Oil separator

An oil separator, a new type of technology, applied in the direction of refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of complex internal structure, large pressure loss, high material cost, etc., achieve simple internal structure, reduce manufacturing cost, speed big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

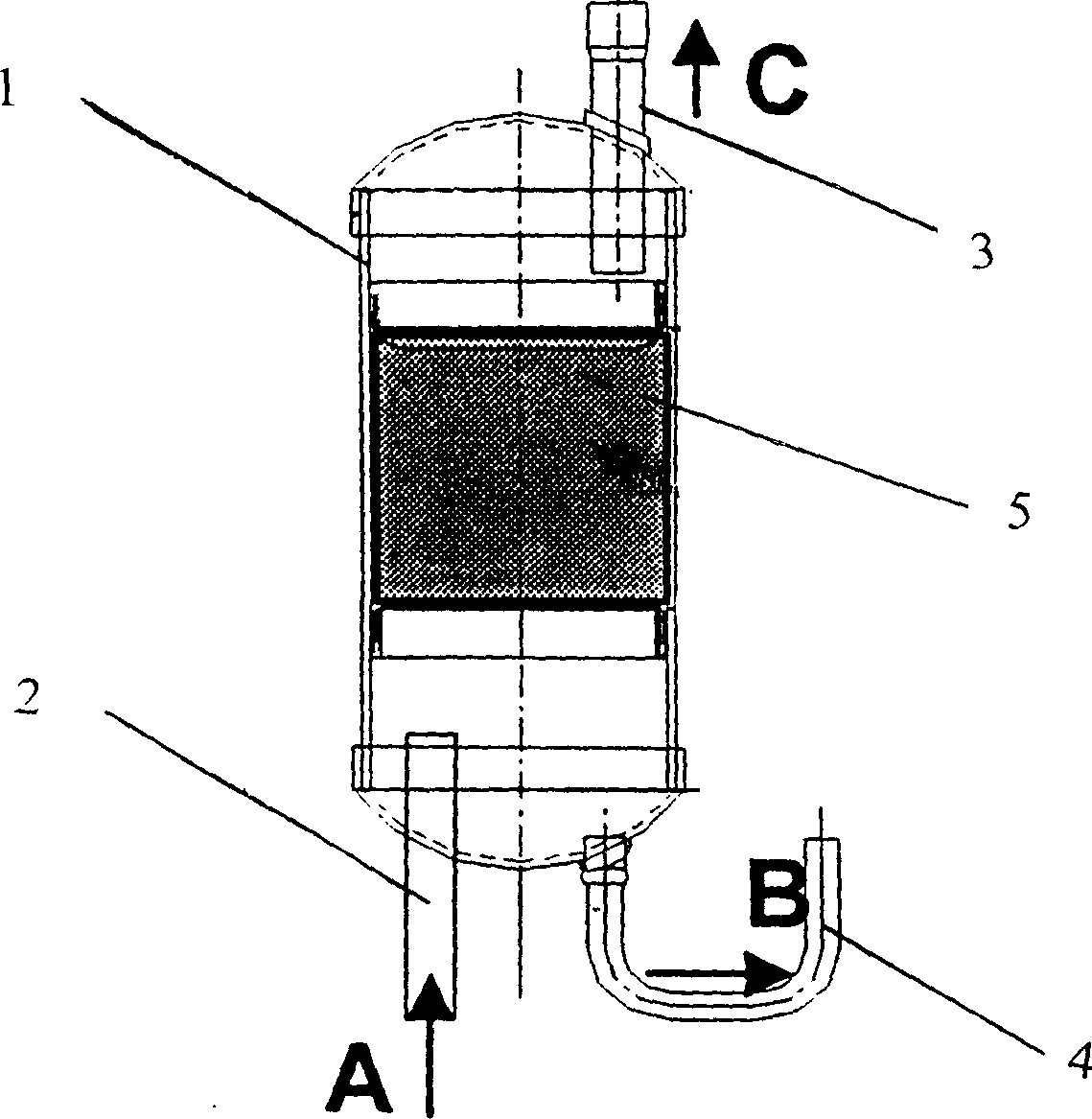

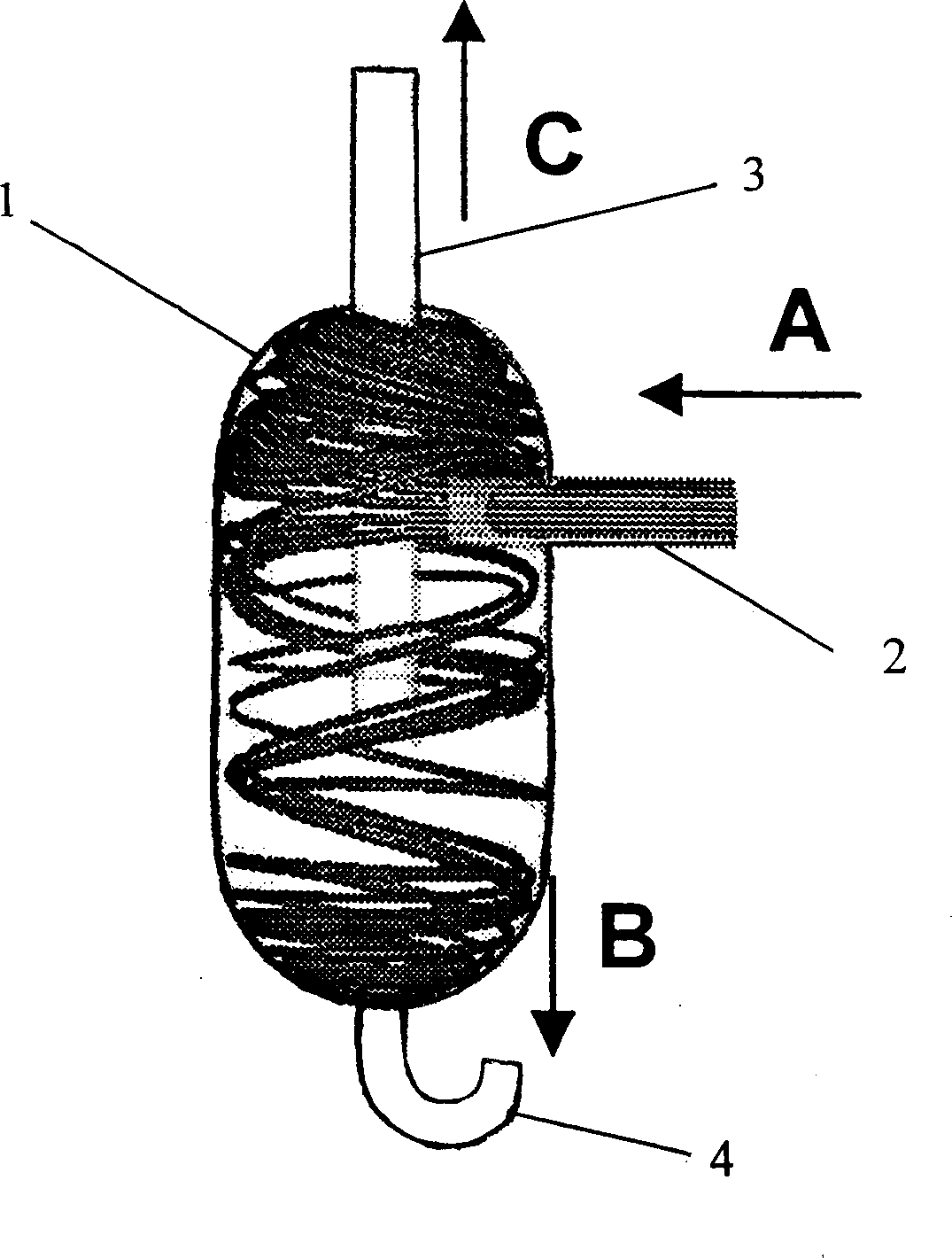

[0016] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings. Such as figure 2 As shown, the novel oil separator involved in the present invention includes a tank body 1 with a cylindrical structure, and the wall thickness of the tank body is 1.2 mm. The side of the tank body is inserted into the intake pipe 2, the top is inserted into the exhaust pipe 3, and the bottom is provided with an oil return pipe 4. The intake pipe 2 , the exhaust pipe 3 and the oil return pipe 4 communicate with the inside of the tank body 1 . The bottom end of the exhaust pipe 3 inserted from the top is inserted into the inner center of the tank body 1 . There is an angle of 120° between the inlet pipe 2 inserted from the side of the tank body 1 and the axis of the tank body, and the end of the inlet pipe 2 inserted into the tank body is higher than the bottom end of the exhaust pipe 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com