Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

307results about How to "Reduce production labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature salting and multi-layer continuous fume smoking method for cured meat

InactiveCN101502329AShorten marinating timeIncrease product yieldFood preparationMeat/fish preservation by dryingNutrientClear Layer

The invention discloses a bacon low-temperature pickling and multi-layer continuous smoking method, belonging to the processing method of bacon. On the basis of traditional firewood bacon, the bacon is produced by combining the traditional processing technique and the current technique. The processing method comprises: pre-processing the fresh pork; pickling the pre-process pork at low-temperature; air-drying the pickled pork; multi-layer continuously smoking the air-dried pork; removing dust and testing the quality of the smoked pork; vacuum packaging the tested pork. The bacon has golden yellow color, dry and compact meat, clear layer, transparent fat lining, red lean meat, fresh taste, rich nutrient and long shelf-life of up to 10 months and so on. The human keeps fit and the life is prolonged after eating the bacon for a long time and the bacon is a common food for guest and a good gift for friend.

Owner:冯廷萃

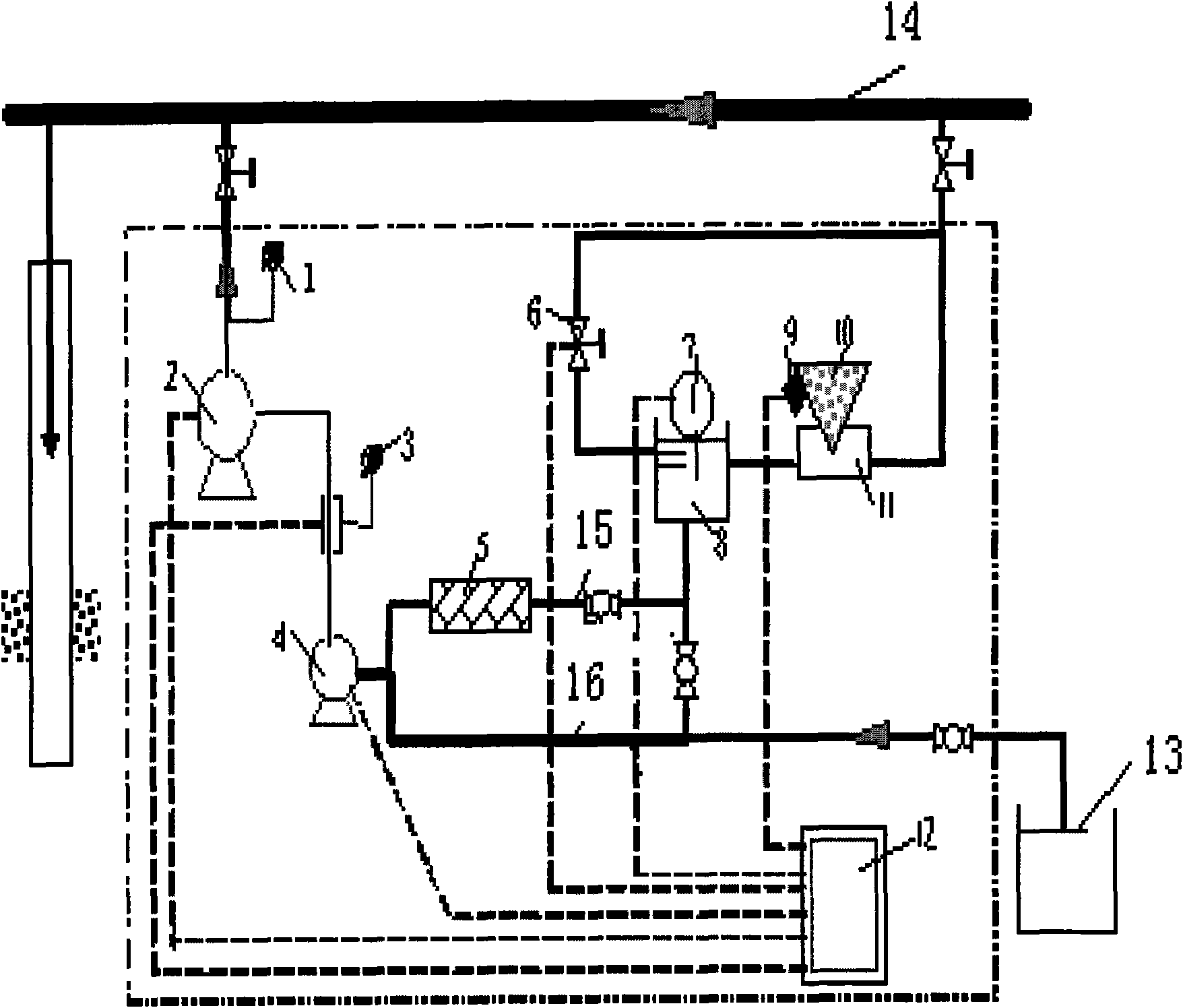

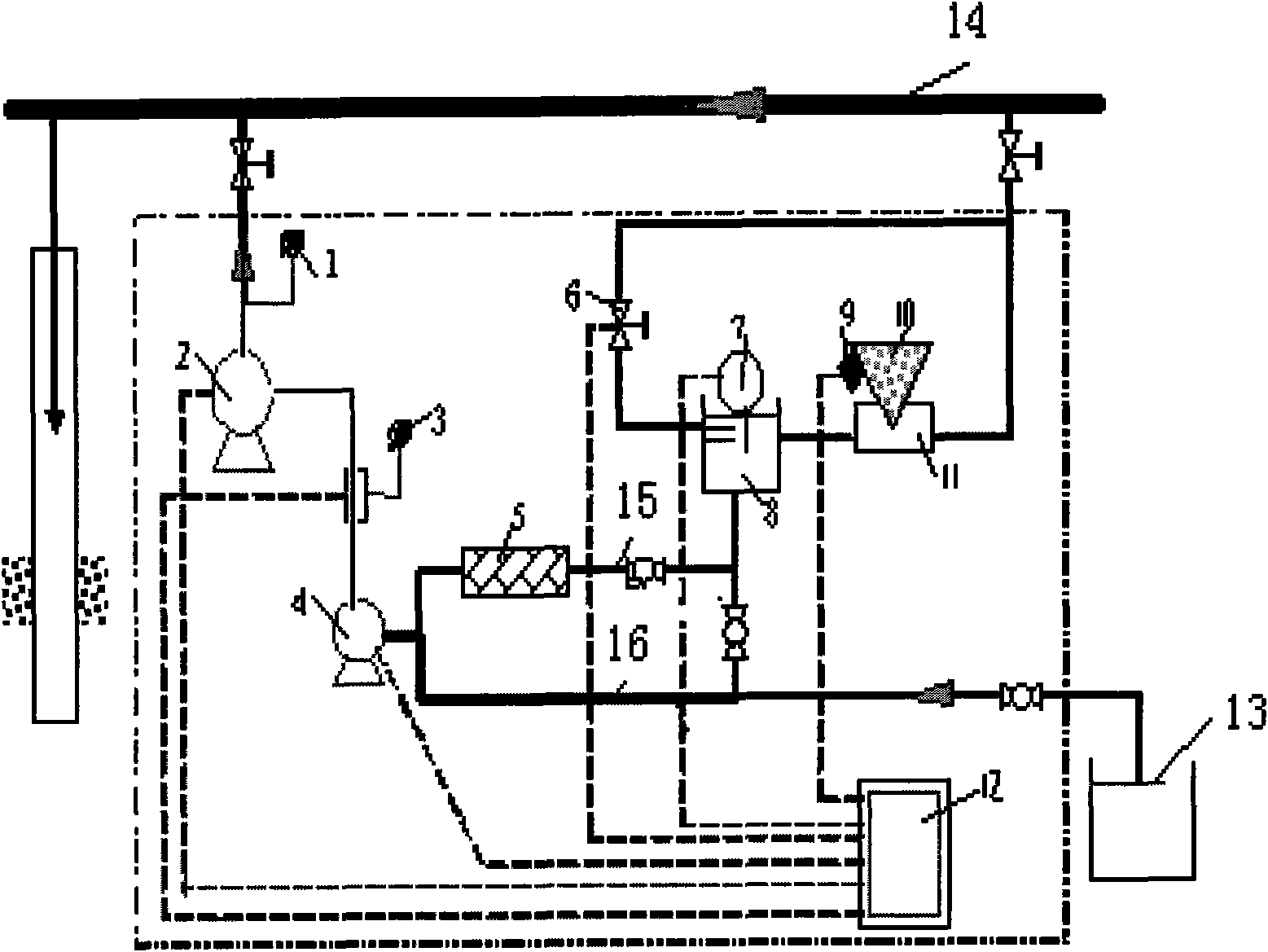

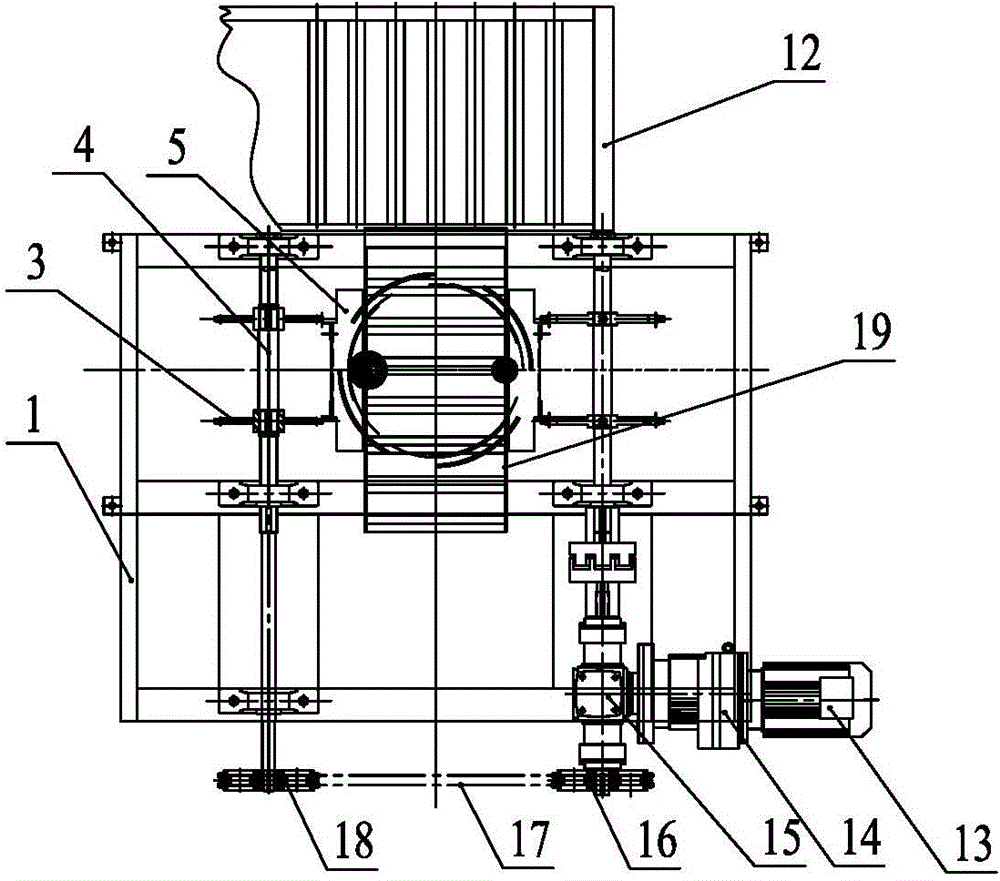

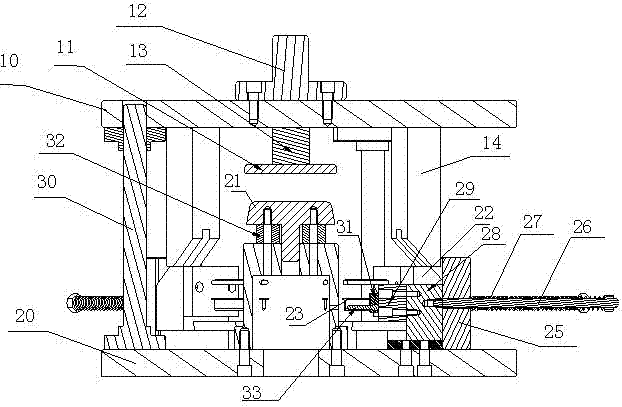

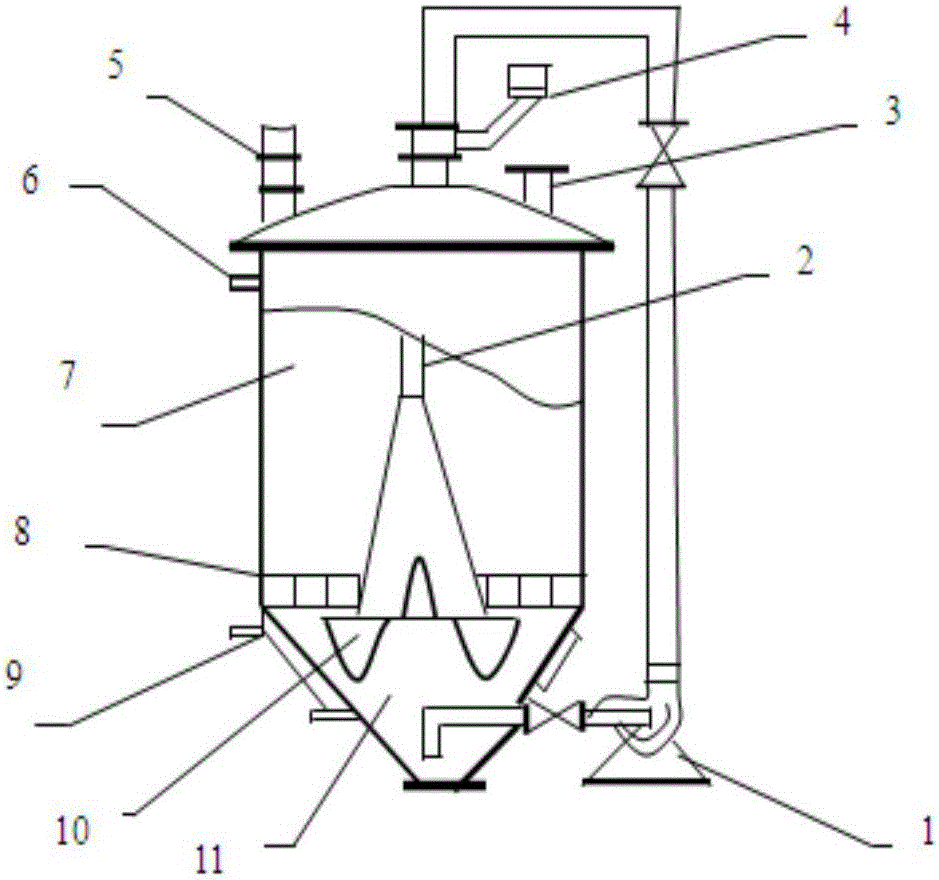

Two-phase multi-material online injection water-plugging profile regulating method and equipment

ActiveCN102383768APlay a role in blocking waterFor the purpose of profile adjustmentFluid removalLiquid storage tankHigh pressure water

The invention relates to a two-phase multi-material online injection water-plugging profile regulating method and equipment. Liquid or solid-liquid mixed phase fluid is pumped by a self-sucking pump from a liquid storage tank, is conveyed to a high-pressure plunger pump and is injected into a high-pressure water-injecting pipeline after being pressurized; solid powders or small particles fall from a hopper under the action of the gravity and the vibrating force, and are sucked by negative pressure and mixed with jet flow; high-flow-velocity fluid carries the solid materials to enter a buffer tank; when the liquid level of the buffer tank is lower than the preset value, a liquid level controller sends out a signal to open an electromagnetic valve and supplement water to the buffer tank; when the liquid level reaches the highest position of the preset liquid level, the liquid level controller sends out a signal to close an electromagnetic valve and stopping water supplement to the buffer tank; and the powdery materials and the small particle materials are mixed with water and then enter the self-sucking pump respectively through a pipeline I with a static mixer or a pipeline II without the static mixer, and are injected into the high-pressure water-injecting pipeline after being pressurized by the high-pressure plunger pump. In the method, a solid-phase, liquid-phase or solid-liquid mixed phase water-plugging profile regulating agent can be injected into the high-pressure water-injecting pipeline in an online manner.

