Filter screen for range hood

The technology of a range hood and a filter screen is applied in the field of filters for range hoods, which can solve the problems of increasing smoke exhaust resistance, affecting the suction and discharge of range hood, and loss of ventilation flow, etc., and achieves the effect of facilitating cleaning and improving the effect of oil separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

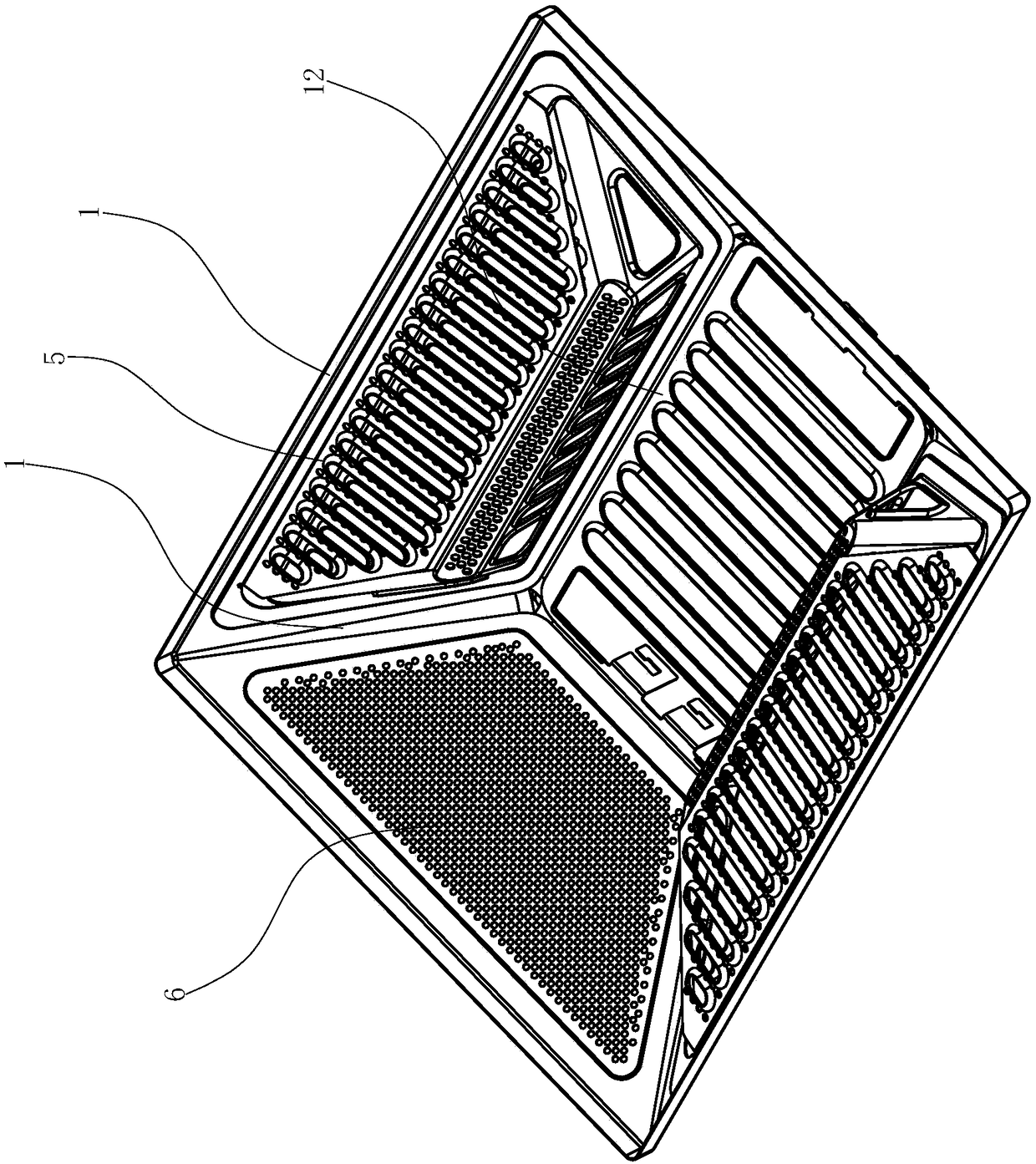

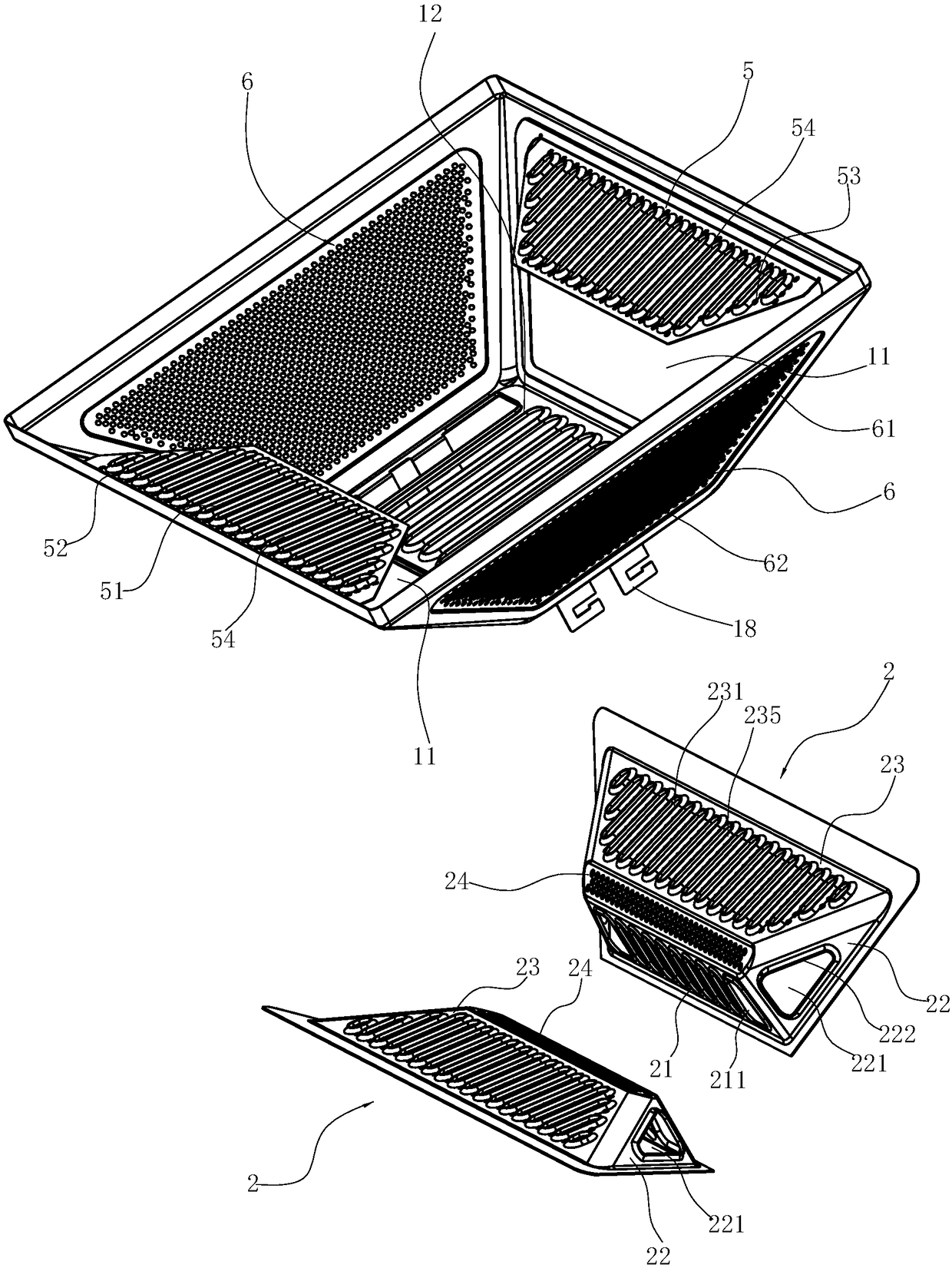

[0029] Such as Figure 1 to Figure 5 As shown, the filter screen for the range hood includes:

[0030] The main body 1, which is the installation foundation of the oil net, has a hollow bottom surface 12, an upper vent 14 communicating with the inner cavity 19 of the body, and four first through holes 11 arranged on the side wall and communicating with the inner cavity 19;

[0031] In this embodiment, the upper vent 14 and the bottom surface 12 of the main body 1 are both rectangular, and the bottom surface 12 is located directly below the upper vent 14, and the area of the bottom surface 12 is smaller than the area of the upper vent 14; the first through hole 11 is inclined The trapezoid; the body 1 is a quadrangular pyramid structure.

[0032] The bottom surface shown in the figure is a grid-like structure, and the grids are arranged parallel to each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com