Method for preparing low-polymerization-degree ammonium polyphosphate aqueous solution

A technology of ammonium polyphosphate and low degree of polymerization, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as difficult production control, slow reaction process, and influence on implementation and promotion, and reduce production labor intensity and environmental protection. The degree of influence is small and the effect of improving production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

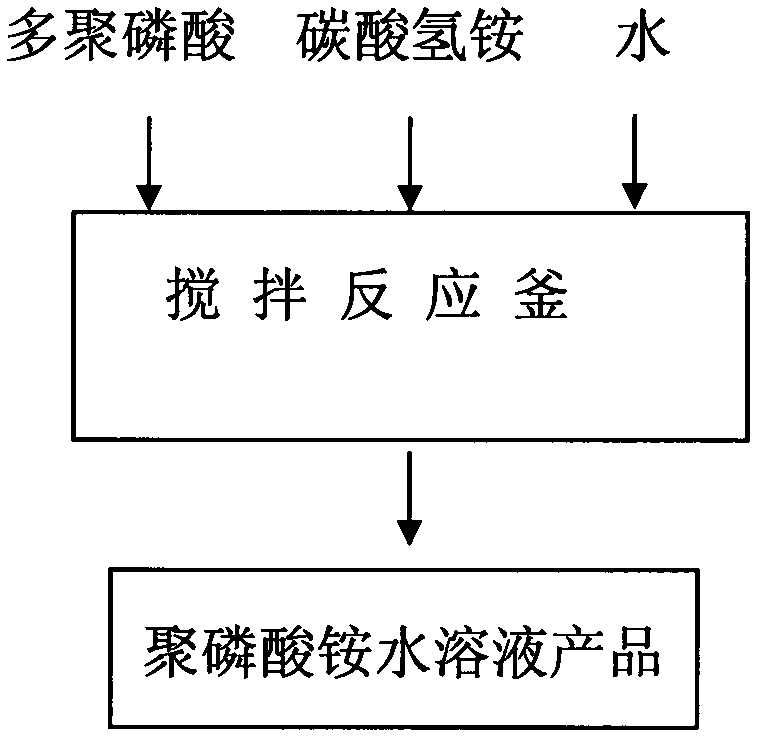

Image

Examples

Embodiment 1

[0017] In the case of constant stirring, 300 kg of water, 1100 kg of ammonium bicarbonate, and 700 kg of 107.5% polyphosphoric acid were continuously added at the same time. After 4 hours, the nitrogen content of the product was measured to be 11.2%, the density was 1.40, and the pH value was 5.6. , the content of phosphorus pentoxide is 38.6%, and the polymerization degree based on dimer (ammonium pyrophosphate) is 70%.

Embodiment 2

[0019] Under the condition of constant stirring, 700 kilograms of water, 2100 kilograms of ammonium bicarbonate, and 1150 kilograms of 108% polyphosphoric acid were continuously added at the same time. The content of diphosphorus is 37.1%, and the degree of polymerization mainly of dimer (ammonium pyrophosphate) is 71%.

Embodiment 3

[0021] Under the condition of constant stirring, 4.5 tons of water, 19 tons of ammonium bicarbonate, and 12 tons of 108.2% polyphosphoric acid were continuously added at the same time. After 8 hours, the nitrogen content of the product was 11.3%, and the pH value was 6. The content of diphosphorus is 38.3%, and the degree of polymerization mainly of dimer (ammonium pyrophosphate) is 72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com