Automobile shock absorber bushing

A technology of automobile shock absorbers and bushings, which is applied in the field of automobile shock absorbers, can solve the problems of poor noise reduction performance, poor dynamic fatigue performance, poor heat resistance and aging resistance, and achieve long service life, excellent resilience, The effect of high tensile strength of rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

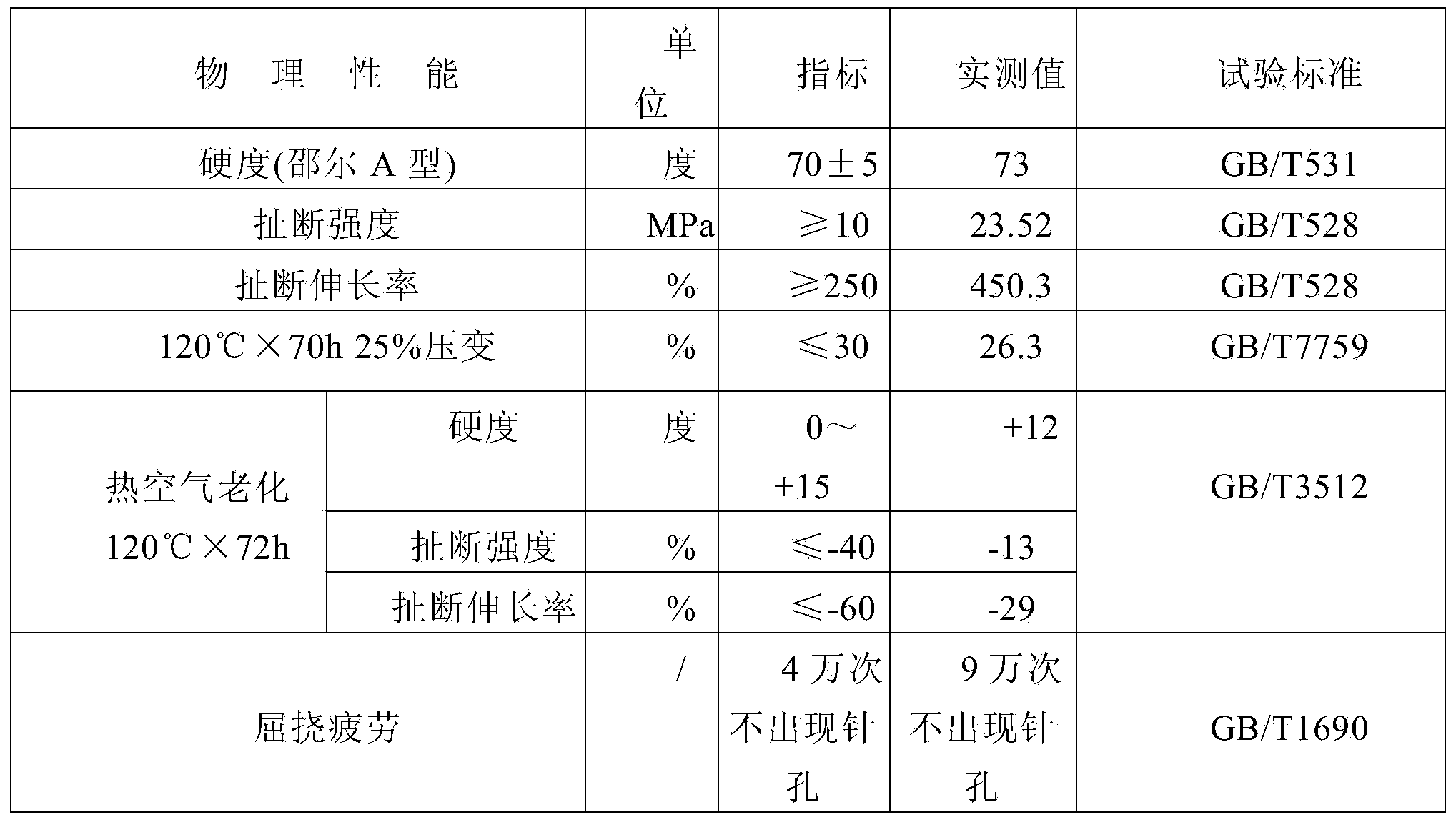

Examples

Embodiment 1

[0016] An automobile shock absorber bushing, comprising the following raw materials in parts by weight: 68 parts of natural rubber, 32 parts of polynorbornene rubber, 18 parts of high wear-resistant carbon black, 50 parts of carbon black N660, 2 parts of accelerator, zinc oxide 5 parts, 4 parts of paraffin, 3 parts of anti-aging agent, 2 parts of dispersant, 5 parts of aromatic oil, 3 parts of vulcanizing agent, 2 parts of bis(2-ethylhexyl) phthalate, 2 parts of silane coupling agent;

[0017] Production method of the present invention: adopt prior art production technological process, with natural rubber, polynorbornene rubber, high abrasion-resistant carbon black, carbon black N660, accelerator, zinc oxide, paraffin, antioxidant, dispersant, aromatic hydrocarbon oil , bis(2-ethylhexyl) phthalate and silane coupling agent are evenly mixed for the first mixing; then adding the vulcanizing agent, performing the second mixing, and vulcanization. The vulcanization temperature is ...

Embodiment 2

[0019] An automobile shock absorber bushing, comprising the following raw materials in parts by weight: 70 parts of natural rubber, 30 parts of polynorbornene rubber, 20 parts of high wear-resistant carbon black, 48 parts of carbon black N660, 3 parts of accelerator, zinc oxide 4 parts, 3 parts of paraffin, 2 parts of anti-aging agent, 3 parts of dispersant, 6 parts of aromatic oil, 4 parts of vulcanizing agent, 3 parts of bis(2-ethylhexyl) phthalate, 3 parts of silane coupling agent;

[0020] Production method of the present invention: adopt prior art production technological process, with natural rubber, polynorbornene rubber, high abrasion-resistant carbon black, carbon black N660, accelerator, zinc oxide, paraffin, antioxidant, dispersant, aromatic hydrocarbon oil , bis(2-ethylhexyl) phthalate and silane coupling agent are evenly mixed for the first mixing; then adding the vulcanizing agent, performing the second mixing, and vulcanization. The vulcanization temperature is ...

Embodiment 3

[0022] An automobile shock absorber bushing, comprising the following raw materials in parts by weight: 65 parts of natural rubber, 35 parts of polynorbornene rubber, 25 parts of high wear-resistant carbon black, 55 parts of carbon black N660, 4 parts of accelerator, zinc oxide 8 parts, 1 part of paraffin, 1 part of anti-aging agent, 1 part of dispersant, 3 parts of aromatic oil, 5 parts of vulcanizing agent, 5 parts of bis(2-ethylhexyl) phthalate, 5 parts of silane coupling agent;

[0023] Production method of the present invention: adopt prior art production technological process, with natural rubber, polynorbornene rubber, high abrasion-resistant carbon black, carbon black N660, accelerator, zinc oxide, paraffin, antioxidant, dispersant, aromatic hydrocarbon oil , plasticizer and silane coupling agent are mixed evenly for the first mixing; then add the vulcanizing agent, carry out the second mixing, and vulcanize. The vulcanization temperature is 160°C, the vulcanization ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com