Phosphogypsum calcining system

A phosphogypsum and calcination technology, applied in the field of calcination treatment system, can solve the problems of large occupied area, secondary pollution, small output, etc., and achieve the effect of reducing floor space, reasonable and compact layout, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

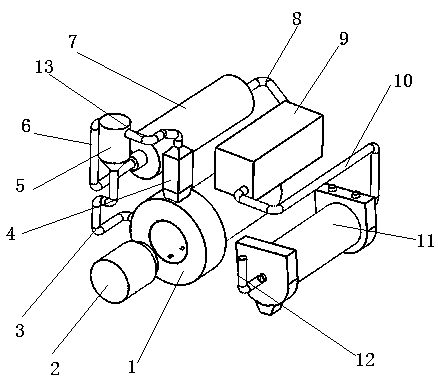

[0016] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as figure 1 In this example, a double-barrel rotary calciner with a diameter of 3 meters that is common in this industry is selected as the calciner 1, and it is installed on the installation base of the calciner; 2. Install the flame-injection furnace 2 at the feed port end of the calciner 1, and ensure that the fire-injection direction faces the open end of the inner cylinder of the calciner 1; in this example, a thin-walled steel pipe commonly used in the industry is selected as the front dust collector The return pipe 3, the front dust collector return pipe 3 is installed between the front dust collector 2 and the calciner 1, one end is connected to the discharge port of the collecting bin of the front dust collector 2, and the other end is connected to the calciner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com