Owner:PETROCHINA CO LTD

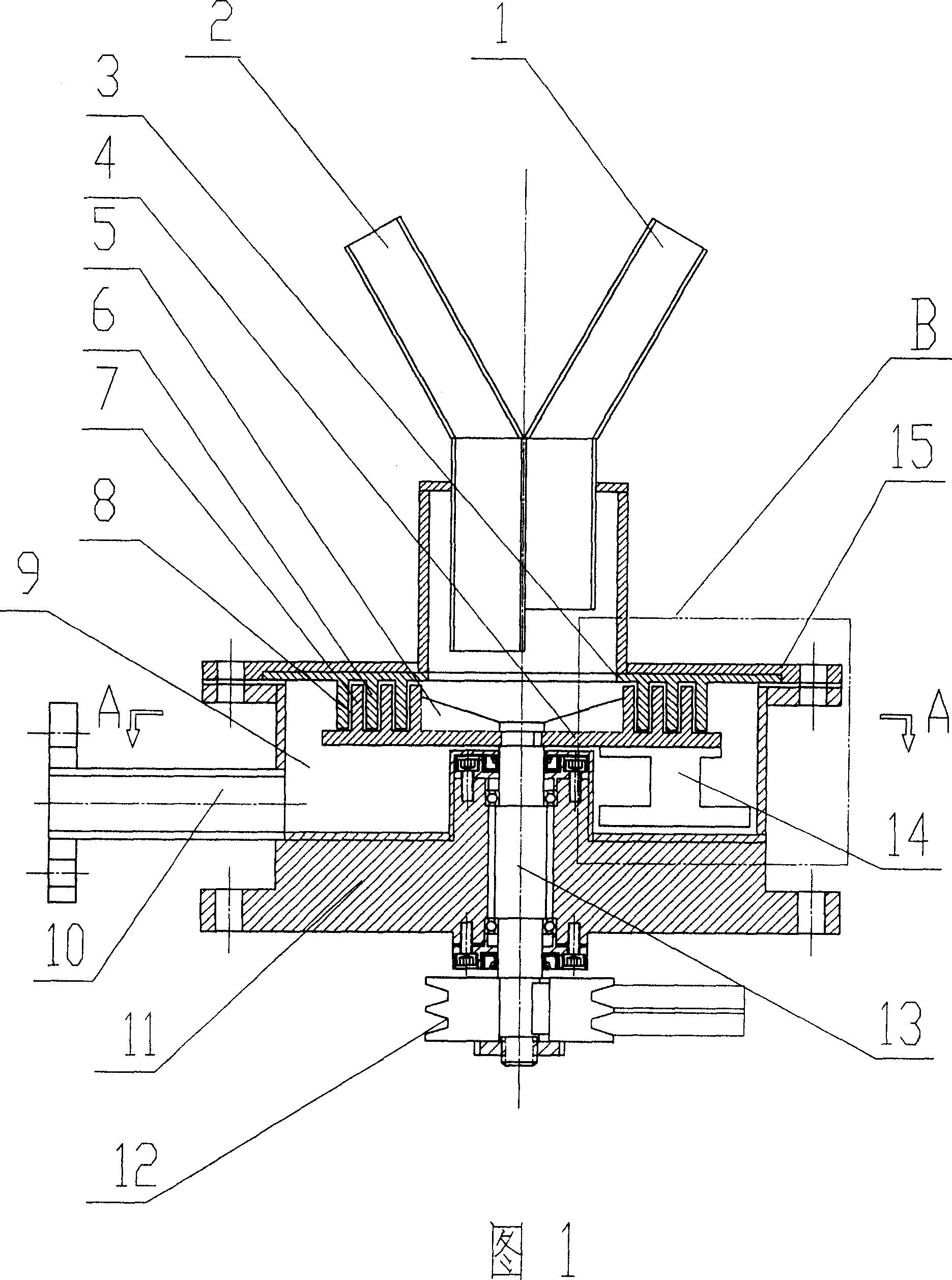

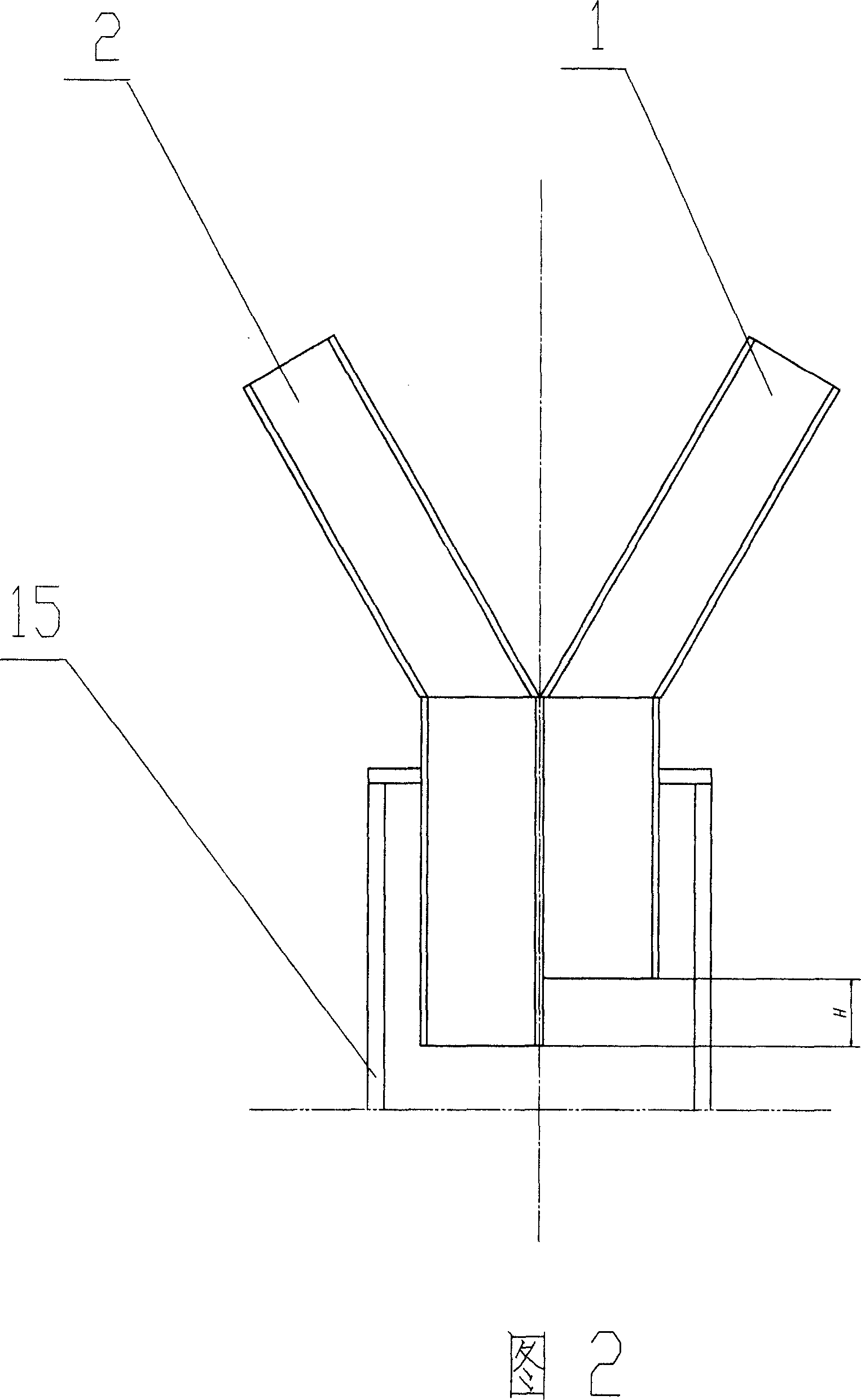

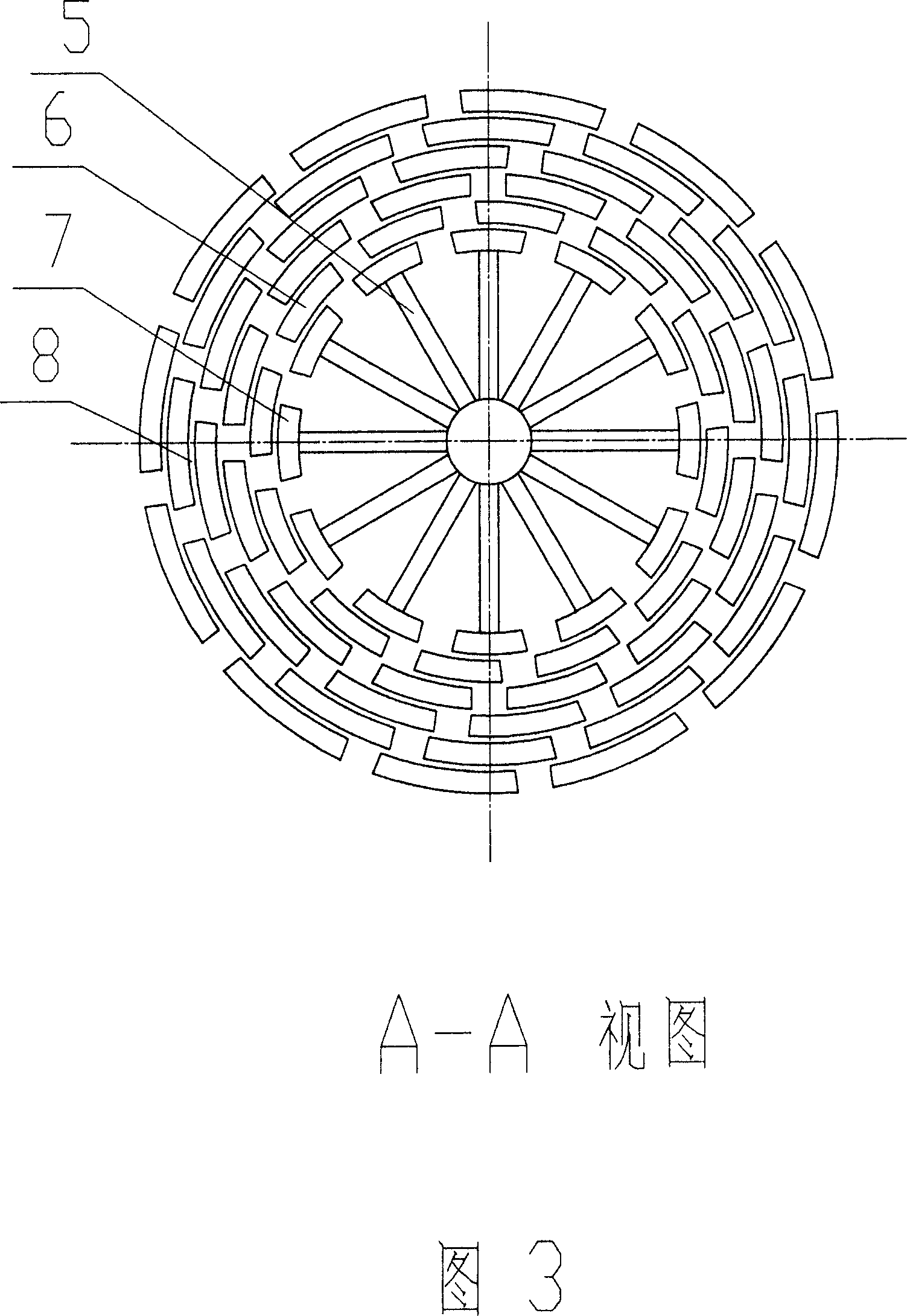

Continuous colloid mixer and its application

ActiveCN1986064ASolve the problem that continuous production cannot be realizedIncrease productivityRotary stirring mixersCocoaDrive shaftEngineering

The continuous colloid mixer includes the following members: solid feeding pipe, liquid feeding pipe, stator, rotor, pedestal, discharge port, rotating shaft and driving shaft. The continuous colloid mixer can mix solid powder and liquid to prepare colloid continuously in high production efficiency, and is used in the continuous production of cracking catalyst. Compared with available intermittent mixer, the present invention has lowered manufacture cost, continuous and stable production and improved product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

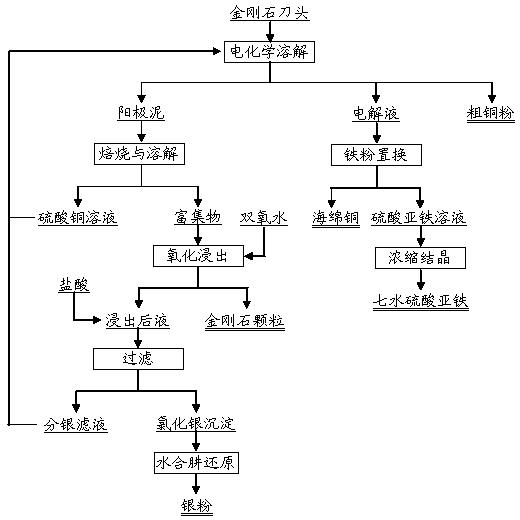

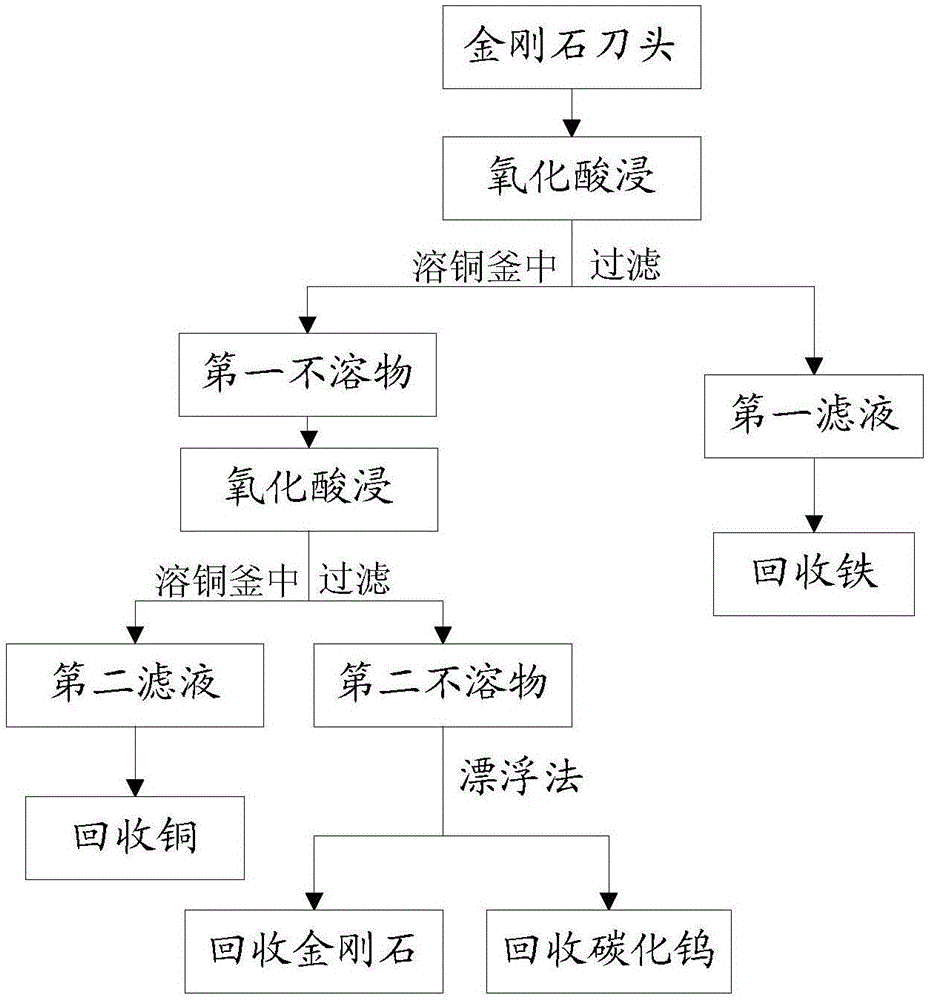

Method for processing waste copper/iron-based diamond tool bit

InactiveCN104046785AEfficient separationRealize closed loopProcess efficiency improvementIron sulfateClosed loop

The invention provides a method for processing waste copper / iron-based diamond tool bit. The method comprises the following steps: firstly, electrochemically dissolving the waste diamond tool bit in a sulfuric acid system so that most part of copper and iron are dissolved into the solution, while silver, diamond and the like are enriched into anode mud; secondly, roasting and oxidizing the anode mud and then adding the oxidized anode mud to the sulfuric acid so that the residual most part of copper is dissolved; next, adding the rest undissolved copper, silver and diamond particles to the sulfuric acid solution of hydrogen peroxide for further oxidizing leaching, recovering the diamond particles which are not dissolved, precipitating the silver in the solution by use of the hydrochloric acid and reducing the hydrazine hydrate to generate simple substance silver powder; finally, after displacing copper with iron powder, concentrating and crystalizing the electrolyte to directly prepare iron sulfate heptahydrate. The recovery rate of the copper is above 96%, while the recovery rate of the diamond particles and the silver is above 99%; the industrial-grade iron sulfate heptahydrate is directly produced, the recovery rate of iron is greater than 98%, closed-loop circulation can be realized, the production labor intensity is low and the method is environmental friendly.

