Integral closed oil separator

A closed oil trap technology, which is applied in liquid separation, grease/oily substance/floating matter removal device, flotation water/sewage treatment, etc. It can solve the problems of influence on the surrounding environment, automatic failure, and odor. Achieve the effect of good oil separation and speed up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

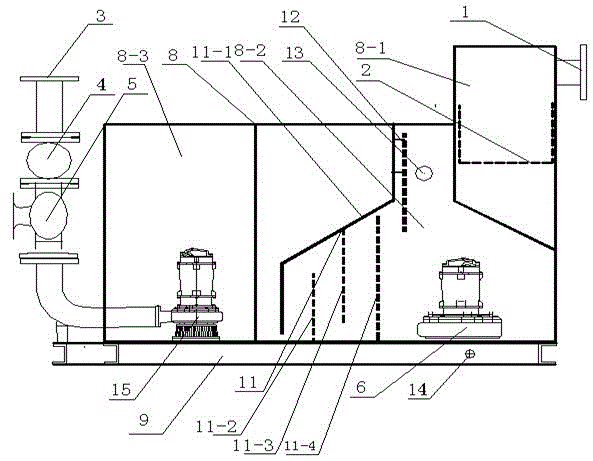

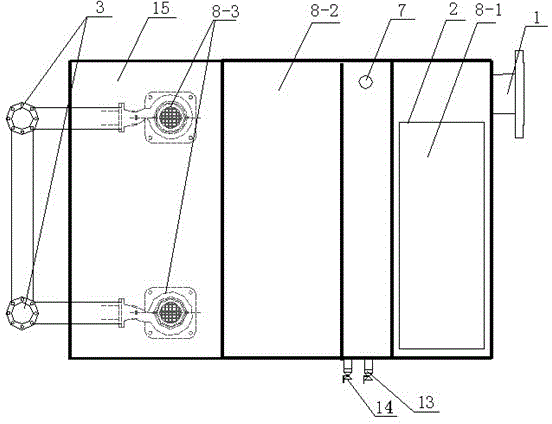

[0020] see figure 1 , figure 2 and image 3 , the closed integrated oil separator includes a box body 8, the box body 8 is composed of a slag removal area 8-1 located at one end of the box body 8, an oil separation area 8-2 located in the middle of the box body 8, and a The liquid level lifting area 8-3 at the other end of the body 8, the oil-water inlet 1 set on the upper part of the slag removal area 8-1, the vent hole 7 set on the upper part of the oil separation area 8-2, and the bottom of the oil separation area 8-2 The sewage discharge hole 14, the oil discharge port 13 arranged in the upper part of the oil separation area 8-2, and the water outlet 3 connected with the liquid level lifting area 8-3 are composed; the oil separation area 8-2 is provided with multiple To the oil control device 11, the multi-directional oil control device 11 includes an inclined plate 11-1 and at least three side plates, and the number of the side plates can be three, four, five, six or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com