Variable volume high-efficiency vertical oil separator for refrigeration compressor testing device

A technology for refrigeration compressors and test equipment, which is applied in the field of oil separation, and can solve problems such as failure to meet the requirements of refrigeration compressor test equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

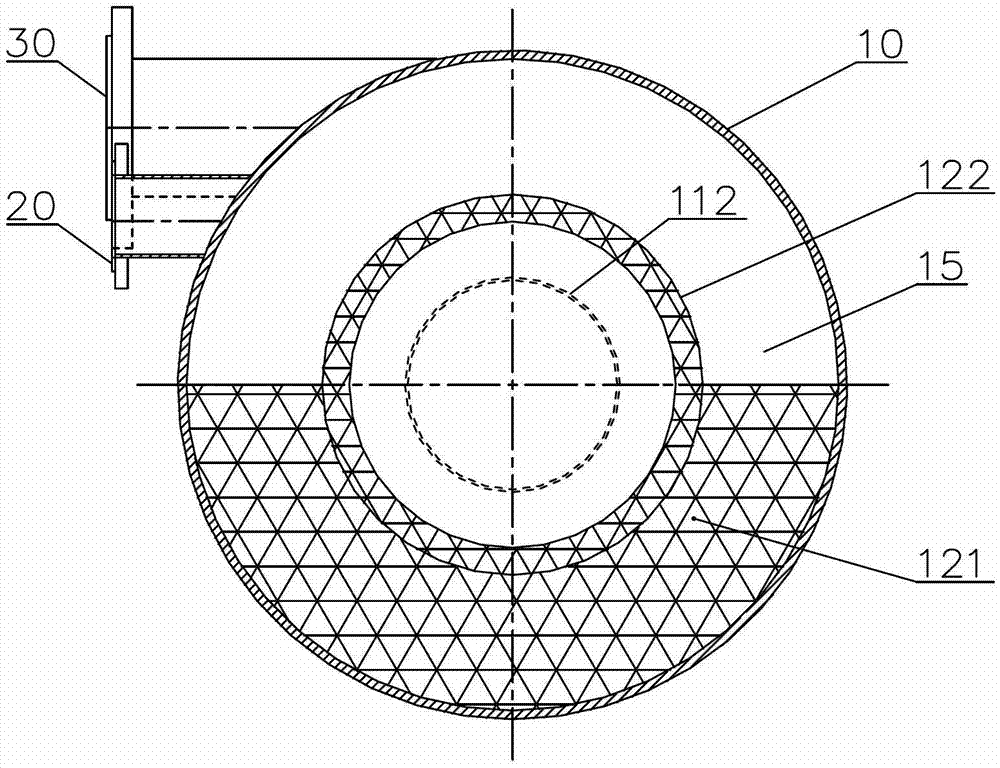

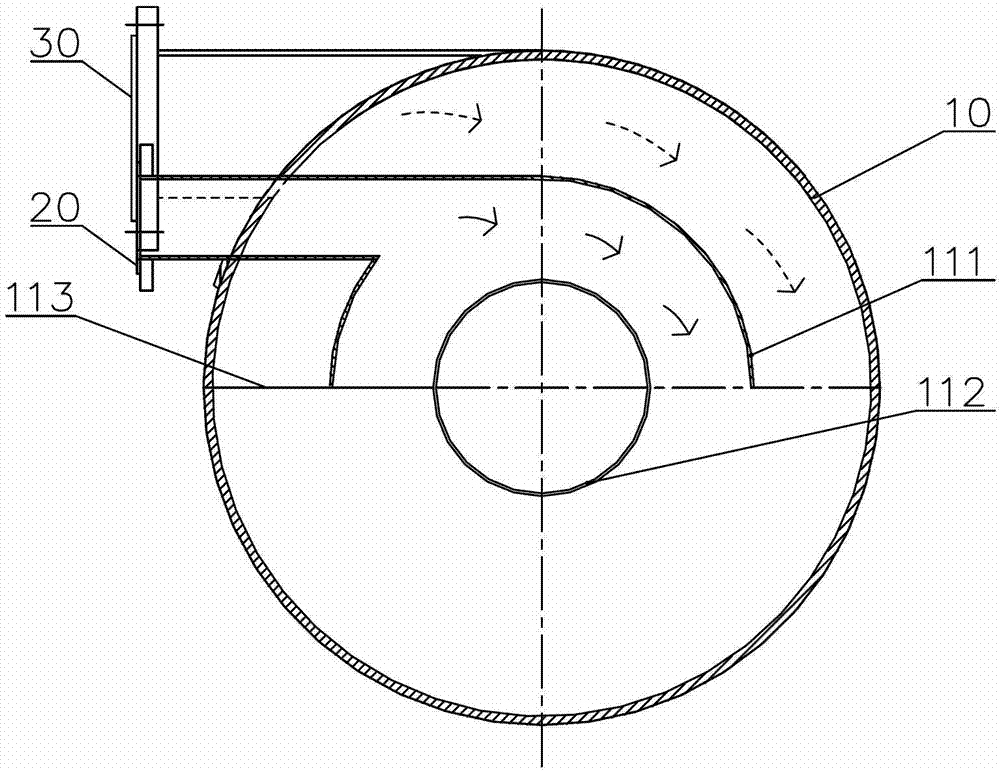

[0043] Such as figure 1 , 5 , shown in 6, a kind of variable-volume high-efficiency vertical oil separator for refrigeration compressor test equipment, said oil separator comprises a closed cylinder 10, said cylinder 10 is provided with a centrifugal separation zone 11, said At least two inlet nozzles are provided on the cylinder wall at the centrifugal separation zone 11, and an independent centrifugal separation channel corresponding to each inlet nozzle is provided on the inner side of the centrifugal separation zone 11;

[0044] The upper side of the centrifugal separation area 11 is provided with a filter separation area 12, the filter separation area 12 is provided with a filter screen which is convenient for gas and oil phase separation, and the upper side of the filter separation area 12 is provided with an outlet connecting pipe 14 which is convenient for gas to flow out;

[0045] A gravity settling zone 13 is provided on the lower side of the centrifugal separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com