Preparation method of magnetic cellulose microsphere and method for separating pigments from grease

A technology of cellulose microspheres and pure cellulose, applied in chemical instruments and methods, production of fat, fat oil/fat refining, etc., can solve problems such as difficulty in filtration, high oil absorption by clay, and small amount of oil hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

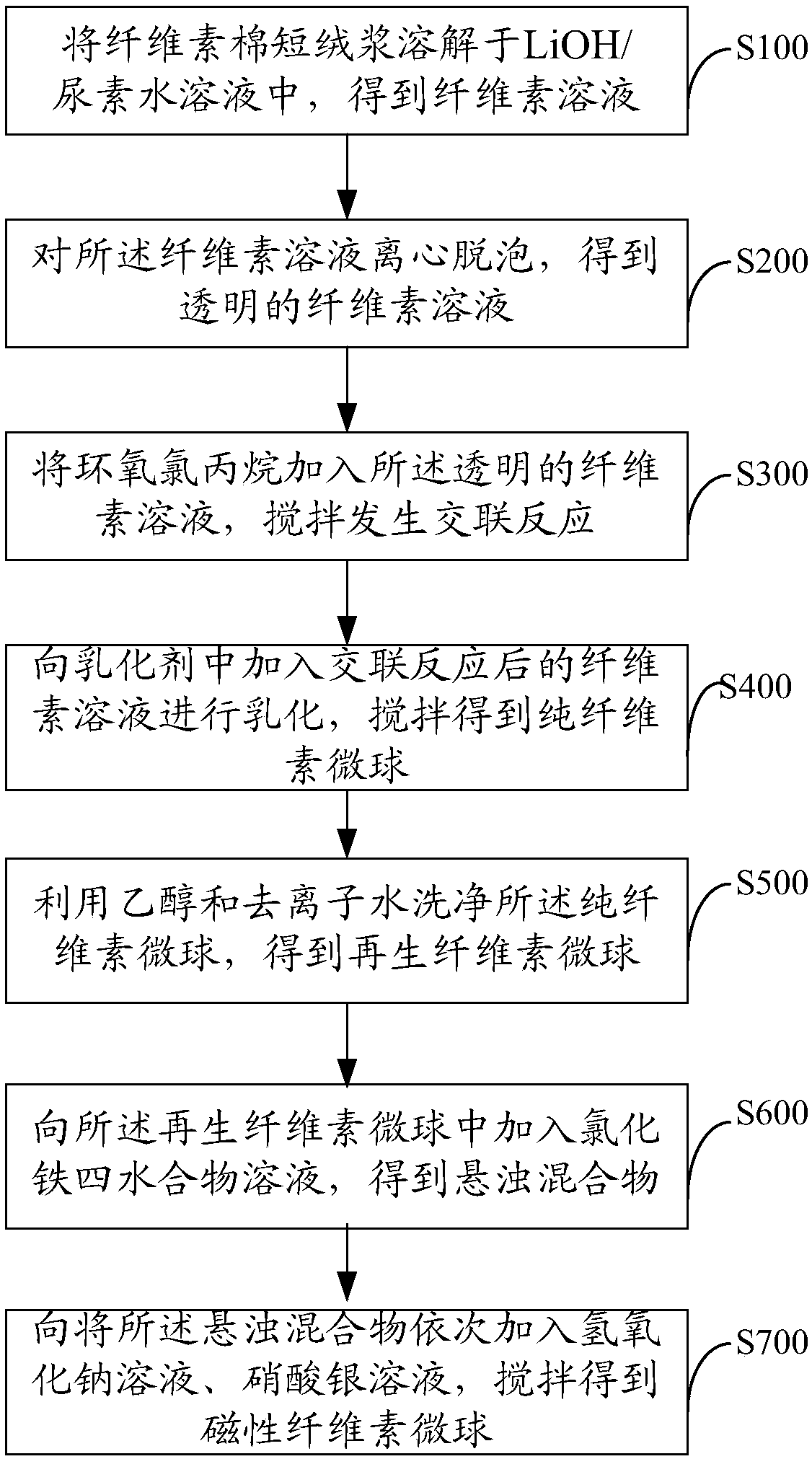

[0040] The present invention provides a preparation method of magnetic cellulose microspheres, please refer to figure 1 , including the following steps:

[0041] S100, dissolving cellulose cotton linter pulp in LiOH / urea aqueous solution to obtain a cellulose solution;

[0042] Cotton linters are the short fibers that remain on the cottonseed (hairseed) after ginning, and these short fibers are peeled off by a stripping machine, which is cotton linters. Cotton linters are composed of three parts; the first part comes from the longer fibers of the "hair head"; the second part comes from the fibers on the wool seeds that were cut by the cotton gin; Dense fibers.

[0043] Preferably, the concentration of the cellulose solution is 4wt%.

[0044] The cellulose cotton fluff pulp was provided by Hubei Chemical Fiber Group Co., Ltd. (Hubei, Xiangfan), in which the α-cellulose content was higher than 95%. The cellulose cotton fluff pulp was dissolved in LiOH / urea aqueous solution an...

Embodiment 1

[0091] (1) Preparation of a transparent cellulose solution: 4.2 g of cellulose cotton fluff pulp was dissolved in 100 g of LiOH / urea aqueous solution (the mass ratio of LiOH to urea was 4.6:15) precooled to -12.6 ° C to obtain 4 wt % of cellulose The cellulose solution was degassed by centrifugation at 5° C. at 6000 rpm to obtain a transparent cellulose solution.

[0092] (2) Preparation of pure cellulose microspheres: under an ice-water bath at 0°C, add 10ml of epichlorohydrin to 100g of transparent cellulose solution, and stir for 2 hours to disperse the epichlorohydrin evenly;

[0093] Add 60g of Span 80 / Span 85 and 300ml of isooctane to a 500ml three-necked flask under an ice-water bath at 0°C, and stir at a speed of 300r / min for 30min to disperse the emulsifier evenly;

[0094] Stir the emulsifier at a speed of 1000r / min, add 60g of 4wt% cellulose solution after cross-linking reaction, continue stirring for 30min, remove the ice bath and continue stirring for 2h to obtain...

Embodiment 2

[0102] (1) Preparation of a transparent cellulose solution: 4.2 g of cellulose cotton fluff pulp was dissolved in 100 g of LiOH / urea aqueous solution (the mass ratio of LiOH to urea was 4.6:15) precooled to -12.6 ° C to obtain 4 wt % of cellulose The cellulose solution was degassed by centrifugation at 5° C. at 6000 rpm to obtain a transparent cellulose solution.

[0103] (2) Preparation of pure cellulose microspheres: under an ice-water bath at 0°C, add 10ml of epichlorohydrin to 100g of transparent cellulose solution, and stir for 2 hours to disperse the epichlorohydrin evenly;

[0104] In an ice-water bath at 0°C, add 60g of Span 80 / Span 85 and 300ml of isooctane into a 500ml three-necked flask, and stir at a speed of 500r / min for 30min to disperse the emulsifier evenly;

[0105] Stir the emulsifier at a speed of 1000r / min, add 60g of 4wt% cellulose solution after cross-linking reaction, continue stirring for 30min, remove the ice bath and continue stirring for 2h to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com