Differential gear pad-choosing measuring system and measuring method

A measurement system and measurement method technology, applied in the direction of measurement devices, machine gear/transmission mechanism testing, instruments, etc., can solve problems such as low production efficiency, large artificial randomness, and unstable product quality, so as to improve work efficiency and reduce The effect of labor intensity and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

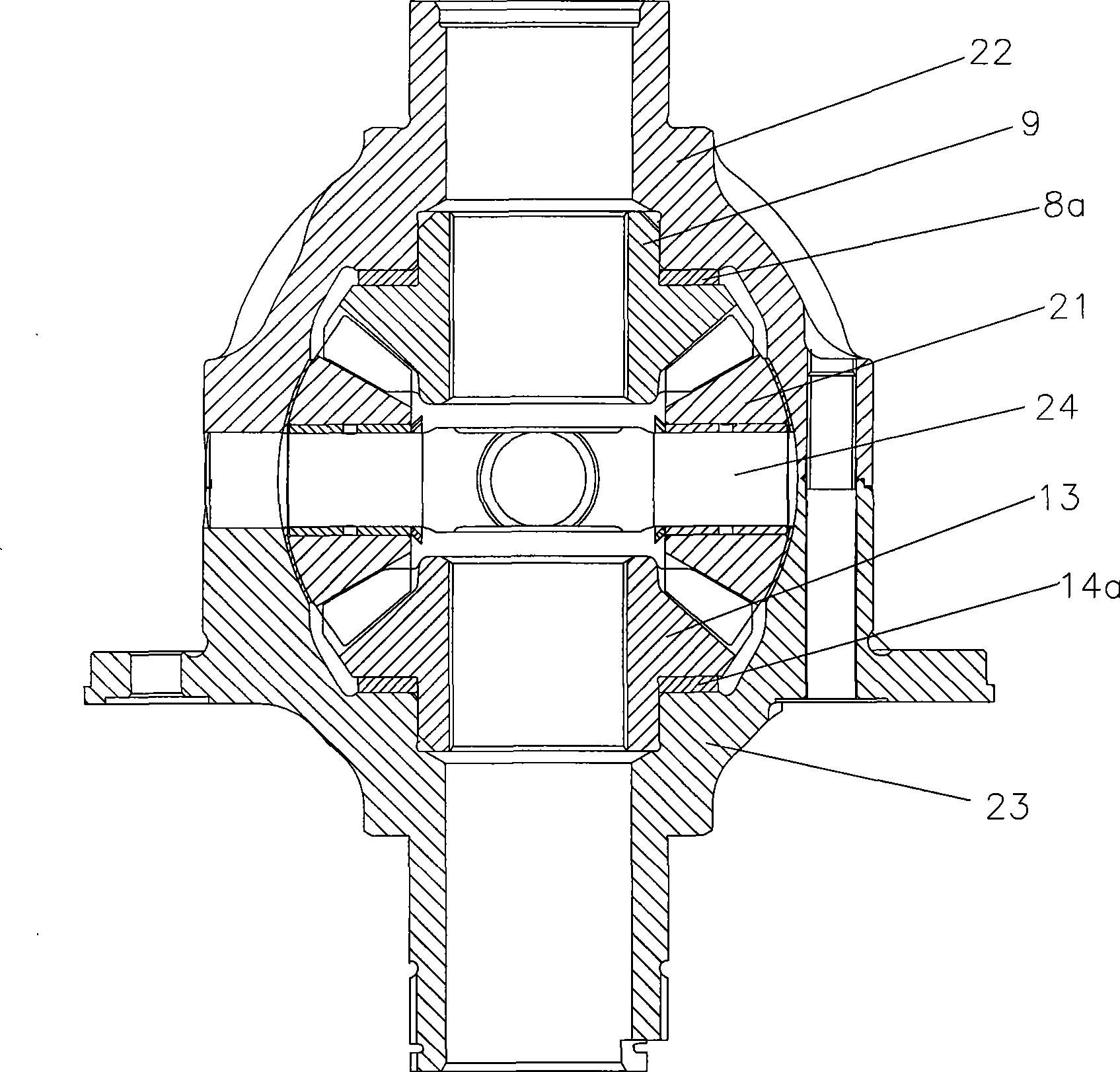

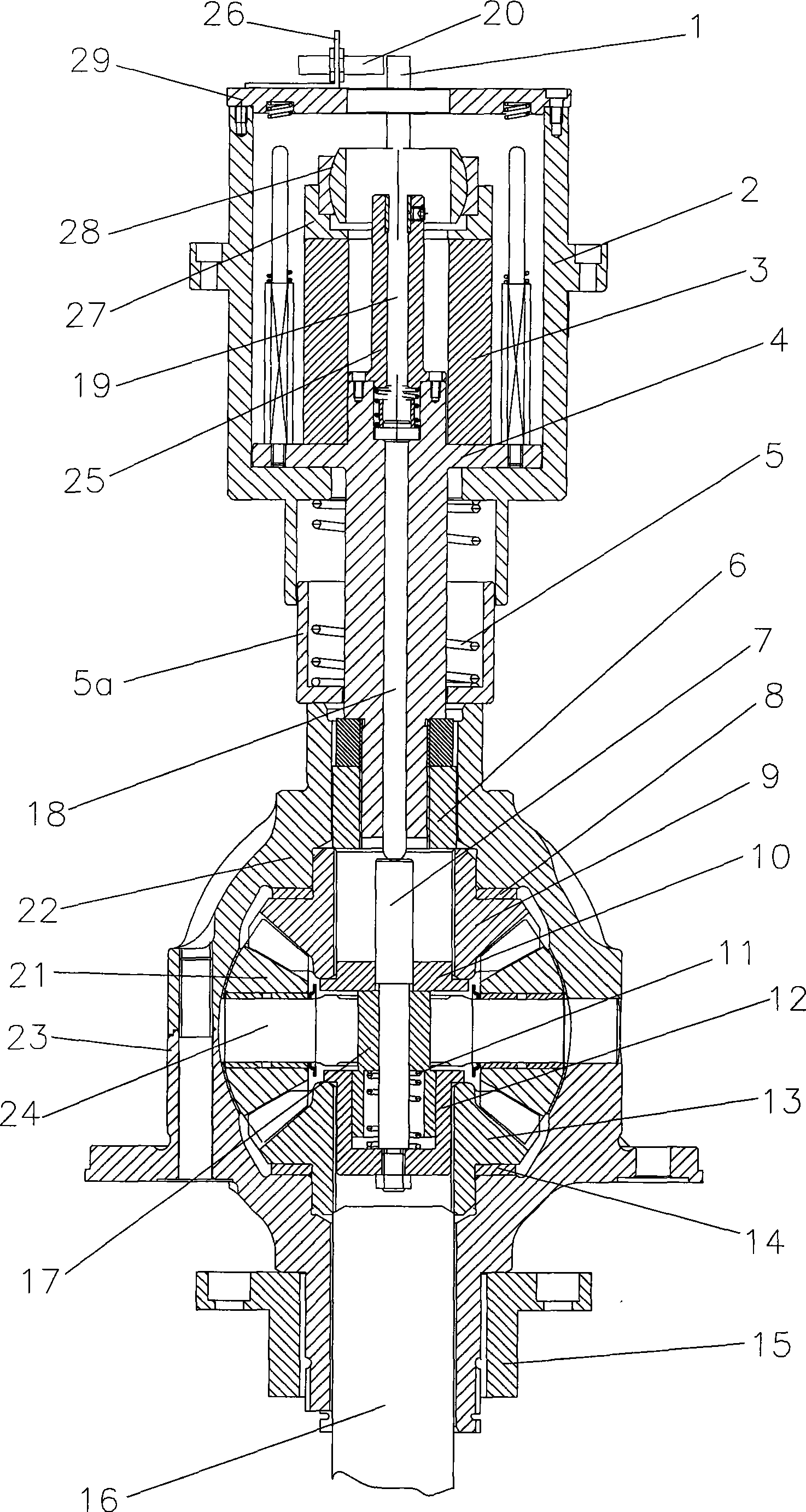

[0023] See figure 2 , The system is set up as follows: Place the left differential housing 23 on the positioning table 15, and place the lower simulation shim 14 between the left differential housing 23 and the lower half shaft gear 13; on the four ends of the cross shaft 24 of the test piece The planetary gear 21 is set and placed in the shaft hole of the left housing 23 of the differential; the lower jacking sleeve 12 located in the shaft hole of the lower half shaft gear 13 is hung on the lower half shaft gear 13 with its upper shoulder. .

