Vertical conveyer for steel drum stereoscopic warehouse

A three-dimensional warehouse and conveyor technology, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., to save labor, optimize layout, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

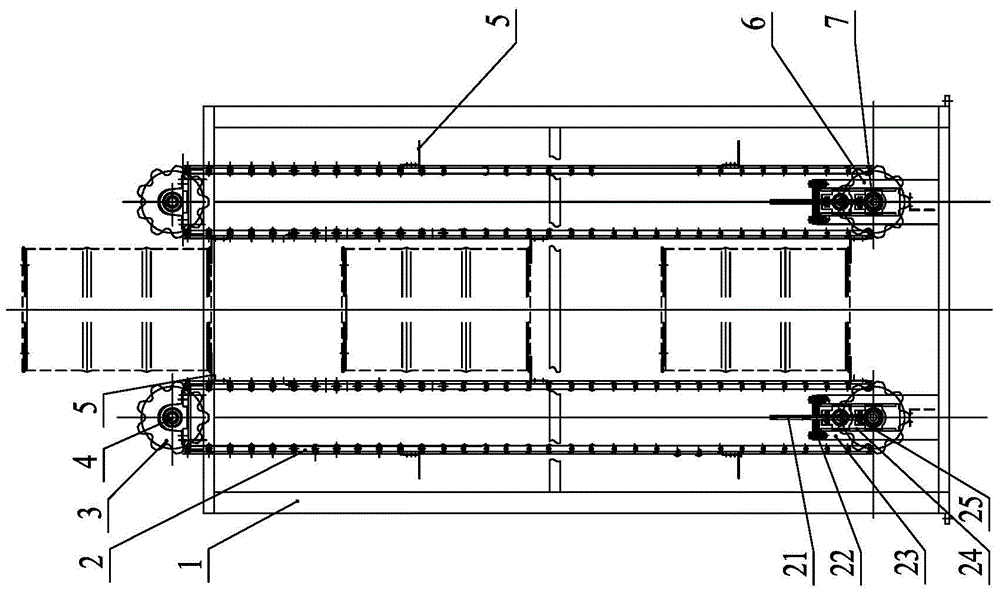

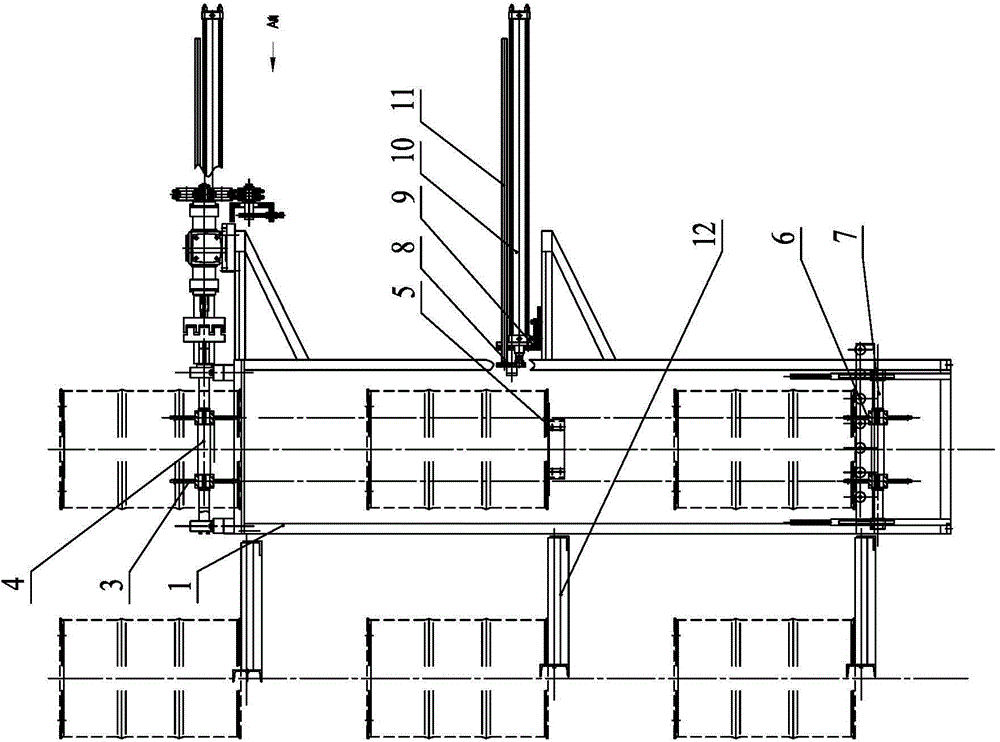

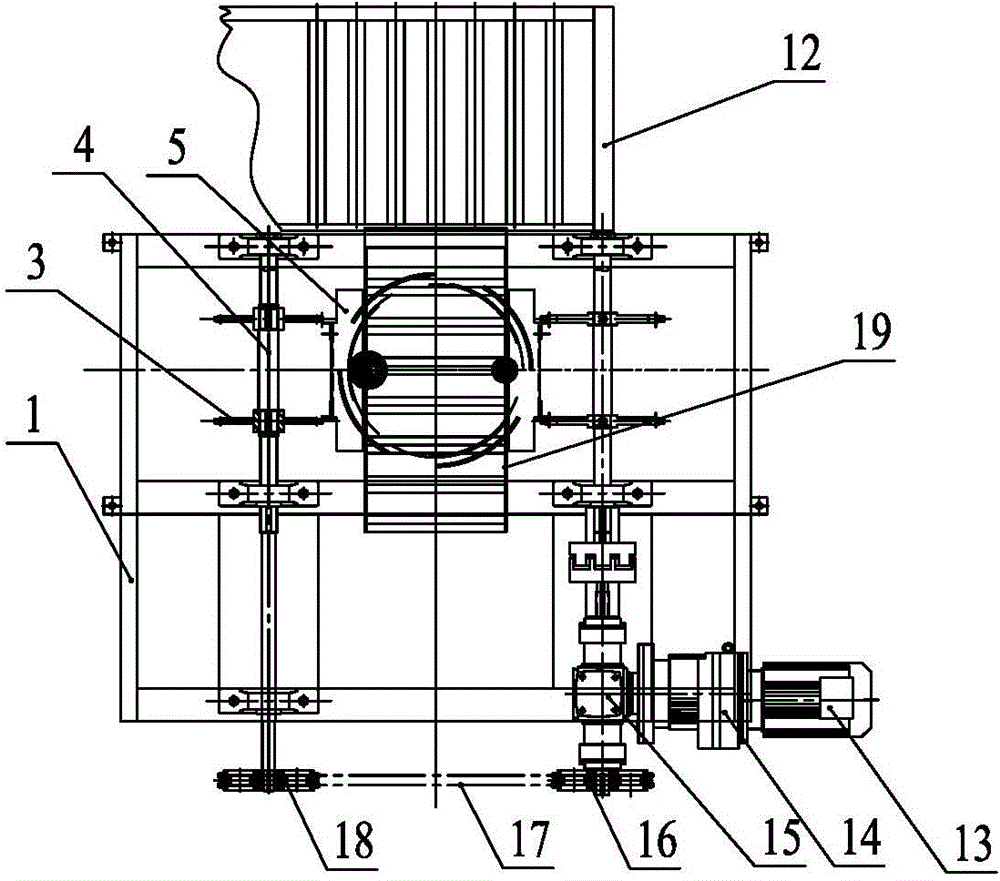

[0017] As shown in the figure: the vertical conveyor of the steel barrel three-dimensional warehouse in the embodiment is mainly composed of a frame 1, a lifting chain 2, an upper sprocket 3, an upper shaft 4, an L-shaped pallet 5, a lower sprocket 6, and a lower shaft 7 , push plate 8, support 9, cylinder 10, guide rod 11, storage conveying roller table 12, motor with brake 13, reducer 14, forward and reverse bevel gear transmission 15, driving sprocket 16, transmission chain 17, driven Sprocket wheel 18, one deck conveying raceway 19, tension sprocket wheel 20, screw rod 21, fixed plate 22, tension frame 23, slide rail 24 and slide seat 25 etc. are formed.

[0018] Such as figure 1 As shown, the middle of the frame 1 is provided with a steel drum lifting and conveying channel, and the one-layer conveying raceway 19 is arranged below the steel drum lifting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com