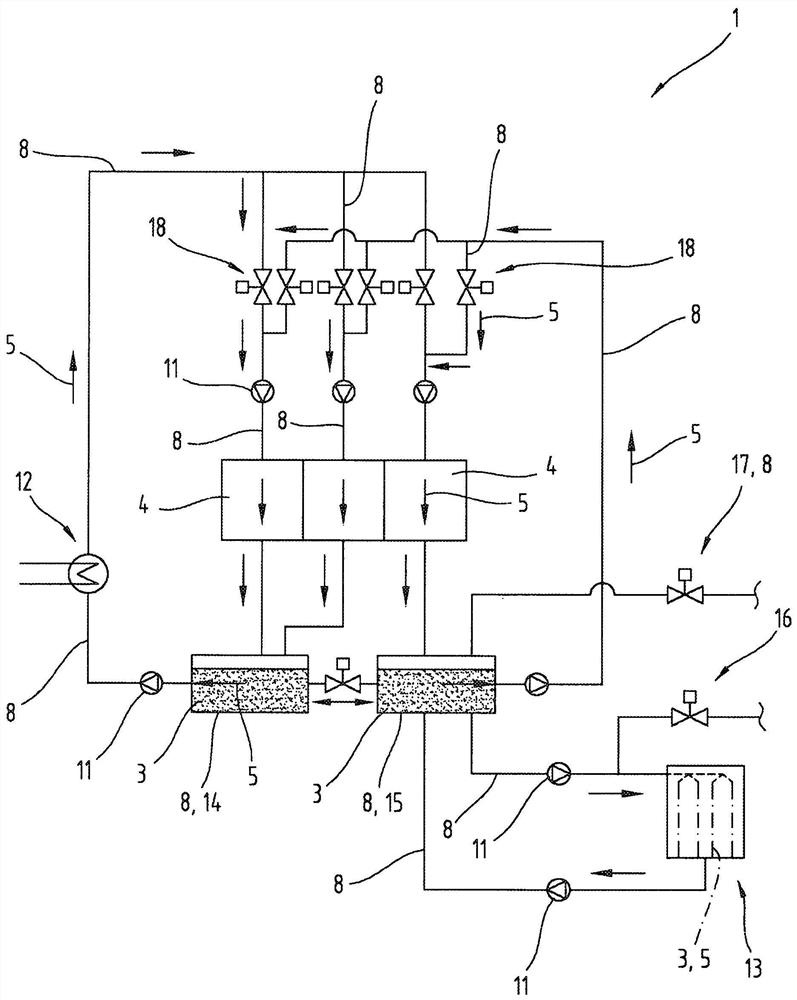

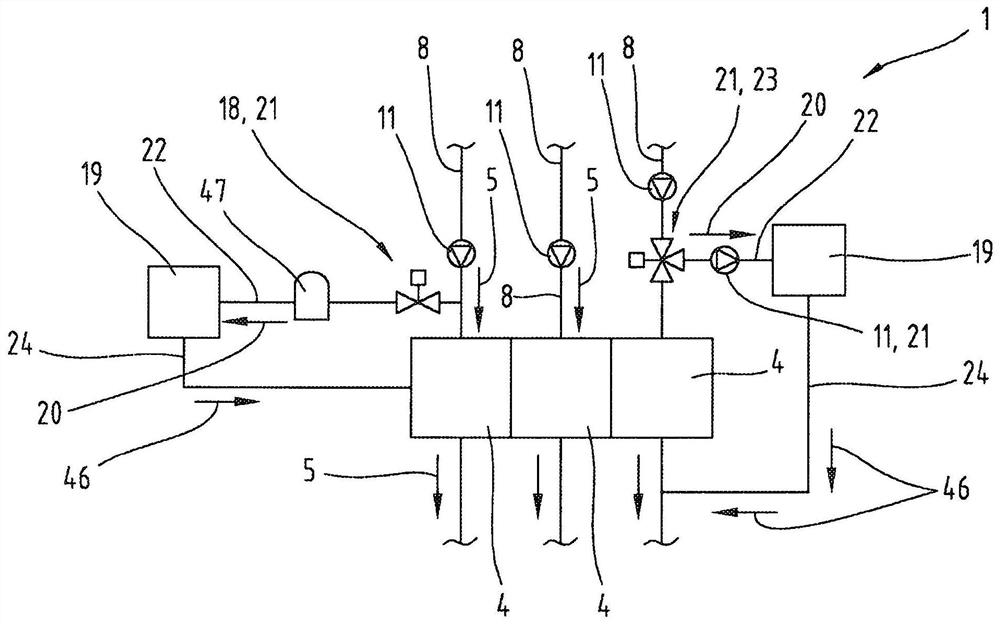

Method and apparatus for processing food and/or containers for containing food

ActiveCN107427039BWater treatment parameter controlWater/sewage treatment by irradiationHandling foodProcess engineering

The invention relates to a method and an apparatus for processing food and / or containers for containing food. Treatment of food and / or containers (2) with a process liquid (3) in at least one treatment zone (4), wherein the process liquid (3) is at least partially in the circuit after the treatment of the food and / or containers (2) Return to the processing area (4) or processing areas (4). It is provided here that in a continuous process operation at least part or all of the process liquid (3) is used per unit of time to form at least one flow (20) of the process liquid (3) by means of at least one membrane filter device (19) filtering the resulting stream (20) and at least partially re-feeding the filtered stream (46) to the element (8) containing and / or conducting the process liquid (3) and / or to the treatment zone (4).

