Speed adjustment control system of steam turbine

A control system, steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

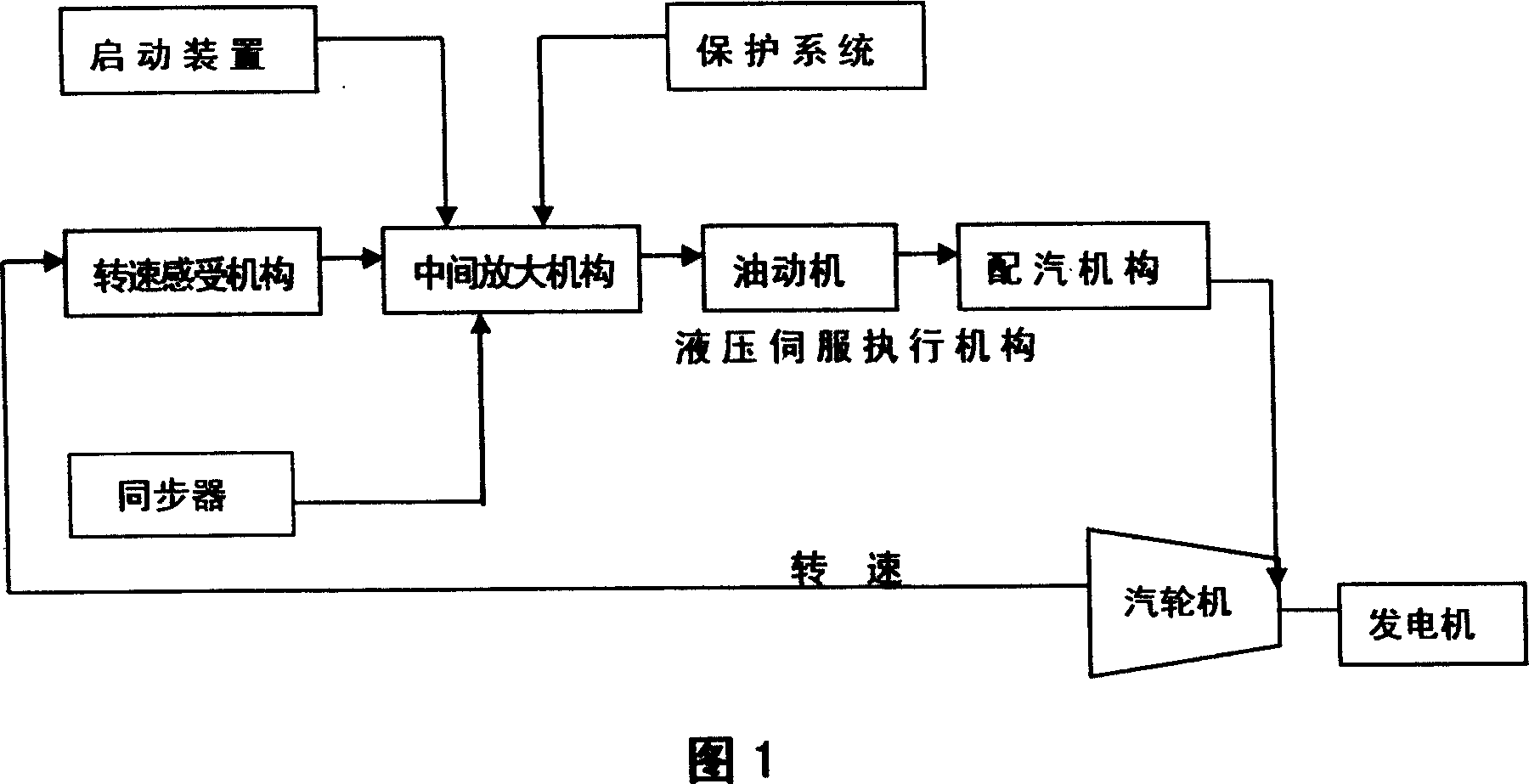

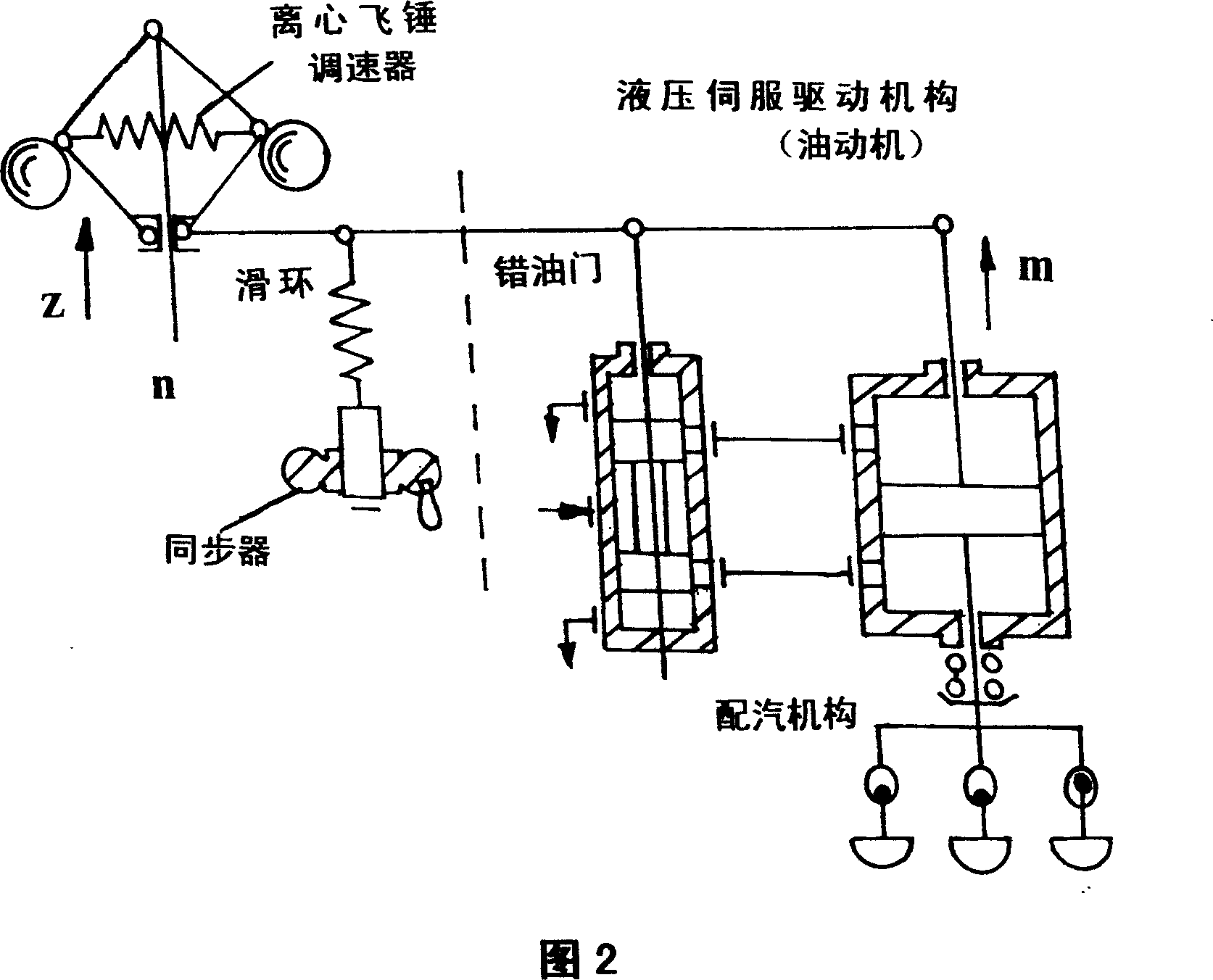

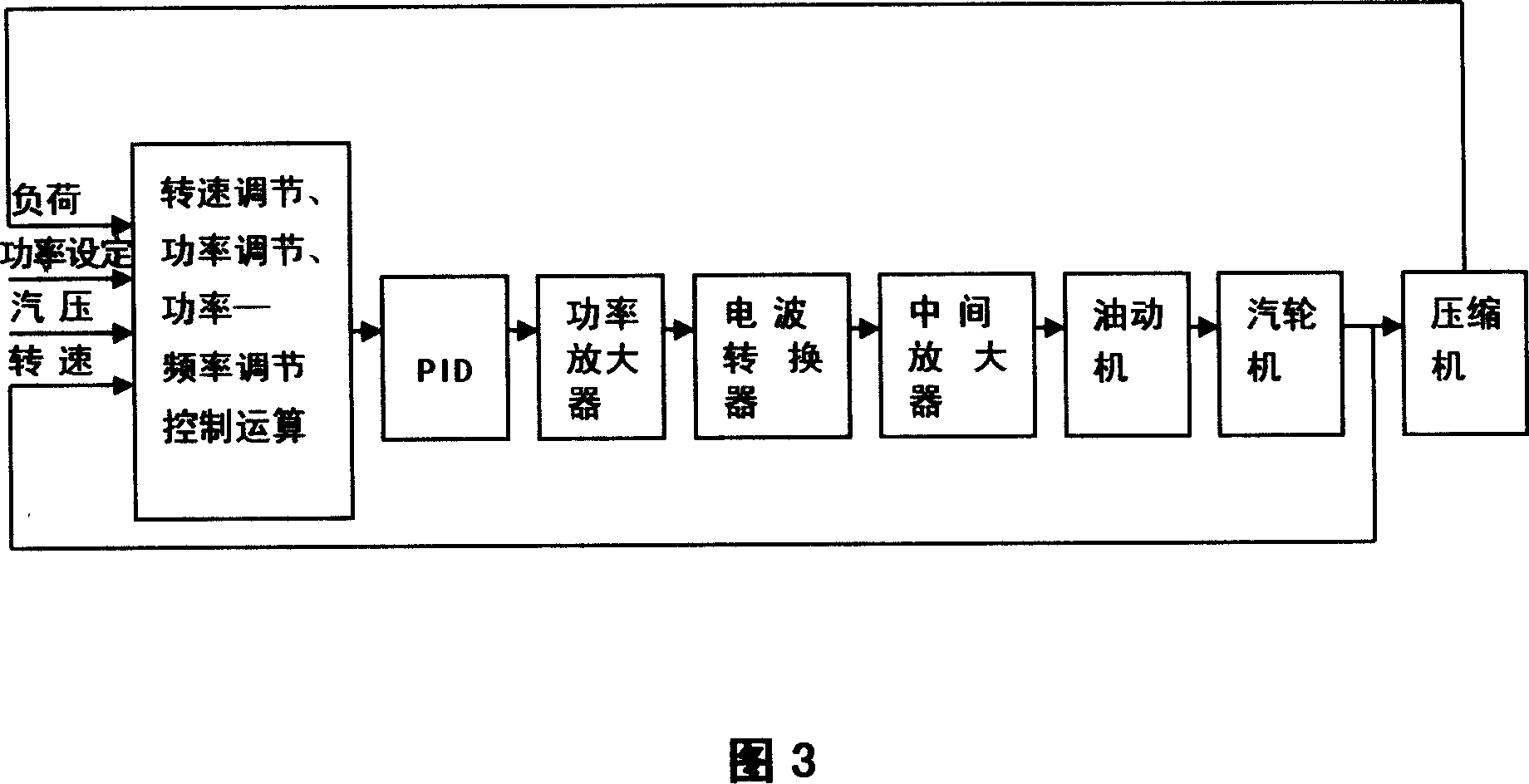

[0016] As shown in the figure, the speed control system of the steam turbine includes: a speed sensing mechanism, an intermediate amplification mechanism, a synchronizer, a starting device, an oil motor, and a steam distribution mechanism; the speed sensing mechanism receives the speed signal of the steam turbine rotor and Transform into a primary control signal; the intermediate amplifier amplifies the power of the primary control signal sent by the speed sensing mechanism, and performs control calculations according to the adjustment target; the oil motor generates the driving force to drive the steam distribution mechanism according to the control signal of the intermediate amplifier , and reach the predetermined opening position; the steam distribution mechanism converts the stroke of the oil motor into the opening of each regulating valve, so that the steam intake of the steam turbine and the stroke of the oil motor are corrected to an approximately linear relationship; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com