Full automatic tobacco processing machine

A cigarette weaving machine and fully automatic technology, which is applied to tobacco, conveyors, tobacco preparation, etc., can solve the problems of high labor intensity and unguaranteed quality of workers, so as to reduce the labor intensity of production, promote sustainable development, and avoid weaving Smoke quality is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

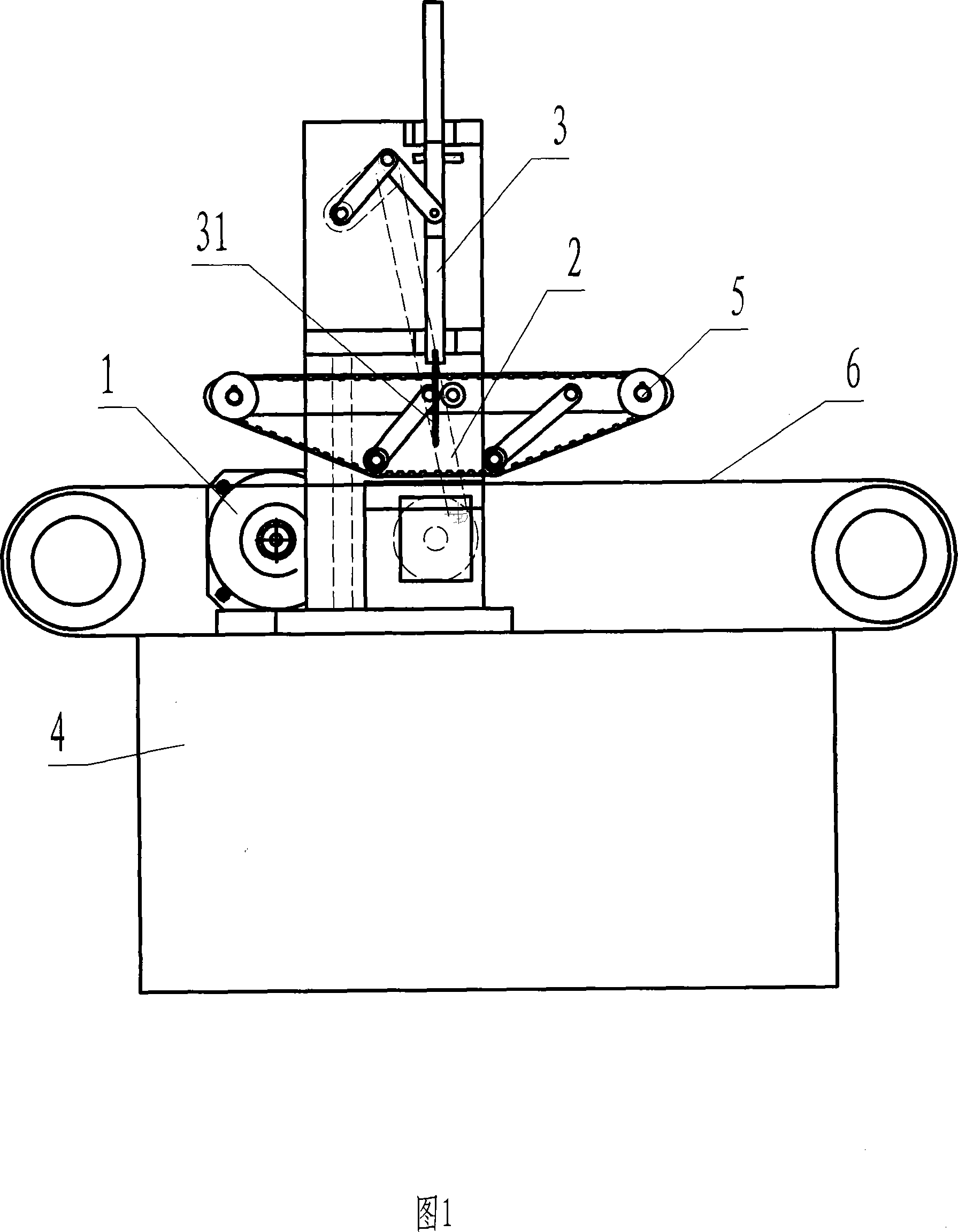

