Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Improve oil separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

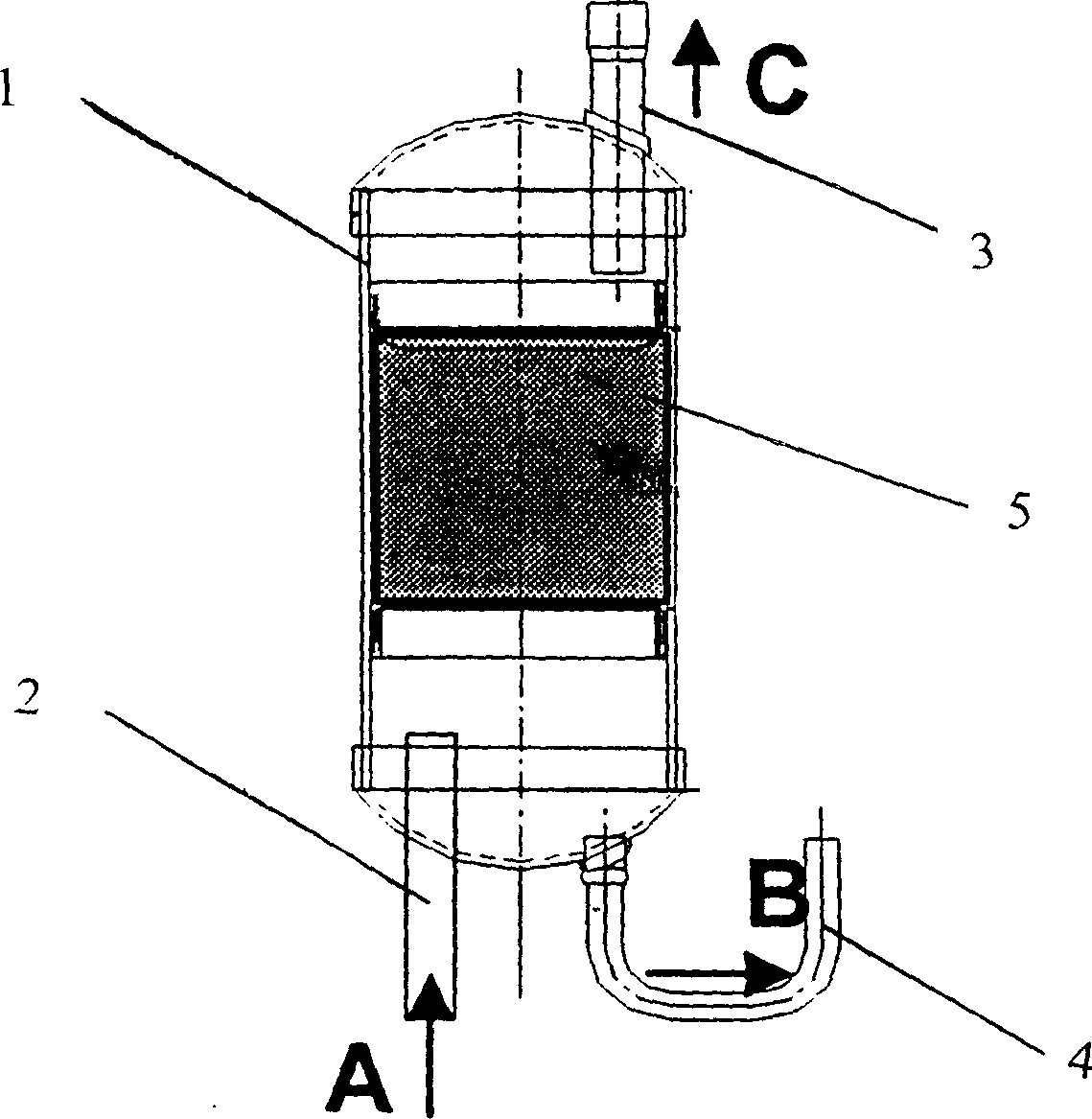

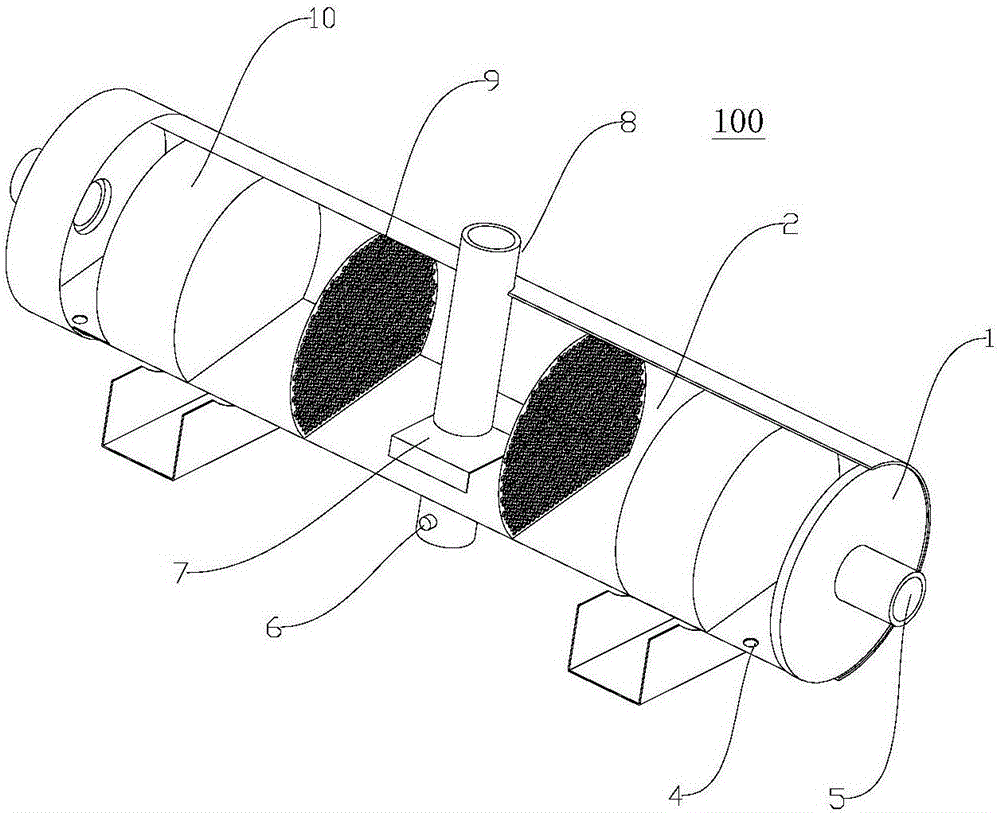

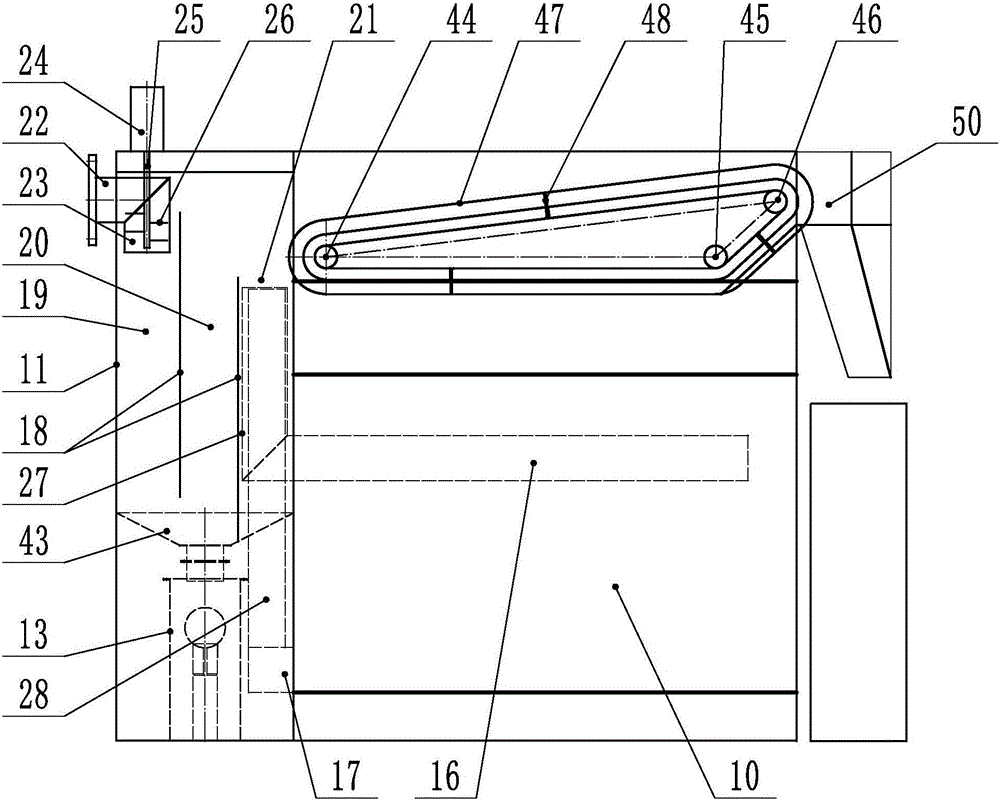

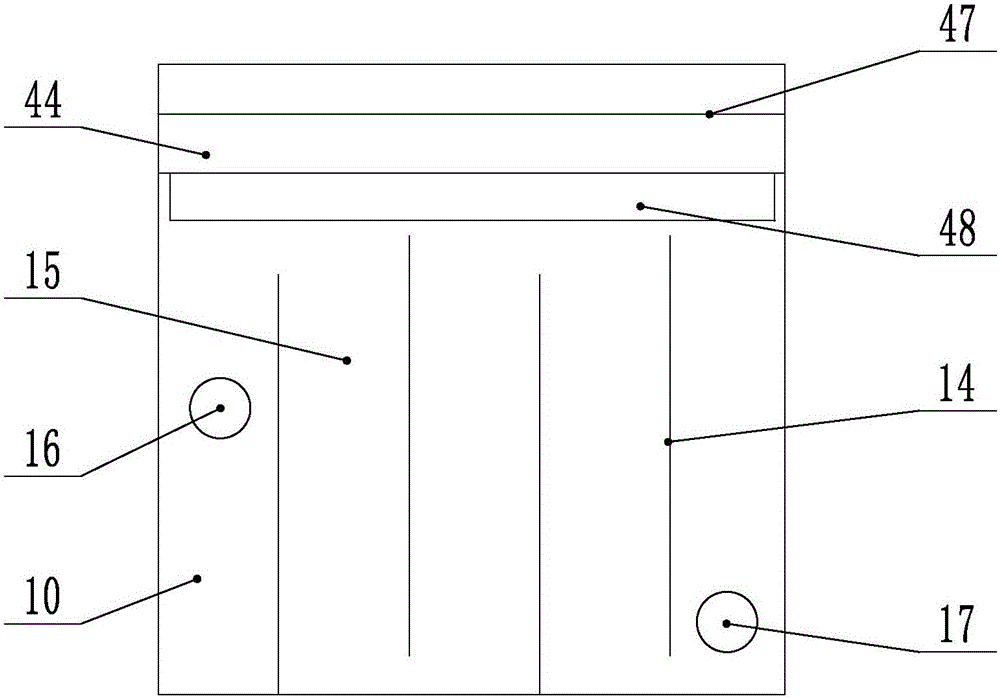

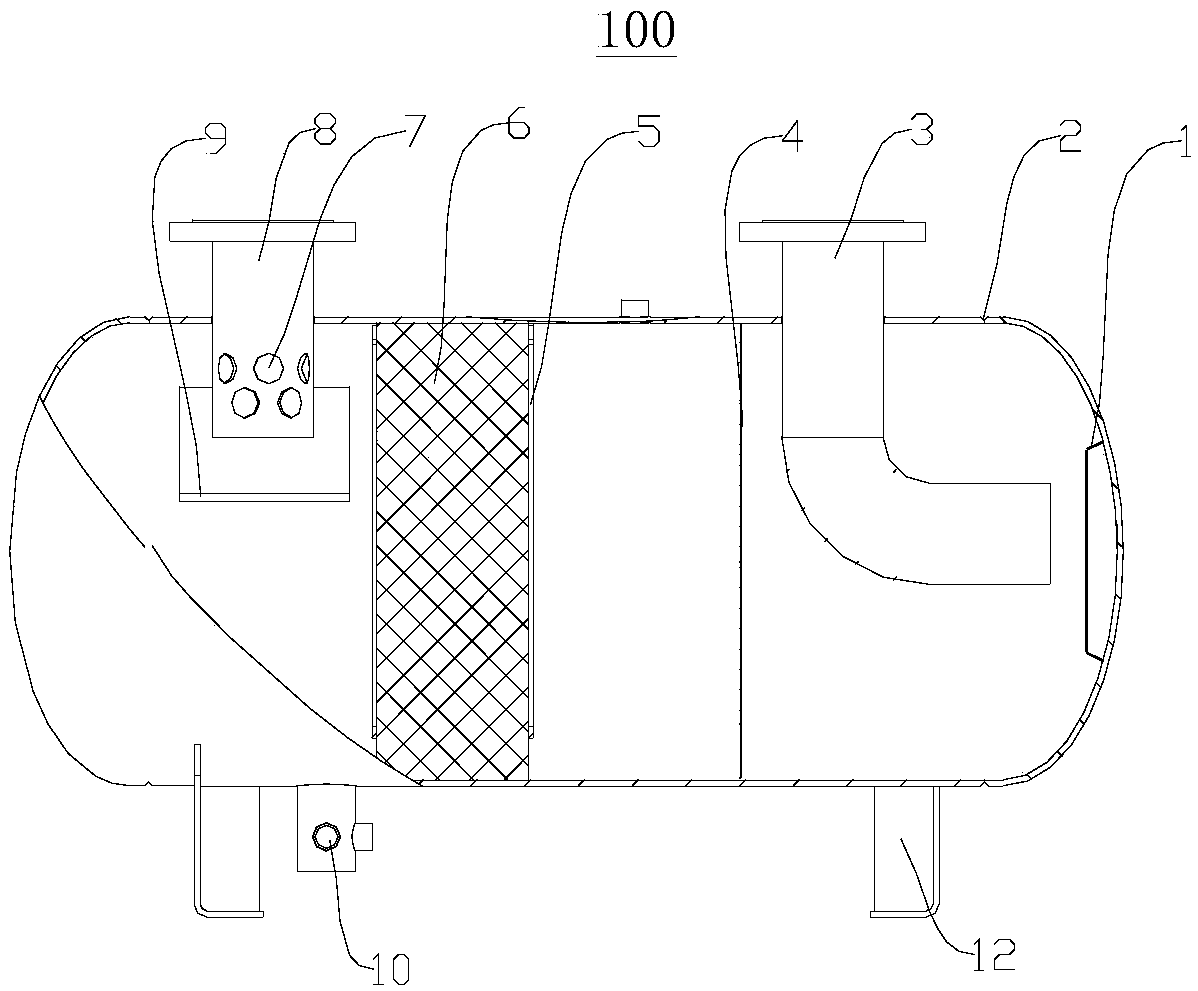

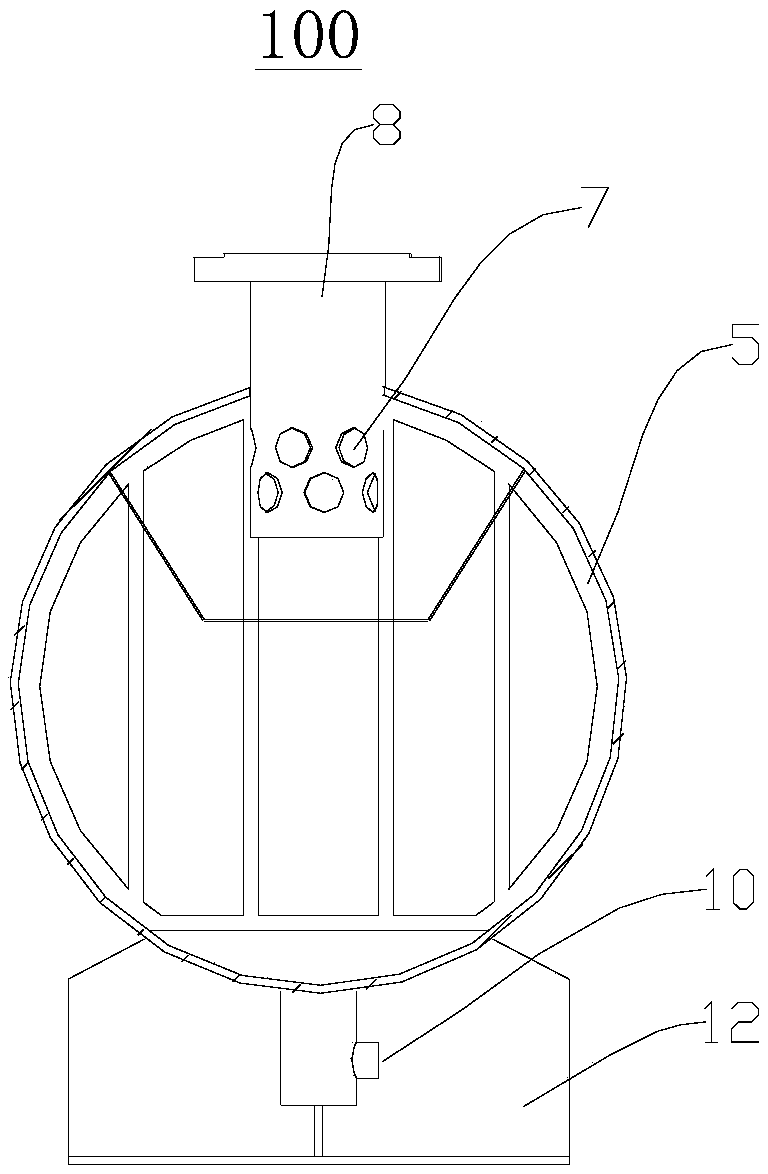

Variable volume high-efficiency vertical oil separator for refrigeration compressor testing device

