Thermally-foamable re-releasable acrylic pressure-sensitive adhesive tape or sheet

a pressure-sensitive adhesive, foam-like technology, applied in the direction of film/foil adhesives, adhesive types, transportation and packaging, etc., can solve the problems of difficult separation or disassembly of the bonded part, difficult to remove the tape, and high peel strength of the like tape, so as to reduce the adhesive strength and reduce the adhesive strength. , the effect of easy separation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

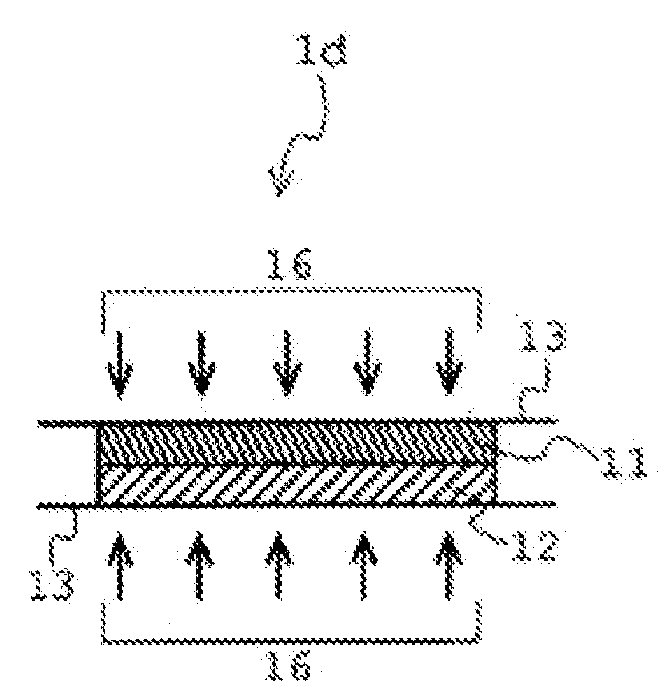

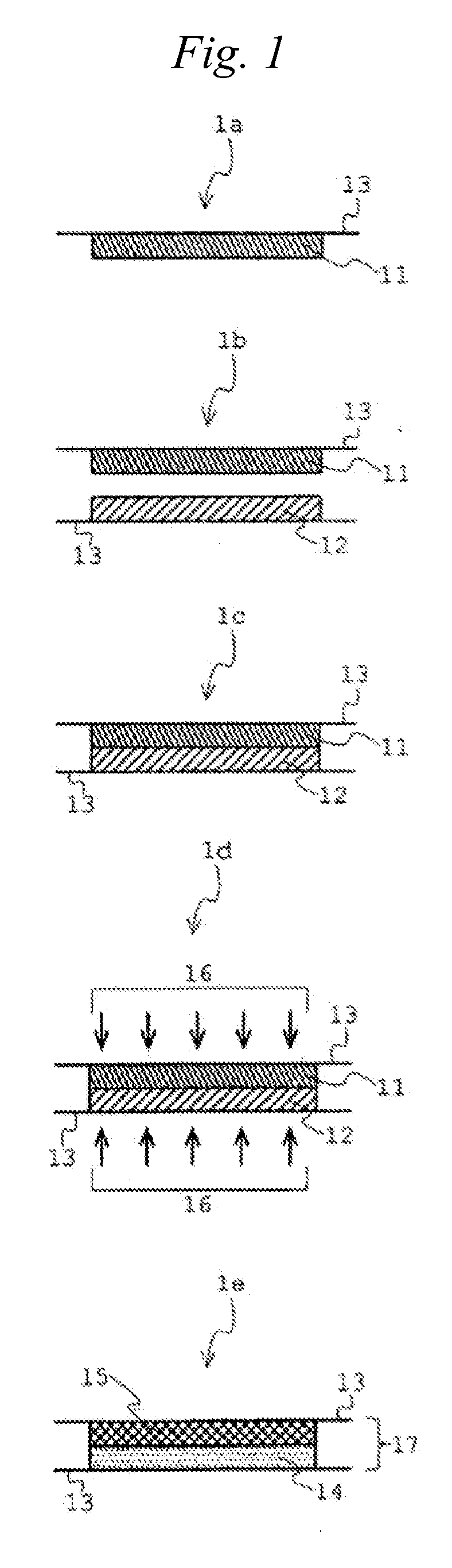

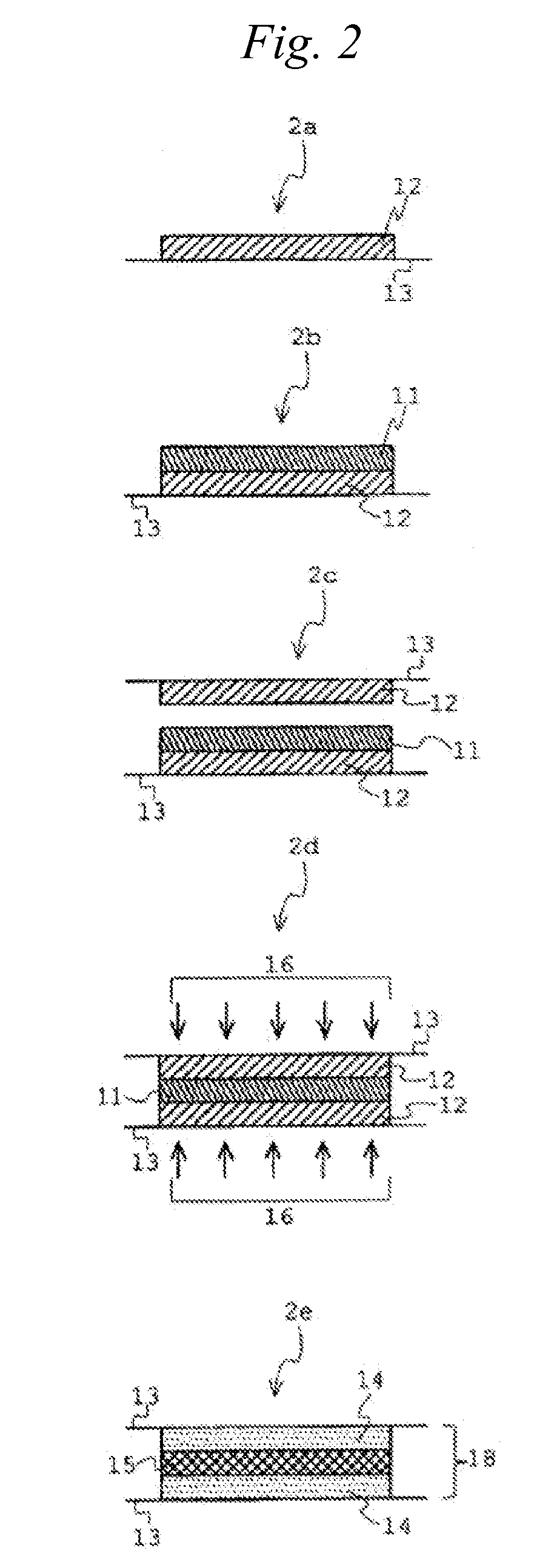

Image

Examples

preparation example 1

of Thermal Foaming Agent-Containing Pressure-Sensitive Adhesive Composition

[0197]Into a four-neck flask, 94 Parts by weight of 2-ethylhexyl acrylate, 6 parts by weight of acrylic acid, 0.05 parts by weight of a photoinitiator (“Irgacure 184”, trade name, produced by Ciba Specialty Chemicals Corp.) and 0.05 parts by weight of a photoinitiator (“Irgacure 651”, trade name, produced by Ciba Specialty Chemicals Corp.) were charged and photopolymerized through exposure to an ultraviolet ray in a nitrogen atmosphere to obtain a partially polymerized monomer syrup in a conversion of 7%.

[0198]To 100 parts by weight of the partially polymerized monomer syrup, 30 Parts by weight of a thermal foaming agent (“Matsumoto Microsphere F-50”, trade names, produced by Matsumoto Yushi-Seiyaku Co., Ltd.) and 0.2 parts by weight of trimethylolpropane triacrylate were added, and these were uniformly mixed to obtain a thermal foaming agent-containing pressure-sensitive adhesive composition (sometimes refer...

preparation example 2

of Thermal Foaming Agent-Containing Pressure-Sensitive Adhesive Composition

