Monitoring device for liquid level and flow velocity of liquid iron in torpedo tank truck

A technology for a torpedo tanker and a monitoring device, which is applied in the monitoring field, can solve the problems of unfavorable installation and use, difficult construction and maintenance, and low measurement accuracy, and achieves the effects of simple structure, low cost, and high monitoring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

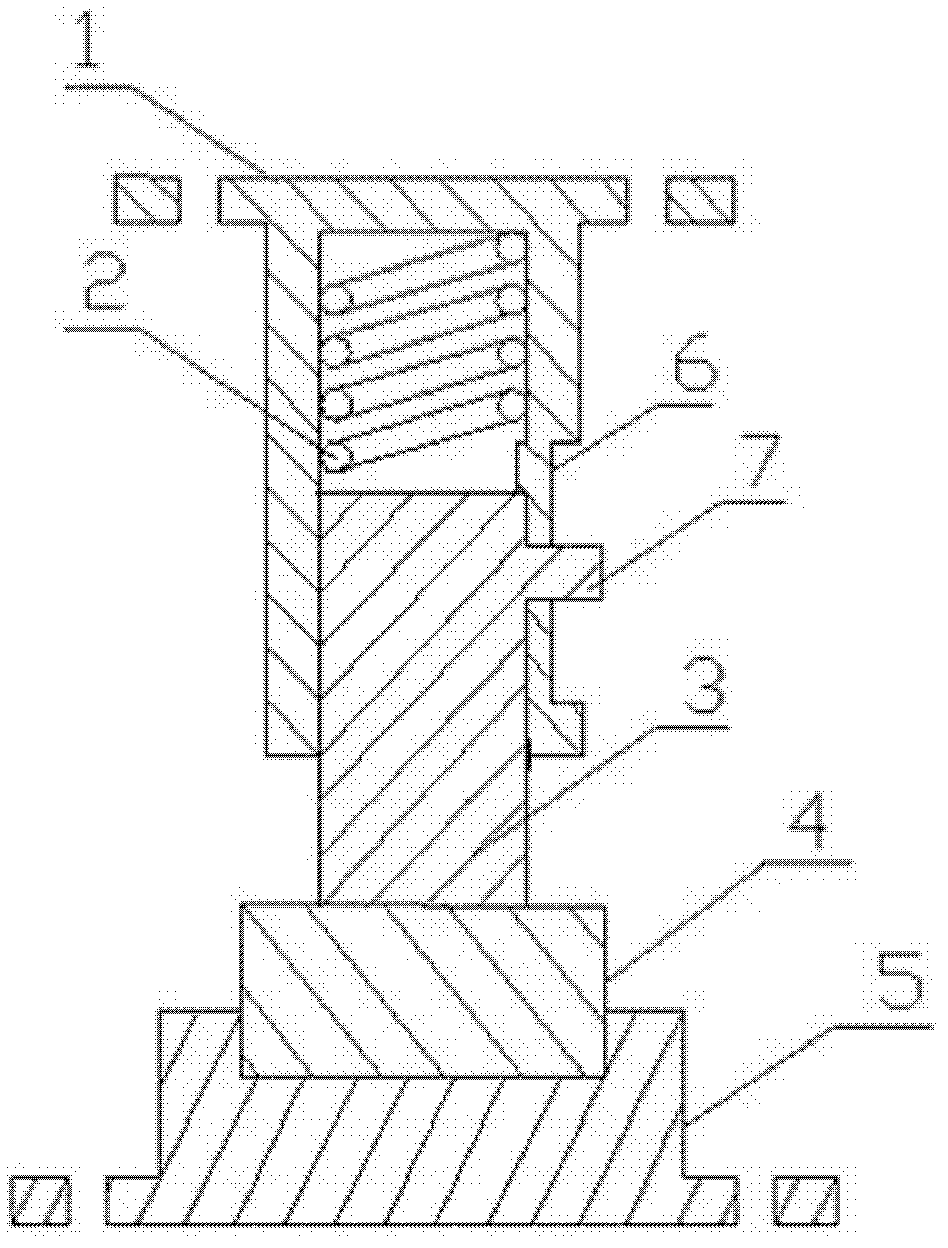

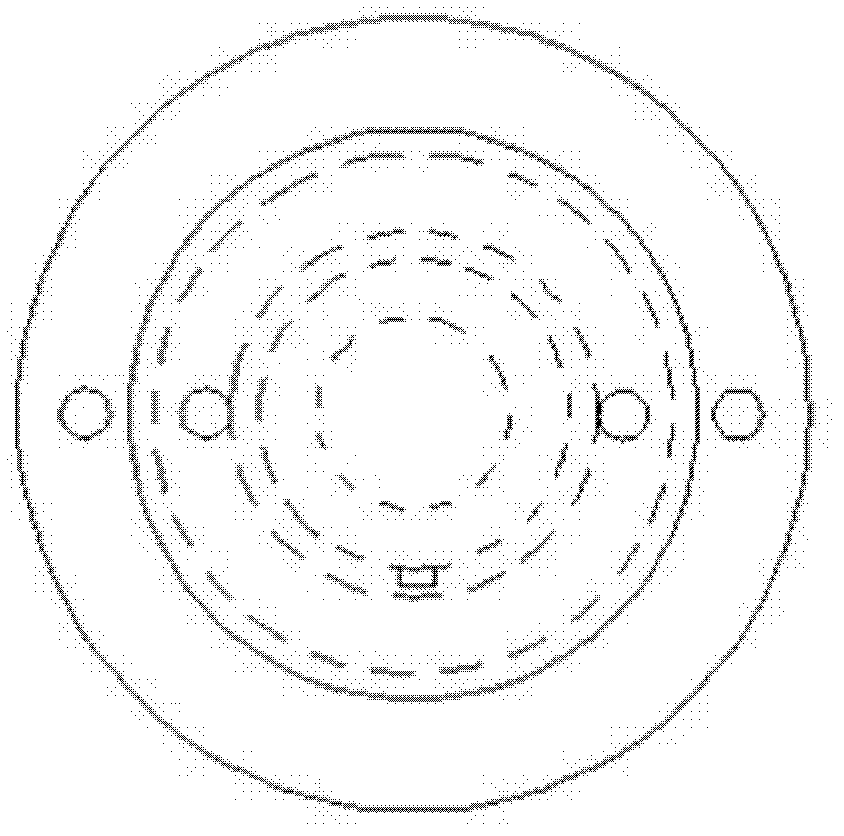

[0030] Such as Figure 1-4 As shown, the monitoring device for the liquid level and flow rate of molten iron in a torpedo tank car, the bogie on the tank car includes a foundation brake device and a bolster, and there is a gap between the bolster and the foundation brake device, and the gap is installed There is a piezoelectric sensing device, the piezoelectric sensing device includes a base 5 installed on the bottom surface of the gap, a sleeve 1, a transfer rod 3 and a transfer spring 2, and a piezoelectric sensor 4 is embedded in a groove on the surface of the base 5, There is a sleeve 1 above the piezoelectric sensor 4, and the upper end of the sleeve 1 rests on the top surface of the gap. A transmission rod 3 is slidingly fitted in the sleeve 1. A transmission spring 2 is arranged between the transmission rod 3 and the sleeve 1. The transmission rod 3 presses On the piezoelectric sensor 4, the piezoelectric sensor 4 is externally connected to a DC power supply 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com