ActiveCN102967095AEasy to separateReduce manufacturing costRefrigeration componentsRefrigeration compressorOil separation

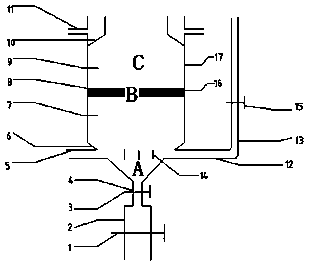

The invention belongs to the technical field of oil separation, and particularly relates to a variable volume high-efficiency vertical oil separator for a refrigeration compressor testing device. The oil separator comprises a sealed barrel. A filtering separation area, a centrifugal separation area and a gravity settling area are sequentially arranged in the barrel from top to bottom. At least two inlet connecting pipes are arranged on a barrel wall in the centrifugal separation area. An independent centrifugal separation channel opposite to each inlet connecting pipe is formed on the inner side of the centrifugal separation area. The barrel is provided with an outlet connecting pipe on the upper side of the filtering separation area, and is provided with an oil drain pipe on the bottom side of the gravity settling area. The oil separator is provided with at least two inlet connecting pipes, so that a single-path gas inlet mode, a two-path gas inlet mode or a multi-path gas inlet mode can be selected according to the displacement of a compressor, and each gas inlet path is connected with an independent centrifugal separation channel to form an independent centrifugal separation area so as to achieve an optimal oil separation effect. The oil separator is simple in structure, small in space and low in cost.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Oil separator

InactiveCN1766466AOvercome the disadvantage of large pressure drop lossHigh speedRefrigeration componentsEngineeringCentrifugal force

The invention discloses a new type oil separator, which comprises the following parts: cylindrical tank with 1.2 mm thickness, inlet pipe on the lateral face of tank, drainage pipe on the top of tank and oil return pipe on the bottom, wherein the separation angle of inlet pipe and tank axial central line displays 120 deg; one end of inlet pipe plugged in the tank is higher than the bottom of drainage pipe; when the coolant (R22) with lubrication oil enters into the oil separator tank, the oil gathers on the bottom of separator tank by the centrifugal effort, which flows into the compressor through oil return pipe. The invention overcomes the present waste of pressure drag and saves the filter net, which improves the compressor frequency and reduces the manufacturing cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

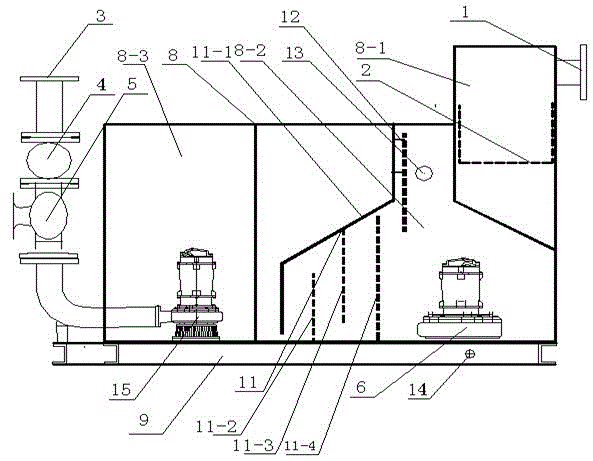

Automatic vertical-flow oil-separating precipitator

InactiveCN1772638AReduce moisture contentImprove oil separation effectFatty/oily/floating substances removal devicesLiquid separationWastewaterEngineering

The present invention is automatic vertical-flow oil-separating precipitator and belongs to the field of oil-bearing waste water treating technology. The precipitator includes a pond comprising separating area and mud bin, water inlet pipe, central guide barrel, conic reflecting board, water outlet pipe and mud discharging pipe. Inside the separating area, there is a guide board with lower bell mouth and coaxial with the central guide barrel, an oil discharge weir connected to the oil outlet pipe in the upper inside part of the guide board, and a water draining weir connected to the water outlet pipe inside the pone wall. The water inlet pipe is connected to the upper part of the central guide barrel. The present invention can separate oil automatically without need of mechanical driving, and is suitable for treating oil-bearing waste water to eliminate oil and suspended matter.

Owner:TSINGHUA UNIV

Adjustable filtration type oil separating tank device for separating oil-water mixture

ActiveCN105293734AImprove oil separation effectReduce depositionMultistage water/sewage treatmentOil and greaseFiltration

The invention discloses an adjustable filtration type oil separating tank device for separating oil-water mixture. The oil separating tank device comprises an oil-water separation box shell, a backflow baffle, an oil-water separation film, an oil-water separation film support net, a funnel type box bottom shell and a deflection baffle, wherein an area of the oil-water separation film is a filtration area; the upper part of the filtration area is a flotation oil area; the lower part of the filtration area is a buffering and settling area; the backflow baffle is arranged at an oil outlet; an oil-water separation film set which can be adjusted up and down and is spaced from the oil-water separation film support net is arranged; an oil-water mixture inlet and a water outlet are formed in two sides of the deflection baffle respectively; a sewage outlet is formed in the bottom of the funnel type box bottom shell; the area of the deflection baffle is an oil-water-solid particle buffering and settling area; a master valve is arranged at the water inlet; a sludge discharging valve is arranged at the sewage outlet located under a sludge-sand buffering and settling area; a sludge discharging pipe is connected with the sewage outlet in turn. The adjustable filtration type oil separating tank device is suitable for separating different concentrations of grease sewage by adjusting the position of the oil-water separation film; the oil, water, sludge and sand can be efficiently separated; the wastewater treatment and the resource regeneration and utilization can be facilitated.

Owner:SHANGHAI UNIV

Oil supplying structure of transmission for vehicle

InactiveUS20060054409A1Improve oil separation effectImprove performanceGearboxesGear lubrication/coolingDrive shaftGear wheel

Disclosed is a structure which is able to supply oil to engagement parts of transmission gears mutually rotatably mounted on a transmission shaft inside a transmission case for a vehicle, even when the vehicle tilts during its run. The transmission shaft in the transmission case, has an oil passage which penetrates through its length axially and communicates with the engagement parts of the transmission gears fluidically, where the transmission shaft extends in a direction of width of the vehicle. Both ends of the oil passage of the transmission shaft fluidically communicate with oil intake passages which extend upwards and open inside the transmission case so as to capture the oil inside the transmission case.

Owner:KAWASAKI HEAVY IND LTD

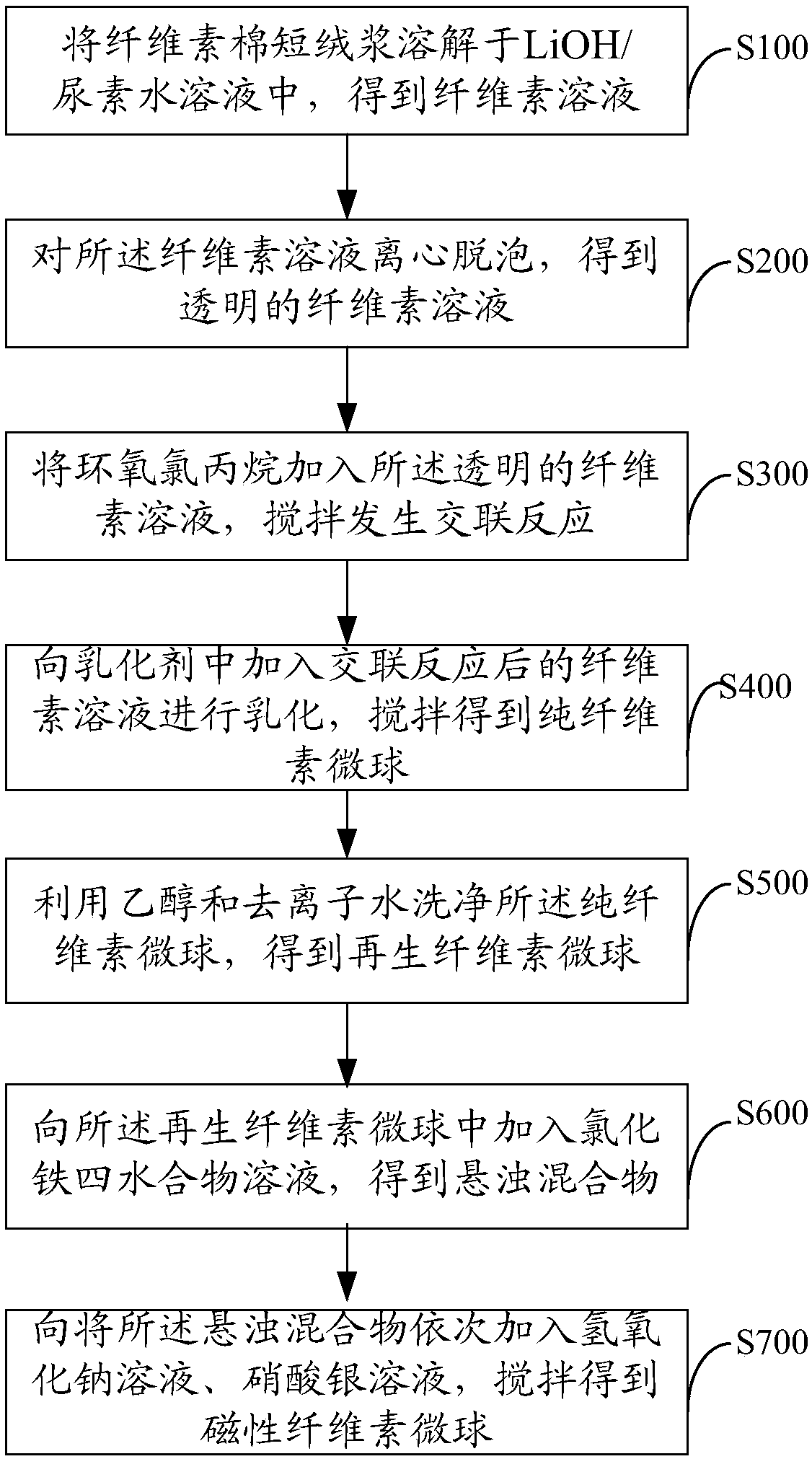

Preparation method of magnetic cellulose microsphere and method for separating pigments from grease

ActiveCN108514868AImprove oil separation effectAchieve recyclabilityOther chemical processesFatty-oils/fats refiningMicrosphereChloride

The invention discloses a preparation method of a magnetic cellulose microsphere and a method for separating pigments from grease. The preparation method comprises following steps: dissolving cellulose cotton short fiber slurry into a LiOH / urea water solution to obtain a cellulose solution; centrifuging and defoaming the cellulose solution to obtain a transparent cellulose solution; adding epoxy chloropropane into the transparent cellulose solution, stirring to trigger crosslinking reactions; adding the cellulose solution into an emulsifier after crosslinking reactions to carry out emulsification, stirring to obtain pure cellulose microspheres; cleaning the pure cellulose microspheres by ethanol and deionized water to obtain regenerated cellulose microspheres; adding a ferric chloride tetrahydrate solution into the regenerated cellulose microspheres to obtain a turbid mixture; adding a sodium hydroxide solution and a silver nitrate solution into the turbid mixture in sequence, and stirring to obtain the magnetic cellulose microspheres.

Owner:WUHAN POLYTECHNIC UNIVERSITY

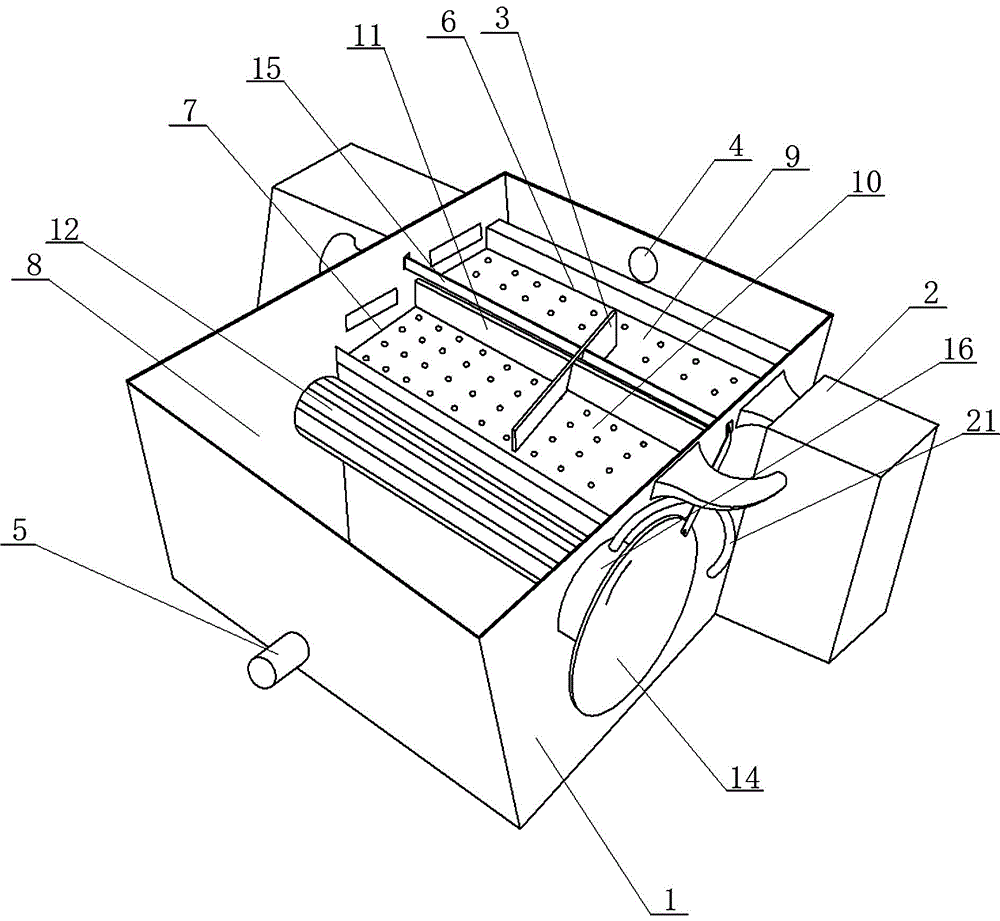

Oil-water separation device for treatment of kitchen wastewater

InactiveCN106830401ASave electricityLow costFatty/oily/floating substances removal devicesTreatment involving filtrationImpellerWater flow

The invention relates to an oil-water separation device for treating kitchen waste water. The method mainly solves the problems that the existing oil-water separation device for treating the kitchen oily wastewater needs an external power source, consumes a lot of electricity, has too high investment and is difficult to implement and popularize. It is characterized in that: the two ends of the impeller device (12) are respectively fixed with a left disc (13) and a right disc (14), the oil scraper (3) is fixed on the steel belt (15), and the steel belt (15) The two ends are respectively hinged on the left disc (13) and the right disc (14), the oil scraper (3) is located above the first sieve plate (9) and the second sieve plate (10), and the impeller device (12) One end is also provided with pumping device (16). The invention utilizes the potential energy of the water flow to impact the impeller device and drive the impeller to rotate, thereby enabling the impeller device to drive the oil scraper and the air pump to work without the need for an external power source (motor, water pump, etc.), which saves electric energy and is low in cost. It can be used by users Acceptance is conducive to promotion.

