A delivery mechanism for an automatic meal vending machine

A technology of automatic food vending machine and driving mechanism, which can be applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., and can solve the problem of uneven force , high power consumption, long time consumption and other problems, to achieve the effect of shortening the conveying time, short moving distance and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

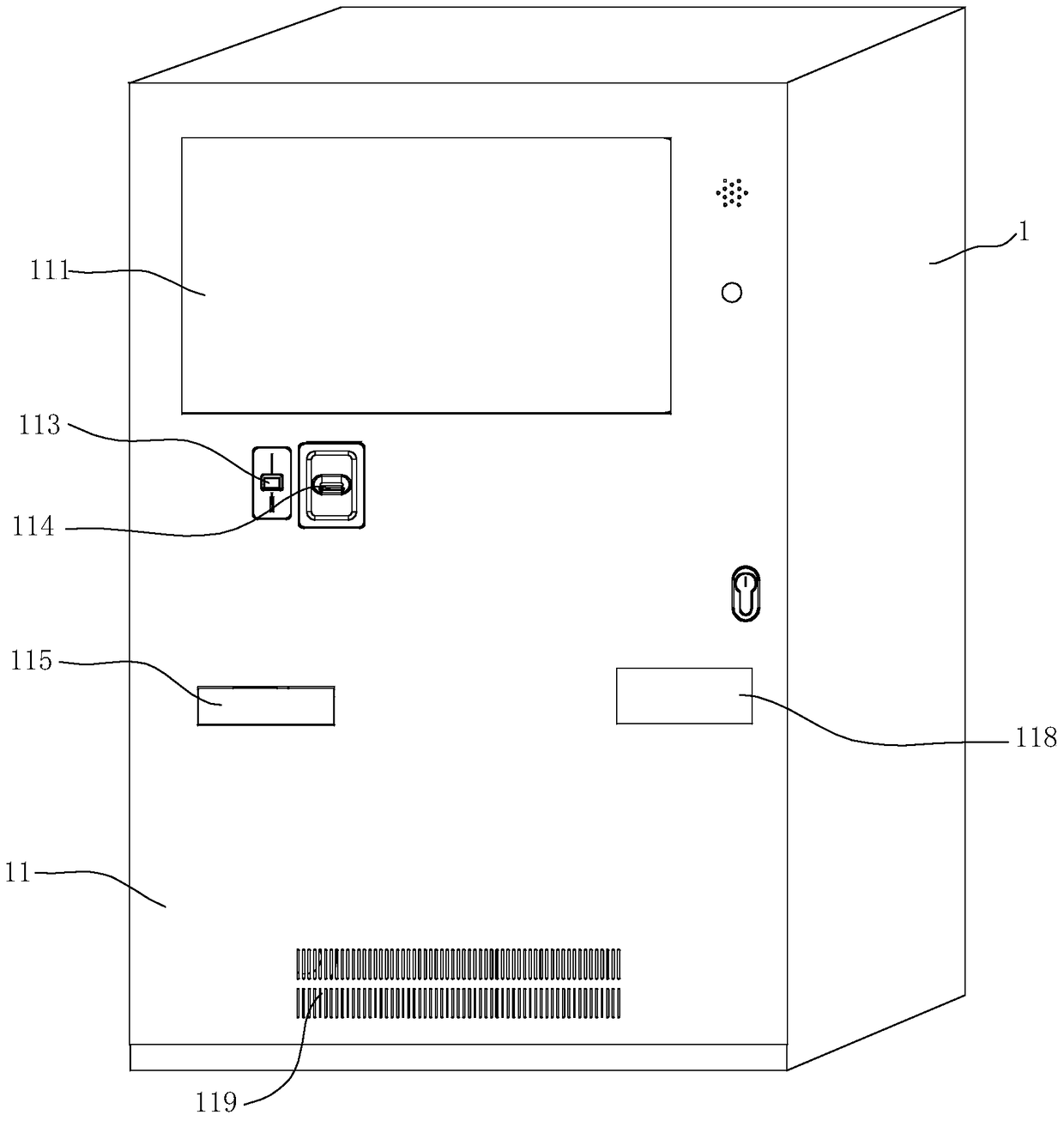