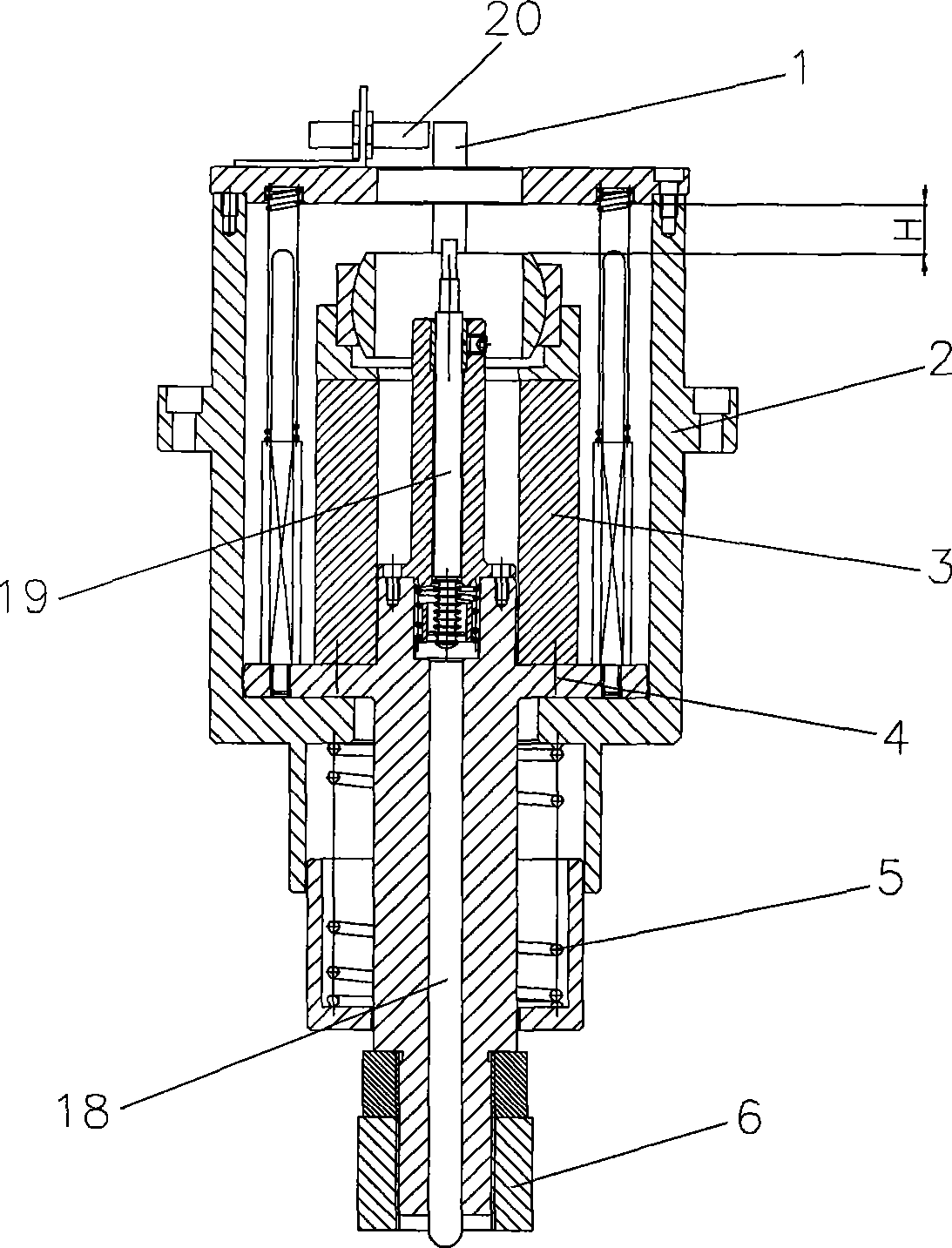

[0024] See figure 2 , image 3 , The measuring tappet 7 and the lower top tightening sleeve 12 are fixedly connected, and the tightening spring 11 is placed between the measuring tappet 7 and the lower top tightening sleeve 12. The spring guide sleeve 17 is sleeved on the measuring tappet 7 and is tightened by the tightening spring 11 Support; set the upper top plate 10 to be press-fitted on the spring guide sleeve 17, the outer periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com