Owner:CENT SOUTH UNIV

Production method of poly ammonium phosphate

A process for preparing ammonium polyphosphate includes such steps as proportionally mixing polyphosphoric acid with the condensating agent chosen from urea, ammonium dicarbonate, melamine, bicynoamine, ammonium sulfate and their mixture, and reacting at 100-500 deg.C under 0.01-0.35 MPa for 5-210 min.

Owner:YUNNAN CHEM RES INST

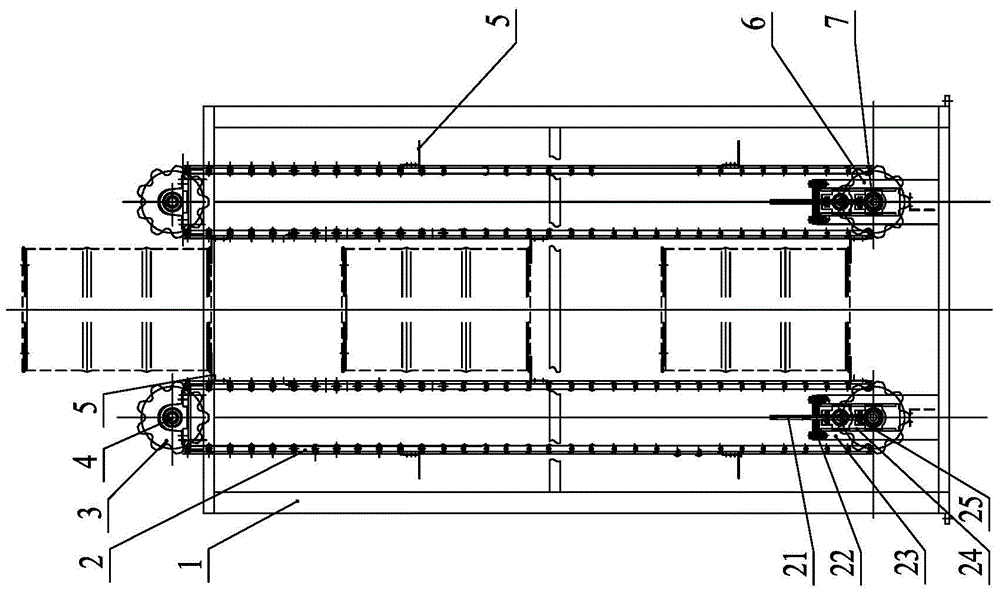

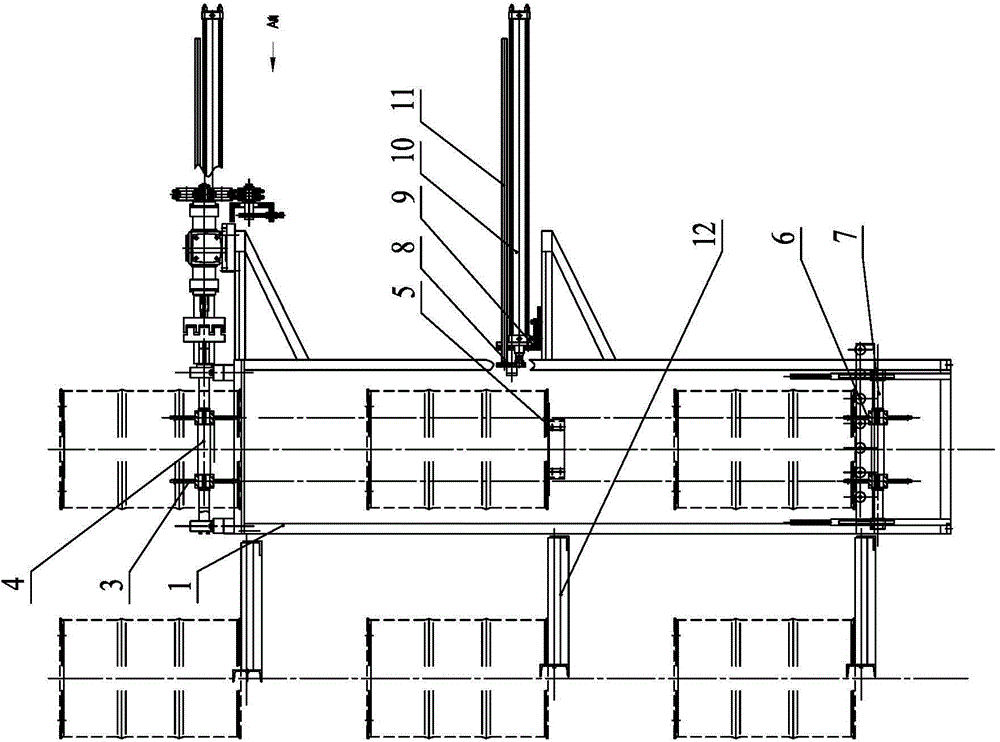

Vertical conveyer for steel drum stereoscopic warehouse

ActiveCN104444000ACompact and reasonable layoutOptimize layoutStorage devicesConveyor partsSprocketChain link

The invention relates to a vertical conveyer for a steel drum stereoscopic warehouse. According to the vertical conveyer for the steel drum stereoscopic warehouse, a steel drum lifting and conveying channel is arranged in the middle of a machine frame, a layer of conveyance rolling way is arranged below the steel drum lifting and conveying channel, the two sides of the steel drum lifting and conveying channel are each provided with a steel drum lifting device, and the two steel drum lifting device are symmetrically arranged; in each steel drum lifting device, an upper chain wheel is installed on an upper shaft on the upper portion of the machine frame, a lower chain wheel is installed on a lower shaft on the lower portion of the machine frame, the upper chain wheel and the lower chain wheel are sleeved with a lifting chain, the upper chain wheel and the lower chain wheel are driven by a driving mechanism to drive the lifting chain to rotate in a circulating mode, multiple L-shaped supporting plates which are distributed at equal intervals are installed on the lifting chain, a steel drum conveyed in place is supported by the L-shaped supporting plates and are lifted, a drum pushing device is installed on the machine frame and is arranged on the side opposite to a storage and conveyance rolling way, and the drum pushing device is used for pushing the steel drum lifted in place to the storage and conveyance roller way. The vertical conveyer for the steel drum stereoscopic warehouse is simple in structure, convenient to operate and capable of achieving automatic lifting and conveyance of the steel drum in the height direction.

Owner:TAICANG SIFANG YOUXIN DRUM-MFG CO LTD

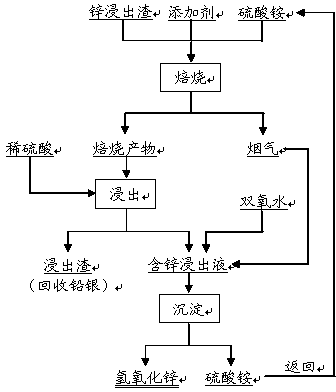

Method for separating zinc and iron from zinc leaching residues

InactiveCN104178642AAchieve regenerationIncrease incidenceProcess efficiency improvementZinc hydroxideSulfate zinc

The invention discloses a method for separating zinc and iron from zinc leaching residues. The method comprises the following steps: firstly, mixing the zinc leaching residues with ammonium sulfate and an additive, then performing roasting to ensure that zinc ferrite and the like in the zinc leaching residues are changed into soluble zinc sulfate and insoluble ferric oxide; secondly, directly leaching out a roasted product by using a dilute sulfuric acid solution; and finally, introducing fume which is produced during roasting and mainly contains ammonia gas into a zinc leaching solution to perform deposition so as to produce zinc hydroxide and an ammonium sulfate solution, and concentrating and crystallizing the ammonium sulfate solution to prepare ammonium sulfate which is returned to the ammonium sulfate roasting process. The ammonium sulfate roasting process in the method can ensure that a zinc ferrite phase in the zinc leaching residues is changed into soluble zinc sulfate, the leaching rate of zinc is more than 97%, and the leaching rate of iron is lower than 2%, so that the separation of zinc and iron is effectively realized; the ammonia gas produced in the ammonium sulfate roasting process is directly used for depositing zinc from the leaching solution, and the regeneration of ammonium sulfate can be realized while a zinc hydroxide product is generated; the comprehensive recovery rate of zinc is more than 96%; the method can realize closed-loop circulation and is relatively environment-friendly.

Owner:CENT SOUTH UNIV

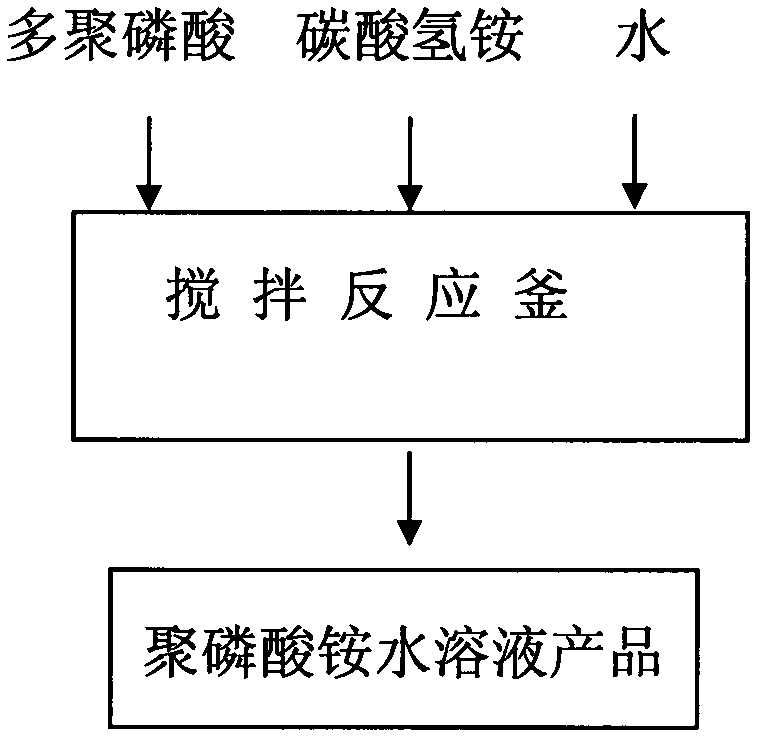

Method for preparing low-polymerization-degree ammonium polyphosphate aqueous solution

ActiveCN103373717AReduce processReduce difficultyPhosphorus compoundsChemical industryEnvironmental resistance

The invention belongs to the technical field of phosphate production in inorganic chemical industry and discloses a novel method for producing a low-polymerization-degree ammonium polyphosphate aqueous solution by using low-temperature methods. Commonly-used ammonium polyphosphate production methods are mainly high-temperature thermal polymerization methods, and methods capable of producing ammonium polyphosphate by using the low-temperature methods do not exist at home and abroad. According to the method, polyphosphoric acid with the concentration of 100% to 120% serves as a main raw material, is adjusted by adding an appropriate amount of water and is mixed with ammonium bicarbonate under a natural, low-temperature and normal-pressure condition, stirring and reacting are carried out, and then, the low-polymerization-degree ammonium polyphosphate aqueous solution with the nitrogen content higher than 11%, the phosphorus pentoxide content higher than 37% and the main content of a dipolymer (ammonium pyrophosphate) is produced in batches, is widely used as a fireproofing flame retardant, a plant nutrient solution (liquid fertilizer) and the like and has high practical values. The method is simple in production operation, high in yield and low in energy consumption, is safe and environmental-friendly and does not need high temperature, the requirements for the performance of equipment and materials are lowered greatly, and the large-scale continuous production is easy to realize.

Owner:BLACK P2 USA INC

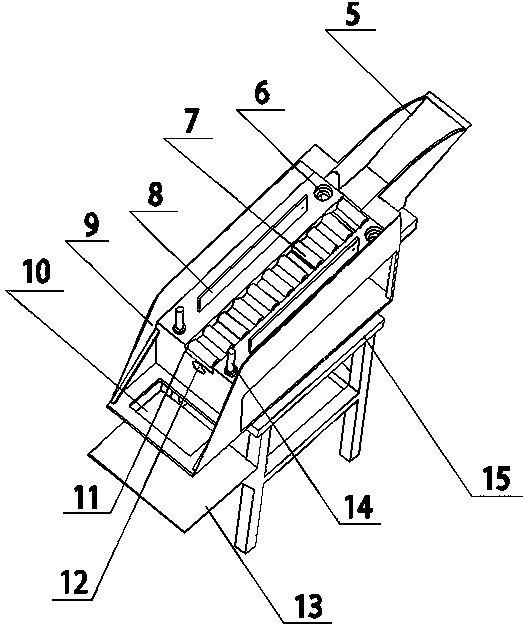

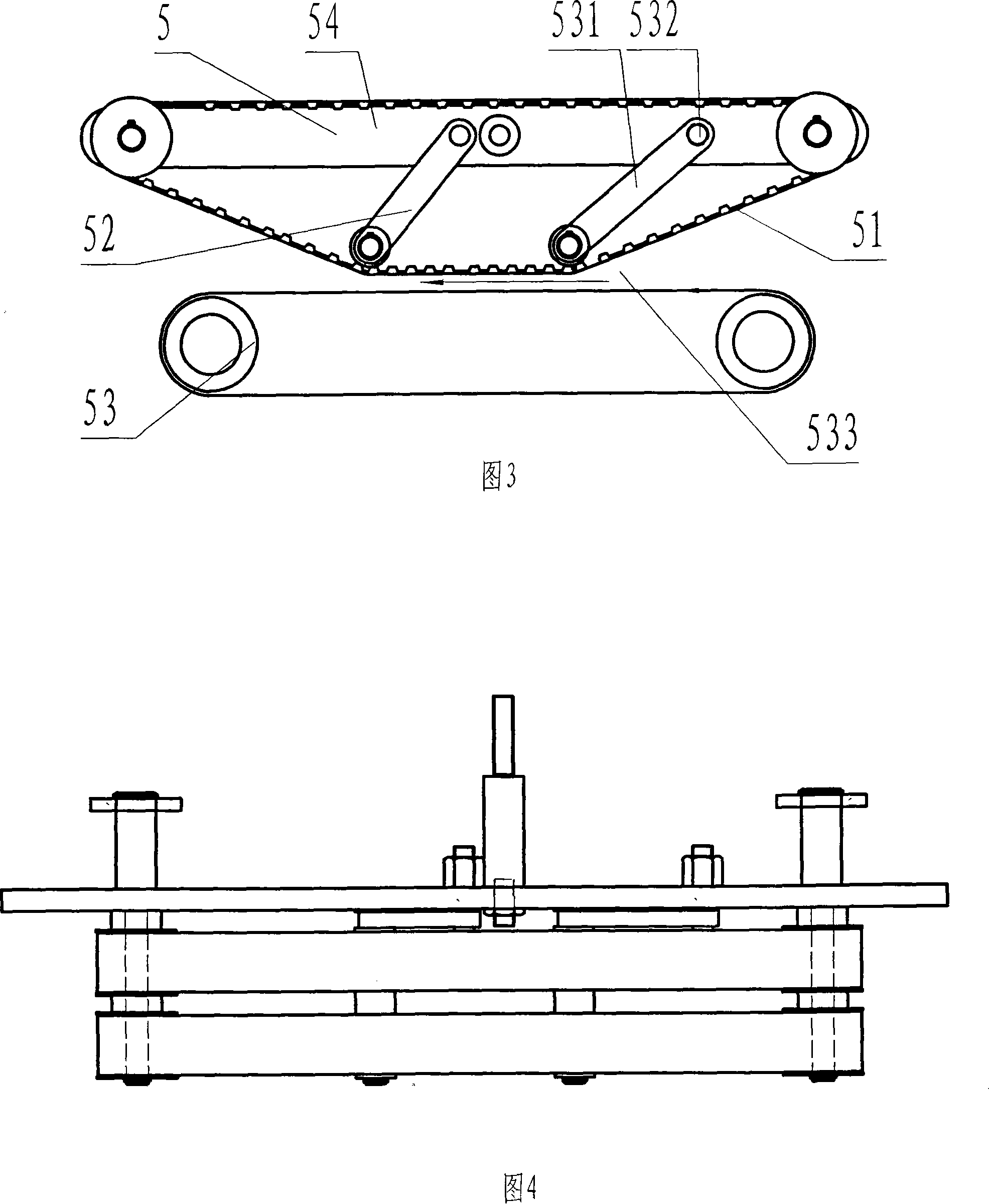

Feeding type automatic lotus root slicing machine

InactiveCN104385338ASlicing is stable and efficientClamp firmlyMetal working apparatusMechanical engineeringLotus root

The invention relates to a feeding type automatic lotus root slicing machine, in particular to novel lotus root processing equipment. The feeding type automatic lotus root slicing machine consists of a frame, a lotus root conveying unit, a lotus root clamping unit, a lotus root slicing unit and a lotus root slice collecting unit, wherein the lotus root conveying unit and the lotus root clamping unit are embedded together; and the lotus root clamping unit is contacted with a conveying belt on the lotus root conveying unit through a roller on a pressurizing chuck, so that processed lotus roots can be smoothly fed in the lotus root slicing unit through the lotus root conveying unit. The lotus root slicing unit is positioned at the tail end of the lotus root conveying unit; and the lotus root slice collecting unit is positioned rightly below the lotus root slicing unit. The feeding type automatic lotus root slicing machine adopts the pressurizing chuck to perform the point clamping for the lotus roots through flexible transition of the conveying belt, the lotus root conveying unit and the lotus root clamping unit are embedded together, and the lotus root conveying unit and the lotus root slicing unit are linked, so that the structure is compact, and the stability is enhanced; and all the component units of the whole machine are higher in working coordination degree, facilitate automatic production control, are excellent in use effect, and are strong in practicability.