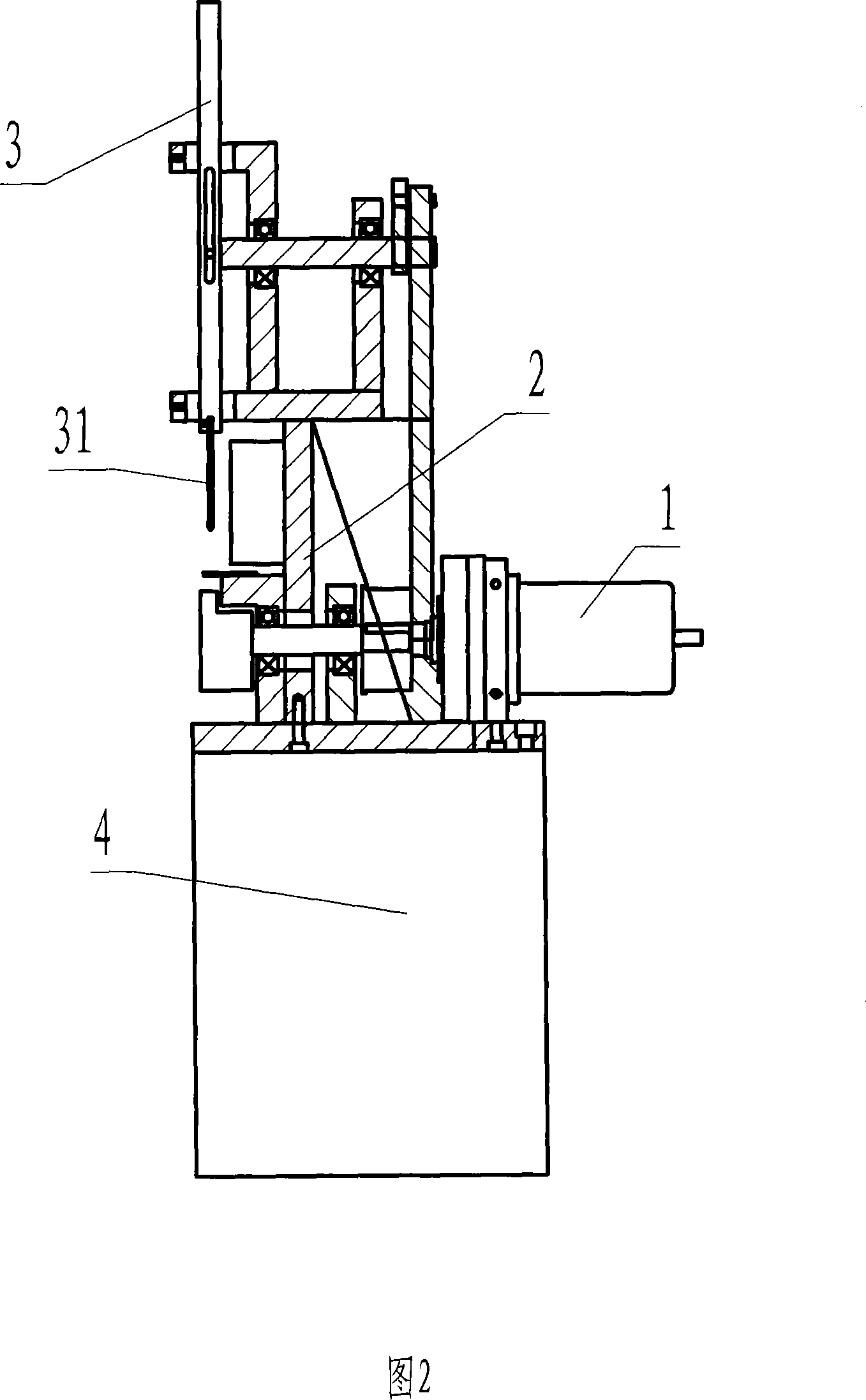

[0047] A fully automatic cigarette knitting machine as shown in Figures 1 and 2, comprising a power source 1, a transmission device 2, a machine head 3, a frame 4, a pressing device 5 and a material conveying device 6. The material conveying device is arranged below the crochet needle 31 of the machine head, and the pressing device 5 is arranged above the material conveying device 6 and fixed on the frame 4 .