Owner:韩炳欣

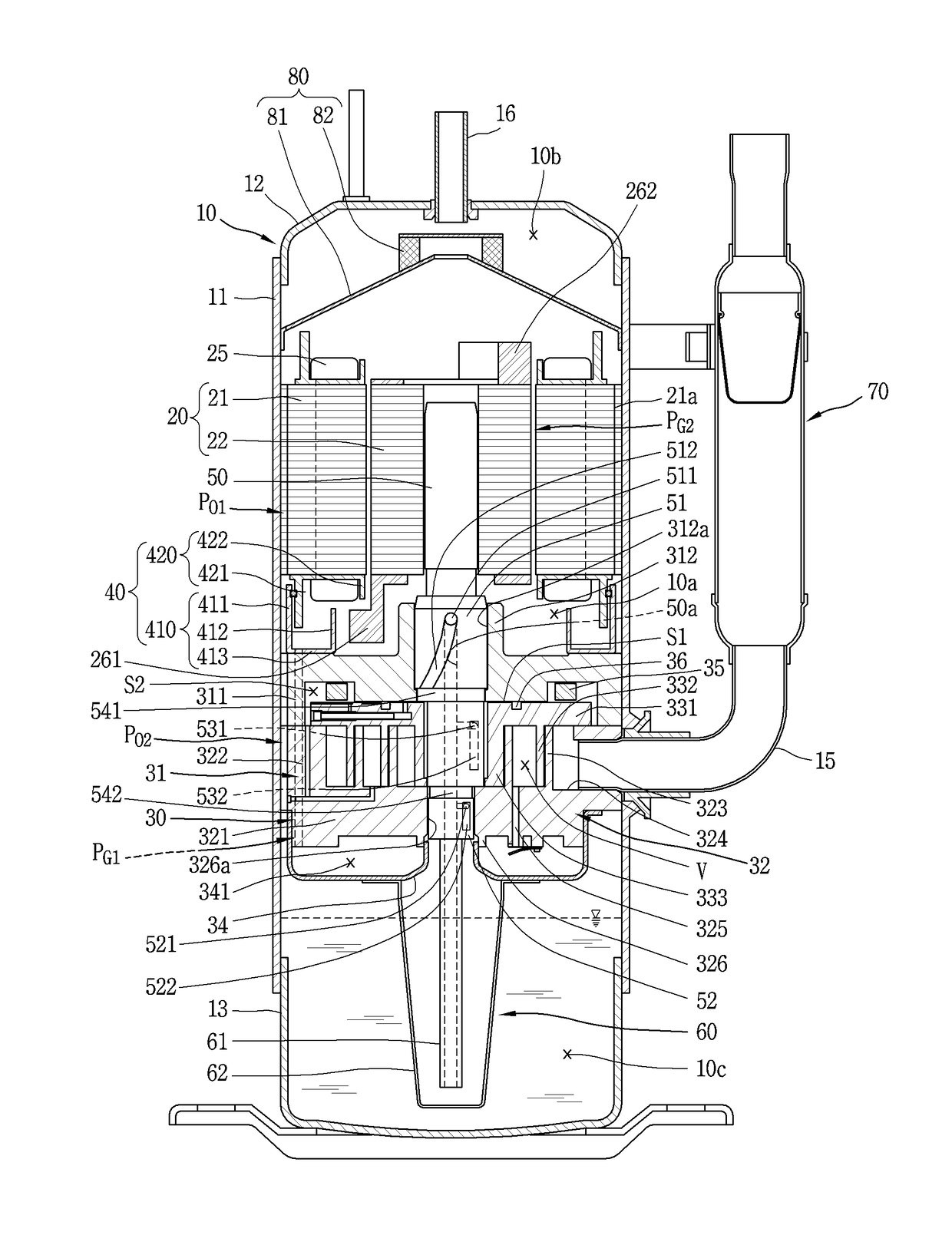

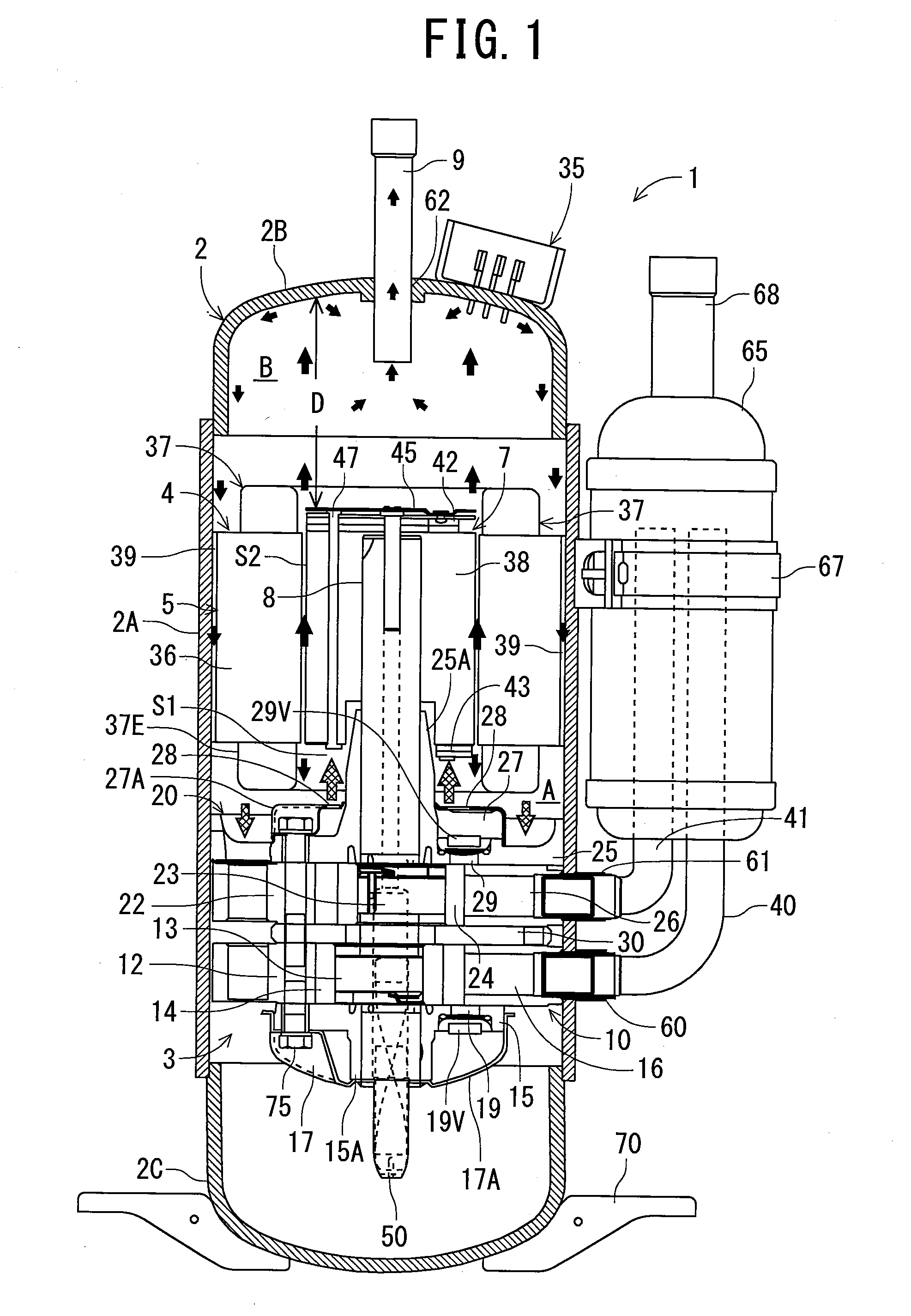

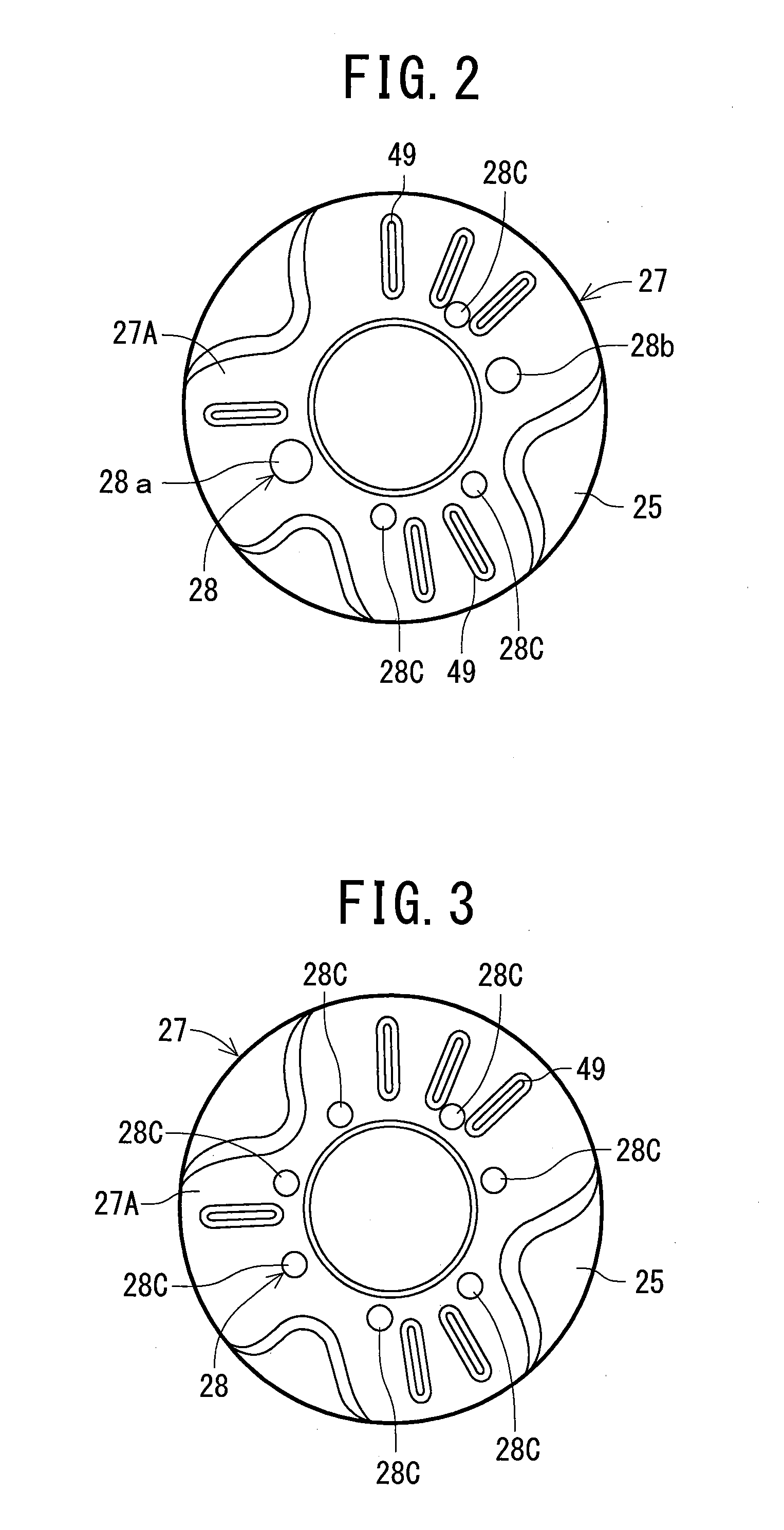

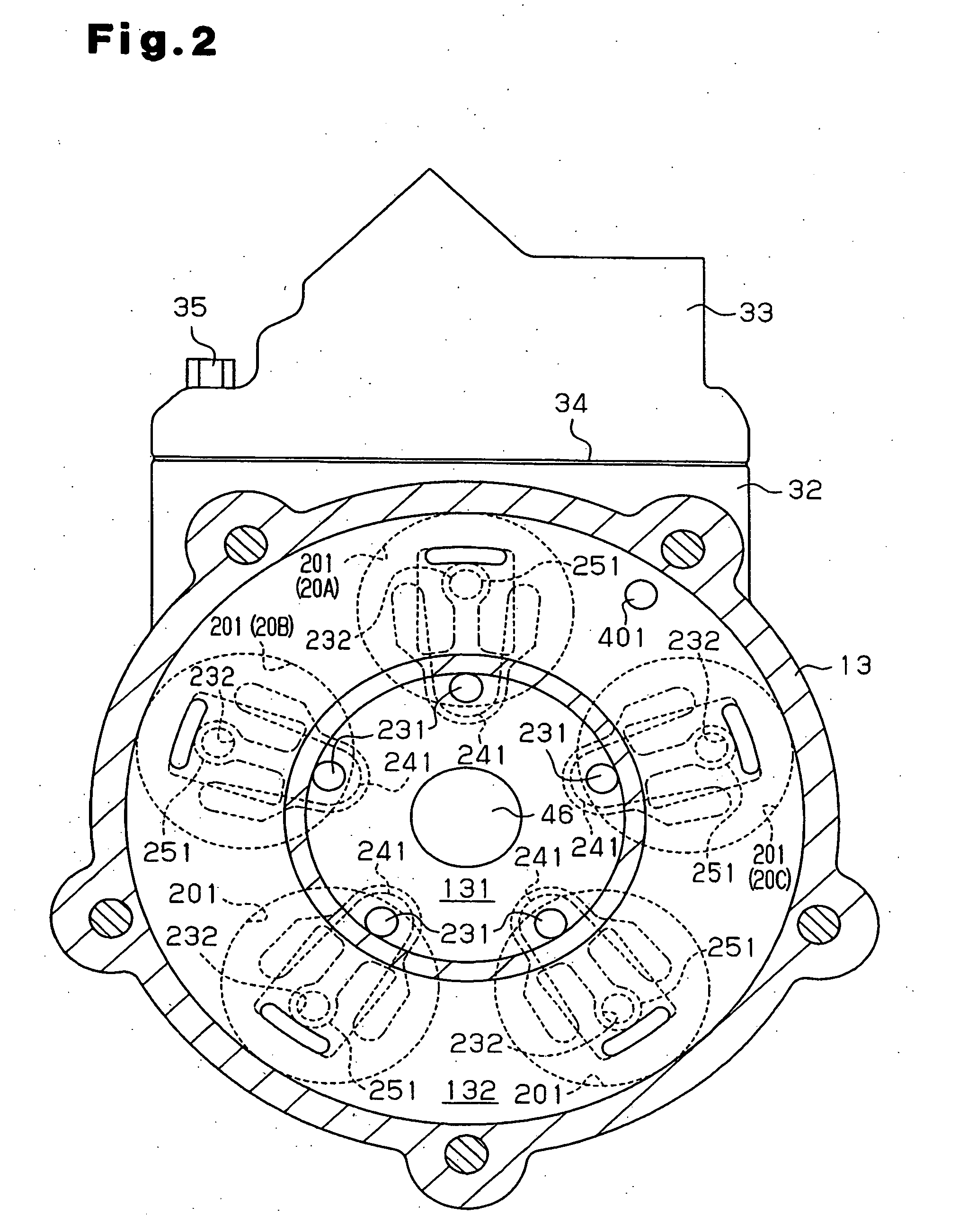

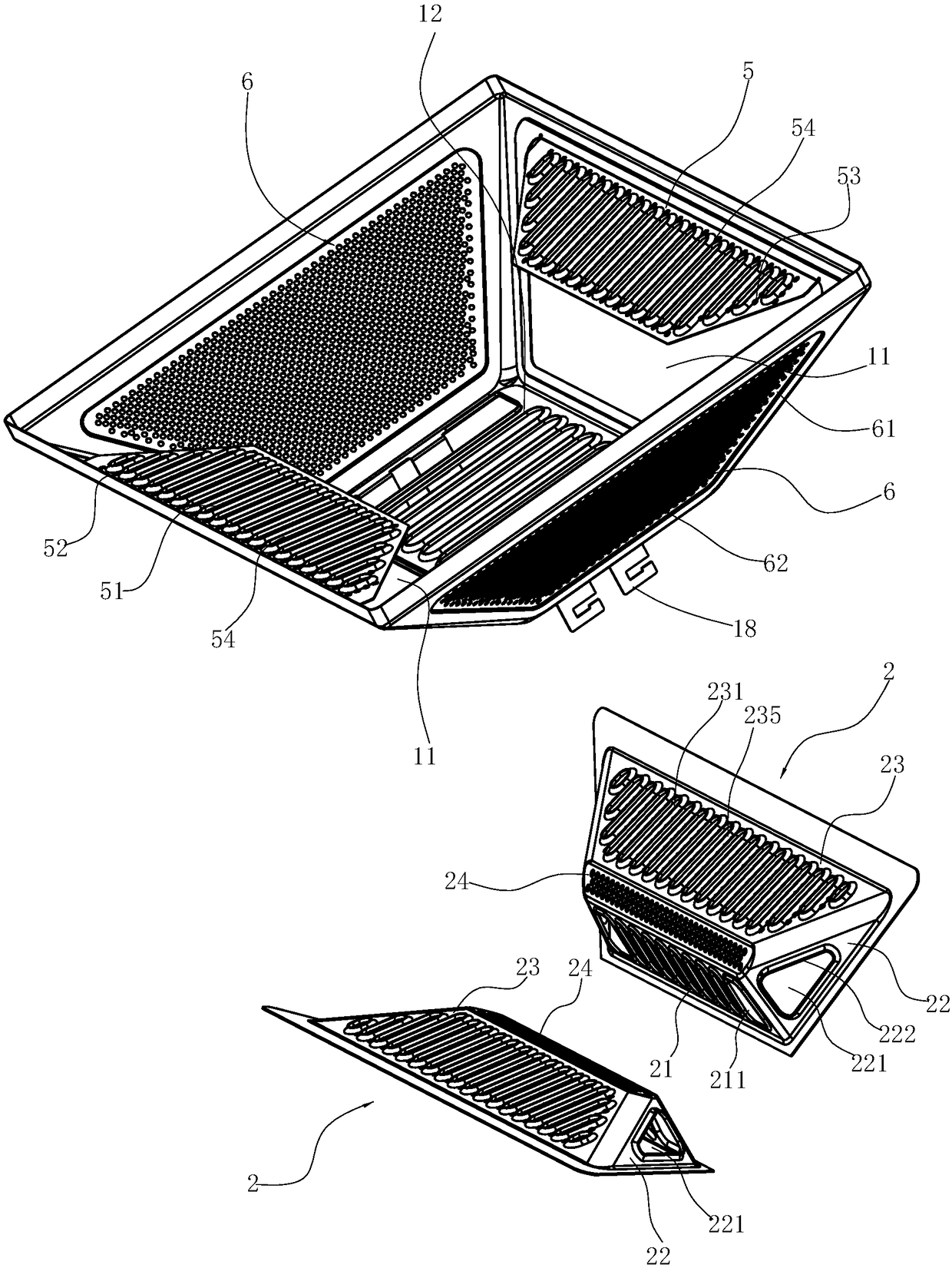

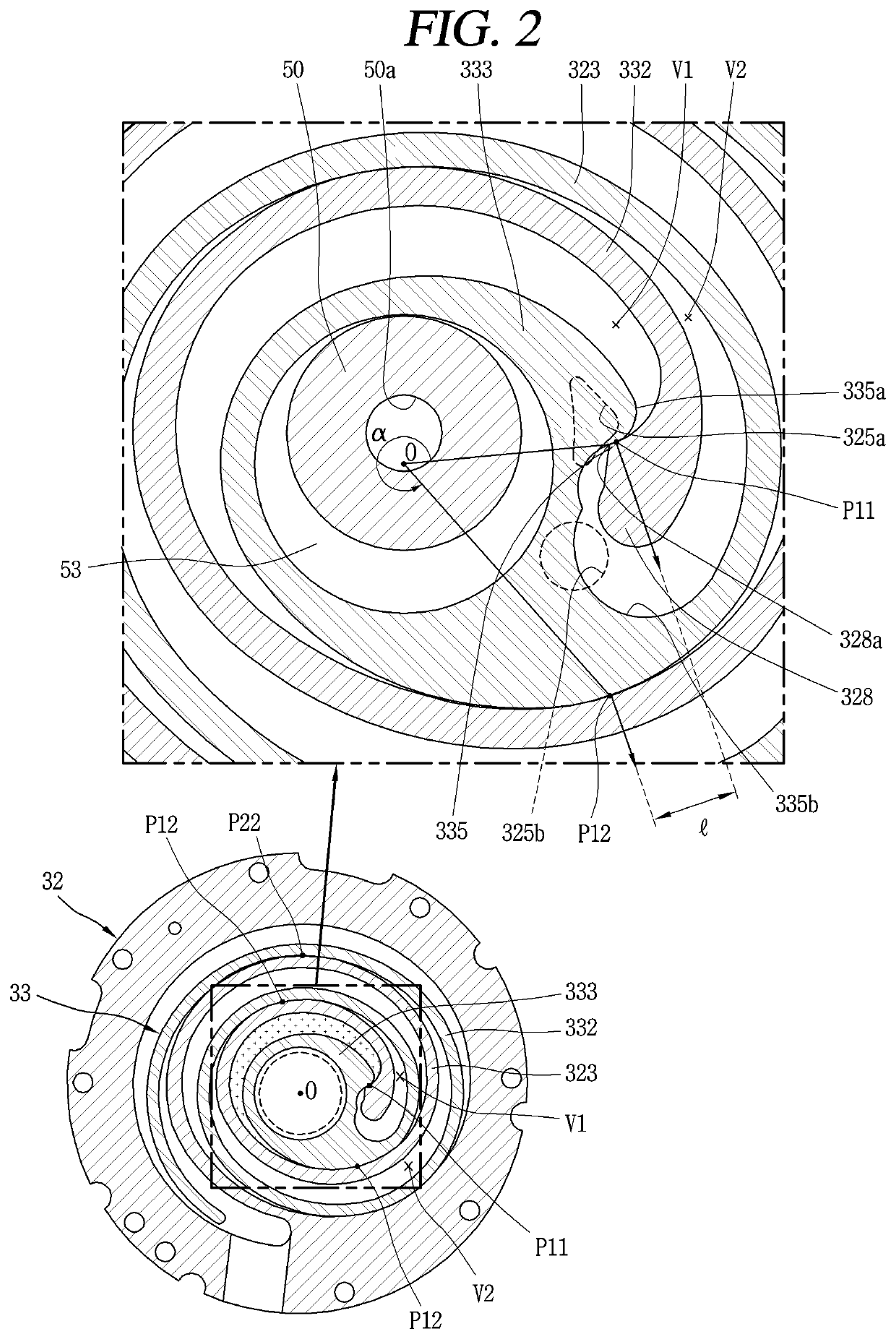

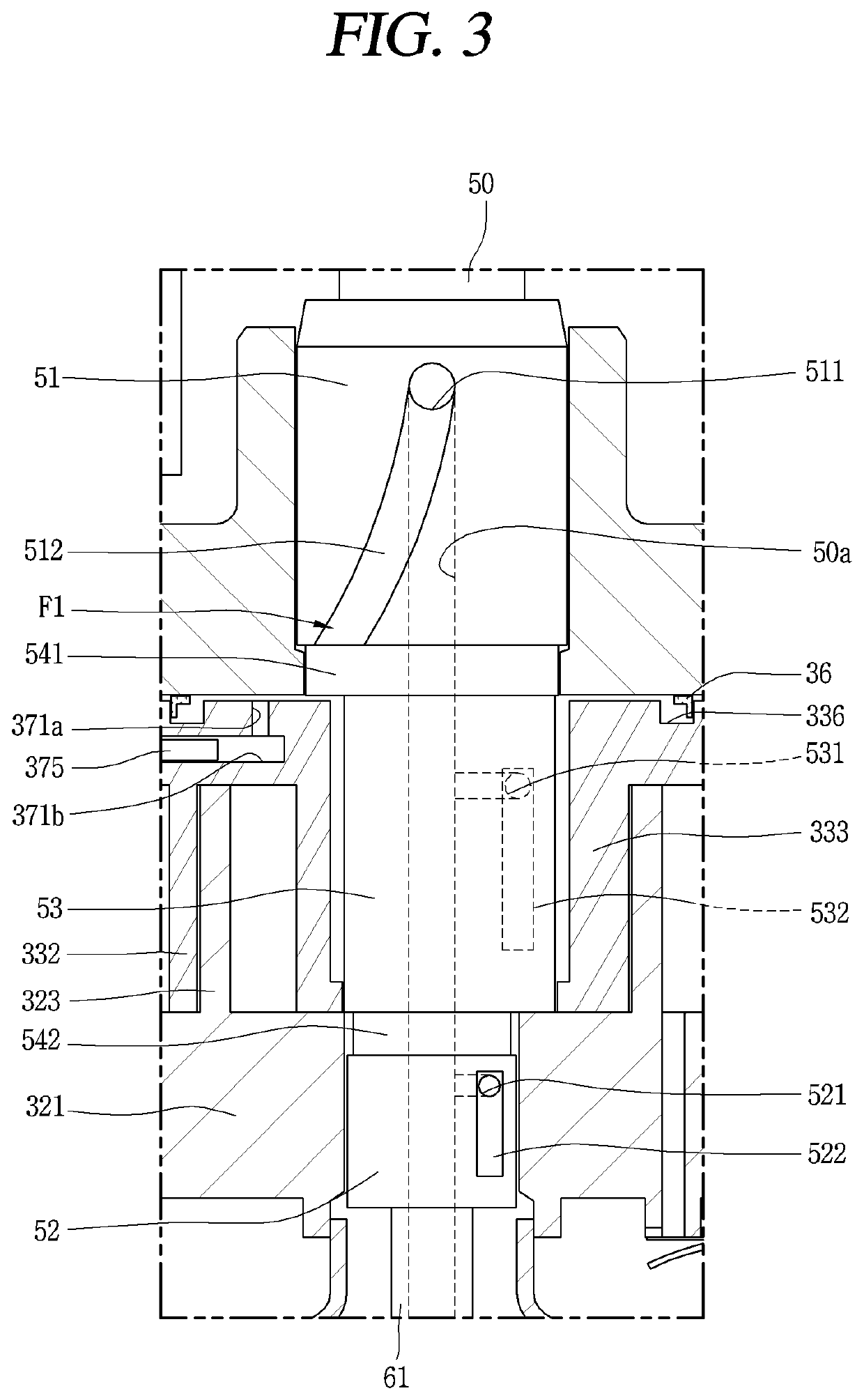

Scroll compressor

ActiveUS20180328364A1Minimizing drivingImprove oil separation effectRotary/oscillating piston combinations for elastic fluidsCombination devicesDrive motorRefrigerant

A scroll compressor includes a casing, and an internal sealed space in the casing; a drive motor configured with a stator and a rotor which rotates within the stator, and that has an internal flow passage and an external flow passage; a rotation shaft connected to the rotor; a compression unit that includes a first scroll, and a second scroll which is engaged with the first scroll to form a compression chamber, with which the rotation shaft is eccentrically combined; a discharge pipe that communicates with an upper space of the internal space; an oil separation member disposed in the upper space; and a guidance member that is provided between an upper end of the drive motor and a lower end of the discharge pipe and guides the refrigerant with which the oil is mixed, to the oil separation member.

Owner:LG ELECTRONICS INC

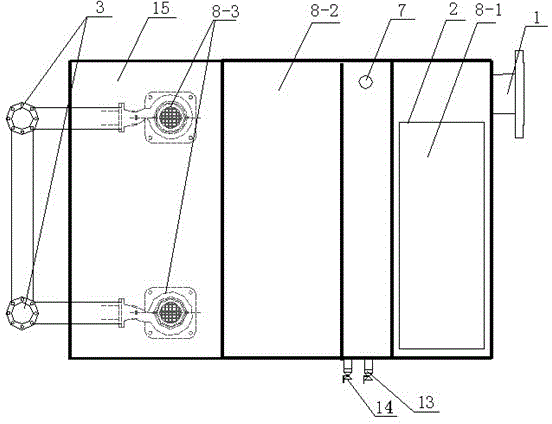

Integral closed oil separator

InactiveCN102923818BLow densityEasy dischargeFatty/oily/floating substances removal devicesLiquid separationThermodynamicsSlag

The invention discloses a closed integrated oil separator, which comprises a box body, and the box body is composed of a slag removal area located at the upper part of one end of the box body, an oil isolation area located at the middle of the box body, and a liquid level control area located at the other end of the box body. The composition of the control lifting area; the oil separation area is provided with a multi-directional oil control device, and the multi-directional oil control device includes an inclined plate and at least three side plates; wherein the bottom end of the first side plate is connected to the bottom of the box body The bottom is connected, and there is a certain space between the upper end and the inclined plate to form a free end. The upper end of the second side plate adjacent to the first side plate is connected to the inclined plate, and a certain space is left between the lower end and the bottom of the box. , forming a free end, the bottom end of the third side plate adjacent to the second