Owner:WUHAN TEXTILE UNIV

Heating method for controlling decarburization in heavy rail billet furnace

InactiveCN101967541AEnsure complete combustionReduce oxidation burnFurnace typesHeat treatment furnacesPollutant emissionsReducing atmosphere

The invention provides a heating method for controlling decarburization in a heavy rail billet furnace in a heat accumulation heating mode. The heating process comprises a pre-heating section, a heating section and a soaking section. A furnace pressure measurement point is positioned at the pre-heating section; the full furnace is controlled at positive pressure; when the billet temperature is controlled to be less than 1,000 DEG C, the atmosphere in the furnace is oxidizing atmosphere, and the air consumption coefficient is between 1.05 and 1.25; and when the billet temperature is controlledto be more than or equal to 1,000 DEG C, the atmosphere in the furnace is weak reducing atmosphere, the air consumption coefficient is between 0.9 and 1.0. Aiming at the operation and decarburizationcharacteristics of the heat accumulation heating furnace different from the traditional heating furnace, the segment control method is adopted on the control aspects of atmosphere in the furnace and temperature, and a limit low-oxygen concentration burning process is realized. The method has the advantages of low heated billet surface decarburization, low oxidized burning loss, high furnace energy utilization, low pollutant discharge, low production cost and the like, is simple, convenient and feasible, and can achieve good effect of saving materials and energy at the same time of improving the heating quality of products.

Owner:武钢集团有限公司

Preparation method for foam model used for lost foam casting based on 3D printing

ActiveCN103934415ASave developmentSave lossAdditive manufacturing apparatusFoundry mouldsSteam pressurePolymer science

The invention discloses a preparation method for a foam model used for lost foam casting based on 3D printing. The method comprises the following steps: subjecting foam particles to steam pressure-maintained foaming so as to allow a foam particle raw material with bulk density of 500 to 600 g / L to become foamed foam particles with bulk density of 17 to 25 g / L through foaming; then filling the raw material box of a 3D printer with foam particles obtained through air blast cooling at 20 to 30 DEG C for printing; allowing every layer of foam particles sprayed on a heating model workbench to be fused and bonded under the action of heating temperature of the heating model workbench, wherein layers of foam particles are accumulated one by one and mutually bonded until a complete foam model is obtained; and completing printing with the 3D printer so as to obtain the foam model used for lost foam casting. The method provided by the invention has the advantages of small die loss, a short manufacturing period, low production cost and easy manufacturing.

Owner:NINGBO TONGDA PRECISION CASTING

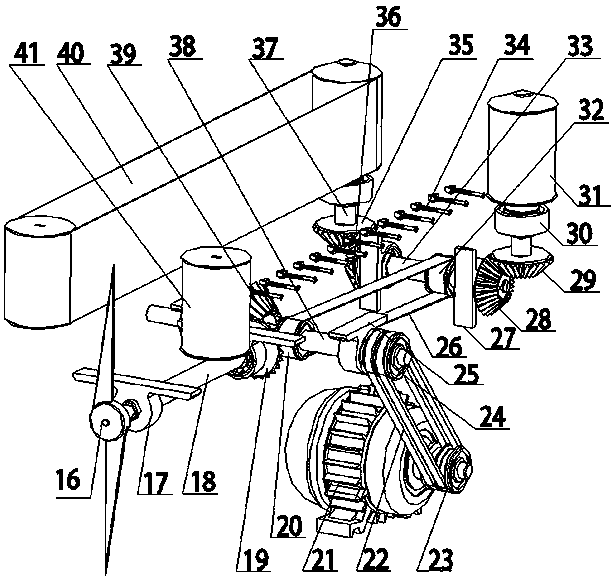

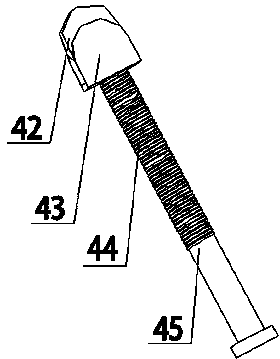

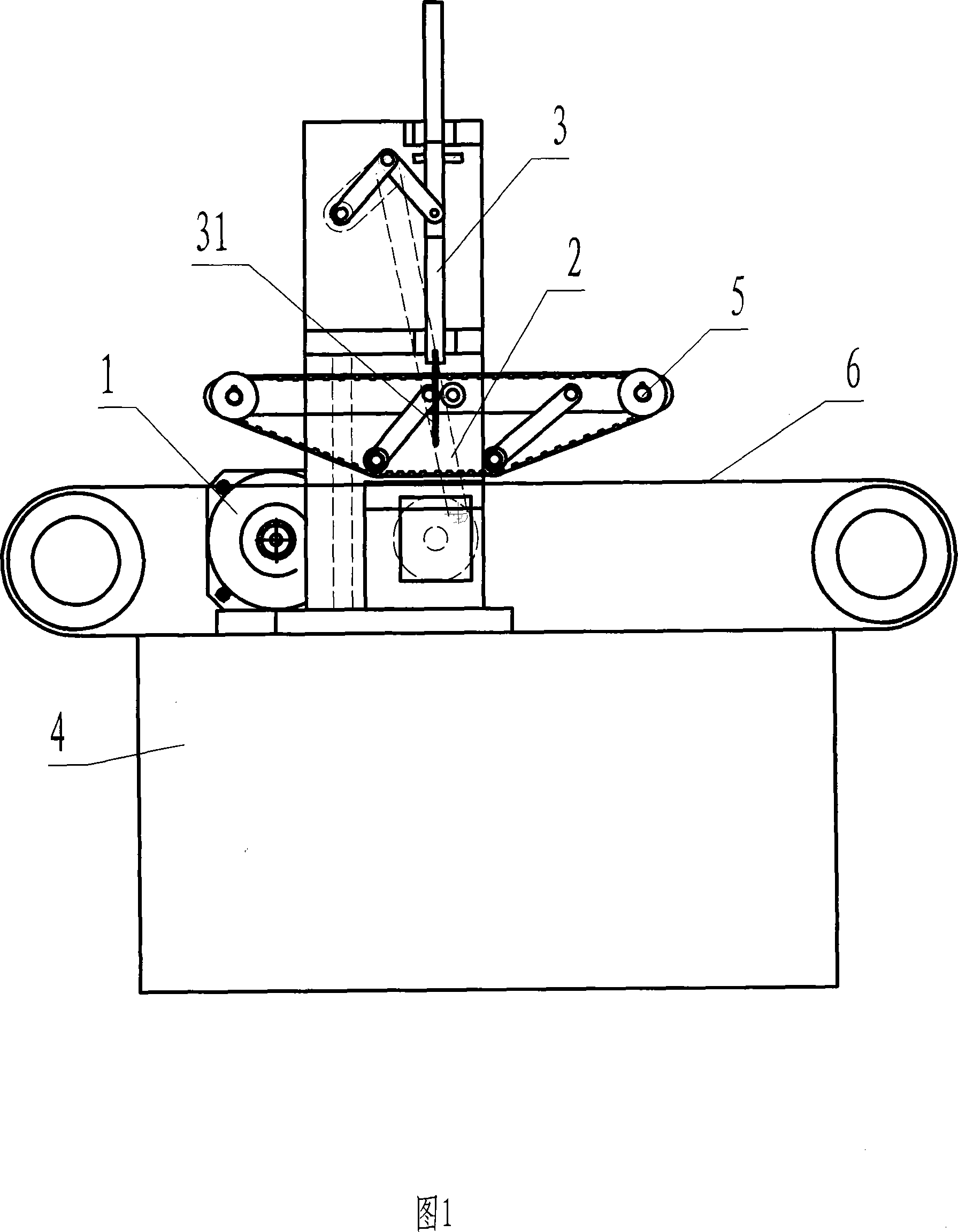

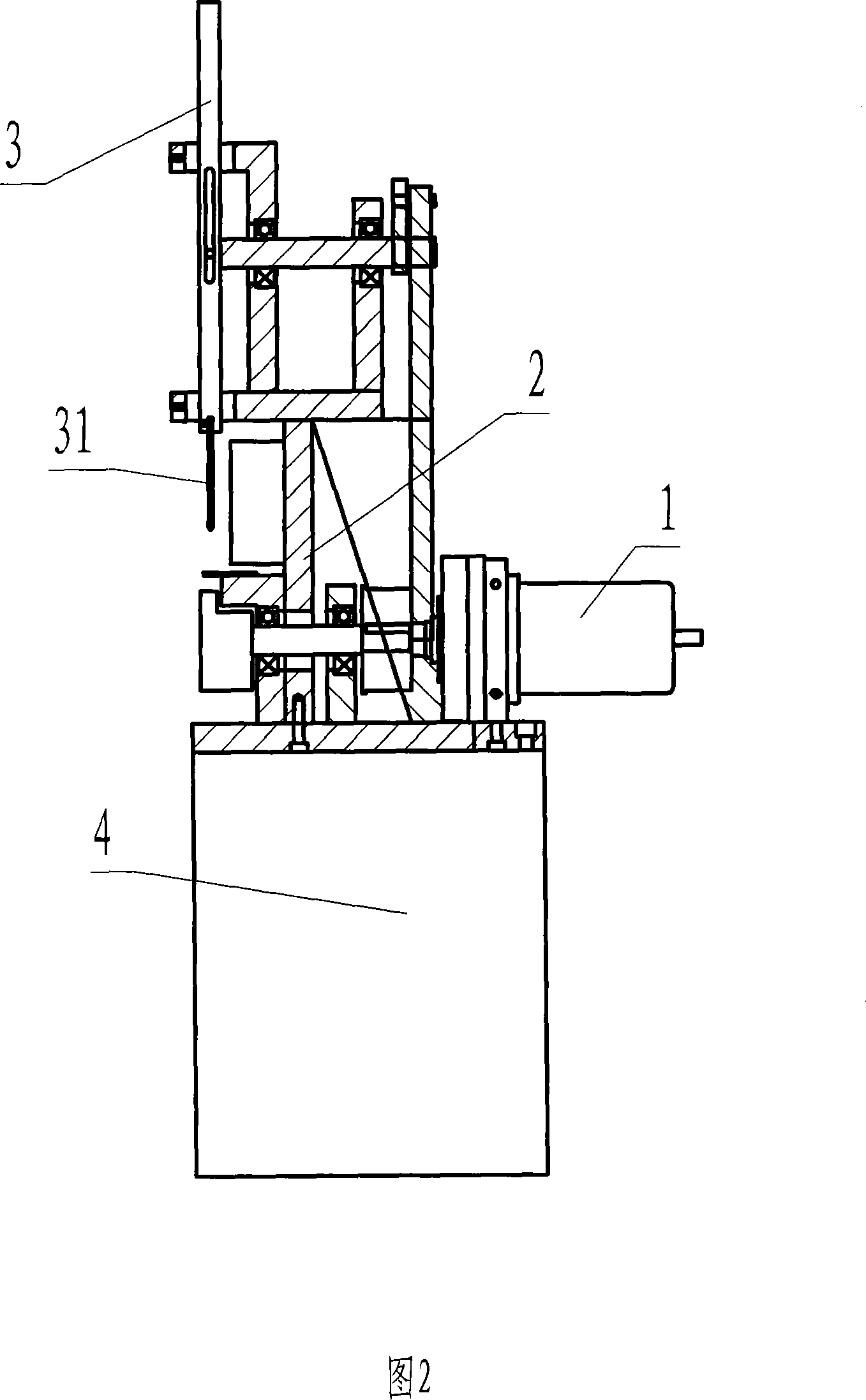

Full automatic tobacco processing machine

InactiveCN101099597AReduce labor intensityAvoid the shortcomings of low quality cigarettesTobacco preparationConveyorsEngineeringMechanical engineering

The present invention discloses a full-automatic tobacco leaf knitting machine. Said tobacco leaf knitting machine includes power source, driving device, machine head and machine frame. Said tobacco leaf knitting machine also includes a material holding device and a material conveying device. The described machine head includes a beard needle, the described material conveying device is placed under the beard needle, and the described material holding device is placed over the material conveying device.

Owner:中国烟草总公司福建省公司 +1

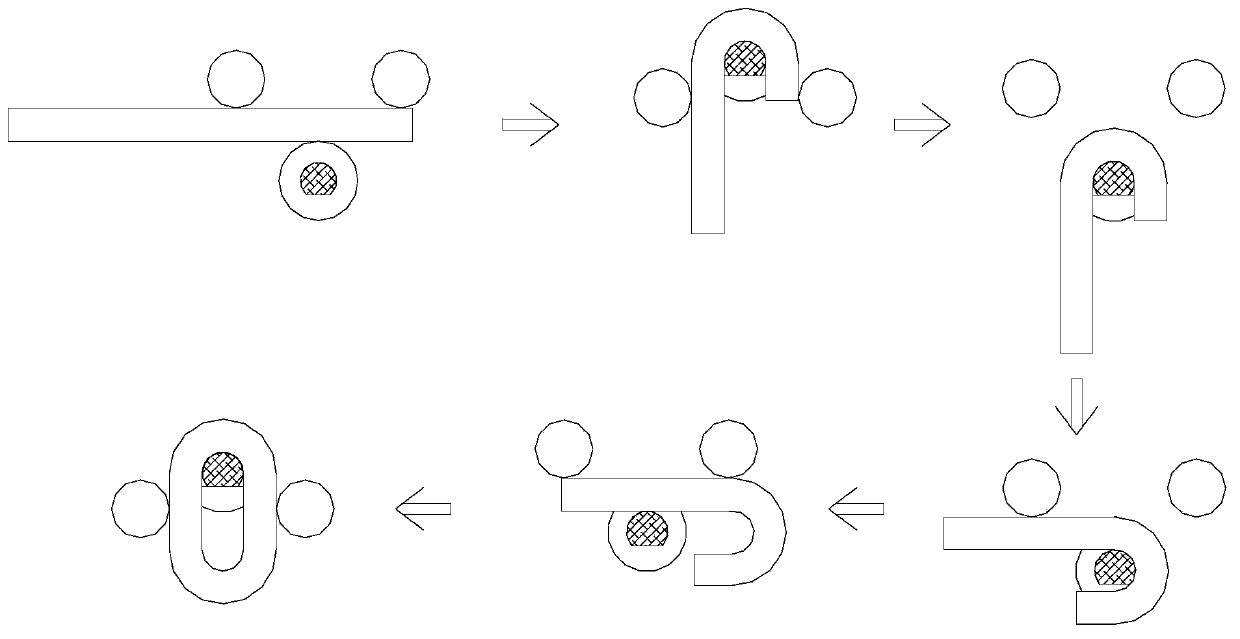

Compact-chain connecting method by once positioning, bending and molding

InactiveCN103418738ALink operation is fastThe link operation is accurateMetal chainsHigh volume manufacturingEngineering

The invention discloses a compact-chain connecting method by once positioning, bending and molding. The compact-chain connecting method comprises the steps of manufacturing a mold core, positioning, primarily bending rings, replacing the mold core and secondarily bending the rings. The compact-chain connecting method disclosed by the invention has the advantages that the compact-chain connecting process only needs once positioning, the positioning positions of bars in twice bending are unified by replacing the mold core, the bending and forming of the bars are consistent, and an obtained product is consistent in ring shape and tolerance; instruction programming control can be adopted, and the fast, accurate and repeatable method is provided for solving the chain connecting operation in large-batch production, so that the production cost and the labor intensity are reduced and the production efficiency is improved.