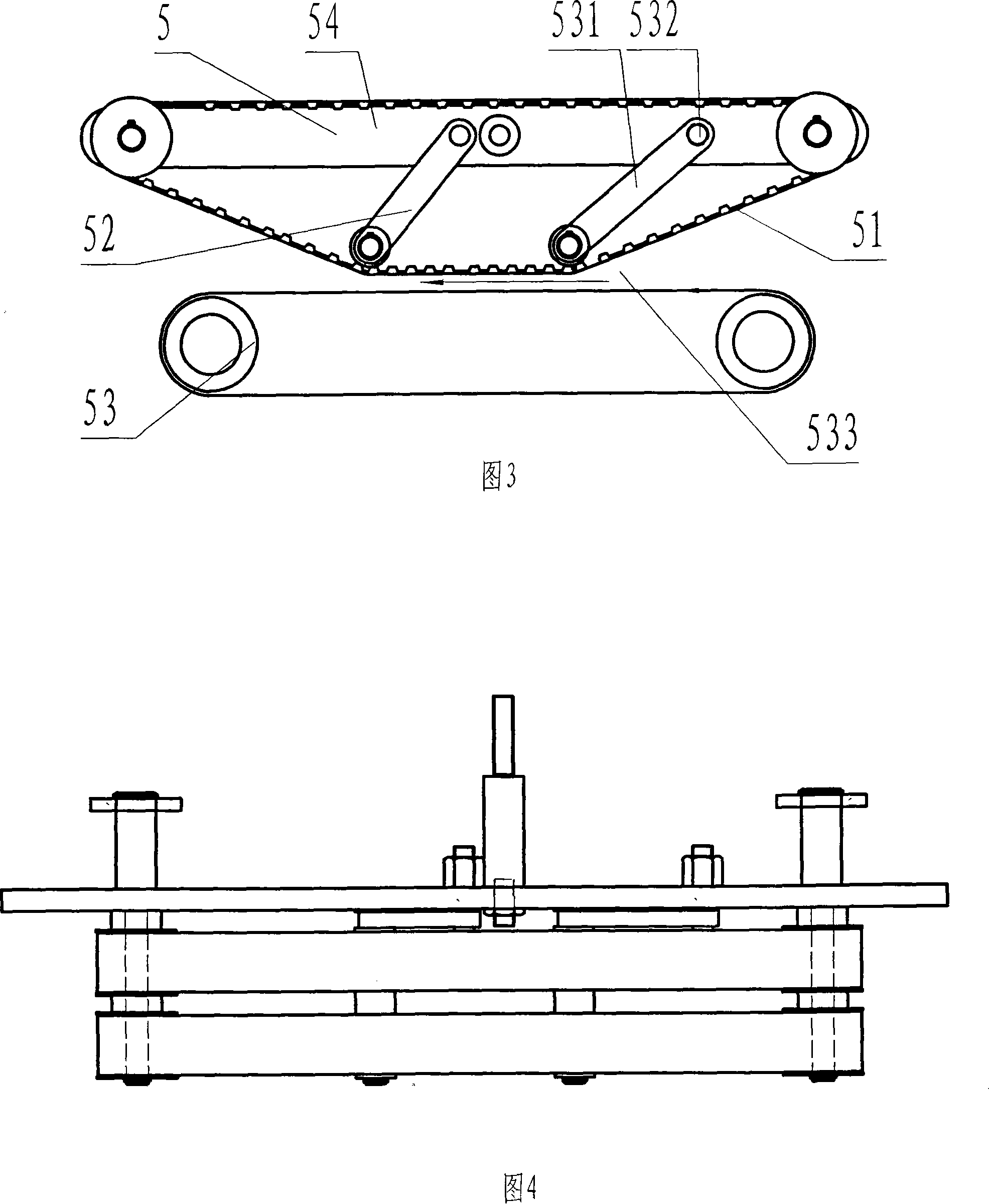

[0048] As shown in FIGS. 3 and 4 , the pressing device 5 includes a pressing belt 51 , a tensioning device 52 and a supporting device 53 . The binder belt is sleeved on two rotary shafts arranged at intervals for rotary motion. A positioning plate 54 is also sleeved on the two rotary shafts, and two parallel tensioning devices 52 at an angle of 60 degrees to the channel formed between the binder belt and the supporting device are fixed on the positioning plate. The tensioning device is rotatably fixed on the positioning plate 54, and simultaneously the tensioning head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com