side plate is connected to the bottom of the box, and there is a certain space between the upper end and the inclined plate to form a free end, so that the side The plates are arranged in a staggered manner between the side plates and the bottom of the box. The invention adopts the slanting plate technology and the dislocation grid technology, and the oil separation effect is better.

Owner:NANJING AOMAI ENG EQUIP

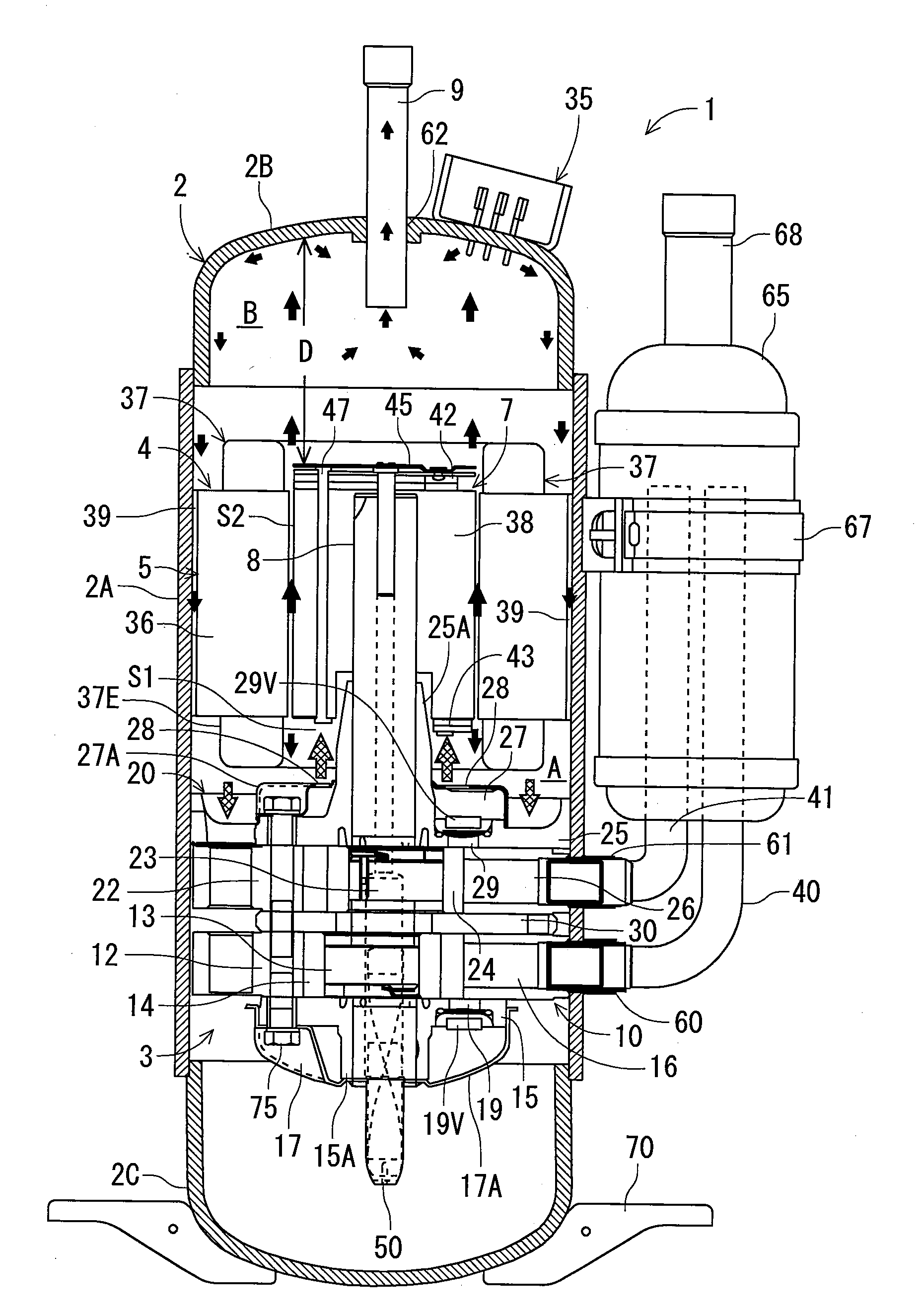

Sealed type rotary compressor

InactiveUS20100215524A1Efficient executionReduce oil dischargeRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsOil separationEngineering

An object of the present invention is to promote oil separation in a sealed container, thereby decreasing the amount of oil discharged to the outside of a compressor. The compressor comprises discharge hole provided at positions facing the end surface of a rotor and through which a compressed refrigerant from first and second rotary compression elements is discharged into the sealed container; and a refrigerant flow path which is extended from a space surrounded with a coil end of a stator projecting from the end surface of the rotor to a rotary compression mechanism side to a space of an air gap between the rotor and the stator, to guide the compressed refrigerant discharged through the discharge hole to an electromotive element opposite to the rotary compression mechanism side, and the outlet of this refrigerant flow path opposite to the rotary compression mechanism side faces the inner wall surface of the sealed container.

Owner:SANYO ELECTRIC CO LTD

Sand blasted surface protective film and protective method for engine metal shell

The invention discloses a sand blasted surface protective film and a sand blasted surface protective method for an engine metal shell. The method comprises the following steps of: dissolving butyl rubber, dicumyl peroxide, zinc oxide, carbon black, magnesium oxide and acetone, and stirring the solution to obtain a protective film material; cleaning the outer surface of a product, and stirring theprotective film material, acetone and aviation washing gasoline uniformly to obtain an accessory; spraying a protective film layer on the surface of the metal shell by using the accessory, and curingthe protective film layer to form a peelable film layer; and removing the peelable film layer on the surface of the engine in use, and cleaning the outer surface of the product for later use. The protective film can be used for isolating air or water, and can be quickly removed.