[0199]Into a four-neck flask, 94 Parts by weight of 2-ethylhexyl acrylate, 6 parts by weight of acrylic acid, 0.05 parts by weight of a photoinitiator (“Irgacure 184”, trade name, produced by Ciba Specialty Chemicals Corp.) and 0.05 parts by weight of a photoinitiator (“Irgacure 651”, trade name, produced by Ciba Specialty Chemicals Corp.) were charged and photopolymerized through exposure to an ultraviolet ray in a nitrogen atmosphere to obtain a partially polymerized monomer syrup in a conversion of 7%.

[0200]To 100 parts by weight of the partially polymerized monomer syrup, 30 Parts by weight of a thermal foaming agent (“Matsumoto Microsphere F-50”, trade names, produced by Matsumoto Yushi-Seiyaku Co., Ltd.) and 0.5 parts by weight of trimethylolpropane triacrylate were added, and these were uniformly mixed to obtain a thermal foaming agent-containing pressure-sensitive adhesive composition (sometimes refer...

preparation example 3

of Thermal Foaming Agent-Containing Pressure-Sensitive Adhesive Composition

[0201]Into a four-neck flask, 92 Parts by weight of 2-ethylhexyl acrylate, 8 parts by weight of acrylic acid, 0.05 parts by weight of a photoinitiator (“Irgacure 184”, trade name, produced by Ciba Specialty Chemicals Corp.) and 0.05 parts by weight of a photoinitiator (“Irgacure 651”, trade name, produced by Ciba Specialty Chemicals Corp.) were charged and photopolymerized through exposure to an ultraviolet ray in a nitrogen atmosphere to obtain a partially polymerized monomer syrup in a conversion of 7%.

[0202]To 100 parts by weight of the partially polymerized monomer syrup, 30 Parts by weight of a thermal foaming agent (“Matsumoto Microsphere F-50”, trade names, produced by Matsumoto Yushi-Seiyaku Co., Ltd.) and 0.2 parts by weight of trimethylolpropane triacrylate were added, and these were uniformly mixed to obtain a thermal foaming agent-containing pressure-sensitive adhesive composition (sometimes refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com