Phaser-actuated continuously variable valve actuation system with lost motion capability

a technology of continuously variable valves and phasers, applied in the direction of valve arrangements, machines/engines, mechanical equipment, etc., can solve the problems of requiring significantly more power than a conventional fixed-lift and fixed-duration valvetrain system, and the cost of a conventional engine itself, and achieve the effect of improving the performance of both spark-ignited and compression-ignited engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The benefits and advantages of a VVA system in accordance with the present invention may be better appreciated by first considering a relevant prior art WA system for varying valve opening timing, valve closing timing, and valve lift.

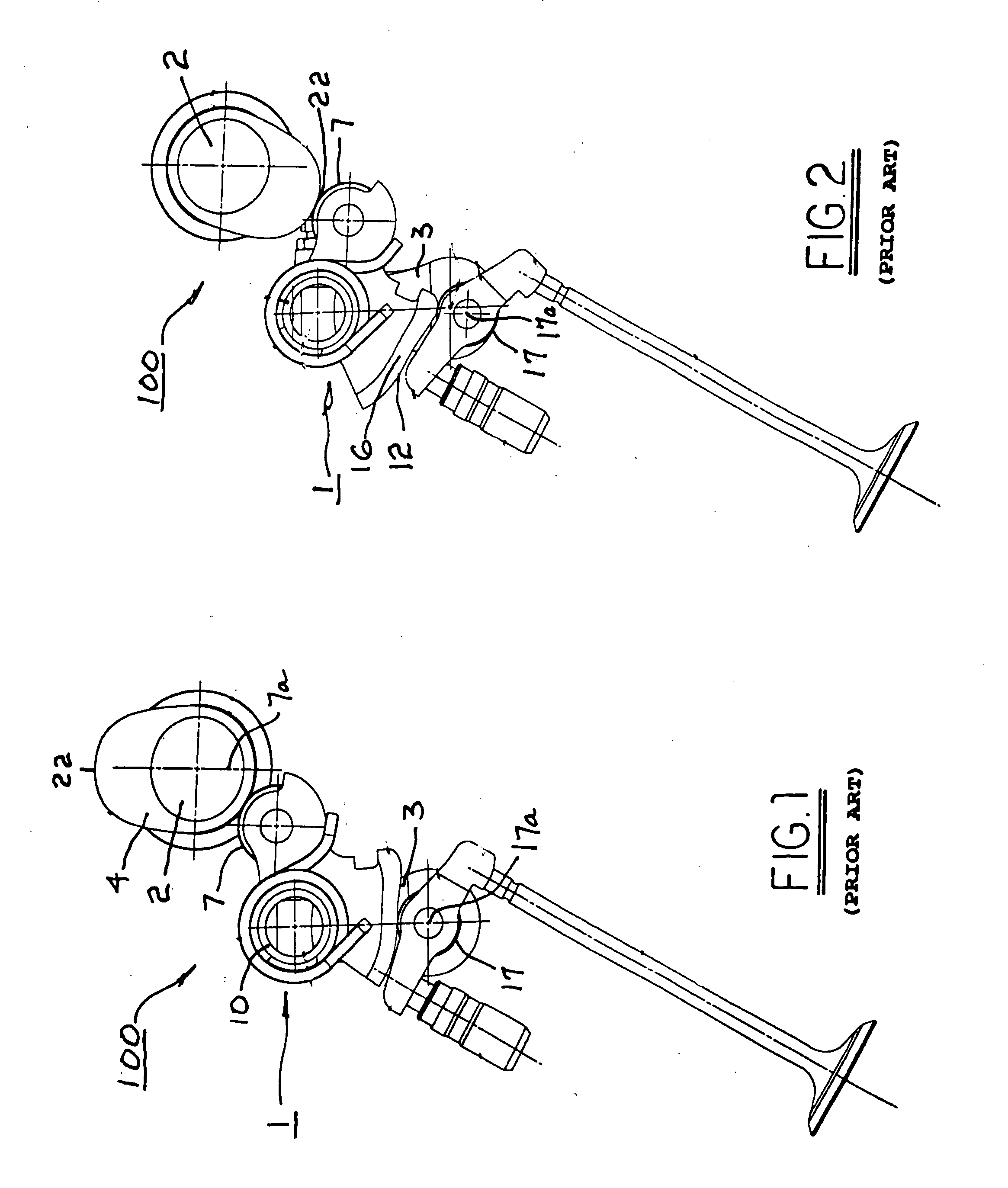

