Cap with visible tamper-indicating seal

a technology of sealing cap and visible tampering, applied in the field of sealing device, can solve the problems of difficult reattachment of the sealing cap to the bottle opening, limited combinations, and more expensive to manufacture caps in an array of colors, and achieve the effect of convenient customization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

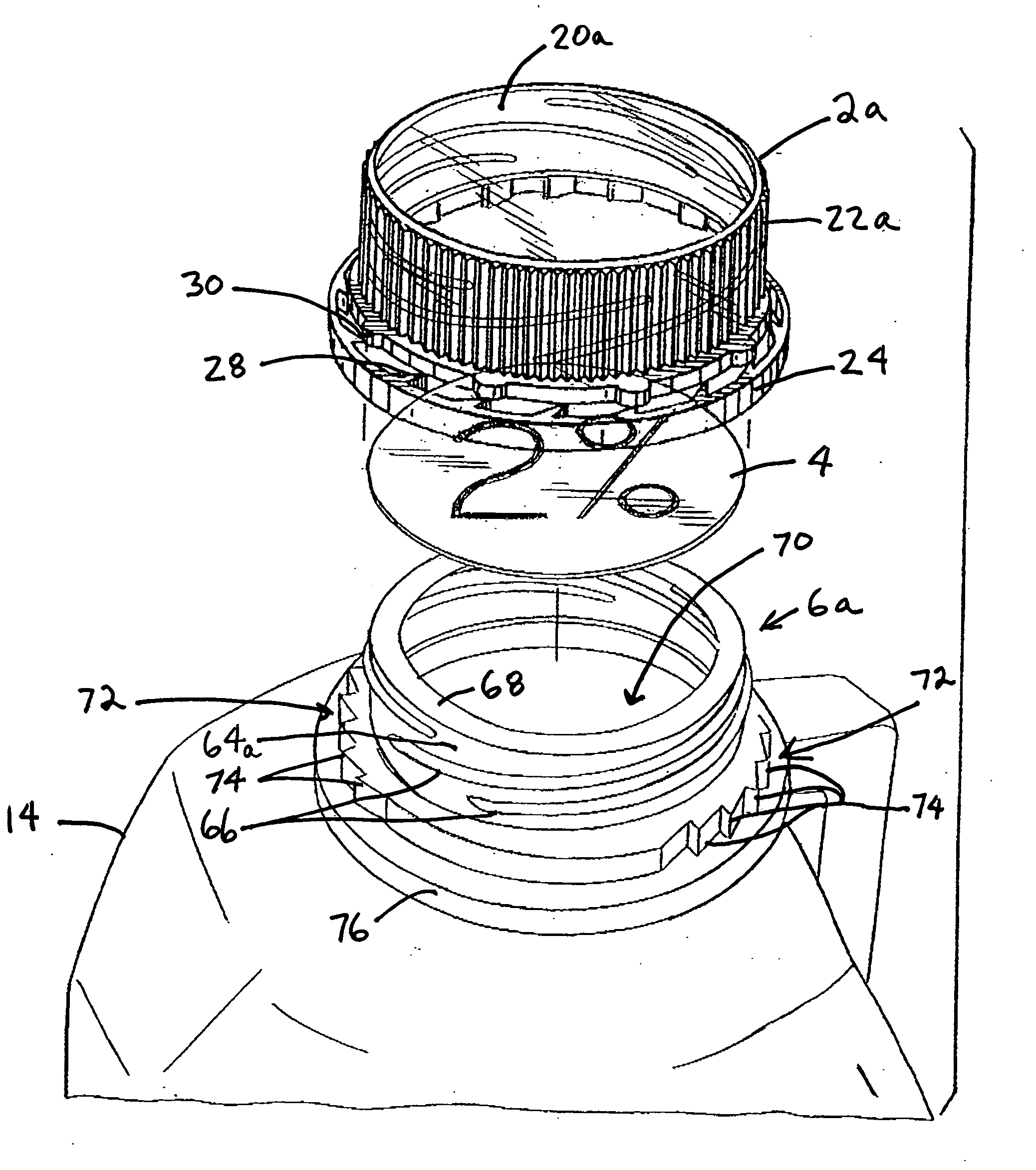

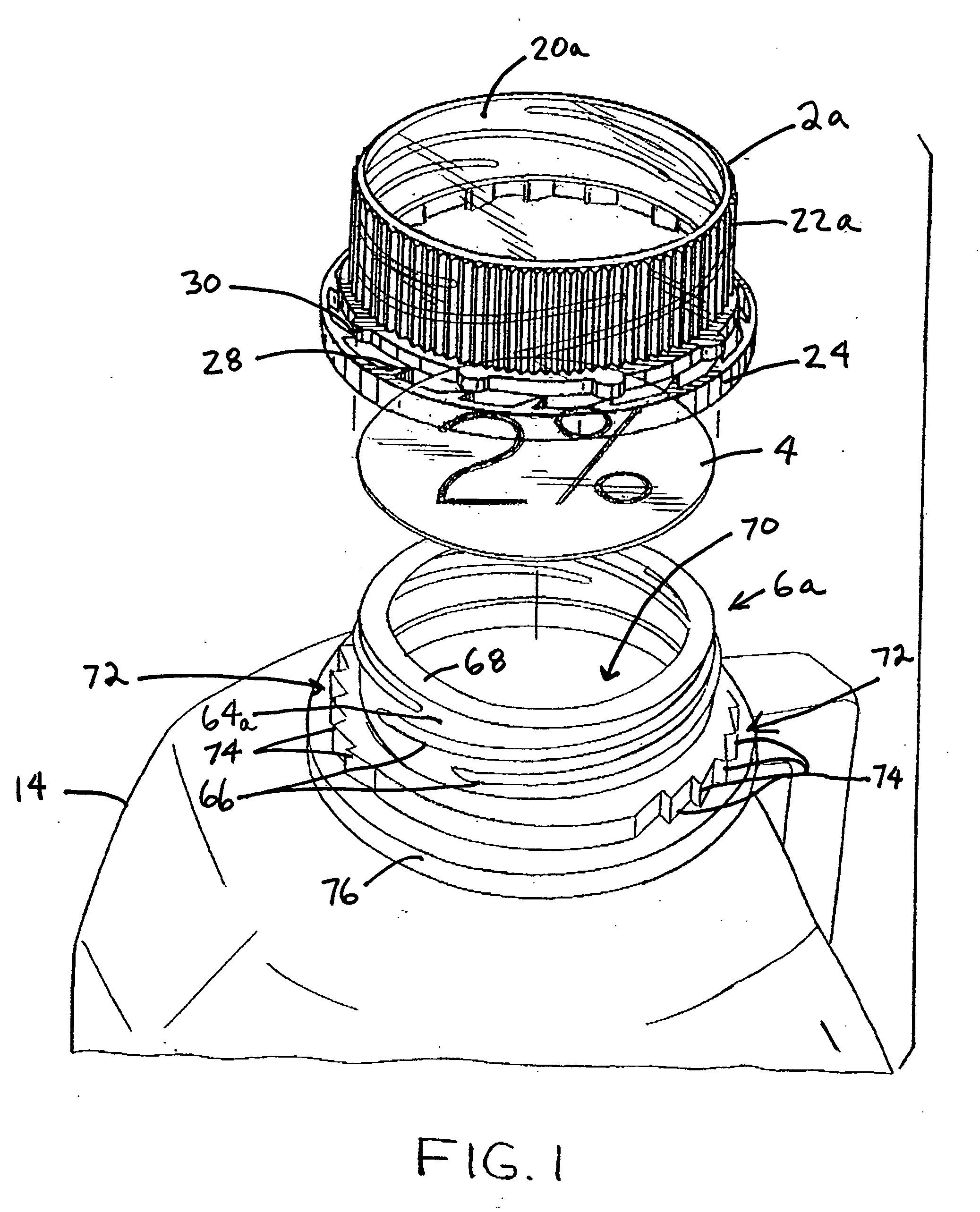

[0025]FIG. 1 generally depicts one of the preferred embodiments of the present invention. An exploded perspective view of a container 14, bottle cap 2a, liner 4, and bottle neck 6a combination is shown. As demonstrated in FIGS. 1 and 2, the cap 2a is non-opaque such that printing on the liner 4 can be perceived through the cap 2a.

[0026] The bottle cap 2a shown in FIG. 1 is a screw-on type cap 2a. Screw-on caps 2a typically comprise a circular cover 20a, a skirt 22a depending from the peripheral edge of the circular cover 20a, and a ratchet ring 24 which is frangibly attached below the skirt 22a. On the inside surface 34a of the skirt 22a are threads 26—preferably four—which are adapted to mate with corresponding threads 66 on the neck 6a of the bottle. The ratchet ring 24 has internal teeth 28 for engagement with the bottle neck 6a, which has external teeth 74. Every other one of the internal teeth 28 are attached to a plurality of semi-circular outwardly directed tabs 30 which are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com