Owner:江苏金茂制链有限公司

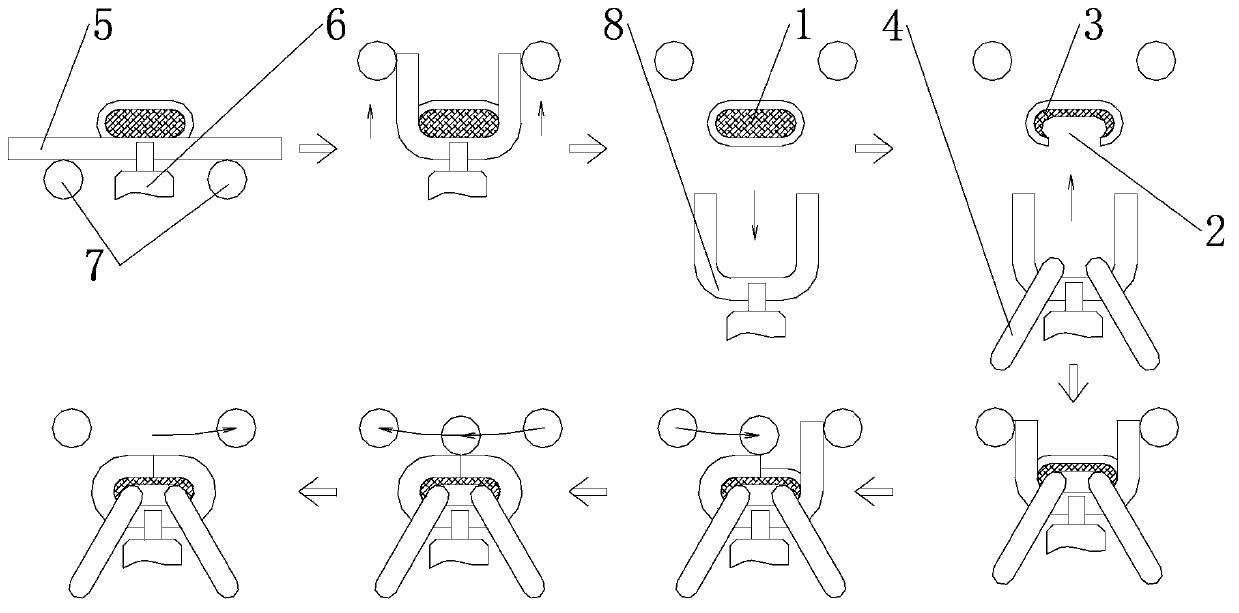

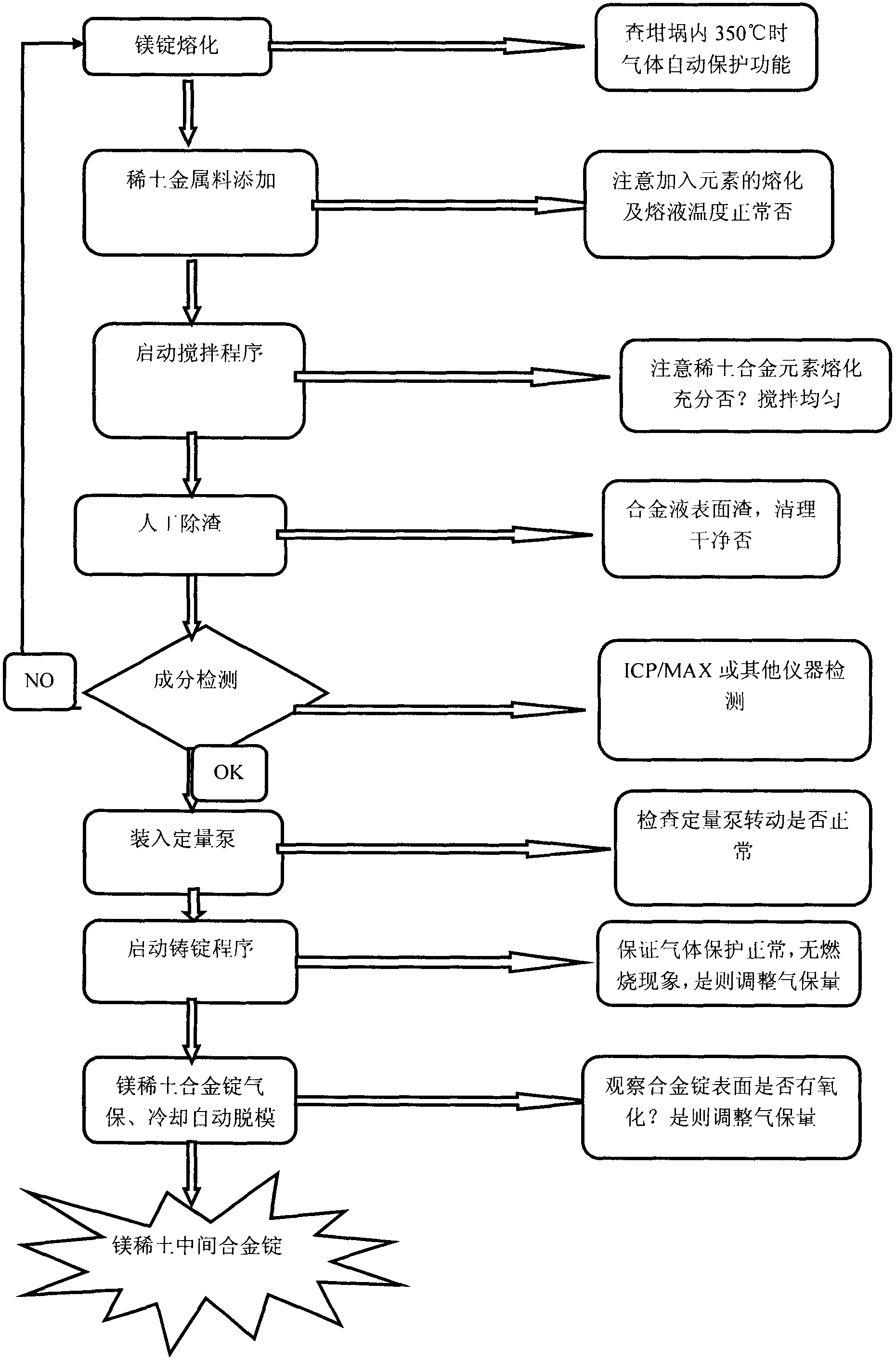

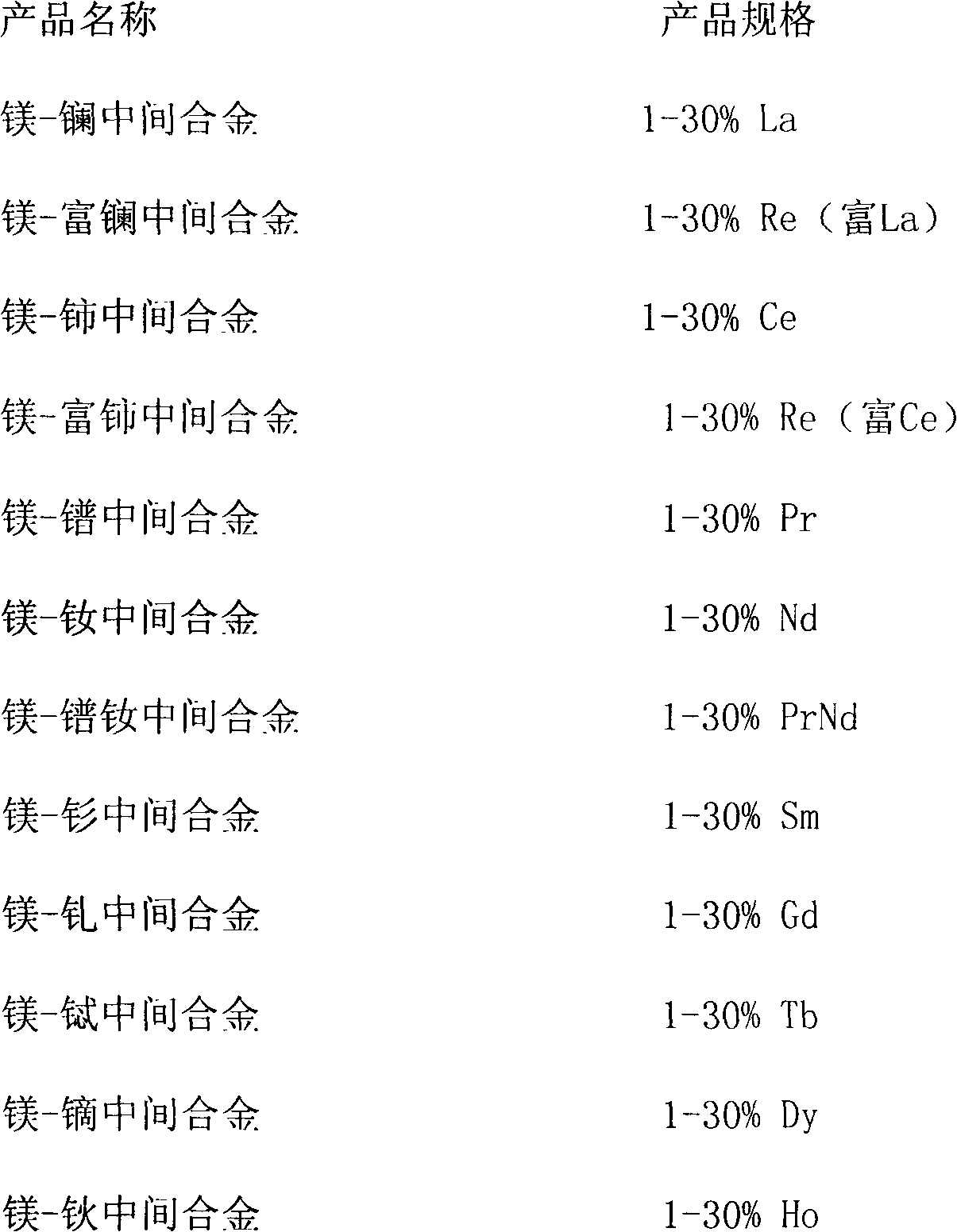

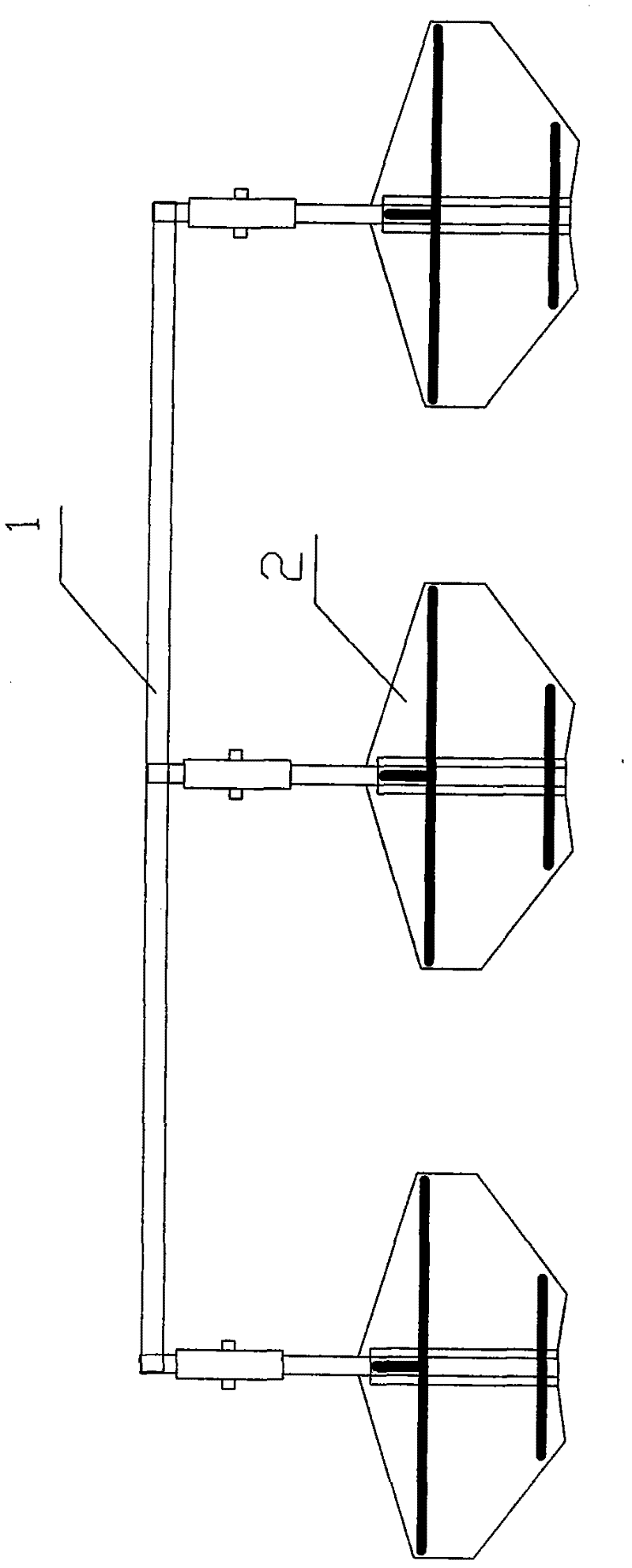

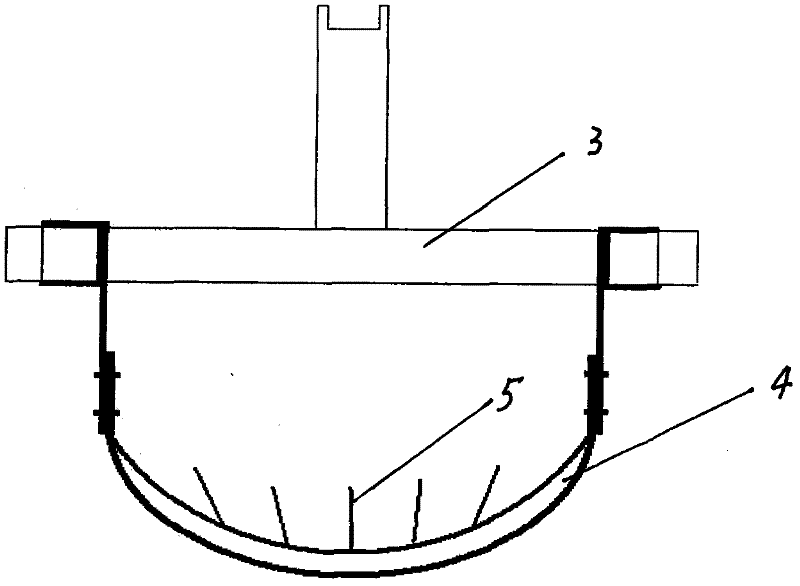

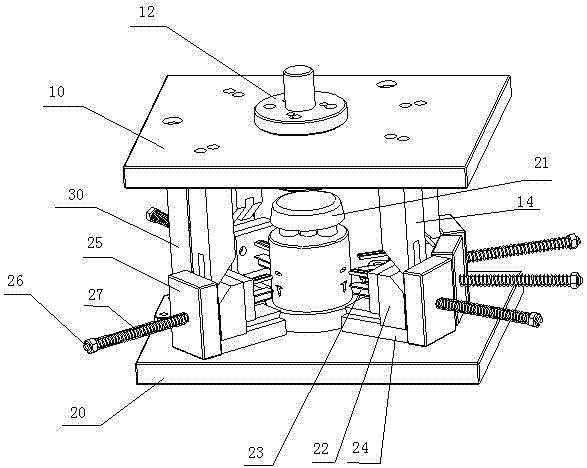

Method for continuously and automatically producing magnesium-rare earth intermediate alloys

ActiveCN103540777ASafe and efficient productionNo pollution in the processMolten metal pouring equipmentsRare earthNickel free

The invention discloses a method of continuously and automatically producing 16 magnesium-rare earth intermediate alloys such as a magnesium-neodymium intermediate alloy. The method comprises the following steps: after melting a magnesium ingot raw material by a finery, adding a rare earth metal material, manually deslagging, and automatically stirring and homogenizing by a system, and sampling and testing alloy components which are qualified; then pouring an alloy liquid to an ingot case of a pig moulding machine through a metering pump to form a continuous and automatic ingot casting; and cooling the alloy liquid to form standard magnesium-rare earth intermediate alloys. The key point of the invention is as follows: the method is applicable to continuous and automatic ingot casting production of 16 magnesium-rare earth intermediate alloys such as the magnesium-neodymium intermediate alloy, so that the labor intensity of production is reduced, and the production safety is greatly improved in anhydrous environment production. The produced product is consistent and high in yield. According to a crucible manufactured by a nickel-free high temperature alloy steel plate, carbon content is not introduced in the production process, the production efficiency is high, and the method is applicable to continuous production on a large scale, free from environmental pollution. Waste residues can be recycled, thereby truly realizing safe and efficient production of the magnesium-rare earth intermediate alloys on a large scale.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Mechanical directional half sleeve pipe yam ridge cultivation method

The invention relates to a yam plantation method, in particular to a mechanical directional half sleeve pipe yam ridge cultivation method which comprises the following steps: (1) carrying out deep plowing in winter to improve soil structure and reduce the diseases, pests and of harmful grass in yam land; (2) mechanically ridging in the middle ten days of April in spring by using a yam land ridging machine, wherein the heights of the ridges are 35-40cm; (3) directionally cultivating by using half sleeve pipes; and (4) mechanically harvesting in the middle or last ten days of October by using a yam harvesting plough. The invention has the advantages of saving yam planting and harvesting cost, creating the novel convenient, efficient, directional and labor-cost saving yam cultivating mode, overcoming the defect that the underground water level raises to cause adverse effect to the formation and the yield of the yam which is the tuber crop, solving the problems of mechanical ridge cultivation, high-density planting and mechanical harvesting and promoting the large-scale intensified and industrialized yam production. Due to the adoption of the method, the labor intensity is greatly reduced, the labor efficiency is improved, and the ridges are uniform and have good shapes.

