Direct steel making process for iron ore

A direct and process technology, applied in the direction of fluidized bed furnace, etc., can solve the problem of no progress, and achieve the effect of high productivity and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

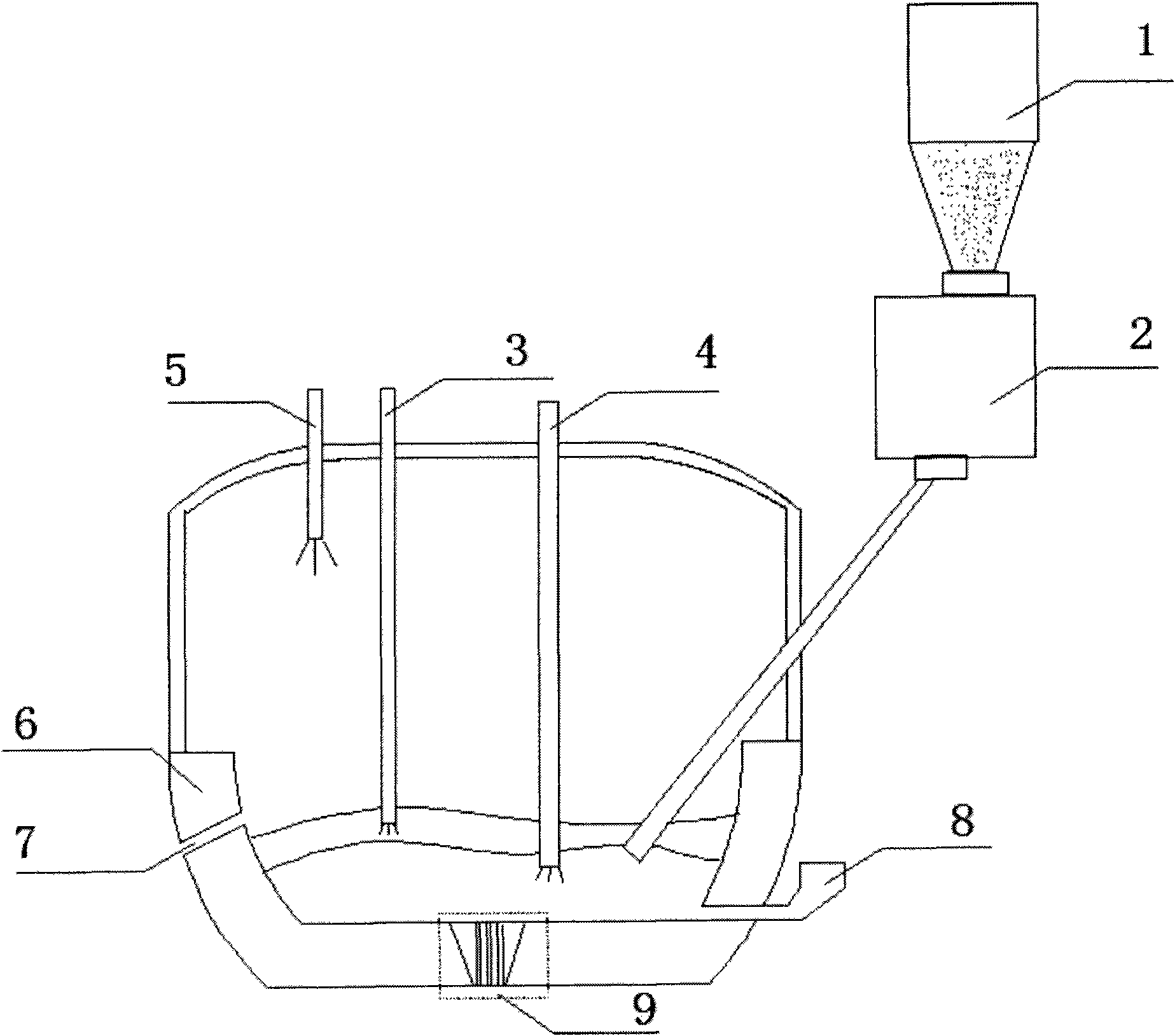

[0041] The direct steelmaking equipment of the present invention comprises: fine ore conveying bed (1), feeding device (2), slag zone oxygen lance (3), molten iron zone oxygen lance (4), gas phase zone secondary combustion oxygen lance (5) ), direct steelmaking furnace (6), direct steelmaking furnace slag outlet (7), direct steelmaking furnace taphole (8); direct steelmaking furnace (6) is a barrel furnace, including slag area and molten iron area , the longitudinal section as figure 1 shown. The direct steelmaking furnace (6) includes a refractory system, a water cooling system, waste gas treatment and waste heat recovery system.

[0042] Above the direct steelmaking furnace, there is a conveying bed equipment (1), which is connected to the continuous steelmaking furnace (4) through a feeding device (2); the slag area oxygen lance (3), the molten iron area oxygen lance (4) Insert into the slag area and the molten iron area respectively, the secondary combustion oxygen lance...

Embodiment 2

[0049] Mix iron concentrate powder with some iron-containing lump ore, limestone, and dolomite. Their ratio is determined according to the composition of the slag in the smelting process of these materials and through material balance calculation. Generally, the alkalinity of the slag is taken 1~1.5, Al 2 o 3 5%~18%, MgO 5%~10%, FeO 10% or less. Coal or coke powder is then also added to these mixes. The amount of coal powder or coke powder is determined by 500-1200kg / ton of iron. Then the mixed material is sprayed into the direct steelmaking furnace 6 with a screw feeder 2 . A molten iron bath with a thickness of 100-800mm is reserved in advance in the direct steelmaking furnace 6, and iron concentrate powder, coal powder and flux quickly form a liquid mixture slag layer, and direct reduction of iron oxides occurs in the slag layer.

[0050] The oxygen lance 3 in the slag area and the oxygen lance 4 in the molten iron area blow oxygen to the slag area and the molten iron ...

Embodiment 3

[0054] Mix the finely ground and pre-reduced iron ore powder with limestone and dolomite, and their ratio is determined according to the composition of the slag in the smelting process of these materials and through material balance calculation. Generally, the alkalinity of the slag is 1~1.5, Al 2 o 3 5%~18%, MgO 5%~10%, FeO 10% or less. Others are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com