Owner:RED BULL GMBH

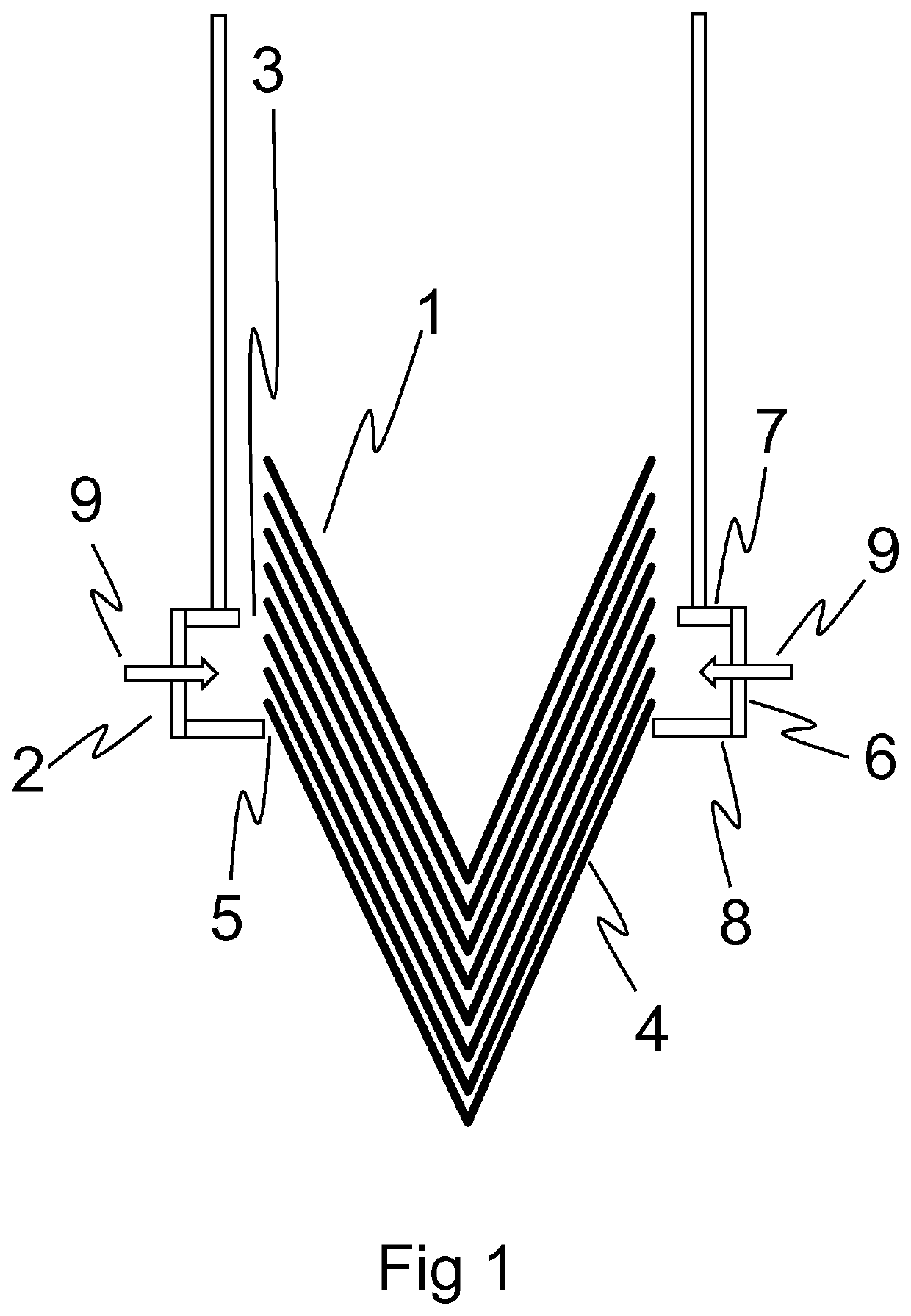

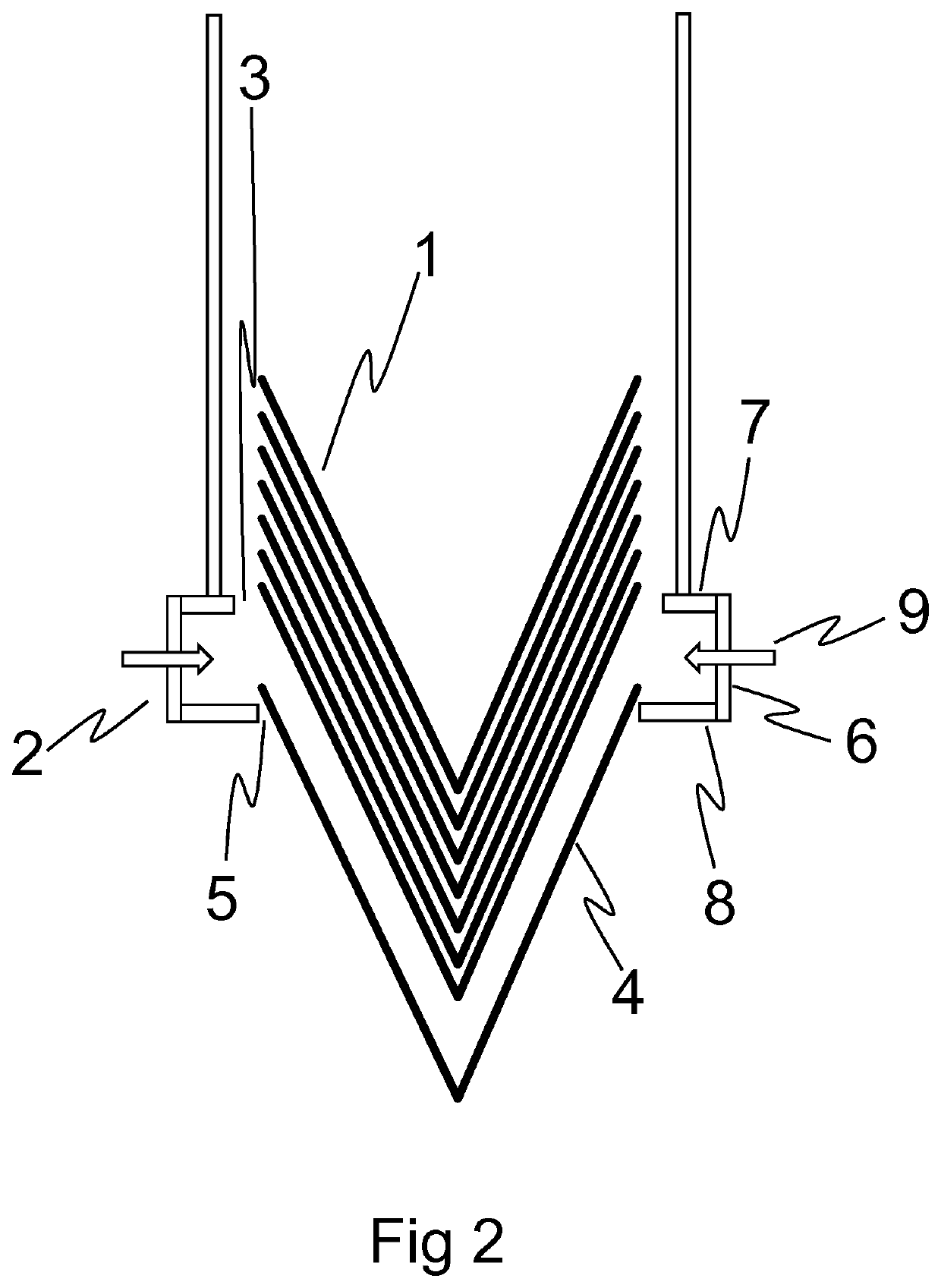

Apparatus and process for handling food packaging

The invention provides an apparatus for separating a cone sleeve (4) from a nested stack of cone sleeves (1) the apparatus comprising a chamber (2) having an upper (7) and a lower (8) surface connected by a wall or walls (6), the upper surface (7) having an upper circular opening (3) and the lower surface (8) having a lower circular opening (5) characterized in that the upper circular opening (3) has a circumference of from 100-135% of the maximum circumference of the cone sleeve (4), the lower circular opening (5) has a circumference of from 95-99.5% of the maximum circumference of the cone sleeve (4), and the chamber (2) has inlets (9) connectable to a pressurized gas supply. The invention also provides process that employs the apparatus, the process comprising the steps of providing a stack of nested cone sleeves (1); placing the lowermost end of the stack into the chamber (2) from above the chamber (2); and allowing the lowermost cone sleeve (4) to sit within the lower circular opening (5) and allowing the cone sleeves above the lower-most cone sleeve (4) to protrude from the top of the chamber (2) characterized in that pressurized gas is introduced into the chamber via the inlets (9) thereby to create an elevated pressure within the chamber (2).

Owner:CONOPCO INC D B A UNILEVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com