Owner:XUZHOU ACAD OF AGRI SCI

Side punching die

InactiveCN102921798AAvoid the defect of inaccurate position of side hole in multiple processingImprove pass ratePerforating toolsPunchingStructural engineering

The invention relates to a side punching die, which comprises an upper template, a lower template, and a guide post connected with the upper and lower templates, wherein a supporting plate for placing a product to be punched, a plurality of punching needle slide blocks, and a reset mechanism for resetting the punching needle slide blocks are arranged on the lower template; one ends of the punching needle slide blocks are connected with the reset mechanism, and a punch used for punching the side of the product to be punched is arranged at the other ends of the punching needle slide blocks; and a pressing plate which corresponds to the supporting plate and a pushing post which corresponds to a punching slide block and drives the slide block to move through pressing are arranged on the upper template. According to the plurality of punching needle slide blocks, a plurality of sides are punched at a time, multiple holes on the side face can be machined through one-step machining, the defect that the position of a repeatedly machined side hole is inaccurate is overcome, the product yield is improved, the production cost and labor intensity are reduced, and the side punching die is reasonable and stable in structure and is suitable for popularization and application.

Owner:KUNSHAN ANLEI LIGHTING TECH

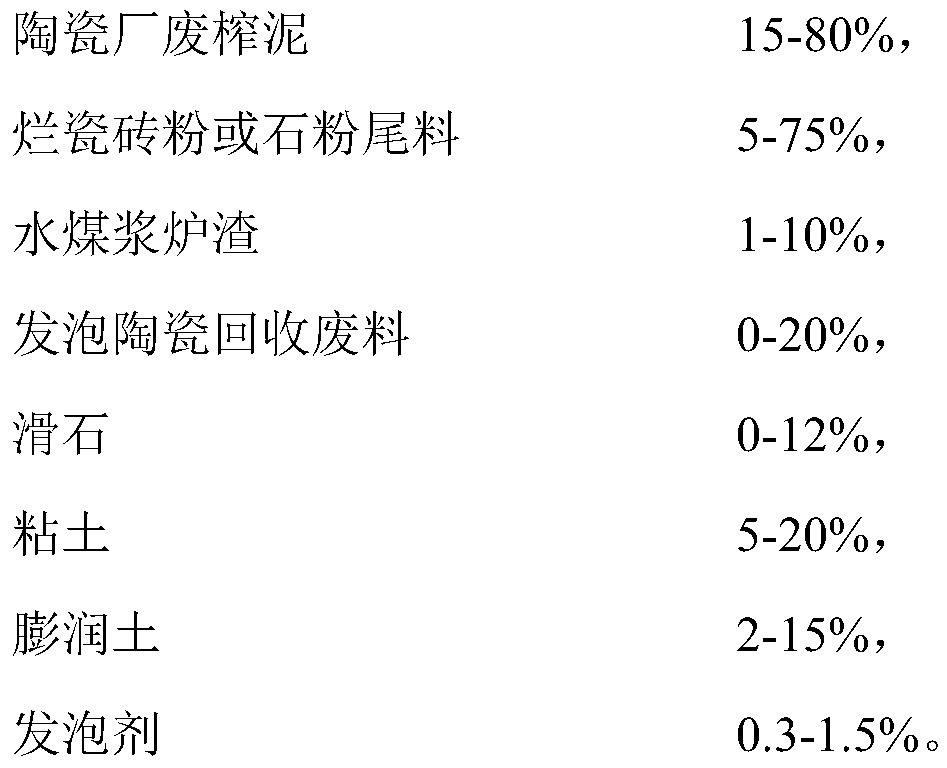

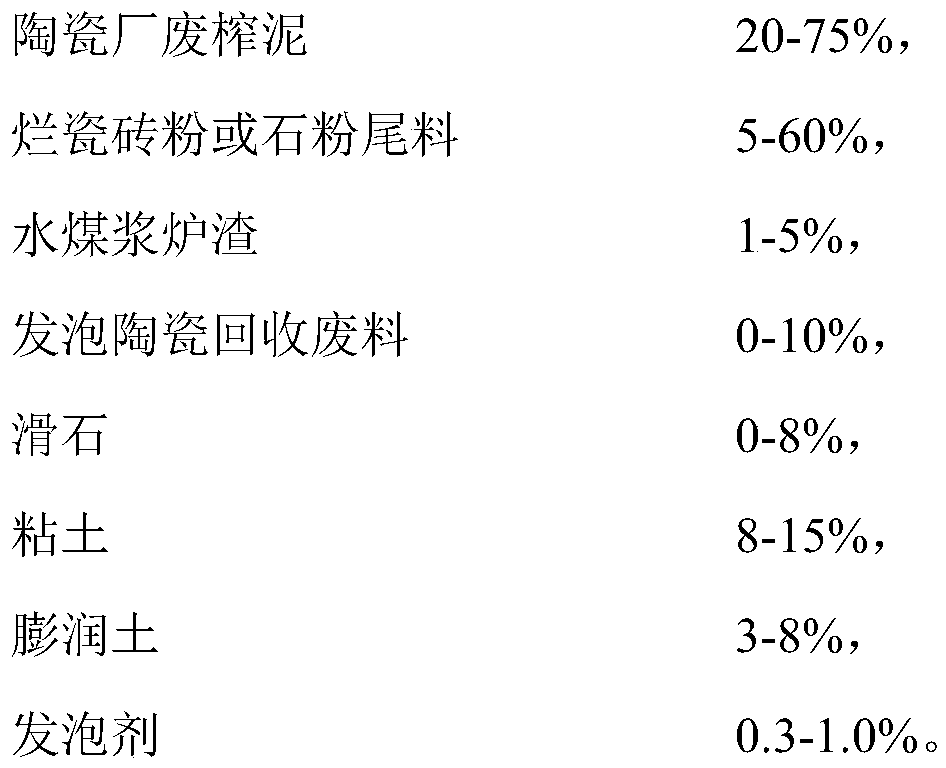

Glazed ceramic decorative wall tile and manufacturing method thereof

InactiveCN110606764AEasy to prepareIncrease productivityCeramic materials productionCeramicwareBrickSodium Bentonite

The invention discloses a glazed ceramic decorative wall tile. The wall tile comprises a ceramic tile body and a glaze surface, wherein the ceramic tile body comprises 15-80% of ceramic factory wastepressed mud, 5-75% of rotten ceramic tile powder or stone powder tailings, 1-10% of coal water slurry slag, 0-20% of foamed ceramic recycled waste, 0-12% of talc, 5-20% of clay, 2-15% of bentonite and0.3-1.5% of a foaming agent; and the glaze surface comprises an isolation glaze located on the surface of the ceramic tile body, a surface glaze located on the isolation glaze and a protective glazelocated on the surface glaze. Solid waste in the ceramic industry is used as main raw materials, and the wall tile and the method conform to the trend of environmental protection, greenness and sustainable development. The foamed ceramic wall tile has a water absorption rate of less than 0.4%, a density of 0.9-1.4 g / cm<3>, compressive strength of more than 8 MPa, breaking strength of more than 5 MPa, tensile strength of more than 2 MPa, a heat conductivity coefficient of 0.25-0.46 w / m.k, and a combustion performance of AI grade.

Owner:恩平市华昌陶瓷有限公司

Method for producing ammonium polyphosphate by using stepwise reaction and polymerization

The invention discloses a method for producing ammonium polyphosphate by using a stepwise reaction and polymerization, relates to a method for producing ammonium polyphosphateproducts with different polymerization degrees in the same set of device, in particular to a production method of ammonium polyphosphate with high purity, high polymerization degree and the average polymerization degree larger than 1000. The method comprises the following steps in sequence: a. adding a polycondensation agent into polyphosphoric acid as a raw material in the weight ratio of 1:1 and mixing evenly; b. adding the material obtained by the step a into a continuous synthetic reactor for reacting; and c. further polymerizing products obtained in the step b for 30-300 minutes at the pressure of 0.00MPa-0.6MPa and the temperature of 120DEG C-500DEG C to obtain the high-purity ammonium polyphosphate products with the polymerization degree of 10-1,800. The invention has the advantages of convenient production and control, high yield, low energy consumption and benefit for large-scale continuous industrial production.

Owner:YUNNAN CHEM RES INST

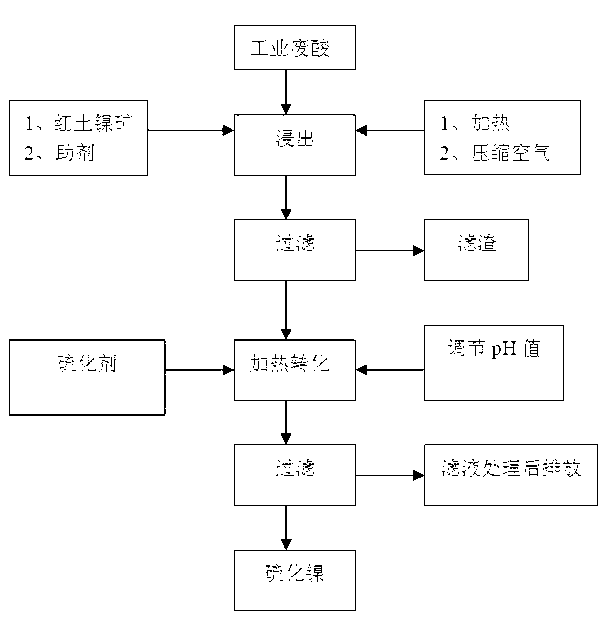

Method for producing nickel sulfide ore concentrate by use of industrial waste acid

ActiveCN102994746ASolve the problem of comprehensive utilizationReduce manufacturing costProcess efficiency improvementEconomic benefitsOxygen

The invention provides a method for producing nickel sulfide ore concentrate by the use of industrial waste acid. The specific technical scheme is as follows: adopting industrial waste acid to soak laterite-nickel ore, heating, stirring and extracting, and after a period of time, adding assistant, blowing in compression air or oxygen, reacting for a period of time, filtering, heating filtrate to a required temperature, and then adding vulcanizing agent, stirring, keeping the temperature for a period of time, and filtering to obtain the nickel sulfide ore concentrate. The method is an effective way for comprehensively utilizing the industrial waste acid to change waste into wealth, thereby reducing the cost for producing nickel sulfide ore by hydrometallurgical process, lowering air pollution and having a good economic benefit.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

Assembly welding process method for aluminum structure ceiling of driver cab of motor train unit

ActiveCN104384740AReduce the workload of the synthesis processShorten the compositing timeWelding/cutting auxillary devicesAuxillary welding devicesModularityEngineering

The invention relates to an assembly welding process method for an aluminum structure ceiling of a driver cab of a motor train unit. The assembly welding process method is characterized in that (1) at the premise of not changing the integral structure of the original structure, ceiling modules are separated, the structure of the original driver cab is re-divided, one part of structure is separated from a left side wall structure and a right side wall structure, and is used as a longitudinal edge beam of the ceiling structure, and then bulk parts which cannot be singly combined in the original structure can form the ceiling welding structure; (2) a welding tooling adopting the reverse assembly and outer positioning method is used for positioning and clamping, the welding sequence of the new ceiling structure is adjusted, the welding of a ceiling window frame structure is firstly completed, then the welding of a ceiling skeleton and a front window frame is completed, and finally the welding of a ceiling skin and the skeleton is completed, so a five-shaft processing center can complete processing at one time. The assembly welding process method has the advantages that the existing production technique of the aluminum structure ceiling of the driver cab of the motor train unit is a full new technique, the product quality of the ceiling part is improved, the assembly welding difficulty of the aluminum structure ceiling of the driver cab is decreased, the production cycle and labor intensity of the driver cab assembly are improved, the production modularizing of the driver cab is improved, and the quality is conveniently guaranteed.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