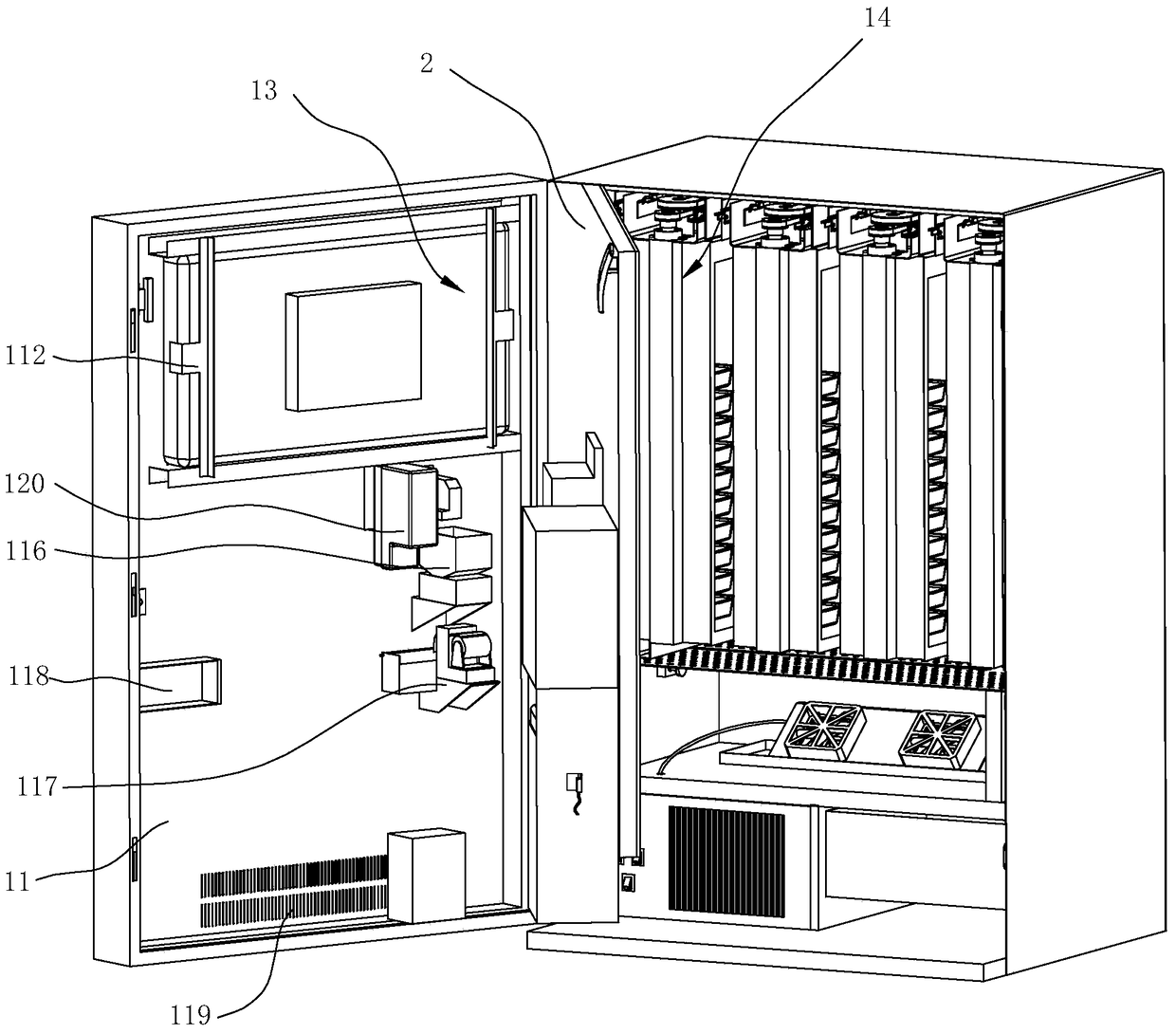

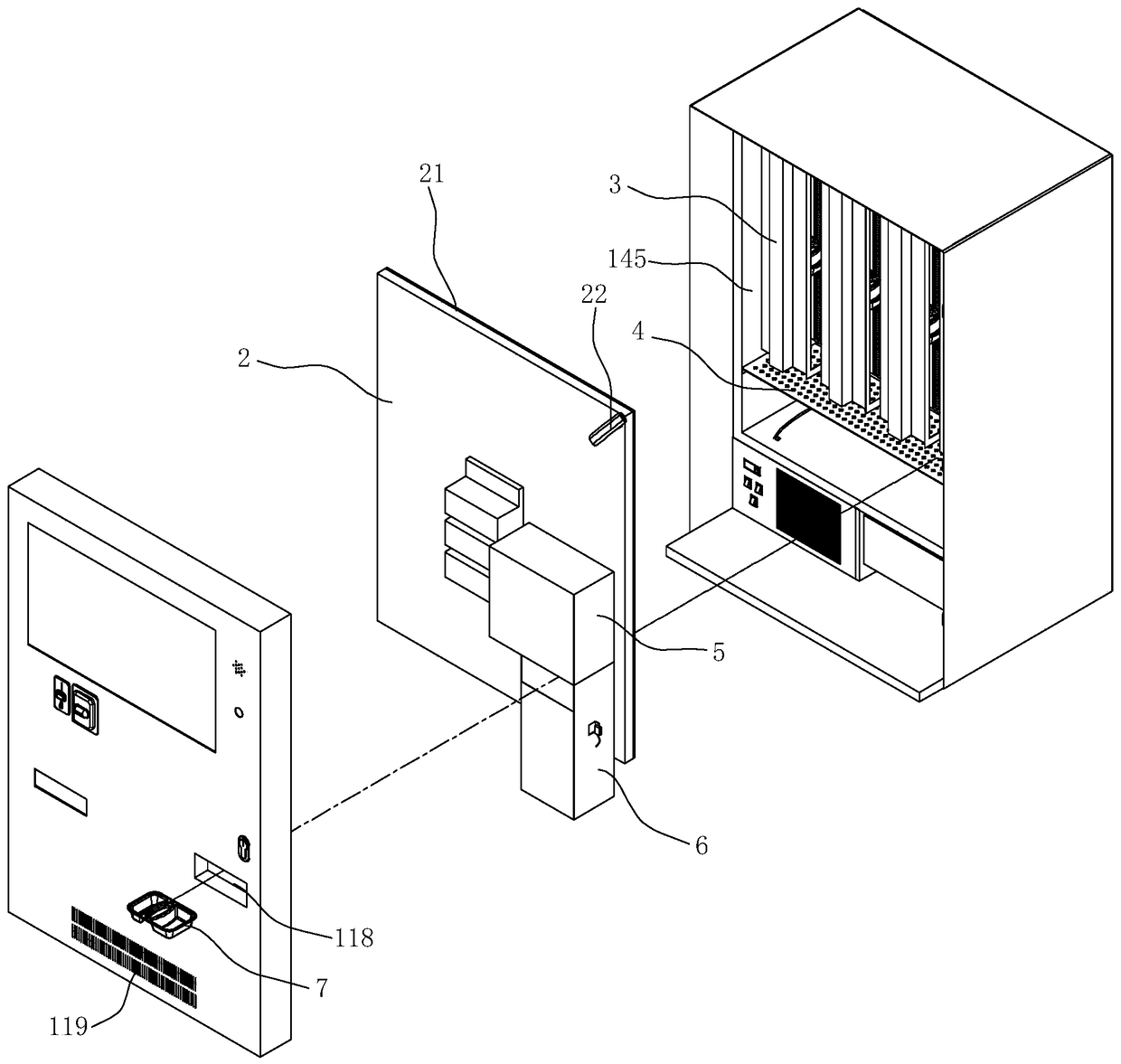

[0035] see Figure 1 ~ Figure 3 , an automatic meal vending machine, comprising a closed housing 1 forming an accommodating space, the housing 1 comprising a top plate, a bottom plate and surrounding panels, wherein the front side panel 11 in the surrounding panels forms a cabinet door, and the front side The panel 11 is provided with a display 111 with a touch screen. The display 111 can be used for displaying menus, ordering operations, etc., and the display 111 is fixed to the front panel 11 by a display bracket 112 arranged on the back of the front panel 11 . The front side panel 11 is also provided with banknote detection and banknote delivery devices, including a coin slot 113, a banknote inlet 114, and a small ticket outlet 115 for change, which are used to confirm payment after ordering, and to confirm the money on the front side. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com