Owner:中国航天科工集团第二研究院二一〇所

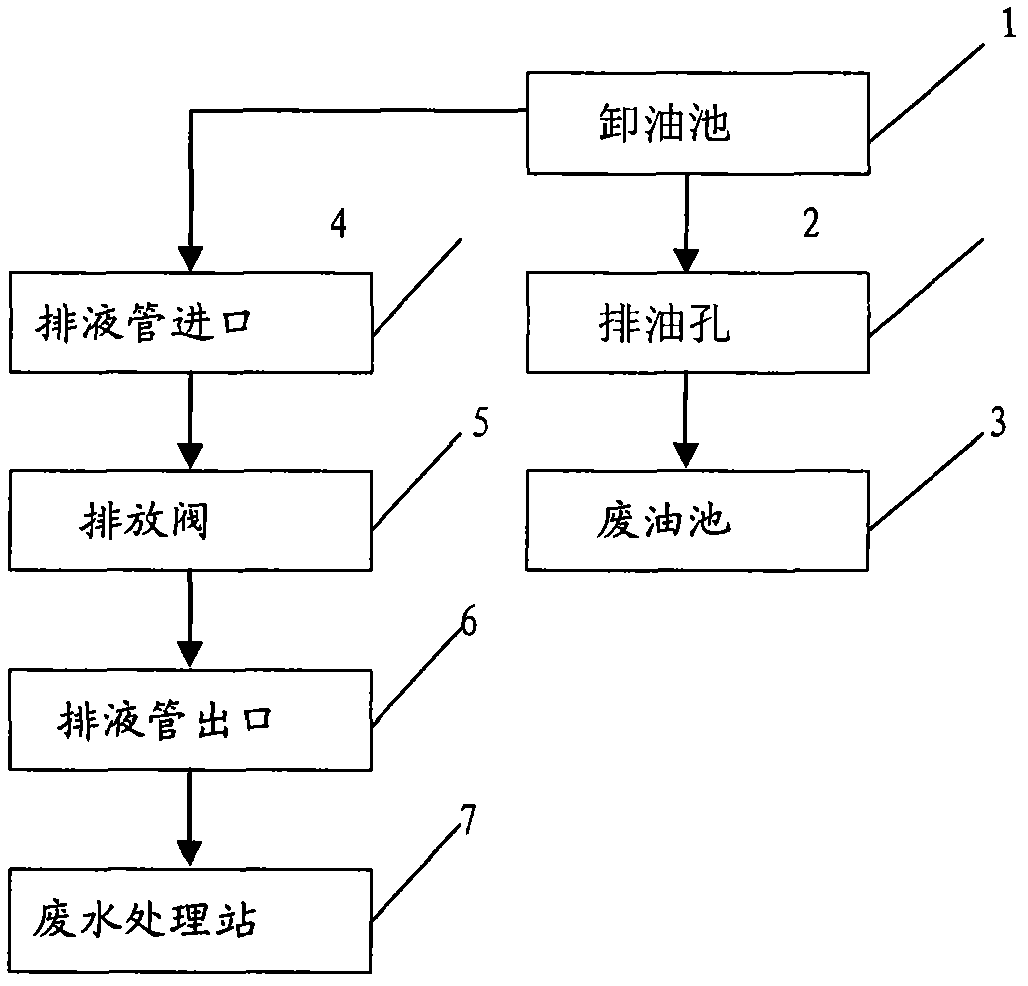

Method for separating oil slick of waste cold-rolling fluid

InactiveCN103011338ASolve the problem of cleaning up oil slicksReasonable processFatty/oily/floating substances removal devicesLiquid separationWaste oilGravitational force

The invention discloses a method for separating oil slick of waste cold-rolling fluid. The device for separating oil slick of waste cold-rolling fluid comprises the following parts: 1, an oil discharging pond, 2, an oil discharging hole, 3, a waste oil pond, 4, a fluid outlet tube inlet, 5, a discharging valve, 6, a fluid outlet tube outlet and 7, a waste oil treatment station. In a production process, the cold-rolling fluid loses effect after being used for certain time and is changed; the waste cold-rolling fluid enters the oil discharging pond; the waste cold-rolling fluid in the oil discharging pond is discharged to the waste water treatment station through a pipeline and the discharging valve; when the discharging valve is opened and the liquid surface of the oil discharging pond is higher than the discharging valve, the waste cold-rolling fluid in the oil discharging pond is automatically discharged to the waste water treatment station without power under the action of the gravity force. When the liquid surface is lower than the discharging valve, the discharging is stopped and the oil slick does not flow to the waste cold-rolling fluid pond. The height of the liquid surface of the waste cold-rolling fluid of the oil discharging pond is controlled by the discharging valve, and the size of a discharging valve switch can be adjusted according to the volume of the waste cold-rolling fluid discharged to the oil discharging pond.

Owner:TIANJIN YIBO STEEL MAKING

Oil separation tank with dissolved air release function

PendingCN111056655AGood oil separation effectEasy to operateFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisParticulatesMicrobubbles

The invention discloses an oil separation tank with a dissolved air release function. A dissolved air release port and a dissolved air water pipeline are designed in the oil separation tank; the oil separation tank can separate and remove suspended oil on the surface of sewage; waste water and gas can form microbubbles, and oil and particles deeply dissolved in the water are separated from the water under the action of the microbubbles and float on the water surface; the oil and particles suspended on the water surface are collected through an oil collecting pipe system, the oil separation effect is more obvious, and operation is more convenient and faster; a nano oil-water separation membrane is arranged in a third compartment, and clear water can be further filtered and separated; an oilguide pipe is arranged in the third compartment, oil absorption treatment can be further conducted on the clear water separated out by the nano oil-water separation membrane, and thus it can be guaranteed that residual oil in the clear water is separated from water.

Owner:GUANGZHOU SHUIRUTIAN ENVIRONMENTAL PROTECTION TECH CO LTD

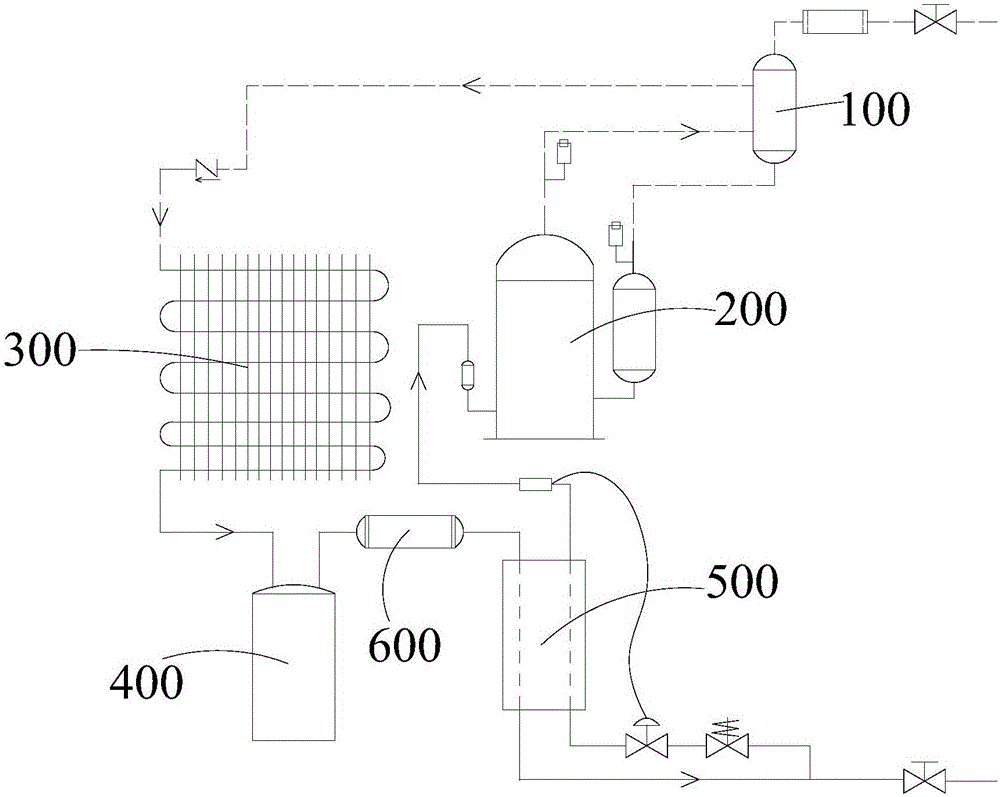

Oil-air separator and air-conditioning system with same

InactiveCN106196773AImprove oil separation effectSimple structureCompressorOil separationAir conditioning

The invention discloses an oil-air separator and an air-conditioning system with the same. The oil-air separator comprises a housing, an oil baffle plate, an air inlet pipe, at least one air homogenizing plate, and an oil filter assembly, wherein the housing comprises an upper chamber and a lower chamber; an oil drain outlet communicating with the lower chamber is formed in a bottom wall of the upper chamber, and an air outlet is formed in the upper chamber, while a collected oil outlet is formed in the lower chamber; the oil baffle plate is disposed on the bottom wall of the upper chamber; one end of the air inlet pipe extends into the upper chamber and is located above the oil baffle plate, and a gap is formed between a bottom end of the air inlet pipe and the oil baffle plate to define a circulation passage; each air homogenizing plate is disposed in the upper chamber, and a plurality of air vents are formed in each air homogenizing plate; the oil filter assembly is disposed in the upper chamber; and in an air circulation direction, each air homogenizing plate is located downstream of the circulation passage, and the oil filter assembly is located downstream of the air homogenizing plate. The oil-air separator provided by the present invention is capable of improving the oil separation effect, and is simple in structure, and simple and reliable in oil separation principle.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

