Fuel supply pump

a technology of fuel supply pump and pump body, which is applied in the direction of liquid fuel engine, machine/engine, positive displacement liquid engine, etc., can solve the problems of insufficient degree of pressurization and fuel flow rate to allow higher power of diesel engine, complicated assembly work, and insufficient degree of pressurization and fuel flow rate, so as to achieve a large flow rate and increase fuel efficiency. , the effect of increasing the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the fuel supply pump will be described concretely with proper references to the drawings.

1. Basic Configuration of Fuel Supply Pump

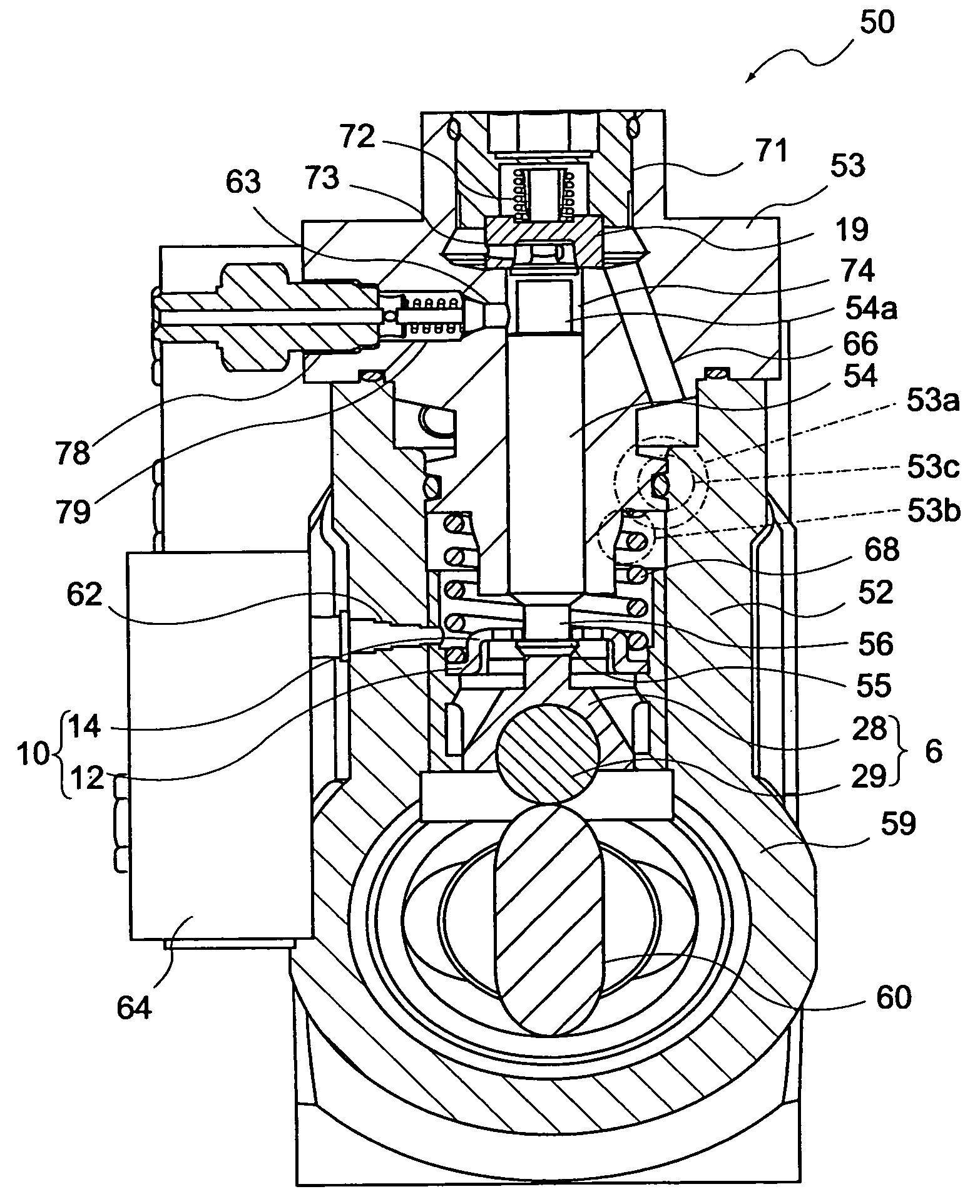

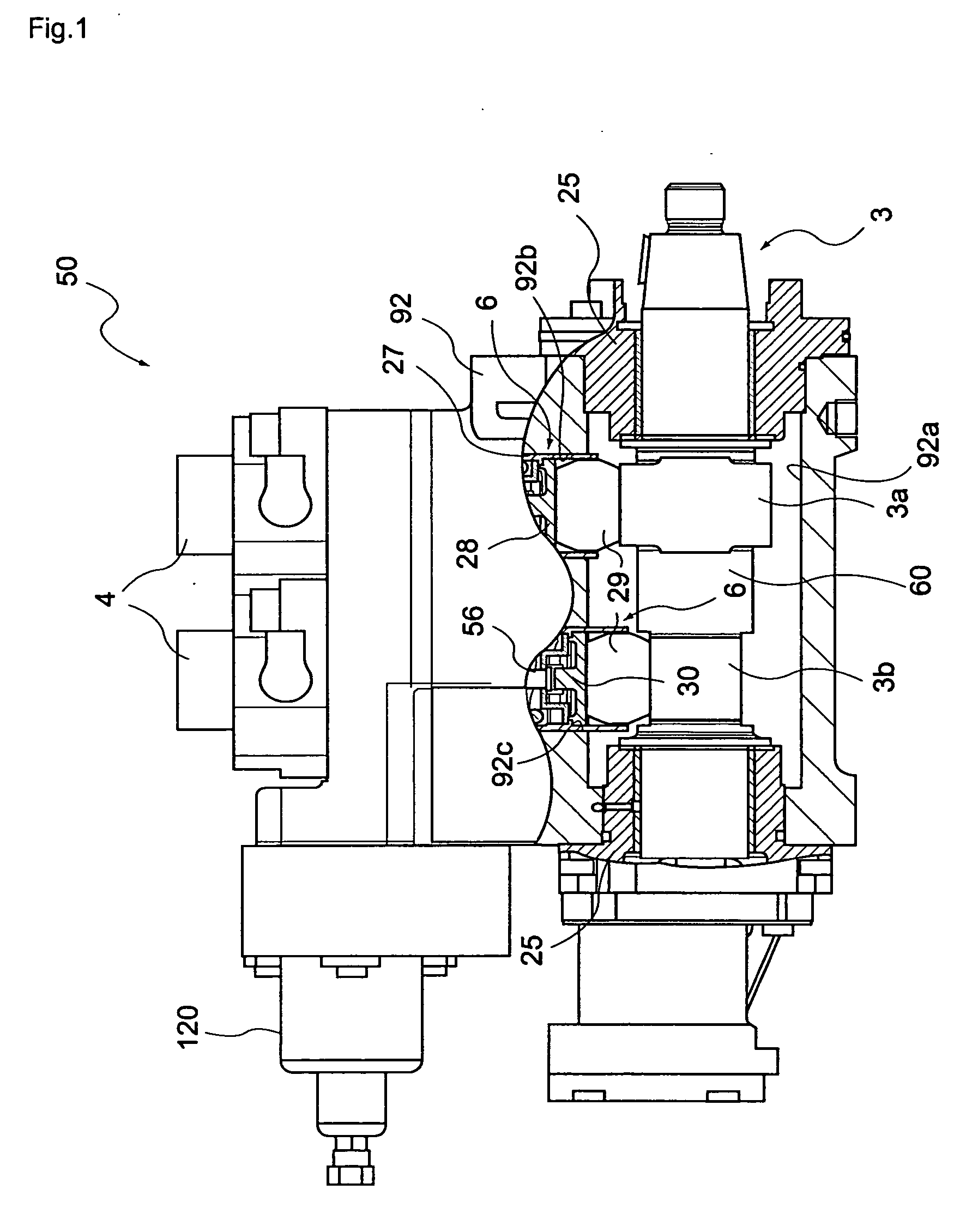

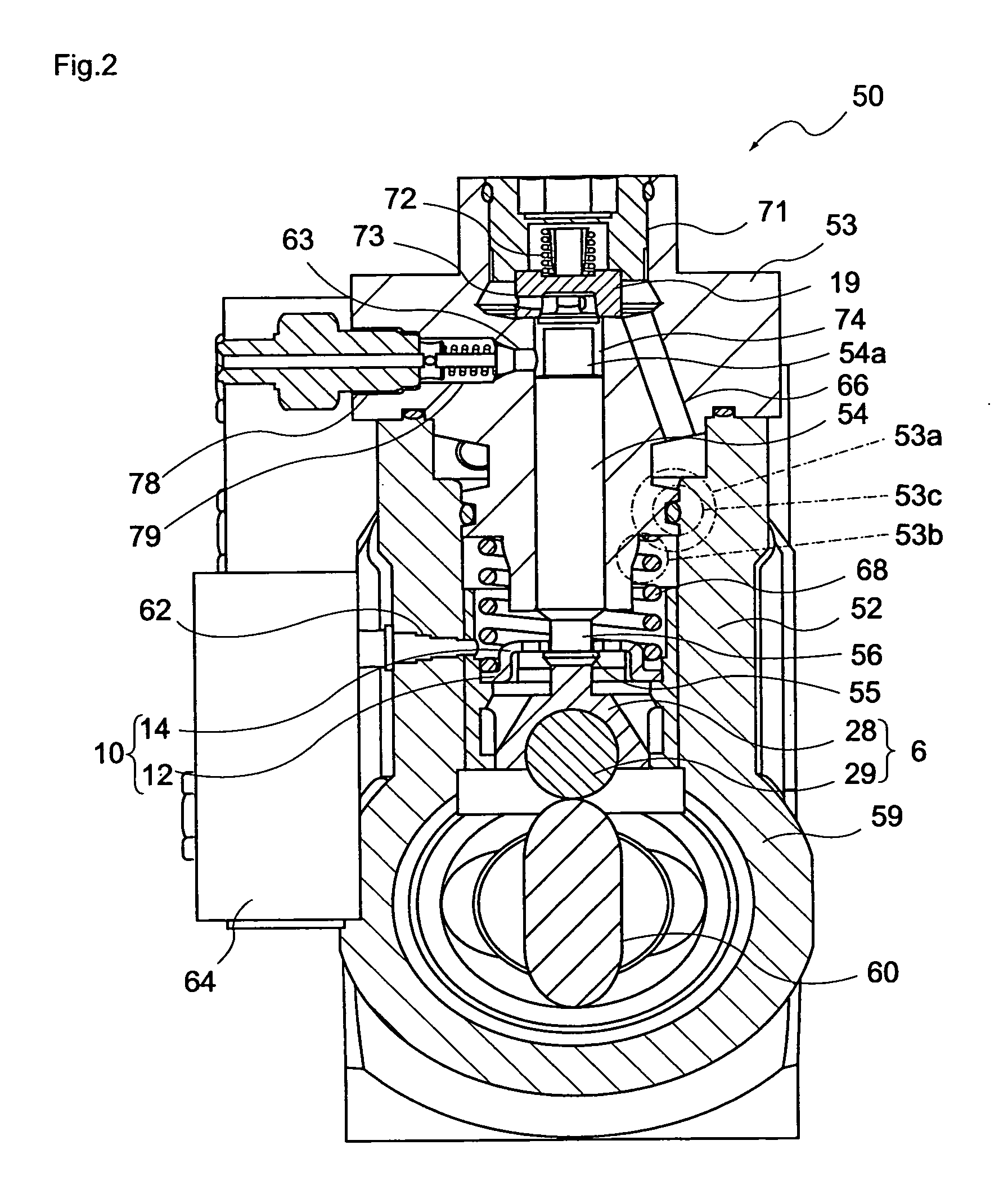

[0042] As shown in FIG. 1 and FIG. 2, the present embodiment is a fuel supply pump 50 comprising: a pump housing 52 having a cylindrical space opened from end to end in the vertical direction; a plunger barrel 53 installed in the upper opening portion of the pump housing 52; a plunger 54 for pressurizing fuel, which is installed in the plunger barrel 53 and the cylindrical space of the pump housing 52 so as to be allowed to move up and down; a cam 60 installed in rotation way below the plunger 54 and integrated with a cam shaft 3 inserted into the pump housing 52; a tappet structure body 6 installed between the cam 60 and the plunger 54 and provided for transmitting a upward or downward movement of the cam 60 caused by the rotation of the cam shaft to the plunger 54; and a return spring 68 for setting lowering force to the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com