Method for continuously and automatically producing magnesium-rare earth intermediate alloys

A rare earth master alloy, automatic production technology, applied in the control of molten metal pouring from the ladle, metal processing equipment, manufacturing tools, etc., can solve the problems of large smoke and serious pollution, and achieve no environmental pollution and high yield High, the effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

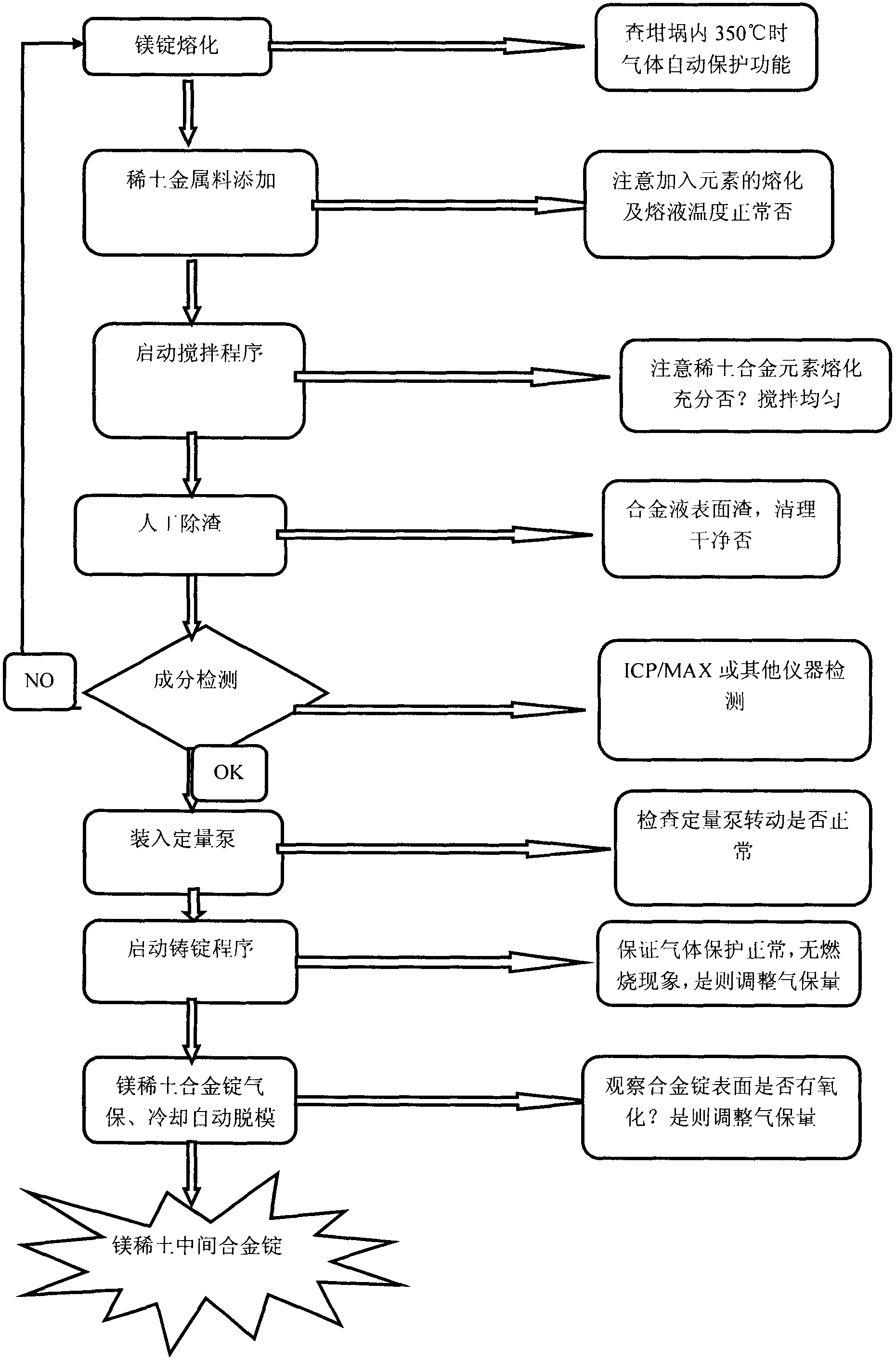

[0050] The magnesium alloy continuous automatic ingot casting system device is used to produce magnesium-rare earth master alloy ingots to realize the flexible production process of continuous melting and continuous casting automatic ingot casting of magnesium-rare earth master alloys. The specific implementation methods are as follows (see figure 1 Process flow chart shown):

[0051] 1) Raw material preparation: crush the rare earth metals into irregular small pieces of 5-10mm, pre-treat the surface of the magnesium ingots with jet sand polishing, remove scale and surface pollutants, cut some magnesium ingots into small pieces to 10-30cm for batching, and put The pretreated magnesium ingots are placed on the furnace cover of the continuous casting furnace and preheated to 80-100°C.

[0052] 2) Batching: According to product requirements and workshop process instructions, the ingredients are weighed according to the proportion.

[0053] 3) Refining: Power on and set the progr...

specific Embodiment approach

[0058] The magnesium alloy continuous automatic ingot casting system device is used to produce magnesium-rare earth master alloy ingots to realize the flexible production process of continuous melting and continuous casting automatic ingot casting of magnesium-rare earth master alloys. The specific implementation methods are as follows:

[0059] (1) Break the rare earth metal material into small pieces of 5-10mm on the hydraulic press, cut at least part of the magnesium ingots into small pieces of 10-30cm for batching, clean the surface of the magnesium ingots and place them on the furnace cover of the continuous casting furnace Preheat to 80-100°C;

[0060] (2) Start the continuous ingot casting machine in advance to preheat for 30 minutes, weigh the ingredients according to the proportion, set the program, and automatically start the gas protection when the temperature reaches 350°C, and add the prepared magnesium ingots to the nickel-free superalloy steel plate crucible firs...

Embodiment 3

[0066] The magnesium alloy continuous automatic ingot casting system device is used to produce magnesium-rare earth master alloy ingots to realize the flexible production process of continuous melting and continuous casting automatic ingot casting of magnesium-rare earth master alloys. The specific implementation methods are as follows:

[0067] (1) Break the rare earth metal material into small pieces of 5-10mm on the hydraulic press, cut at least part of the magnesium ingots into small pieces of 10-30cm for batching, clean the surface of the magnesium ingots and place them on the furnace cover of the continuous casting furnace Preheat to 80-100°C;

[0068] (2) Start the continuous ingot casting machine in advance to preheat for 30 minutes, weigh the ingredients according to the proportion, set the program, and automatically start the gas protection when the temperature reaches 350°C, and add the prepared magnesium ingots to the nickel-free superalloy steel plate crucible Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com