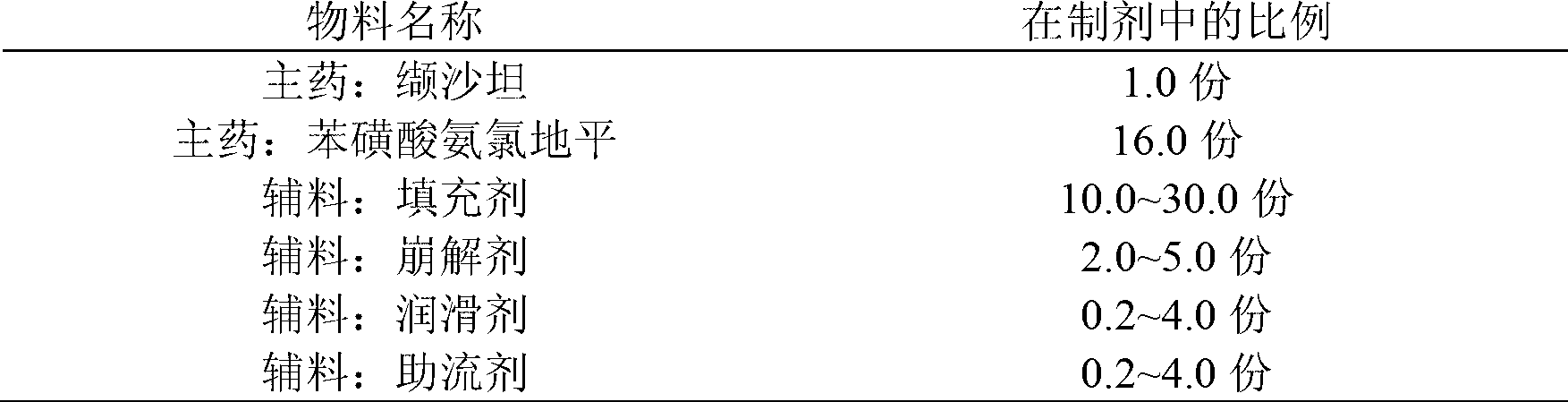

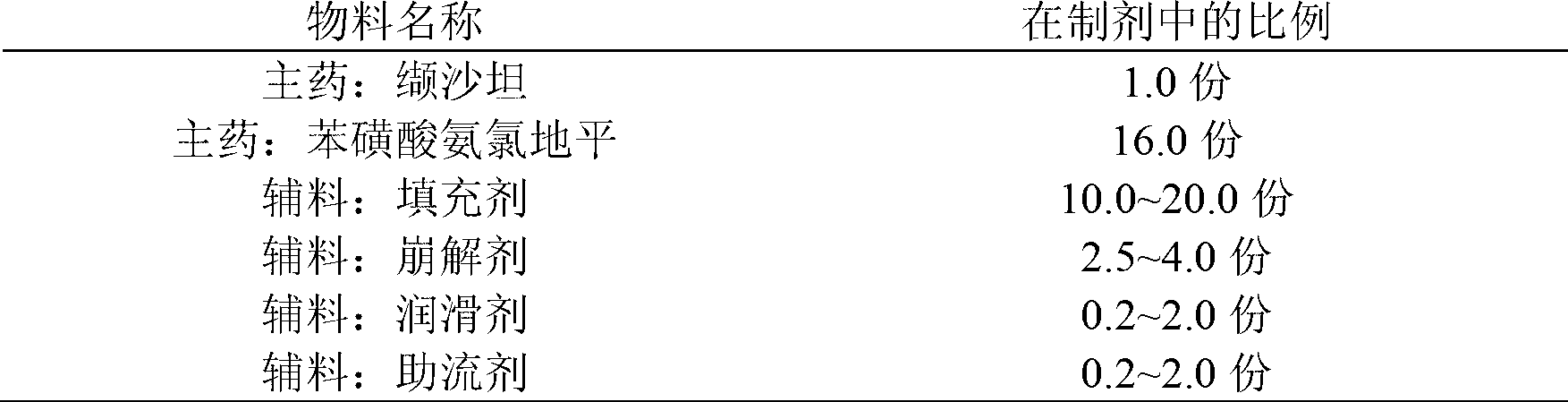

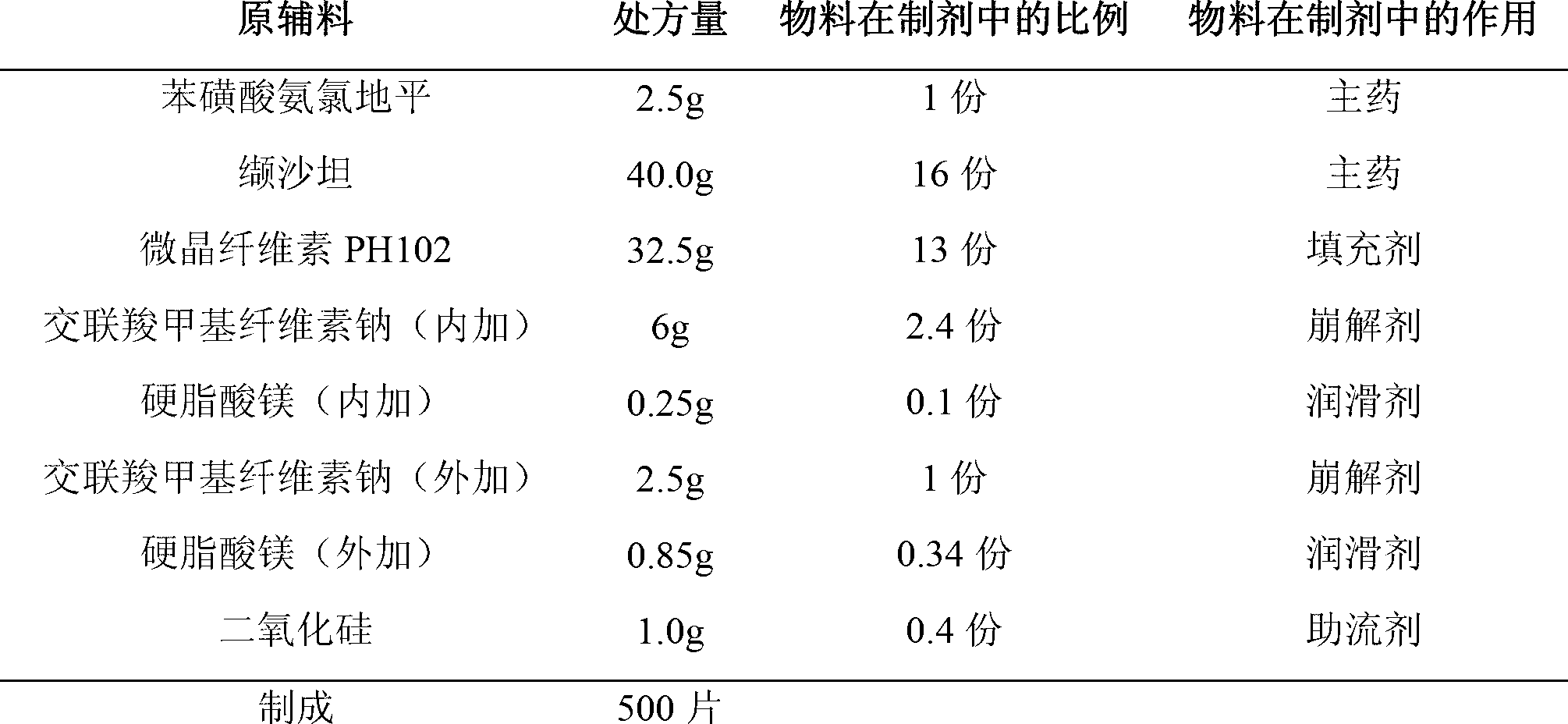

Compound preparation of valsartan amlodipine tablet (I) and preparation method thereof

ActiveCN103006649AReduce the introductionReduce lossesDrageesCardiovascular disorderValsartanAmlodipine besilate

The invention provides a compound preparation of valsartan amlodipine tablet (I) and a preparation method thereof. The compound preparation comprises a tablet, a film coating layer, the tablet comprises main drug and auxiliary materials, the main drug comprises valsartan, benzenesulfonic acid amlodipine, the auxiliary material comprises filler, a disintegrating agent, a lubricant, and glidant, the tablet comprises the valsartan, benzenesulfonic acid amlodipine, the filler, the disintegrating agent, the lubricant and the glidant, and the tablet is obtained by being coated with the film coating layer. According to the method, the defect of unsafety of medicine use caused by increase of relevant material due to wet granulation is overcome, and manufacture cost can be lowered and labor intensity can be relieved due to the dry granulation technology.

Owner:SHIJIAZHUANG HUAXIN PHARMA

Method for planting gerbera jamesonii

ActiveCN106358671AReduce physical impairmentReduce pests and diseasesMagnesium fertilisersExcrement fertilisersMonopotassium phosphateCulture mediums

The invention belongs to the technical field of agriculture, and particularly relates to a method for planting gerbera jamesonii. The method comprises the following steps: S1, preparing soil; S2, topping; S3, planting; S4, topdressing, namely additionally applying base fertilizer twice a year and water manure twice a year after the following year of planting; S5, controlling water; and S6, hoeing, wherein the base fertilizer is prepared from the following raw materials in parts by weight: 20-30 parts of a coating material, 10-15 parts of chestnut shells, 10-20 parts of charcoal-based fertilizer, 10-20 parts of edible fungus culture medium byproducts, 10-20 parts of beneficial bacteria, 10-15 parts of yellow sand, 5-15 parts of a nitrification inhibitor and the like; and the water manure is prepared from the following raw materials in parts by weight: 10-50 parts of monopotassium phosphate, 10-30 parts of potassium sulfate, 1000-3000 parts of water and the like. According to the method, starting from the fertilization treatment of field management, an insect dispelling effect is achieved by adopting the base fertilizer and water manure with a reasonable application formula and uniform nutritional proportions, so that nutritional ingredients can be slowly released, proper fertility absorption of the gerbera jamesonii in the growing process can be ensured, big flowers and uniform leaves can grow out, the ornamentation and decoration values can be improved, and the economic benefits can be further increased.

Owner:台州中知英健机械自动化有限公司

Graphite anode anti-oxidation coating for producing rare earth metal

The present invention relates to antioxidant coating of graphite anode for producing RE metal and its preparation process. The coating consists of mainly the fluoride of the produced RE metal and alloy, RE oxide, fluoride of alkali metal and alkali earth metal, and adhesive. The preparation process includes mixing the said components, high temperature fusion, cooling, crushing into powder, mixing with adhesive, painting the mixture onto the graphite electrode and stoving or air drying. The coating has simple forming process, and may be used to lower the oxidation speed of graphite anode, raise the utilization rate of the graphite anode and lower the RE metal producing cost.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Industrial robot stacking jaw

InactiveCN106078788AFast and stable palletizing workReduce manufacturing costGripping headsPulp and paper industryIndustrial robot

The invention relates to the technical field of robots, in particular to an industrial robot stacking jaw. The industrial robot stacking jaw comprises a connecting frame and a mounting frame; the connecting frame is fixedly connected with the mounting frame; fixed bases are connected to the left and right two bottom ends of the connecting frame; the fixed bases are fixedly connected with guide rods; the guide rods are movably connected with slide bases; the bottom ends of the slide bases are fixedly connected with mounting plates; the left and right two bottom ends of the connecting frame are fixedly connected with cylinders I; extension shafts of the cylinders I are connected with the mounting plates; the left and right two bottom ends of the mounting plates are movably connected with swing sleeves; the swing sleeves are fixedly connected with hand backs; and the bottom ends of the hand backs are fixedly connected with fingers. The industrial robot stacking jaw can quickly and stably finish the goods stacking work, can stack goods on a large scale, reduces the production cost and the labor intensity, is high in stability, effectively prevents generation of accidents, and guarantees the production safety.

Owner:NOBOT INTELLIGENT EQUIP (SHANDONG) CO LTD

Diamond tool bit recovery processing method

ActiveCN106629706AHigh economic valueEasy to reusePhotography auxillary processesDiamondTool bitPregnant leach solution

The invention discloses a diamond tool bit recovery processing method and belongs to the technical field of wet metallurgy. The processing method comprises steps as follows: a diamond tool bit is added to first leaching liquor in the mass ratio of the diamond tool bit to the first leaching liquor being 1:(2.4-3.5) to react, air is pumped into the first leaching liquor continuously, and sulfuric acid with the concentration being 5-15 g / L is contained in the first leaching liquor; when spongy copper occurs in the first leaching liquor, solid-liquid separation is performed, a first insoluble substance and first filtrate are obtained, and the first filtrate is a solution containing ferrous sulfate; the first insoluble substance and sufficient second leaching liquor react, air is introduced continuously until the reaction ends, solid-liquid separation is performed, a second insoluble substance and second filtrate are obtained, the second filtrate is a solution containing copper sulfate, and the second leaching liquor contains sulfuric acid with the concentration being 100-150 g / L; 20 parts of deionized water and 0.001-0.010 parts of kerosene are added to one part of the second insoluble substance by mass, and diamond is separated out with a flotation method.