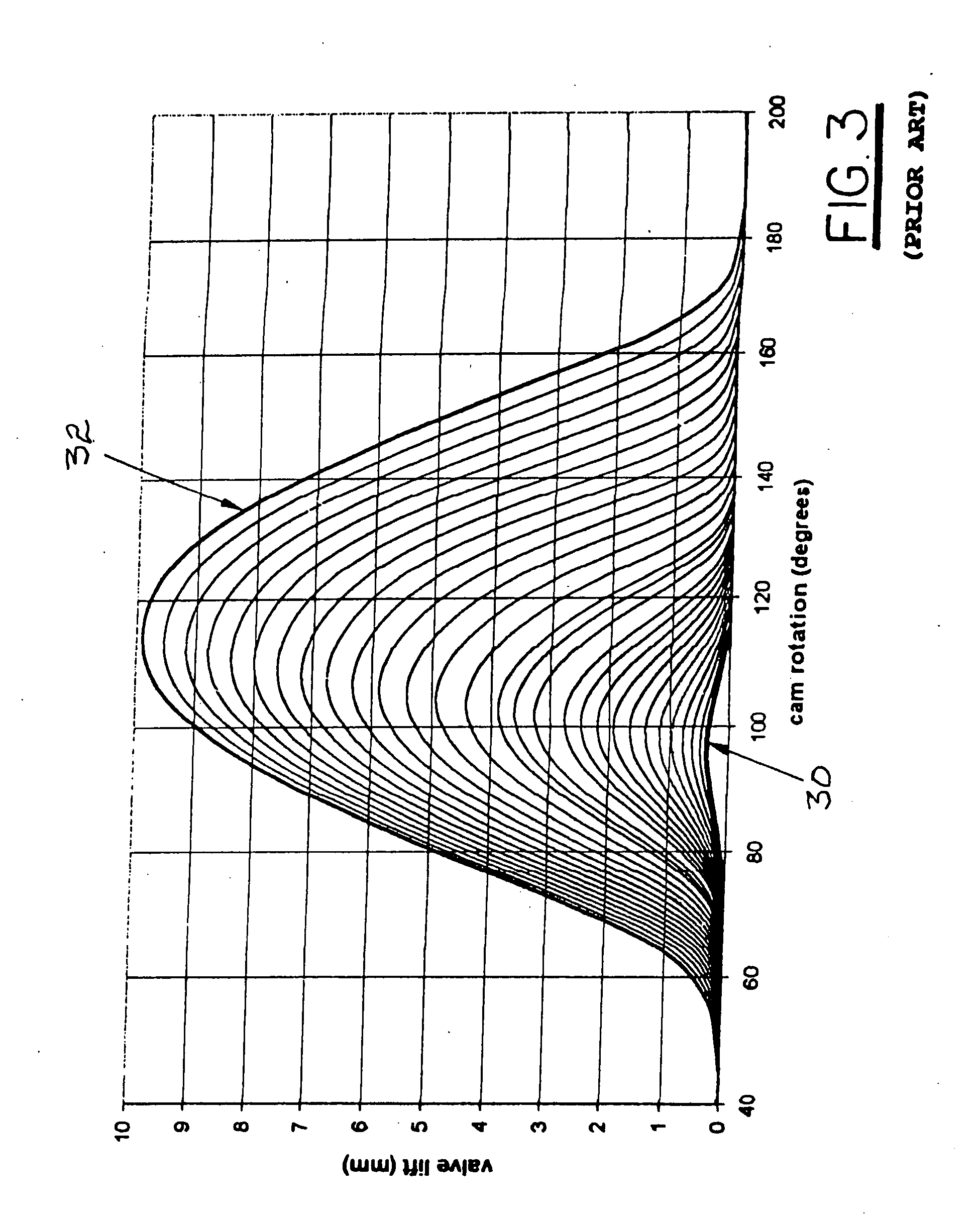

[0034]Referring to FIGS. 1 through 3, a prior art VVA valvetrain system 100, substantially as disclosed in Published United States Patent Application No. 2007 / 0125329, includes a control shaft assembly 1 shown at the intake valve camshaft 2 of an inline 4-cylinder engine which may be spark-ignited or compression-ignited. Control shaft assembly 1 manages an engine's gas exchange process by varying the angular position of the control shaft assembly. In FIGS. 1 and 2, system 100 is shown in its full engine load position. In FIG. 1, the input camshaft is on its base circle portion, and in FIG. 2, the input camshaft is at its peak lift point. High lift events with full duration are produced by the system whenever the control shaft arms 3 are in the nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com