Diamond tool bit recovery processing method

A technology of diamond cutter head and processing method, which is applied in the field of diamond cutter head recycling and processing, can solve the problem of ineffective separation of diamonds, etc., achieve the effect of low labor intensity in production and increase economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

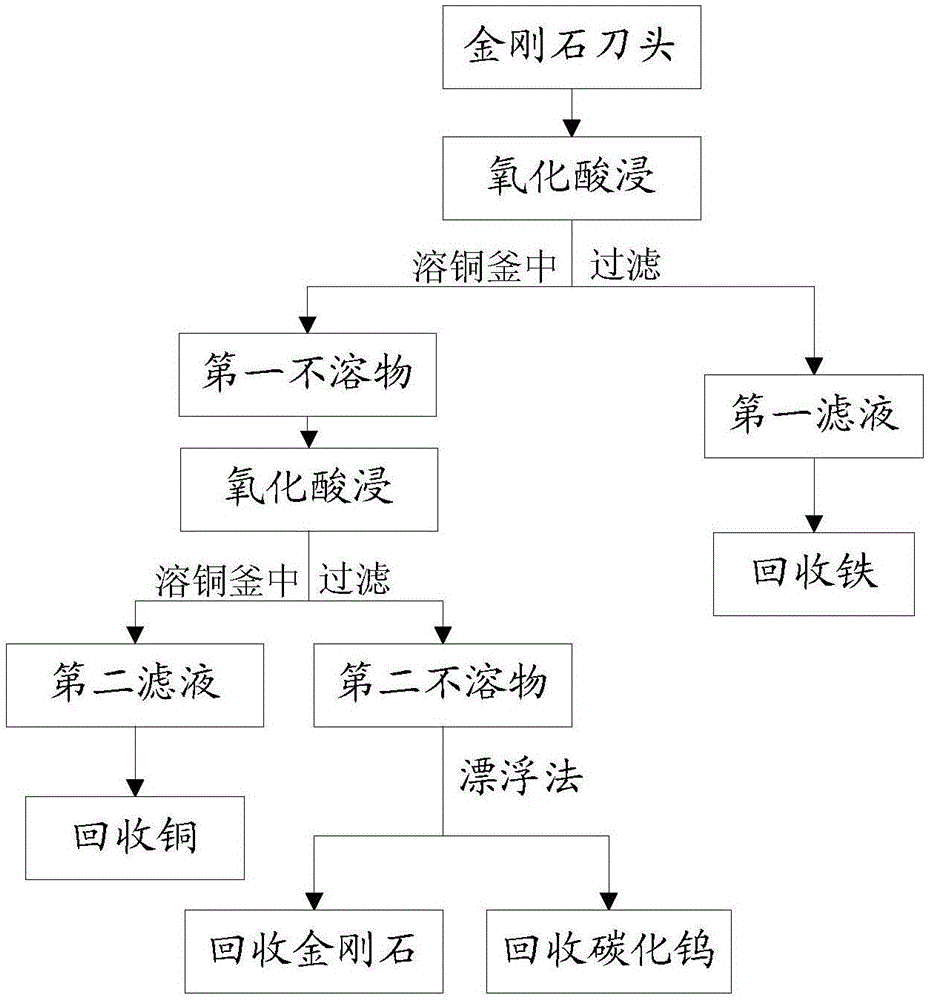

[0031] figure 1 It is a flow chart of the diamond cutter head recovery treatment method provided by the embodiment of the present invention, see figure 1 , this treatment method is suitable for copper-iron-based diamond cutter head, the diamond cutter head mainly contains copper, iron, artificial diamond, in addition, also contains a small amount of tungsten carbide, zinc, nickel, cobalt, wherein, the mass fraction of main components includes: Cu 20-70%, Fe 20-80%, artificial diamond 0.5-6%, the treatment method includes:

[0032] Step 101: According to the mass ratio of the diamond cutter head to the first leaching solution is 1:2.4-3.5, add the cleaned diamond cutter head to the first leaching solution, and react in the first copper melting kettle, the reaction temperature is 80- 90°C, air is continuously fed during the reaction process, and the first leachate contains 5-15g / L sulfuric acid;

[0033] Step 102: When fine powdery sponge copper appears in the first leaching s...

Embodiment 2

[0061] In this embodiment, the mass percentages of the main components of the diamond cutter head used are: 23.50% Cu, 56.34% Fe, and 0.56% synthetic diamond. The sulfuric acid used is industrial grade sulfuric acid, wherein the mass fraction of sulfuric acid is greater than 98%.

[0062] In this embodiment, the mass percentages of the main components of the diamond cutter head used include: Cu is 23.50%, Fe is 56.34%, and artificial diamond is 0.56%, which also contains a small amount of metals such as tungsten carbide and nickel, cobalt, and zinc. Since the contents of tungsten carbide and metals such as nickel, cobalt, and zinc are extremely small, no detailed description is given here. The sulfuric acid used in the treatment process is industrial grade sulfuric acid, wherein the mass fraction of sulfuric acid is greater than 98%.

[0063] First prepare industrial-grade sulfuric acid into a dilute sulfuric acid solution with a mass fraction of 5-15g / L as the first leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com