Owner:JIANGHAN UNIVERSITY

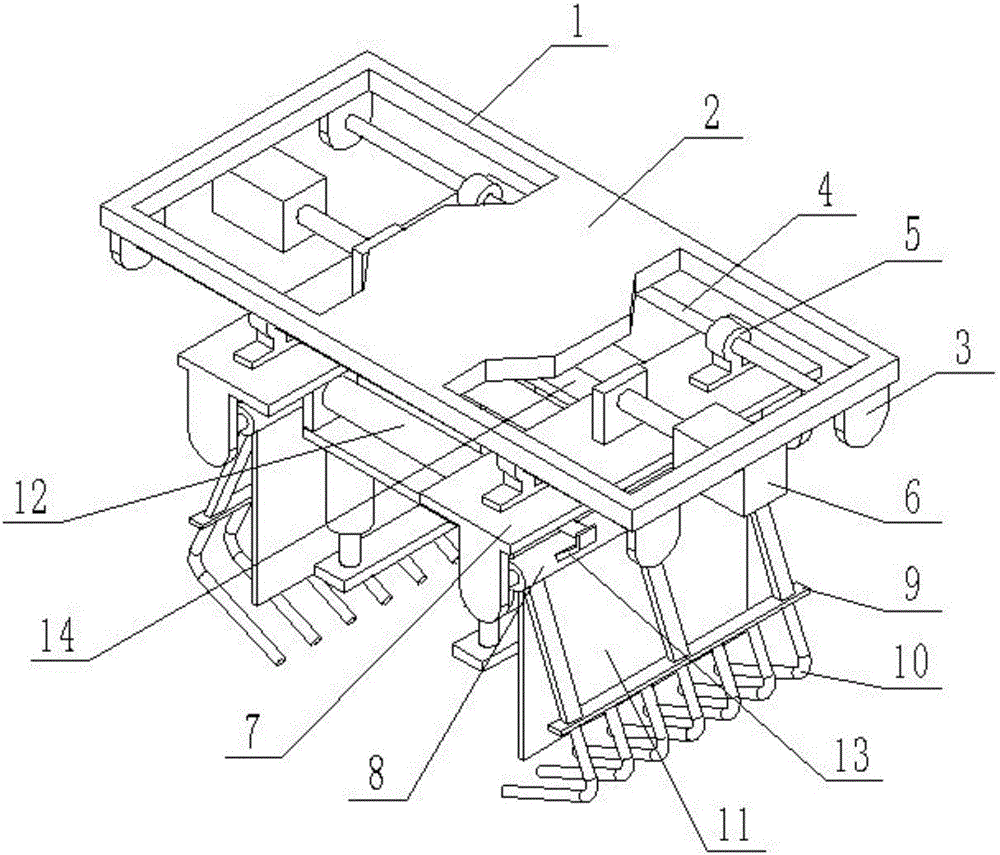

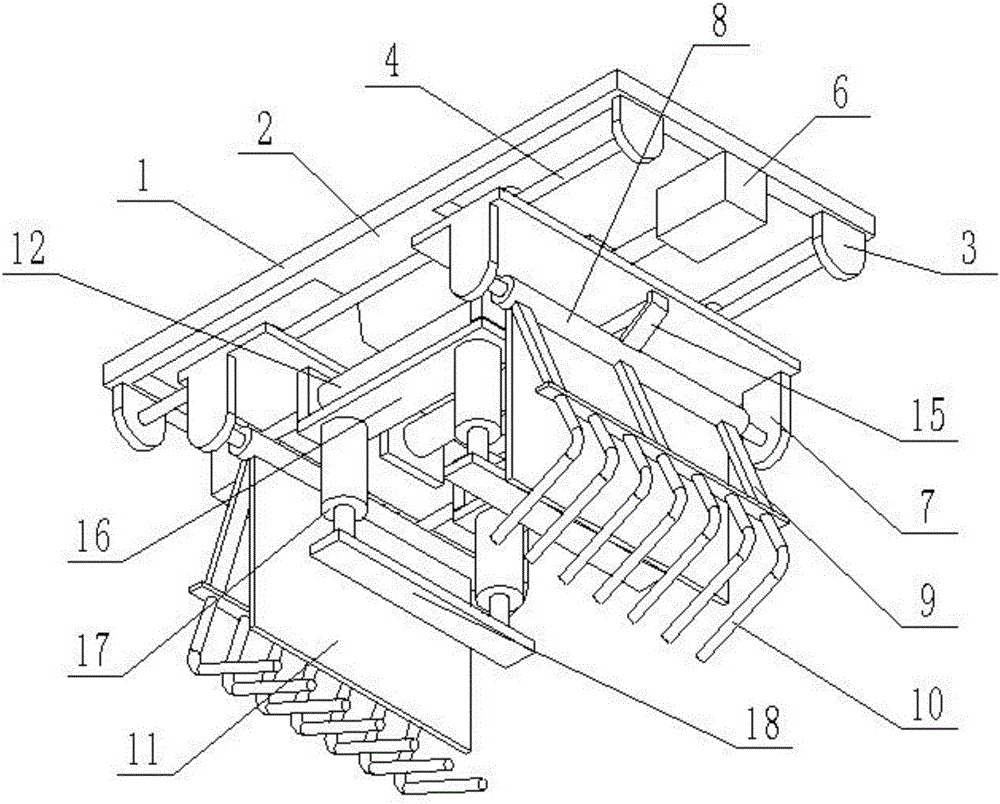

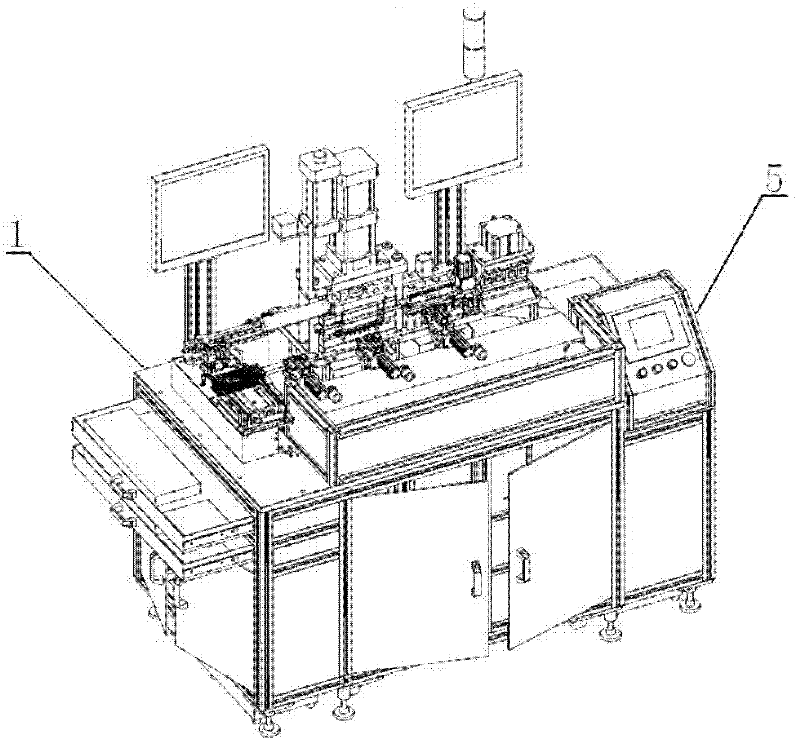

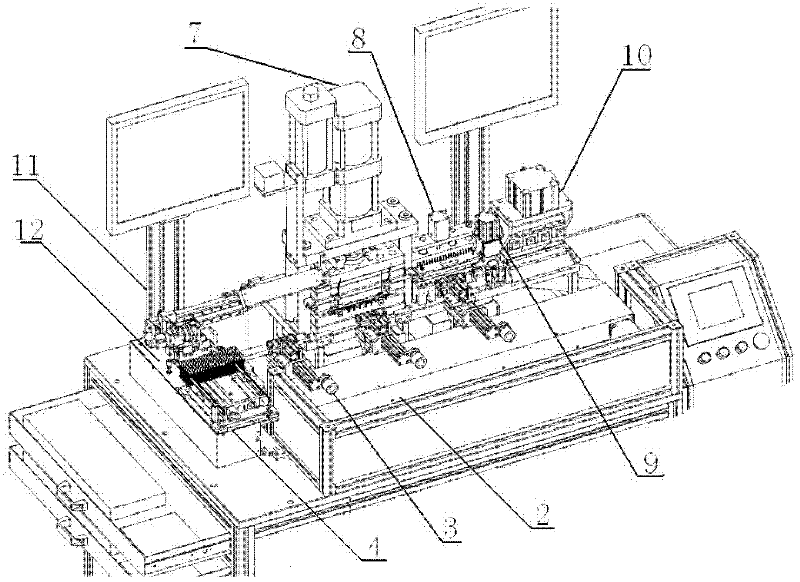

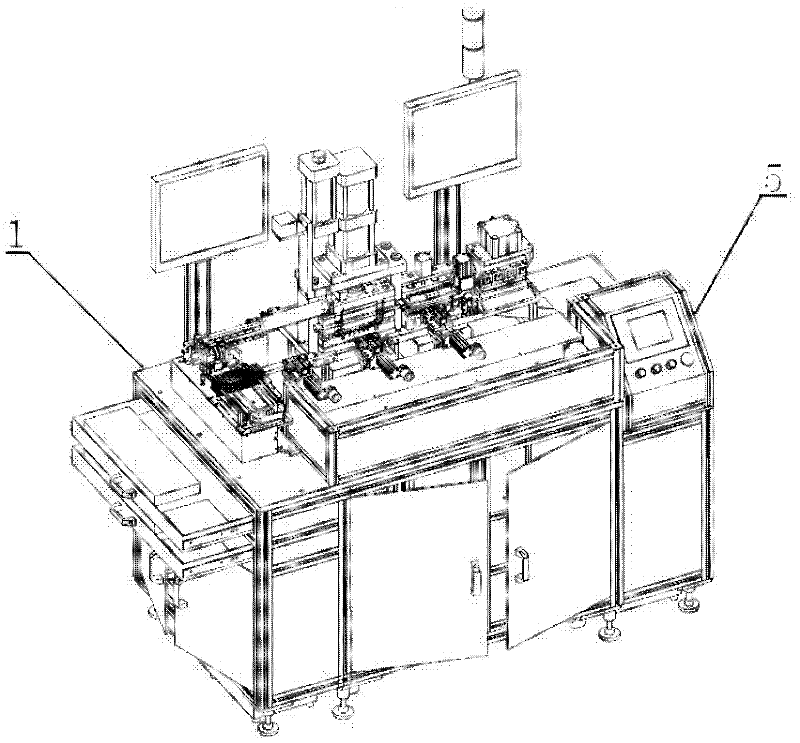

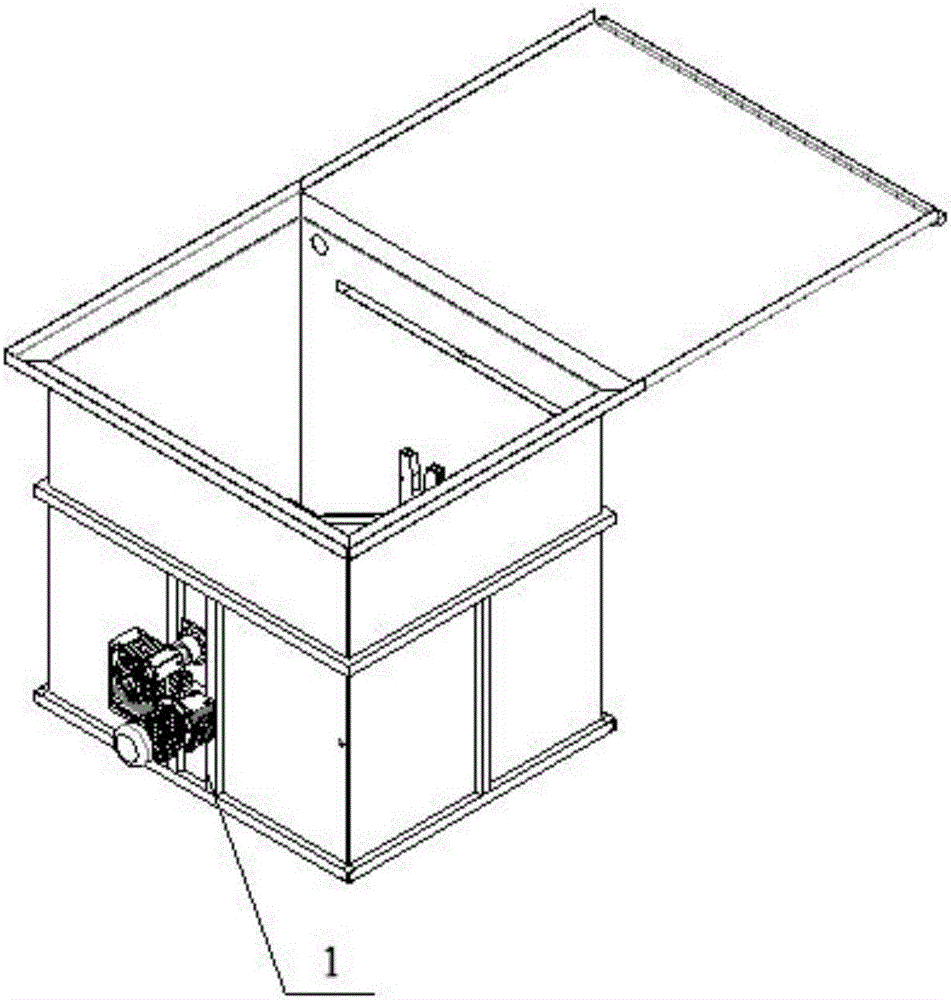

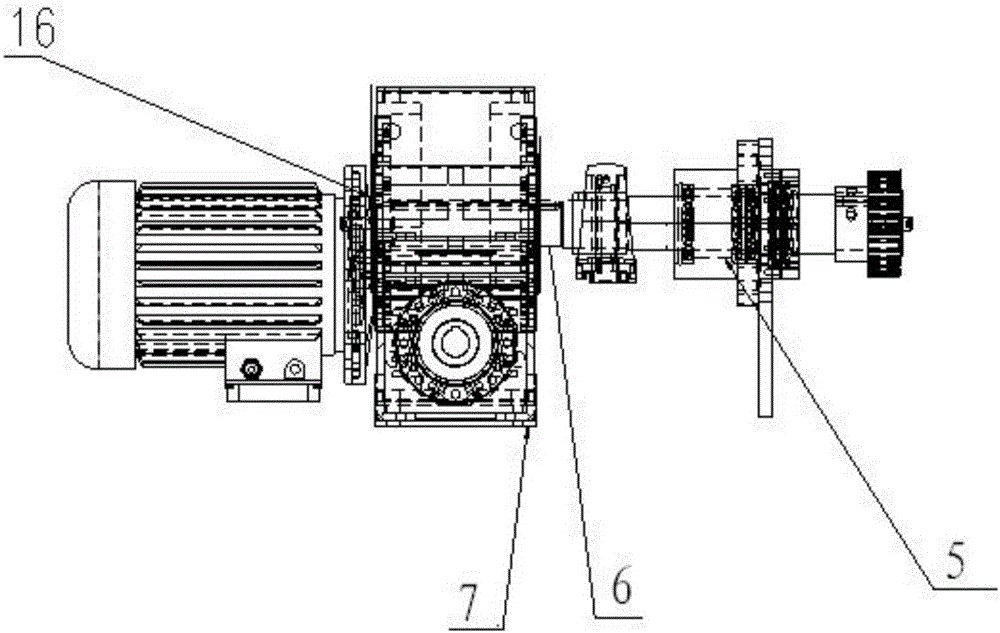

Equipment for automatically cutting and detecting appearance and electric property of light-emitting diode (LED) lamp semi-finished products

ActiveCN102544254ASimple equipment structureEasy to useMaterial analysis by optical meansSemiconductor devicesGrippersWork in process

The invention relates to equipment for automatically cutting and detecting the appearance and electric property of light-emitting diode (LED) lamp semi-finished products, which comprises a rack (1) and an operating system (5), wherein a feeding device, a shifting unit, a testing device, a cutting device and a finished product outlet (6) are sequentially arranged on a bottom plate of the rack (1); the feeding device comprises a motor positioning and magnetic taking device (12) and a rotary device (4); the shifting device comprises a servo positioning system (2) and a mechanical gripper (3); the testing device comprises a charge coupled device (CCD) visual inspection system (11) and an electric property testing system (8); and the cutting device comprises a mould cutting device (7), a defective product cutting device (9) and a finished product cutting device (10). The equipment is low in production cost, is convenient to use and realizes the automatic production of LED lamps, so the production efficiency is improved, and the equipment has very good popularization prospect.

Owner:东莞市鼎力自动化科技有限公司

Precise forging-continuous rolling production technology of large and heavy single molybdenum rod

ActiveCN103042389ARealize deep processingIncrease productivityTemperature control deviceOther manufacturing equipments/toolsThermal treatmentContinuous rolling

The invention provides a precise forging-continuous rolling production technology of a large and heavy single molybdenum rod. The production technology comprises the following steps of: 1, carrying out billet forging on the molybdenum rod by a precision forging machine to obtain a precision forging bar; 2, heating the precision forging bar; 3, rolling for the first time by a Y-shaped three-roller continuous mill to obtain a rolled molybdenum rod; 4, heating the rolled molybdenum rod; and 5, rolling for the second time by the Y-shaped three-roller continuous mill and obtaining the large and heavy single molybdenum rod of which the piece weight is 45-50kg. Deep processing of a molybdenum bar is successfully achieved by setting and optimizing each parameter in precision forging, thermal treatment and continuous rolling processes; the large and heavy single molybdenum rod, which is suitable for subsequent wire drawing, and of which the piece weight is 45-50kg, is finally produced; and the production efficiency is obviously improved. The piece weight of the molybdenum rod produced by the production technology is much greater than that of the molybdenum rod produced by a traditional technology; and the precise forging-continuous rolling production technology has no welding spot on the whole, and is even in internal organization, high in product quality and suitable for large-scale industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

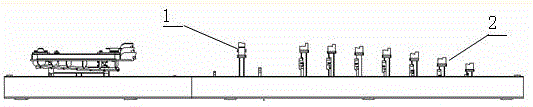

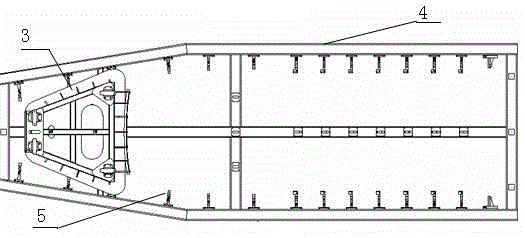

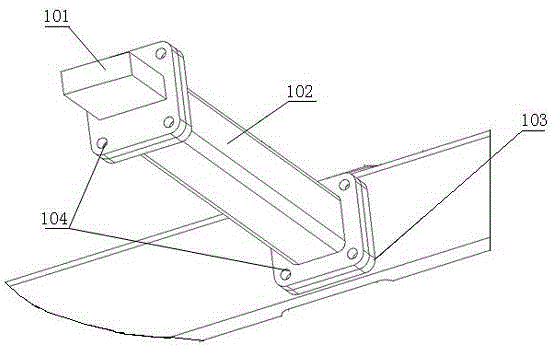

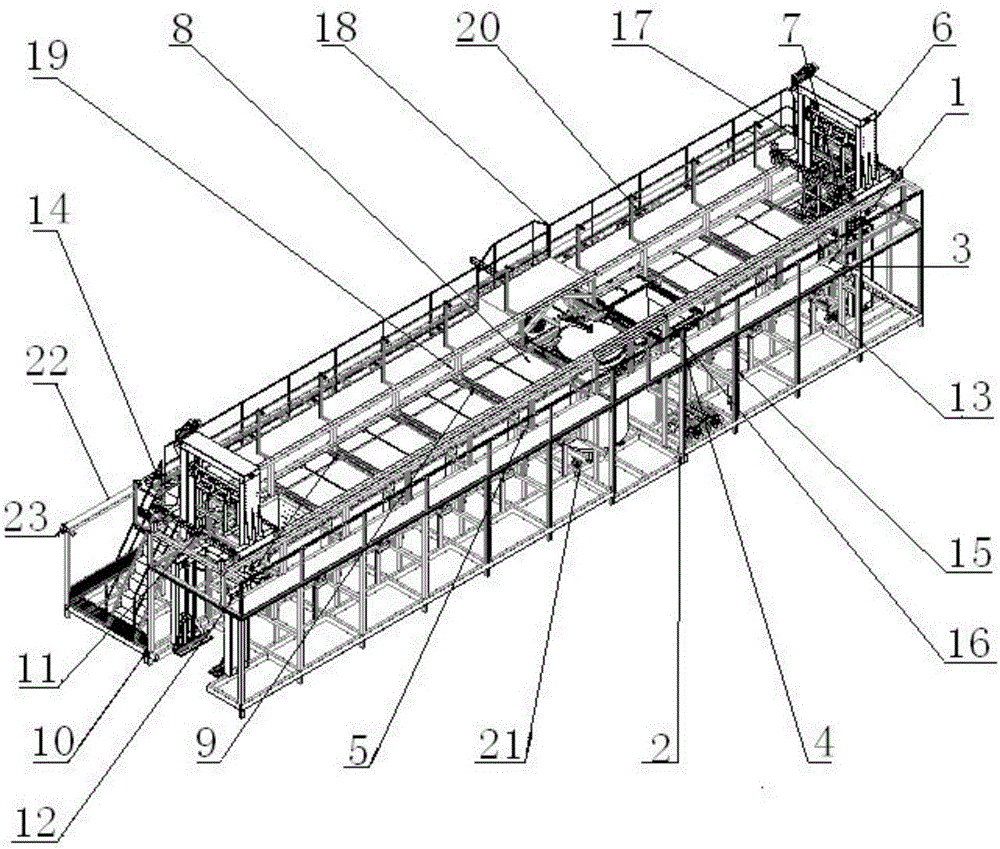

Full-automatic infiltration cleaning line

PendingCN107520432AReduce Occupational HazardsReduce production labor intensityTurnover timeTime efficient

The invention discloses a full-automatic impregnation cleaning line, which includes nine stations; the full-automatic impregnation cleaning line provided by the invention can 1) reduce production labor intensity and reduce occupational hazards to operators; 2) clean before solving The sewage discharge pollution problem caused by the waste water treatment system can reduce the discharge of waste water, turn the waste water into waste residue and discharge it, which is convenient for transportation and treatment. The actual waste water can reach within 3%-5% of the discharge; Infiltration and then cleaning turnaround time in the middle of assembly, greatly saving time, reducing manpower input and cost, can save more than 20% of production cost.

Owner:上海科伟达超声波科技有限公司

Transmission shaft spline shaft metal processing technique

The invention discloses a transmission shaft spline shaft metal processing technique. The processing technique comprises the following steps of: performing thermal refining by using a thermal refining automatic line; milling a small end surface by using a milling and drilling machine, and drilling centre bores at two ends; performing fine turning by using a numerically controlled lathe; milling a spline by using a numerical control spline milling machine; removing front points and burr; and performing mid frequency induction hardening by using a mid frequency induction hardening machine. The processing technique can guarantee the part accuracy to the maximum extent, eliminate various errors caused by position reference conversion, shortens the whole metal processing flow, reduce a large number of manpower and material resources, greatly reduce the processing cost, reduce the labor intensity, improve the working efficiency, and save processing cost.

Owner:XUCHANG YUANDONG DRIVE SHAFT

Micropropagation method for rubber tree good variety somatic embryo plant

InactiveCN103125382AHigh quality glue materialHigh speedPlant tissue cultureHorticulture methodsPlantletSeedling

Owner:YUNNAN INST OF TROPICAL CROPS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com