Method for preparing high-strength and toughness martensitic steel through strip cast rolling and aging process

A tough martensitic steel, thin strip casting and rolling technology, applied in the preparation of high-strength toughness martensitic steel, economical maraging steel thin strip manufacturing field, can solve the problems of limited plasticity, hinder the application of steel, etc. The effect of short production process, cost reduction and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment test adopts the chemical composition shown in Example 1 in Table 1, and the implementation steps are as follows:

[0035] (1) Hoist the molten steel with qualified composition to the ladle turret: hoist the maraging steel molten steel after refining the LF ladle to the ladle turret, and calm it down for 20 minutes.

[0036] (2) Molten steel is injected into the large tundish: the tundish is blown with argon for 15 minutes to drive out the air in the tundish, and then the molten steel is injected from the ladle into the tundish through the long nozzle, and the superheat is controlled at 40°C, and a covering agent is added on the surface of the molten steel for heat preservation and adsorption Inclusion.

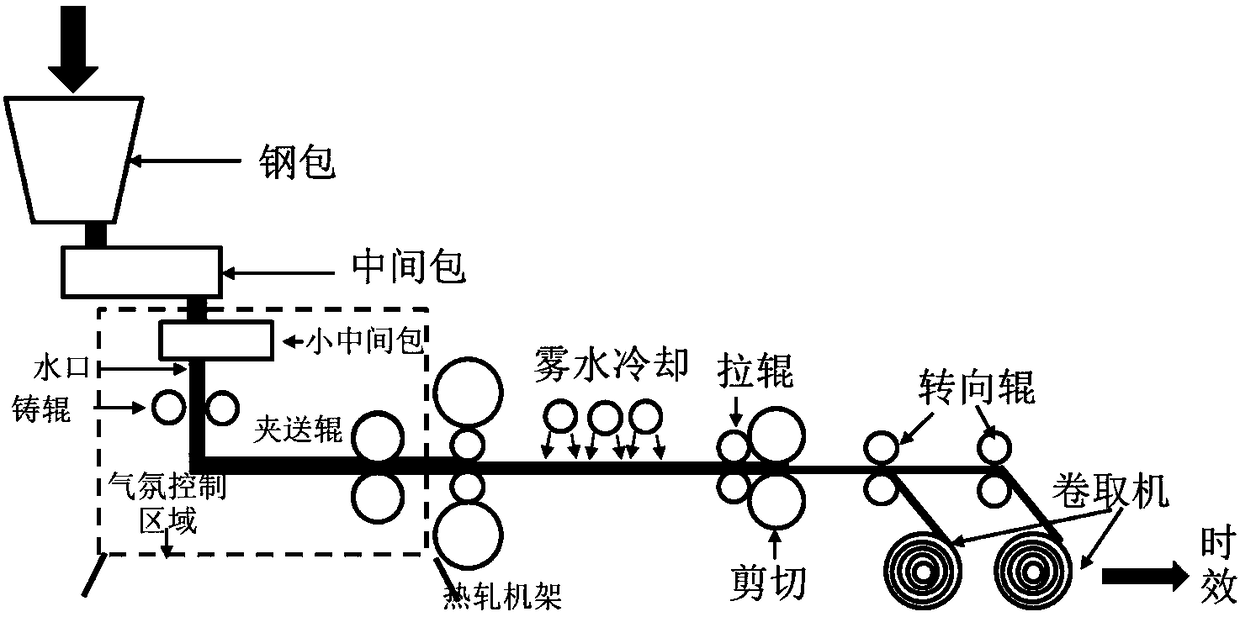

[0037](3) Twin-roll casting and rolling: pour the molten steel from the tundish in step (2) into the lower tundish to supply molten steel to the twin-roll thin strip continuous casting machine, and pour the molten steel in the small tundish into t...

Embodiment 2

[0042] The present embodiment test adopts the chemical composition shown in embodiment 2 in table 1, and implementation steps are as follows:

[0043] (1) Hoist the molten steel with qualified composition to the ladle turret: hoist the maraging steel molten steel after refining the LF ladle to the ladle turret, and calm it down for 20 minutes.

[0044] (2) Molten steel is injected into the large tundish: the tundish is blown with argon for 20 minutes to drive out the air in the tundish, and then the molten steel is injected from the ladle into the tundish through the long nozzle, and the superheat is controlled at 60°C, and a covering agent is added on the surface of the molten steel for heat preservation and adsorption Inclusion.

[0045] (3) Twin-roll casting and rolling: pour the molten steel from the tundish in step (2) into the lower tundish to supply molten steel to the twin-roll thin strip continuous casting machine, and pour the molten steel in the small tundish into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com