Industrial robot stacking jaw

An industrial robot and gripper technology, applied in the field of robots, can solve the problems of injury to workers, unfavorable palletizing of goods, high labor intensity, etc., to achieve high stability, reduce production costs and labor intensity, and avoid accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

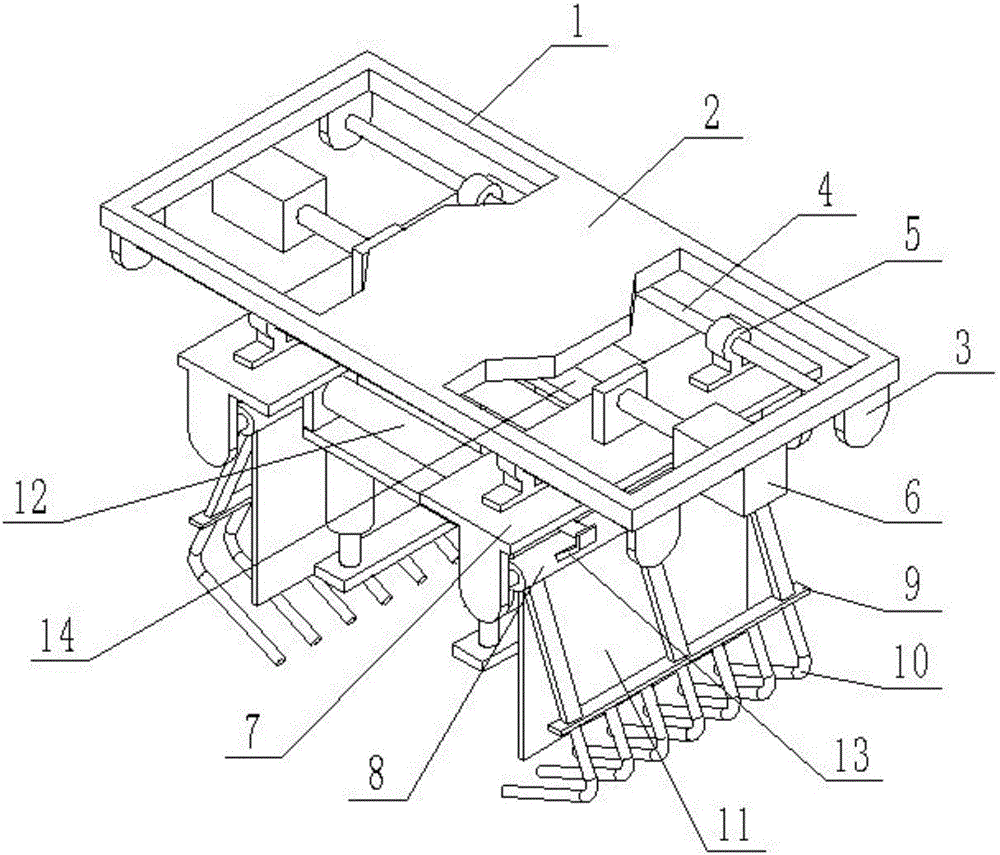

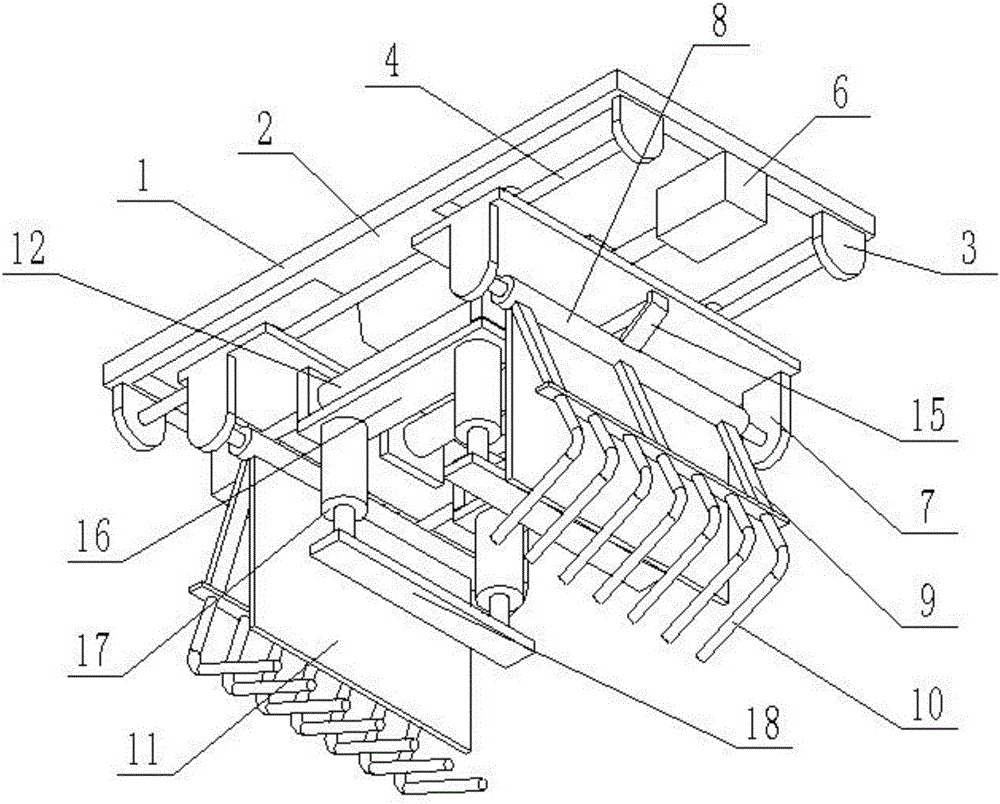

[0017] Combine below figure 1 , 2 This embodiment is described. The present invention relates to the field of robot technology, more specifically, the industrial robot palletizing gripper. The industrial robot palletizing gripper includes a connecting frame 1 and a mounting frame 2, and the connecting frame 1 is fixedly connected with a mounting bracket. Frame 2, the left and right bottom ends of the connecting frame 1 are connected with a fixed base 3, the fixed base 3 is fixedly connected with a guide rod 4, and the described guide rod 4 is movably connected with a sliding seat 5, the described The bottom end of the sliding seat 5 is fixedly connected with the installation plate 7, the left and right bottom ends of the connecting frame 1 are fixedly connected with the cylinder I6, and the telescopic shaft of the cylinder I6 is connected with the installation plate 7, so The left and right bottom ends of the mounting plate 7 are movably connected with a swing sleeve 8, the s...

specific Embodiment approach 2

[0021] Combine below figure 1 , 2 The present embodiment will be described. The sliding seat 5 according to the present embodiment can slide on the guide rod 4 .

specific Embodiment approach 3

[0022] Combine below figure 1 , 2 To describe this embodiment, there are multiple fingers 10 in this embodiment, and the multiple fingers 10 are evenly distributed at the bottom end of the back of the hand 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com