Dry slag-draining device of coal boiler

A technology for dry slag removal and coal-fired boilers, applied in lighting and heating equipment, etc., can solve the problems of heat loss of combustible substances, coking of bottom slag, over temperature of conveyor belt box, etc., and achieve the effect of improving the cooling effect of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

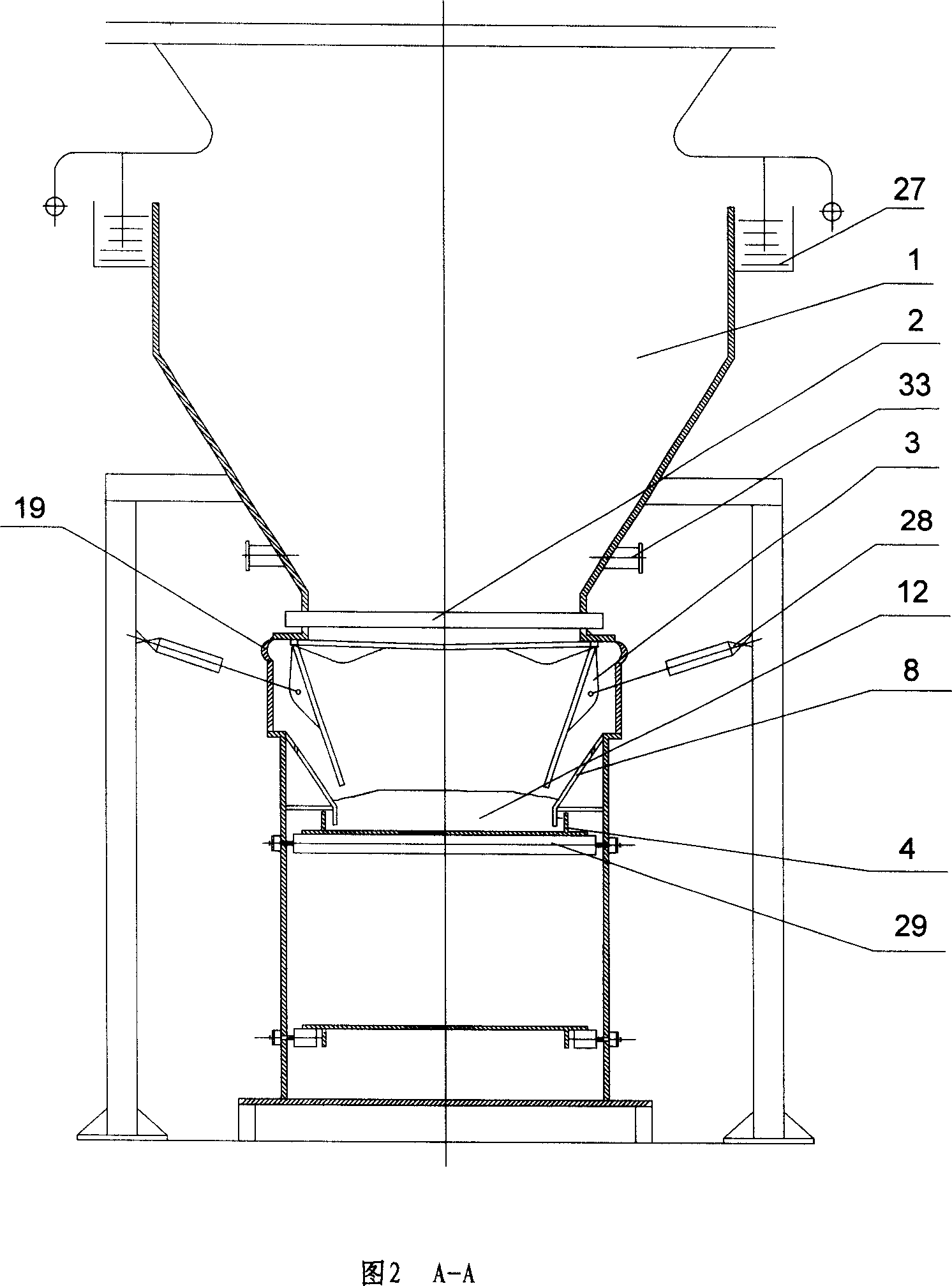

[0024] Referring to Fig. 1 to Fig. 5, the boiler slag storage hopper 1 of the dry slagging device of the present invention is connected with the combustion chamber of the boiler through a water seal groove 27 (a high temperature resistant metal expander can also be used), and the water seal groove 27 is mainly used for absorbing The high-temperature thermal expansion of the boiler body in the X, Y, and Z (three-dimensional) directions, and the boiler slag storage hopper 1 is supported by a steel structure.

[0025]Under the boiler slag storage hopper 1, a number of grids 2 made of high-temperature-resistant and impact-resistant materials are evenly distributed. The grids 2 are also supported by the steel structure of the boiler slag storage hopper 1. The distance between the grids 2 is generally designed according to the coking condition of the boiler. 300-1000mm. The high-temperature furnace bottom slag falling from the combustion chamber of the boiler has a temperature of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com