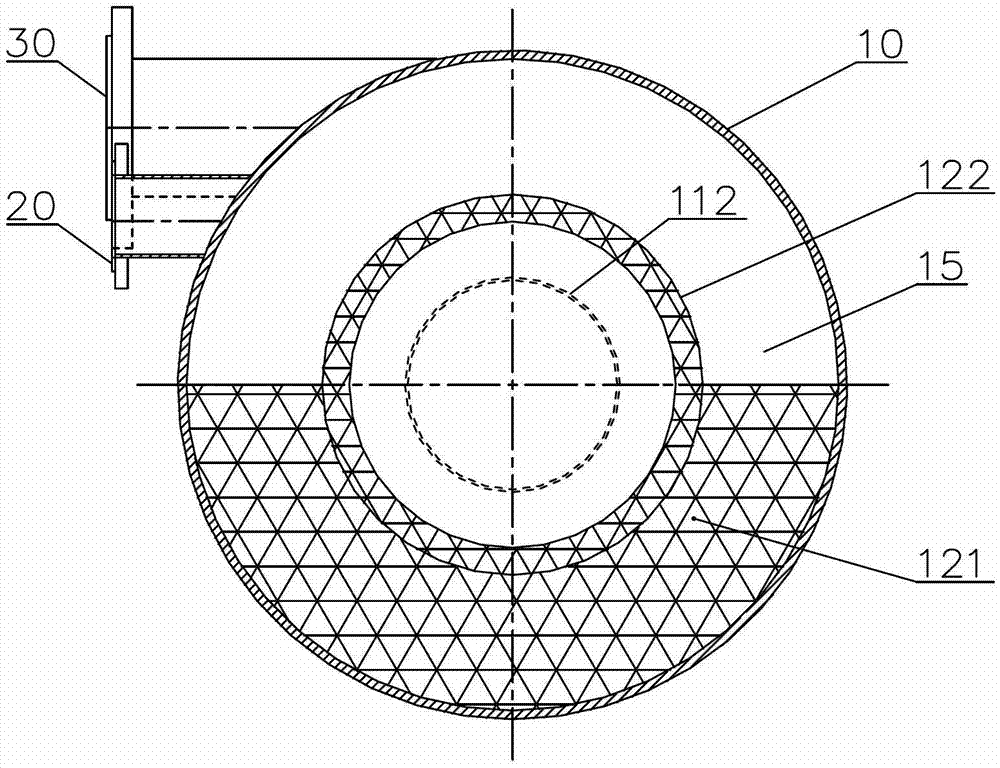

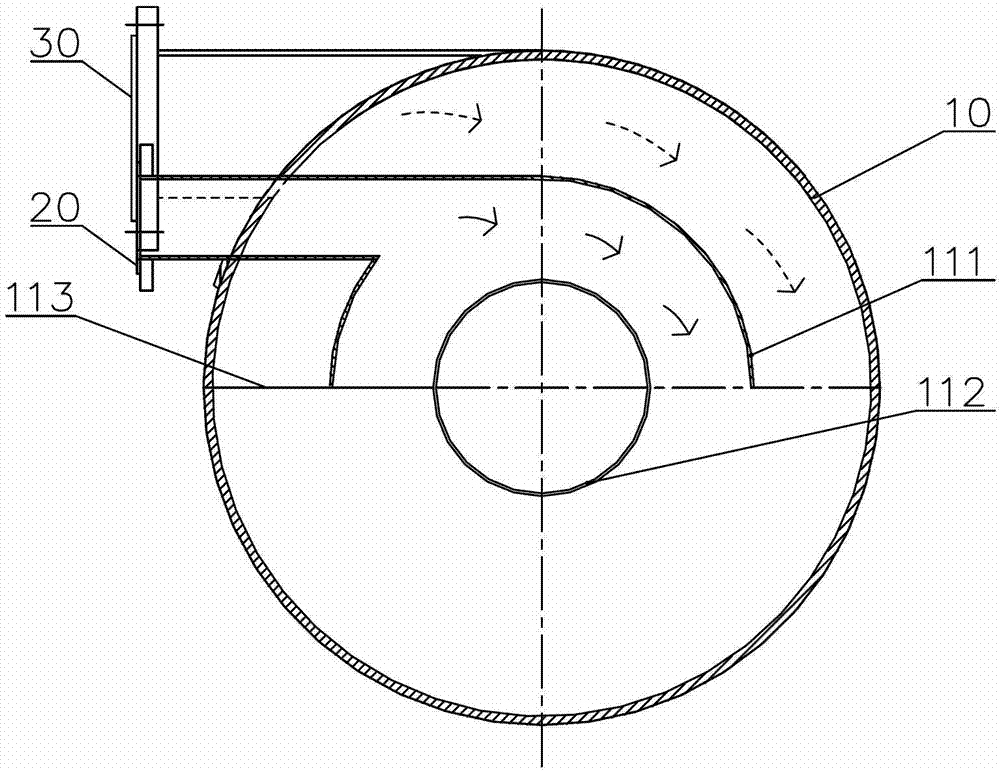

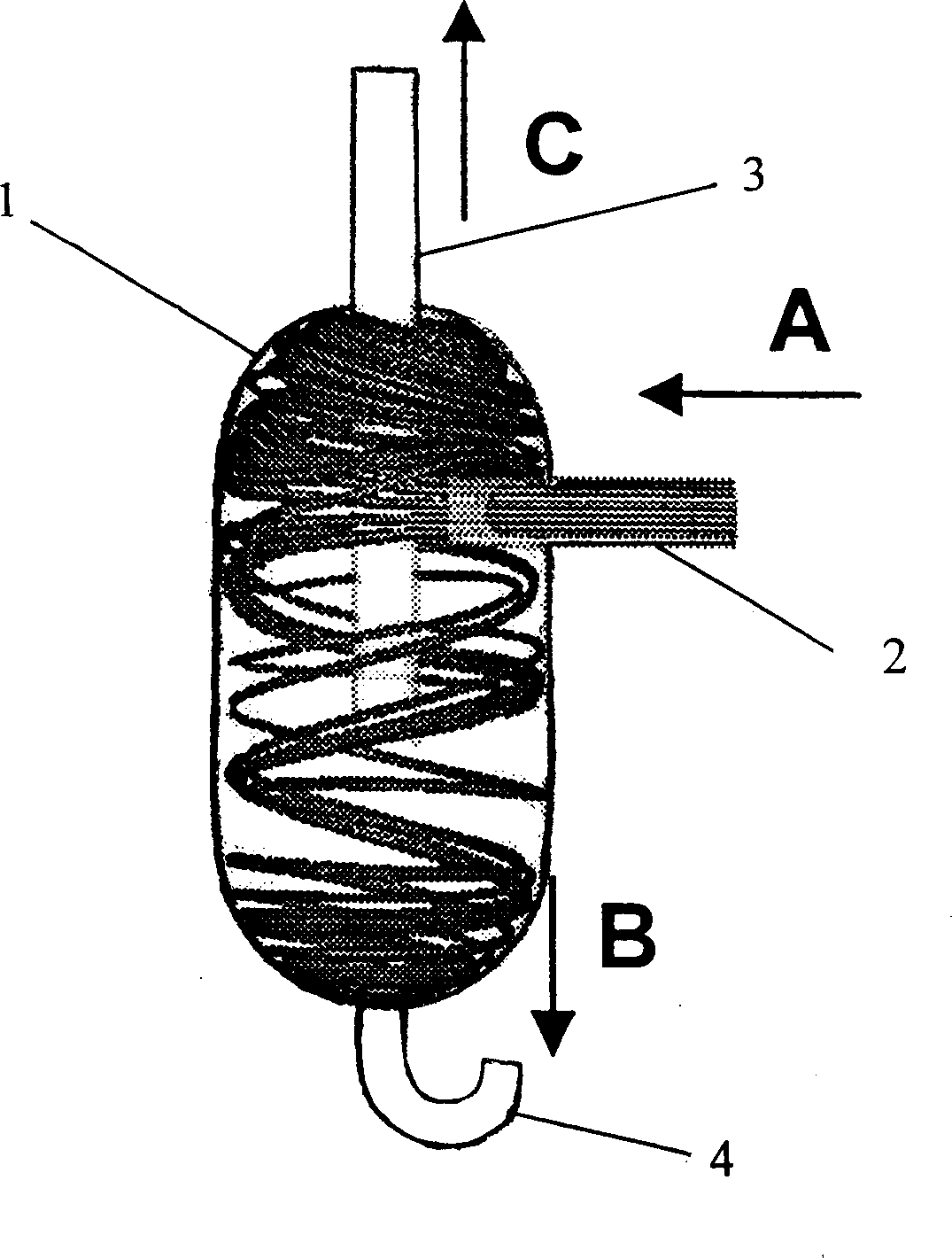

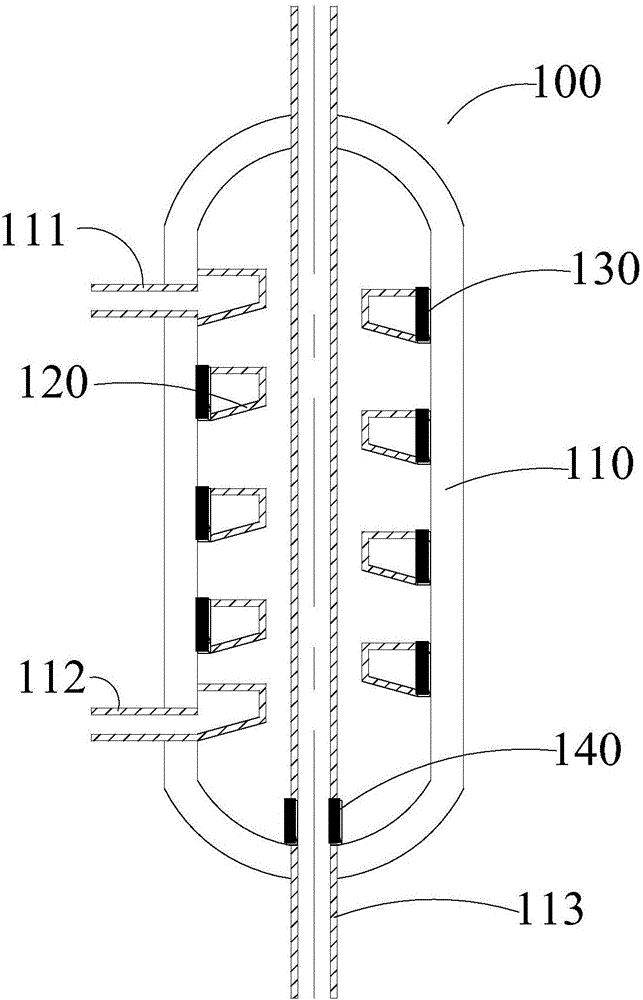

Refrigerating unit, oil supplying system and oil separator of oil supplying system

ActiveCN106500418ASimple and reasonable structural designImprove oil separation effectRefrigeration componentsRefrigerantReturned Amount

The invention provides an oil separator. The oil separator comprises a hollow shell, spiral separation channels and first filtering assemblies, wherein the spiral separation channels are used for separating mixtures and are arranged in the shell; the first filtering assemblies are used for filtering and are arranged on the outer walls of the spiral separation channels, and the spiral separation channels communicate with the shell through the first filtering assemblies. The mixtures containing refrigerants and lubricating oil are separated through the spiral separation channels by means of centrifugal action, the problem that at present the occupied space of a refrigerating system is increased due to the fact that the oil return amount is increased through increase of the size of an oil separator is effectively solved, and the oil separation path is increased while the oil separation effect is guaranteed, so that oil return efficiency is improved; meanwhile, the structure size of the oil separator can be compact, and the occupied space of a refrigerating unit is reduced. The invention further provides the refrigerating unit and an oil supplying system thereof.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

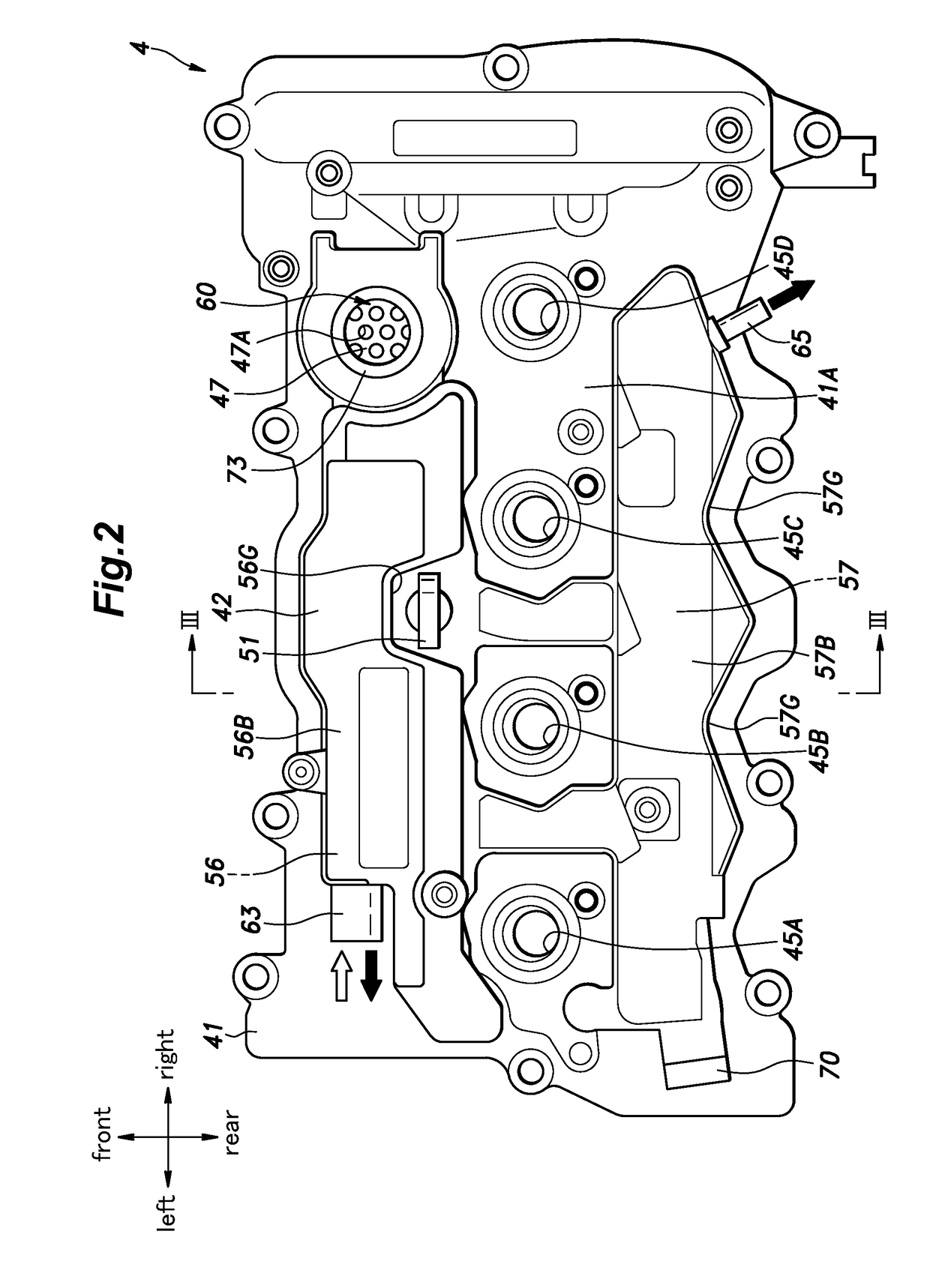

Oil separation device for internal combustion engine

ActiveUS20170321580A1Improve oil separation effectInternal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineOil separation

To improve the oil separation performance in an oil separation device for an internal combustion engine. The oil separation device (10) comprises a gas liquid separation passage (56) internally defined by a lower wall, an upper wall and a pair of side walls, and extending in a horizontal direction, a gas inlet (54) and a gas outlet (63) provided on either end of the gas liquid separation passage, a plurality of lower partition walls (56H) projecting upward from the lower wall, and a plurality of upper partition walls (56J) projecting downward from the upper wall. The lower partition walls and the upper partition wall are tilted with respective the length wise direction in plan view so as to define a spiral passage. The lower wall is inclined with respect to a horizontal plane such that an upstream part of the lower wall is lower than a downstream part of the lower wall with respect to a direction of the swirl flow.

Owner:HONDA MOTOR CO LTD

Kitchen oil separator tank with waste oil recycling function

InactiveCN107954499AAchieve recyclingGood oil separation effectFatty/oily/floating substances removal devicesLiquid separationOil separationWater flow

The invention discloses a kitchen oil separator tank with a waste oil recycling function, comprising a wastewater inlet, a slow flow baffle, a partition, a grille, an oil collecting plate, a water outflow pipe, an oil guide channel and an oil collecting box; the slow flow baffle is arranged below the wastewater inlet; the grille is arranged at the bottom of the partition that is arranged at the bottom of the tank; the oil collecting plate is arranged at the top of the tank; both the water outflow pipe and the oil guide channel are arranged at the bottom of the tank; the oil collecting box is arranged below the oil guide channel. The kitchen oil separator tank with the waste oil recycling function has the advantages that the slow flow baffle is used to retard water flows so that wastewaterslows at decreased speed after entering a primary separator tank, and oil dirt particles are crushed more finely; the angle of the oil collecting plate and arrangement of oil collecting holes in the oil collecting plate provide double filtering for oil dirt; therefore, oil separation effect of the separator tank is significantly better than separator tanks based on prior principles, and recyclingof waste oil is achieved.

Owner:DALIAN GAOMA ART DESIGN ENG

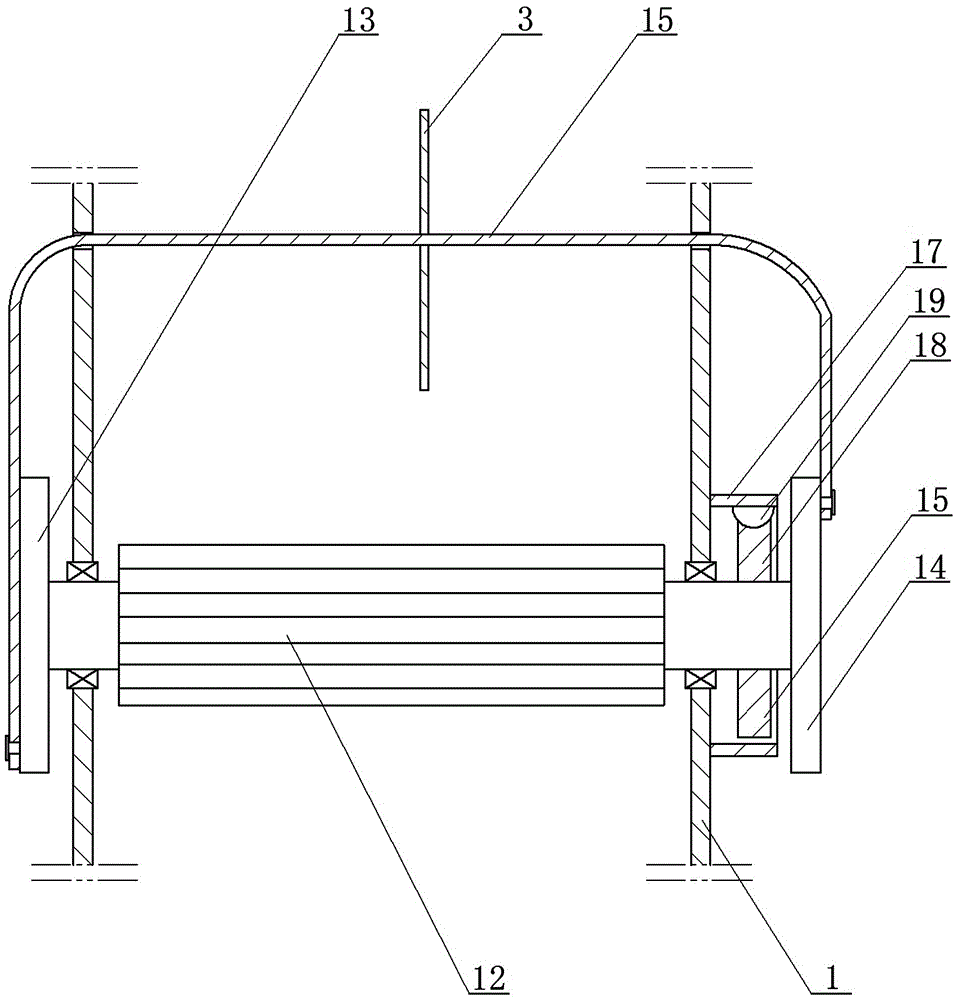

Integrated oil separation hoisting equipment

InactiveCN105858933AAvoid destructionImprove oil separation effectFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWastewaterOil separation

The present invention relates to the technical field of oil separation treatment equipment for catering wastewater, in particular to an integrated oil separation lifting device. At least N oil separation partitions are arranged in the oil separation chamber, and at least N oil separation partitions divide the oil separation chamber Divided into N+1 oil separation chambers, there is a distance between the lower edge of the oil separation plate with an odd number and the bottom of the oil separation chamber, and the lower edge of the oil separation plate with an even number and the oil separation chamber The upper edge of the oil separator with an odd number is higher than the upper edge of the oil separator with an even number; the upper side of one of the most two sides of the oil separator A horizontal water diversion pipe is provided which runs through the side wall of the oil-separating chamber and protrudes out of the side wall, and an overflow port is provided on the lower side of the other oil-separating chamber at the most two sides in the oil-separating chamber. The advantages are: the oil separation effect is more significant, a large amount of manpower is saved, there is no need for long-term regular cleaning and maintenance of the equipment, it is energy-saving and environmentally friendly, and effectively prevents damage to the living and working environment.

Owner:ZHEJIANG LEO ENVIRONMENT TECH CO LTD

Oil separation structure in compressor

InactiveUS20070177991A1Increase lengthImprove oil separation performancePositive displacement pump componentsEngine fuctionsDischarge pressureRefrigerant

A muffler forming member defines a muffler chamber. Refrigerant discharged from a cylinder bore is sent to the muffler chamber. The muffler forming member is coupled to a circumferential surface of a housing of a compressor. An oil separation chamber is defined in a discharge pressure zone of the compressor. The oil separation chamber separates the oil from the refrigerant discharged from the cylinder bore. The oil separation chamber extends into both the muffler forming member and the housing. The oil separation chamber has a refrigerant inlet through which the refrigerant flows into the oil separation chamber. The refrigerant inlet is formed in the muffler forming member. Therefore, the oil separation chamber is prolonged in the direction from the muffler forming member toward the housing, thereby improving the oil separation performance.

Owner:TOYOTA IND CORP

Oil filtering and noise reducing structure of range hood

PendingCN110131765AImprove noise reductionSimple structureDomestic stoves or rangesLighting and heating apparatusBreathingSmoke

The invention discloses an oil filtering and noise reducing structure of a range hood. The range hood comprises a smoke machine main body, wherein the smoke machine main body is provided with an air inlet, an oil net is arranged at the air inlet, and a fan is arranged in the smoke machine main body. A plurality of partition plates are arranged between the oil net and the fan in an interval settingmode, ventilation openings are formed between the partition plates and the side wall of the smoke machine main body, and the partition plates are arranged in an oblique mode. The oil filtering and noise reducing structure of the range hood has the advantages of being simple in structure and can effectively improve noise reducing performance of the range hood.

