Fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal

A three-axis servo, thermal fluid solid technology, applied in the direction of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of single influencing factors of permeability, cumbersome measurement process, and unguaranteed accuracy, etc., to achieve Good air permeability, stable loading process, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

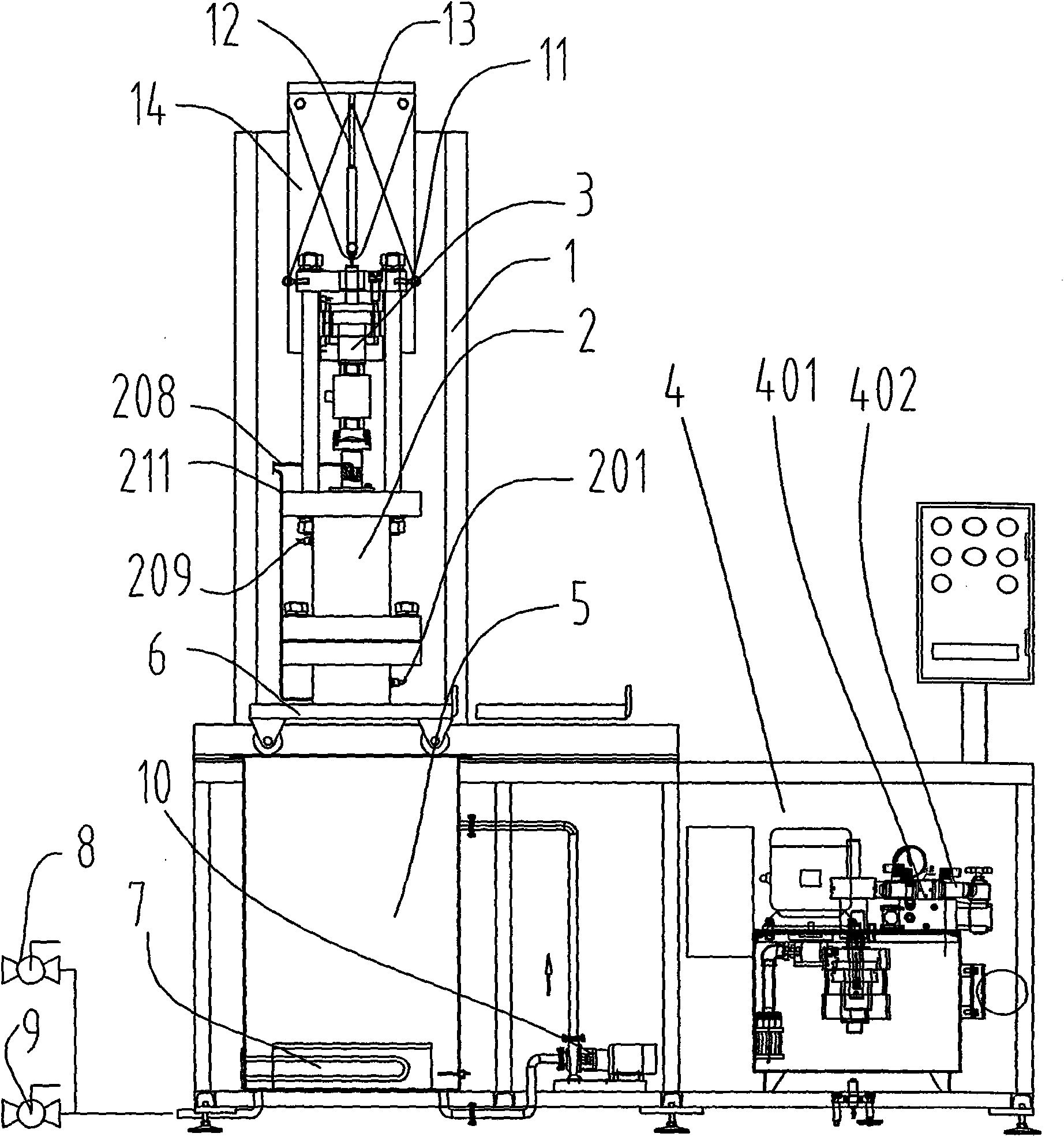

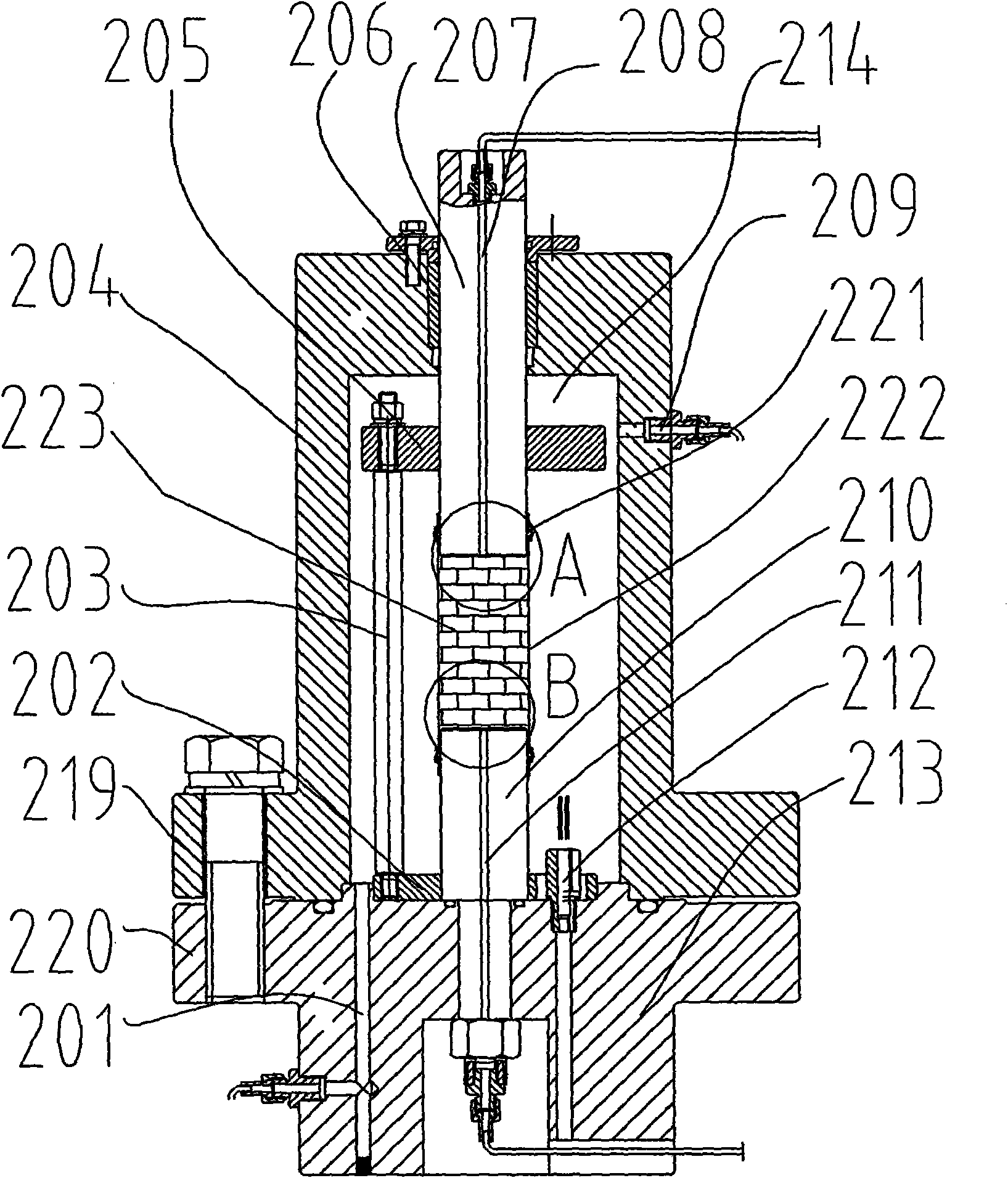

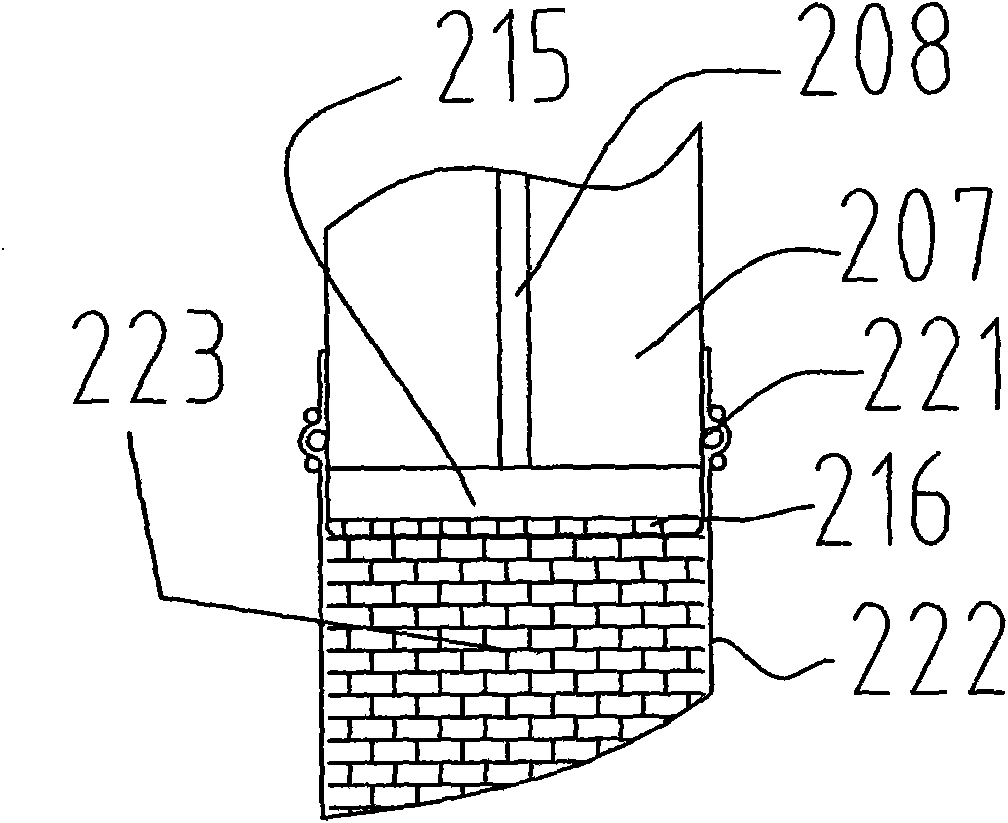

[0055] See figure 1: The heat-fluid-solid coupled three-axis servo percolation device for gas-containing coal shown includes an elevator frame 1, a hydraulic servo control system 4, an axial loading device 3 installed on the top of the elevator frame 1, and an axial loading device 3 installed in the middle of the elevator frame 1 and connected in the axial direction The triaxial pressure chamber 2 at the lower end of the loading device 3 is provided with a constant temperature water tank 5 below the triaxial pressure chamber 2, and a movable workbench 6 is arranged on the constant temperature water tank 5, and the lower end of the triaxial pressure chamber 2 is placed on On the movable workbench 6;

[0056] A heating pipe 7 is arranged in the constant temperature water tank 5, and a pipeline is connected to the constant temperature water tank 5, and a water inlet valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com