Owner:VATTI CORP LTD

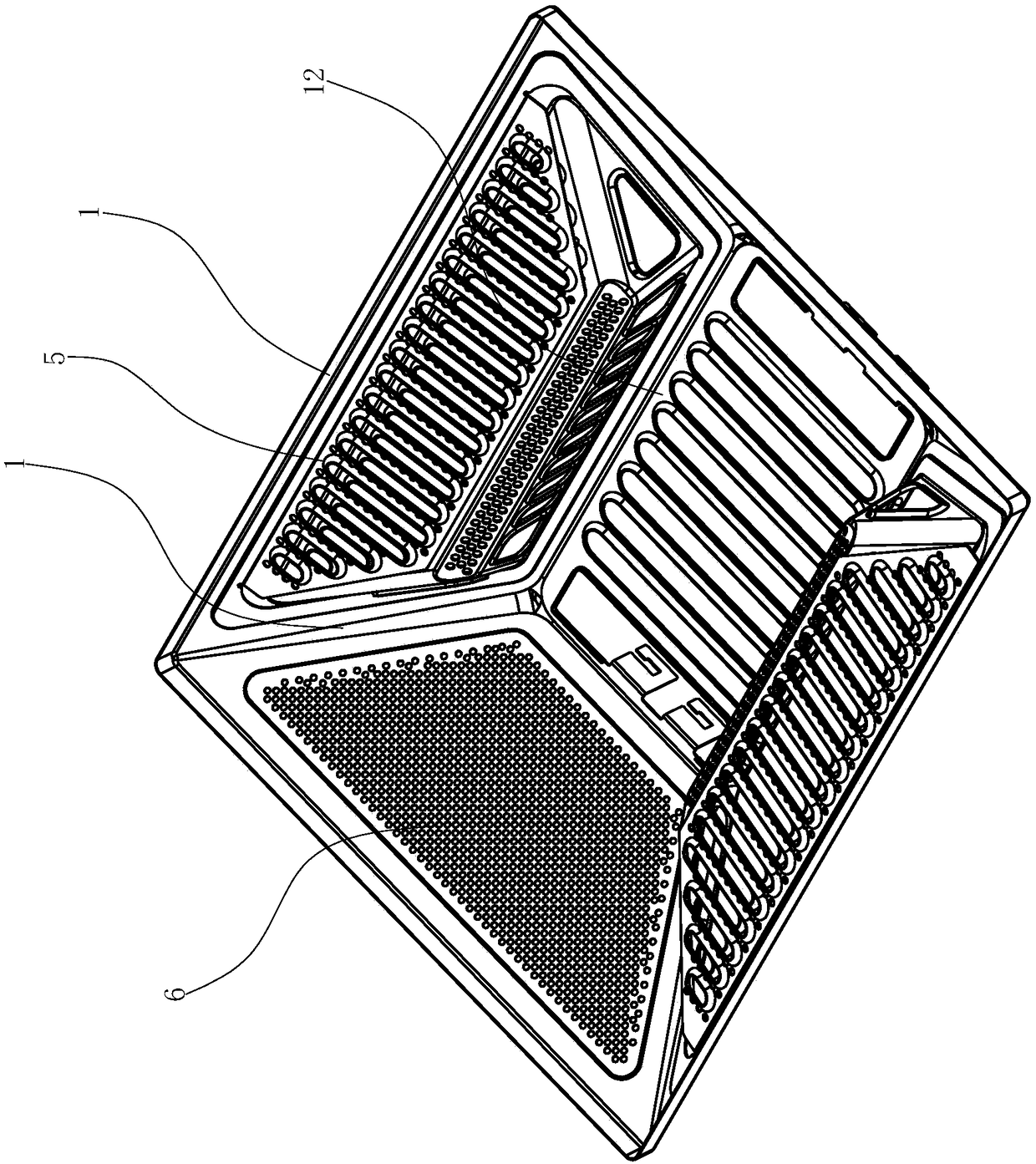

Filter screen for range hood

PendingCN108061320AEasy to cleanImprove oil separation effectDomestic stoves or rangesLighting and heating apparatusLarge mouthEngineering

The invention relates to a filter screen for a range hood. The filter screen comprises a bucket-shaped body with a large mouth and a small bottom, the body has a hollow-out bottom surface, and the sidewall of the body is provided with at least three first through holes for communicating the inner cavity of the body; at least one of the first through holes is detachably connected with a hollow-outfirst filter frame; elongated second air inlet holes are arranged in the first filter frame at intervals, a gap between the adjacent second gas inlet holes forms a first rib plate, and every first ribplate is a netted structure; the body is also connected with a folded filter; the folded filter is located above the first filter frame, and a gap exists between the folded filter and the first filter frame; a plurality of elongated third air inlet holes are arranged in the folded filter at intervals, a part between the adjacent third air inlet holes forms a second rib plate, and every second ribplate is a netted structure; and the second rib plates on the laminated filter are arranged corresponding to the second air inlet holes in the first filter frame, and the first rib plates are arranged corresponding to the third air inlet holes.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Scroll compressor with oil separation member

ActiveUS10895260B2Minimizing drivingImprove oil separation effectRotary/oscillating piston combinations for elastic fluidsCombination devicesRotational axisInterior space

A scroll compressor includes a casing, and an internal sealed space in the casing; a drive motor configured with a stator and a rotor which rotates within the stator, and that has an internal flow passage and an external flow passage; a rotation shaft connected to the rotor; a compression unit that includes a first scroll, and a second scroll which is engaged with the first scroll to form a compression chamber, with which the rotation shaft is eccentrically combined; a discharge pipe that communicates with an upper space of the internal space; an oil separation member disposed in the upper space; and a guidance member that is provided between an upper end of the drive motor and a lower end of the discharge pipe and guides the refrigerant with which the oil is mixed, to the oil separation member.

Owner:LG ELECTRONICS INC

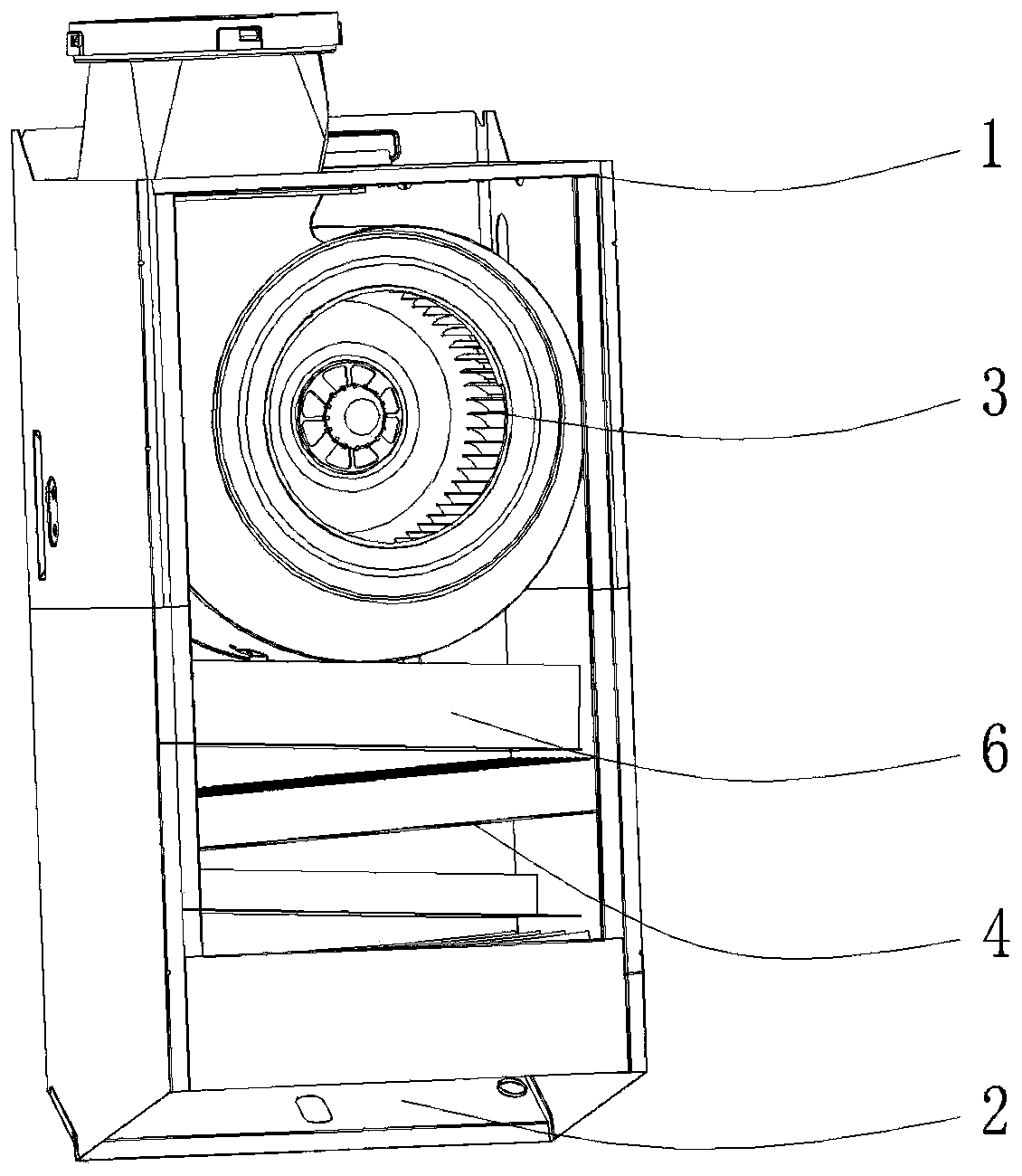

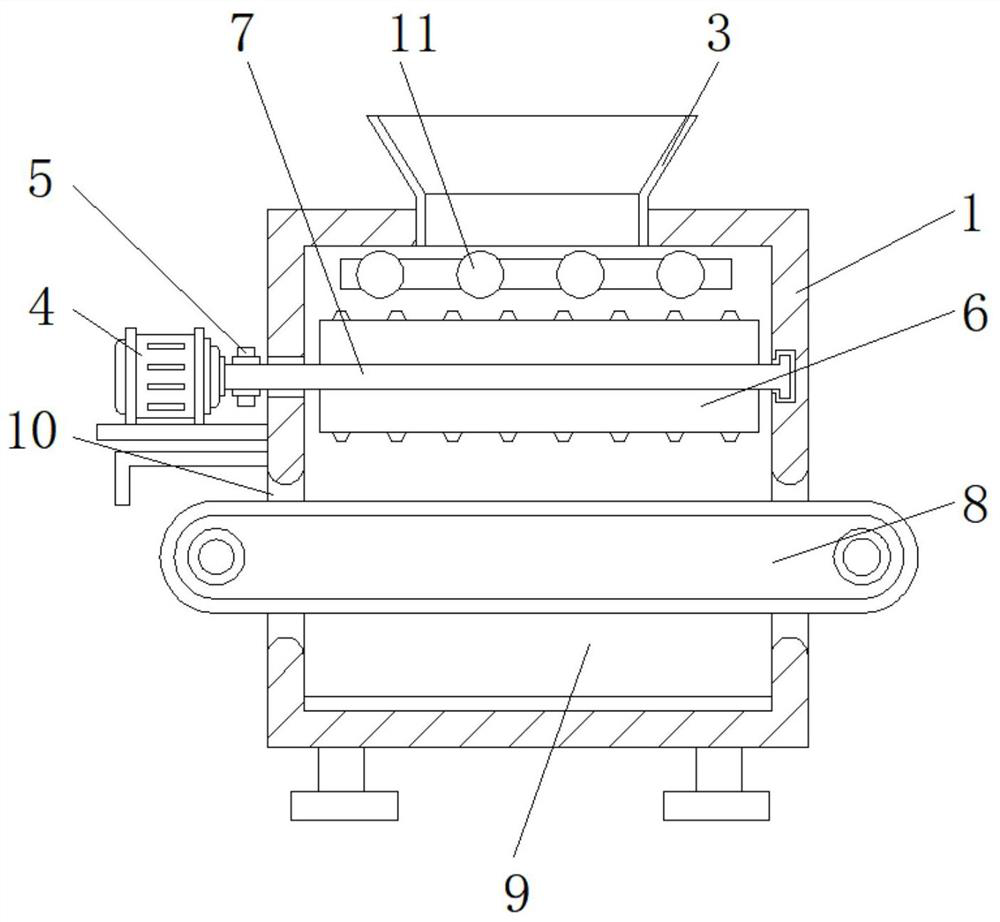

Kitchen waste collection and oil separation integrated machine

InactiveCN104415964AEasy to separateNo smellFatty/oily/floating substances removal devicesSolid waste disposalRefuse collectionOil separation

The invention relates to a kitchen waste collection and oil separation integrated machine. The kitchen waste collection and oil separation integrated machine comprises a box body formed by sequential connection of a residue removal region, an oil separation region and an oil-water separation region, wherein a kitchen waste inlet is formed in the box body of the residue removal region, a vent hole, a sewage draining exit and an oil drainage outlet are formed in the box body of the oil separation region, a water inlet and outlet pipe is arranged on the box body of the oil-water separation region, a solid-liquid separation device and a draining pump are arranged in the oil-water separation region, one end of the water inlet and outlet pipe stretches into the oil-water separation region, the other end of the water inlet and outlet pipe is communicated with a water inlet by a water inlet pipe, and one end of the water inlet and outlet pipe, communicated with the water inlet, is also communicated with a water drainage hole by a water drainage pipe. The kitchen waste collection and oil separation integrated machine is of a full-automatic closing type, cannot cause peculiar smell and cannot influence the surroundings, and besides, the kitchen waste collection and oil separation integrated machine can be operated intelligently, has a good oil separation effect and can be used for separating oil from water thoroughly.

Owner:天津今誉源科技发展有限公司

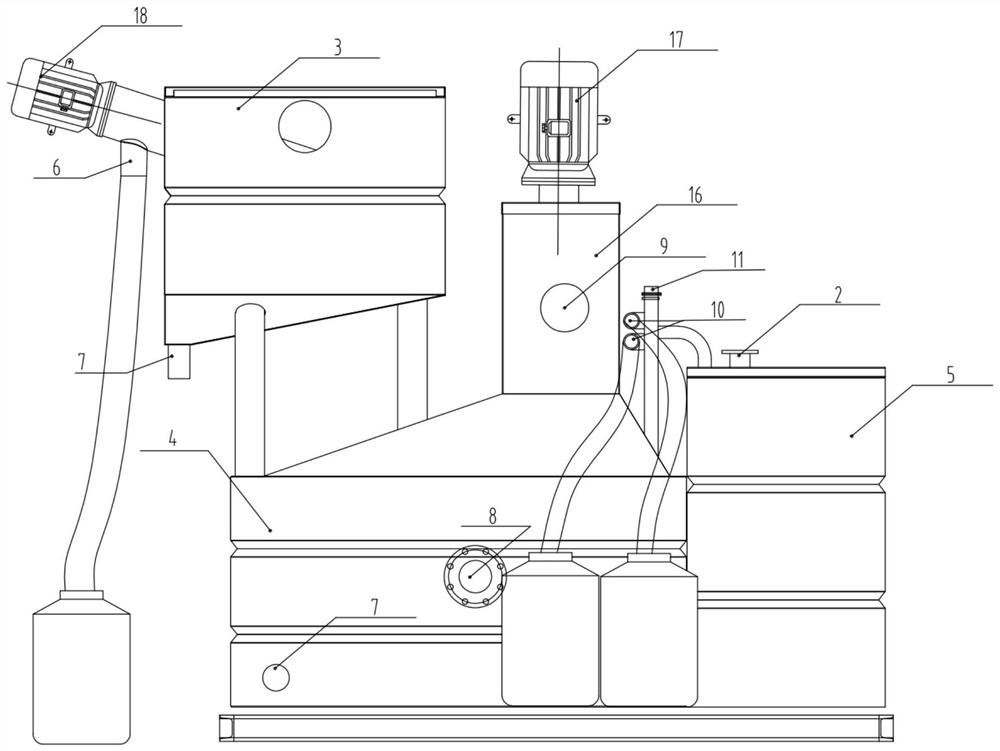

Oil separation equipment

PendingCN111874992AAuto Quick GatherSave installation spaceFatty/oily/floating substances removal devicesLiquid separationTemperature controlSludge

Oil separation equipment is disclosed. The equipment comprises a residue-liquid separation tank, an oil-water separation tank, an oil storage tank and a sewage lifting tank, wherein a liquid outlet ofthe residue-liquid separation tank is communicated with a liquid inlet of the oil-water separation tank, the bottom of the residue-liquid separation tank is arranged in an inverted cone shape, a sludge discharge port is formed in the cone bottom of the inverted cone, the upper portion of the oil-water separation tank is arranged in a right cone shape, the upper part of the right cone shape is communicated with the oil storage tank, an oil outlet of the oil storage tank is externally connected with a waste oil collecting barrel through a pipeline to discharge oil; a stirring device, a heatingdevice and a temperature control device are arranged in the oil storage tank; a water outlet of the oil-water separation tank is connected with a water inlet of the sewage lifting tank. The equipmentintegrates an automatic oil separation function, an electric heating constant-temperature function and an automatic sewage forced drainage function, is ingenious in design and excellent in configuration, and is special equipment for oil separation and forced drainage of underground restaurant wastewater. The whole process is automatic and integrally designed, oil separation, forced drainage and auxiliary heating are integrated, installation and operation are easy, the appearance is compact and attractive, and the basement installation space is reduced.

Owner:上海双解泵业制造有限公司

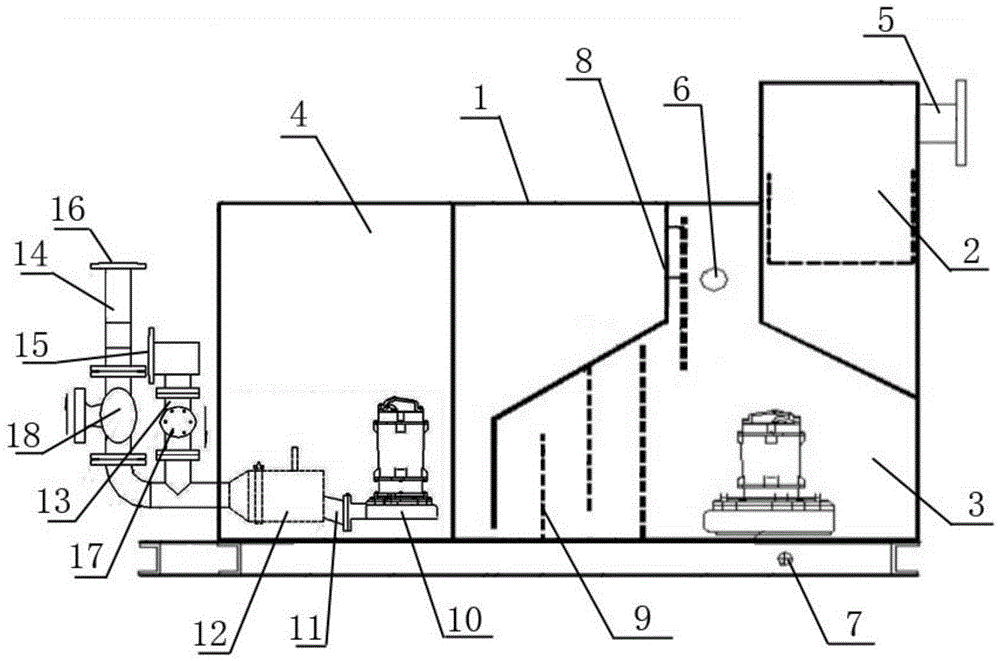

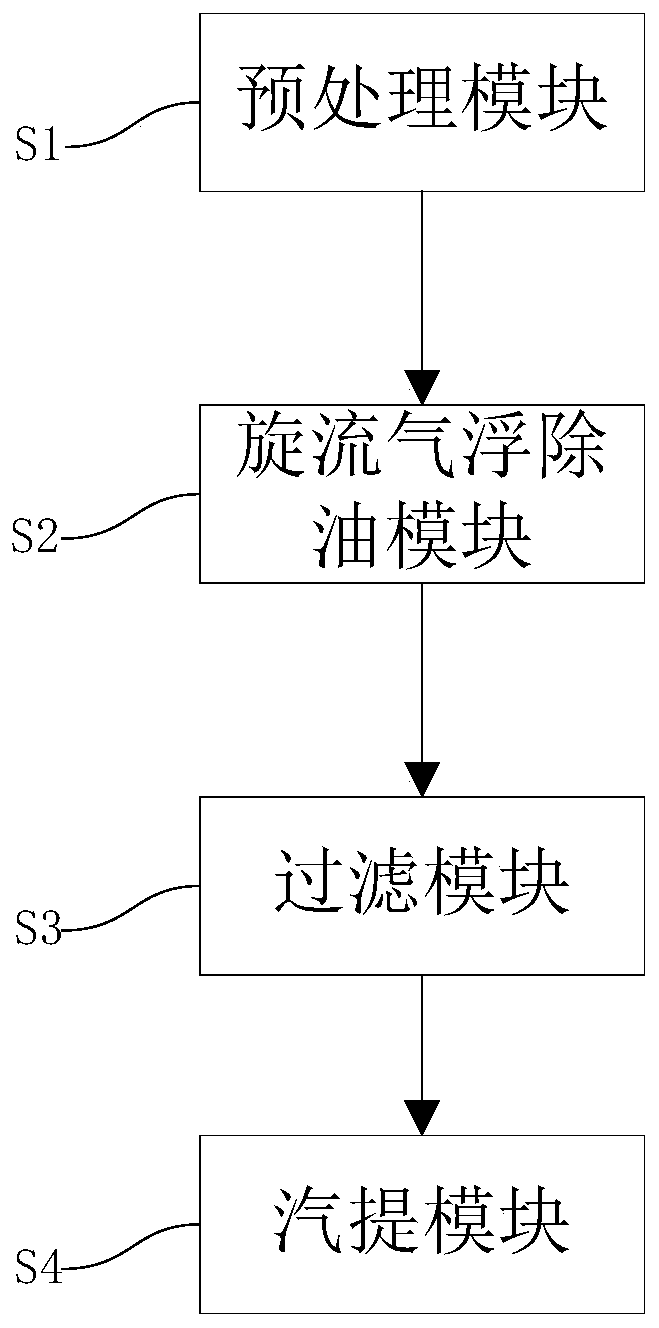

Sewage treatment method of a delayed coking device

PendingCN111533353ATargetedReduce pollutionWater treatment parameter controlFatty/oily/floating substances removal devicesSewage treatmentSulfur hydride

The invention discloses a sewage treatment method of a delayed coking device, belongs to the field of petrochemical engineering, aims to solve the technical problem that coking sewage is difficult totreat such as oil, coke powder and hydrogen sulfide in a delayed coking device at present. The adopted technical scheme is that the method comprises the following steps: pretreatment: adding a demulsifier added with an active conversion agent, a high-efficiency dispersing agent and a flocculating agent into a pretreatment module; oil removing: discharging gas, oil, water and settled sewage from agas-liquid separation area, a floating oil layer area, a sewage separation area and a settling area in a layered mode through a rotational flow air floatation oil removal module, and discharging sewage discharged from the sewage separation area to the downstream to be treated; filtering: carrying out two-stage backwashing filtering by adopting a filtering module, and sending to downstream treatment; and steam stripping: performing steam stripping through a steam stripping tower of a steam stripping module, sending acid gas at the top of the steam stripping tower after steam stripping to the inlet of a coking compressor, and using purified water at the bottom of the steam stripping tower directly as water injected at the top of the coking fractionating tower and in front of a compressed rich gas air cooler or as cold coke water replenishing water.

Owner:SHANDONG JILIAN PETROCHEM ENG

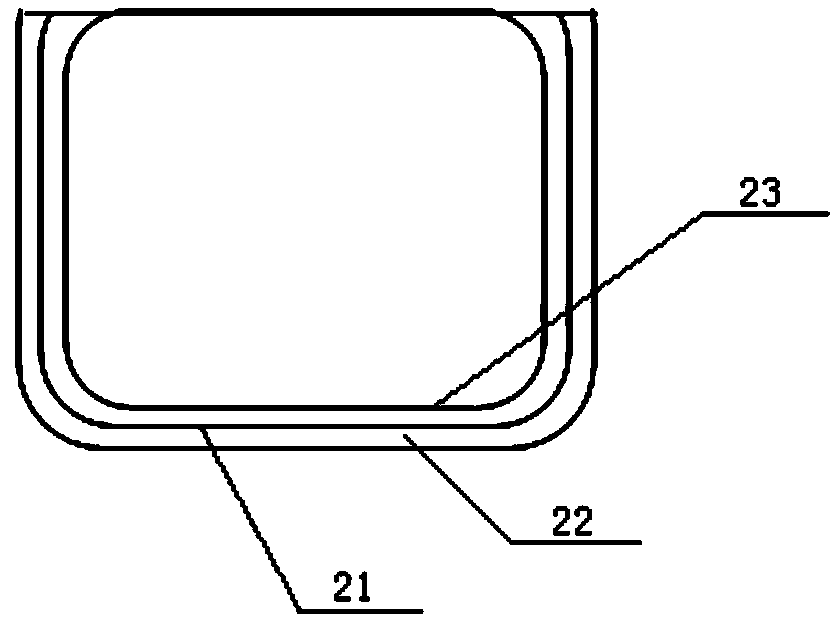

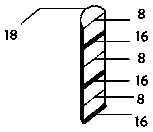

Oil separation water tank

InactiveCN103526807ALow costSuitable for mass productionDomestic plumbingHigh volume manufacturingOil separation

The invention discloses an oil separation water tank, which is a multilayer composite structure. The inner layer of the multilayer composite structure is a base material, which is an alumina ceramic material. A middle layer is designed and attached to the outside of the inner layer. The outermost layer of the multilayer composite structure is an oil separation layer. The middle layer is a stainless steel material. The oil separation layer is a film structure formed by a hydrophobic material. The oil separation water tank provided by the invention adopts the multilayer composite structure, the inner layer employs a cheap ceramic material, the middle layer is designed as a stainless steel material, and the outermost layer is designed as the oil separation layer. With a low cost, the oil separation water tank is suitable for mass production, is rust-proof and corrosion-proof, has good oil separation effect, and is easy to clean.

Owner:聂晓鸿

Oil separation and residue removal integrated garbage treatment system

InactiveCN112718786AEasy to separateReduce pollutionSolid waste disposalTransportation and packagingElectric machineOil separation

The invention discloses an oil separation and residue removal integrated garbage treatment system. The system comprises a body, a smashing roller and a filter screen type conveying belt, wherein a feeding port is formed in the outer side of the top end of the body, a first motor is arranged on the outer side of the left end of the body, the right end of the first motor is connected with a connecting rod, a belt is arranged on the outer side of the left end of the connecting rod, the filter screen type conveying belt is arranged below the smashing roller, a guide plate is installed at the lower end of the filter screen type conveying belt, heat dissipation holes are formed in the rear end of the body, a water tank is installed at the front end of the body, a water pipe is arranged in the water tank, an oil separation pool is installed at the rear end of the body, and an installation block is fixedly installed at the upper end of the oil separation pool. The oil separation and residue removal integrated garbage treatment system has the advantages that oil separation and residue removal are integrated, oil stains and residues can be thoroughly separated conveniently, the working efficiency is improved, pollution to the environment is reduced, and meanwhile the oil separation effect and the heat dissipation performance are enhanced.

Owner:WUHAN JIAFU ENERGY SAVING & ENVIRONMENT PROTECTION HIGH TECH CO LTD

Grease trap device for adjustable filter oil-water mixture separation

ActiveCN105293734BImprove oil separation effectReduce depositionMultistage water/sewage treatmentOil and greaseFiltration

The invention discloses an adjustable filtering type oil-water mixture separation oil trap device, which comprises an oil-water separation box shell, a backflow baffle, an oil-water separation membrane, an oil-water separation membrane support net, a funnel-type tank bottom shell, a baffle plate, an oil-water separation The area where the separation membrane is located is the filter area, the upper part of the filter area is the oil slick area, the lower part of the filter area is the buffer settlement area, the oil outlet is equipped with a backflow baffle, and there is an oil-water separator that can be adjusted up and down and placed at a distance from the oil-water separation membrane support net. The separation membrane group, the two sides of the baffle plate are the feed port and the discharge port of the oil-water mixture, and the bottom of the funnel bottom shell is the sewage discharge port. The area where the baffle is located is the oil-water-solid particle buffer settlement area. There is a main valve at the water inlet, and the sewage outlet set under the sediment buffer settlement area has a mud discharge valve, and the mud discharge pipe is connected to the sewage outlet in turn. By adjusting the position of the oil-water separation membrane, the invention is suitable for the separation of oil and sewage with different concentrations, can realize efficient separation of oil, water and sediment, and is convenient for waste water treatment and resource recycling.

Owner:SHANGHAI UNIV

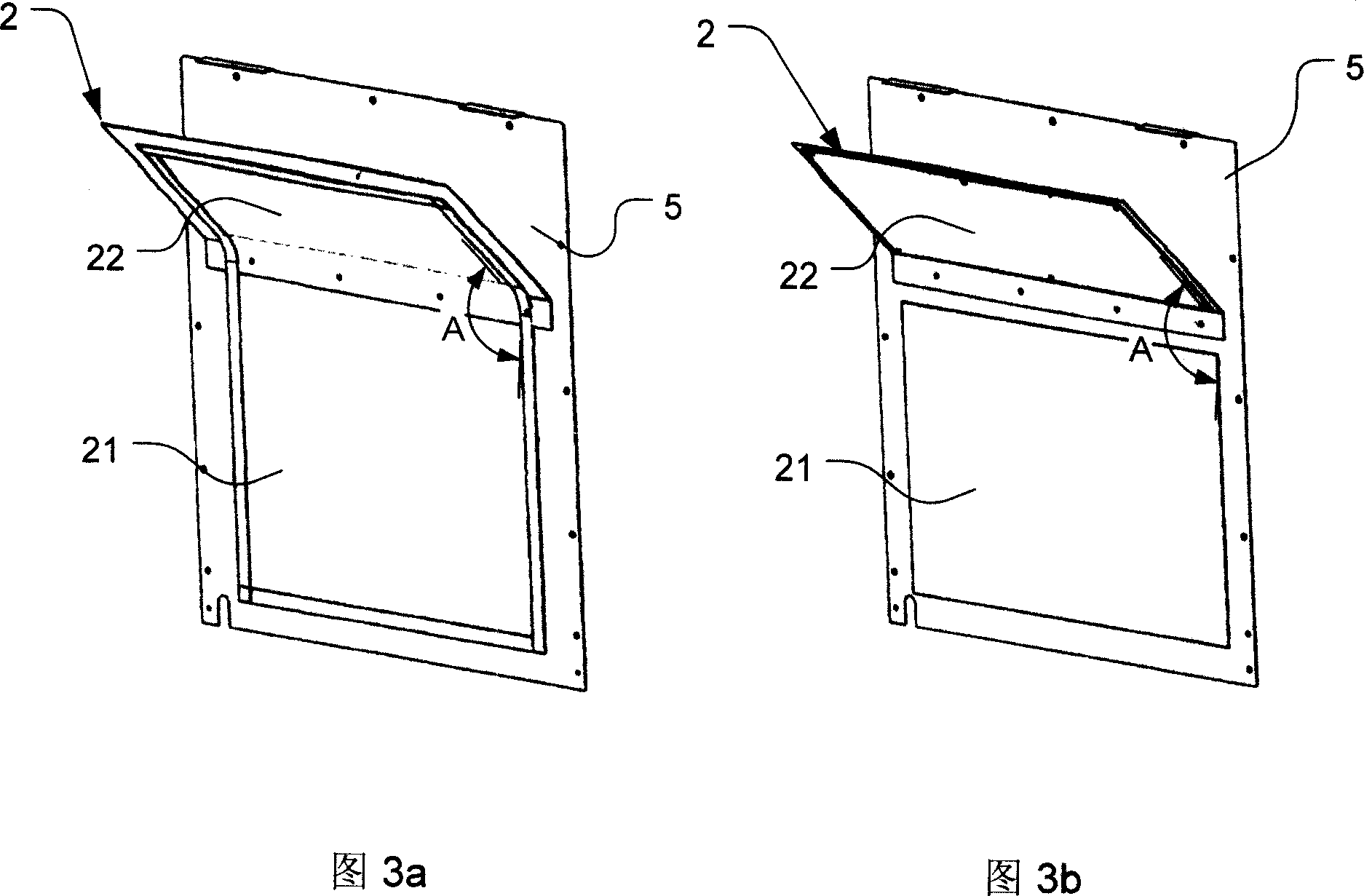

Cooking fume exhauster

ActiveCN101118067AImproved Grease Separation CapabilityReduce noiseDomestic stoves or rangesLighting and heating apparatusSurface elementEngineering

The present invention relates to a smoke vacuation machine (1) provided with a surface element (2) with a plane being contacted with oil smoke containing oil smoke particles in particular fat and / or oil. The surface element (2) is designed according to replacing a plane by a surface increased on a surface area, thereby improving the degree of separation of the oil smoke particles contained in the oil smoke.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Oil-gas separator and air-conditioning system having the same

ActiveCN106352621BImprove oil separation effectSimple structureRefrigeration componentsOil separationAir conditioning

The invention discloses an oil-gas separator and an air conditioning system with the oil-gas separator. The oil-gas separator comprises a shell, wherein an oil collection opening is formed in the bottom wall of the shell, an air baffle plate is arranged on the inner wall of the shell, an air exhaust pipe is arranged on the shell; an air inlet pipe, one end of the air inlet pipe extending into the shell towards the air baffle plate, and an oil-gas mixture entering the shell from the air inlet pipe colliding the air baffle plate; an air homogenization plate which is arranged in the shell, a plurality of ventilating holes are formed in the air homogenization plate, and an oil filter assembly which is arranged in the shell, wherein the air baffle plate is located at the upstream of the air homogenization plate in the flowing direction of the oil-gas mixture; the air homogenization plate is located at the upstream of the oil filter assembly, and the air homogenization plate and the oil filter assembly are arranged in a spacing manner; the air exhaust pipe is located at the downstream of the oil filter assembly. The oil-gas separator disclosed by the invention can enhance the oil separation effect, and is simple in structure; the oil separation principle is simple and reliable.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com