Two-component addition type high-fire-retardant silica gel with low compression deformation and preparation method thereof

A low-compression-set, two-component technology, applied in the field of silicone gel, can solve the problems such as the decrease of flame retardant performance of addition-type liquid silicone gel, and achieves simple and easy preparation method, good storage performance and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]The preparation method of the above-mentioned two-component addition type high flame-retardant silicone gel with low compression set comprises the following steps:

[0043] (1) Preparation of base rubber: Add 100 parts by mass of vinyl silicone oil into the kneader and stir at room temperature for 0.5-1h, add MQ silicone resin with a formula amount of 25%-50% and stir for 0.5-1h, then add the remaining MQ silicone resin, and continue stirring 3 to 5 hours to obtain base rubber;

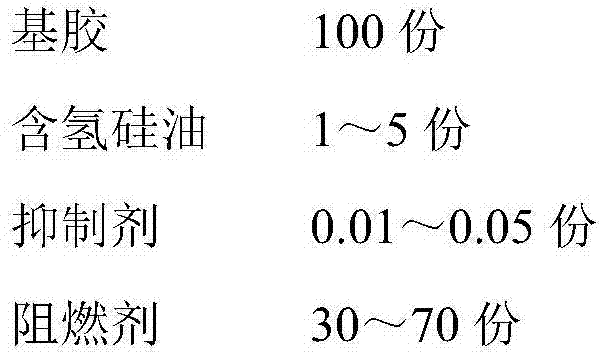

[0044] (2) Preparation of component A: add 100 parts by mass of rubber base, 0.01 to 0.05 parts by mass of platinum catalyst and 30 to 70 parts by mass of flame retardant into the stirring tank, and mix evenly to obtain component A;

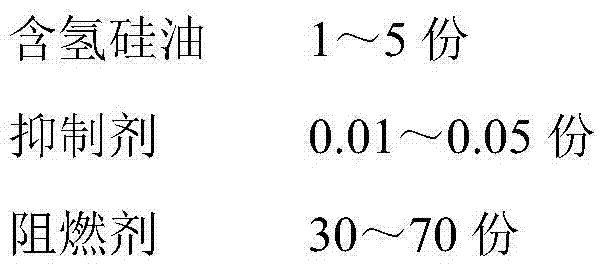

[0045] (3) Preparation of component B: add 100 parts by mass of rubber base, 1 to 5 parts by mass of hydrogen-containing silicone oil, 0.01 to 0.05 parts by mass of inhibitor and 30 to 70 parts by mass of flame retardant into the stirring tank, and mix well to obta...

Embodiment 1

[0048] The vinyl silicone oil involved in this example has a viscosity of 500 mPa.s at 25° C. and a vinyl mass content of 0.8%. MQ silicone resin has a viscosity of 200mPa.s at 25°C and a vinyl mass content of 2%. The mass content of platinum in the platinum catalyst is 500ppm. The hydrogen-containing silicone oil has a viscosity of 60 mPa.s at 25°C and a hydrogen mass content of 0.1%. The inhibitor is compounded and modified by heptamethylcyclotetrasiloxane and ethynyl-1-cyclohexanol in a molar ratio of 1:1 under the action of chloroplatinic acid.

[0049] (1) Prepare the base rubber: add 400Kg vinyl silicone oil into the kneader and stir at room temperature for 1 hour, add 60Kg of MQ silicone resin and stir for 1 hour, then add 60Kg of MQ silicone resin, and continue stirring for 3 hours to obtain the base glue;

[0050] (2) Preparation of component A: Take 200Kg of rubber base, 0.1Kg of platinum catalyst, 40Kg of quartz powder and 20Kg of soft carbon black and add them to...

Embodiment 2

[0056] The vinyl silicone oil involved in this example has a viscosity of 750 mPa.s at 25° C. and a vinyl mass content of 1%. The MQ silicone resin has a viscosity of 300mPa.s at 25°C and a vinyl mass content of 2.6%. The mass content of platinum in the platinum catalyst is 2000ppm. The hydrogen-containing silicone oil has a viscosity of 250 mPa.s at 25°C and a hydrogen mass content of 1.2%. The inhibitor is compounded and modified by heptamethylcyclotetrasiloxane and ethynyl-1-cyclohexanol at a molar ratio of 1.2:1 under the action of chloroplatinic acid.

[0057] (1) Prepare the base rubber: add 400Kg vinyl silicone oil into the kneader and stir at room temperature for 1 hour, add 40Kg of MQ silicone resin and stir for 1 hour, then add 50Kg of MQ silicone resin, and continue stirring for 3 hours to obtain the base glue;

[0058] (2) Preparation of component A: Take 200Kg of rubber base, 0.1Kg of platinum catalyst, and 80Kg of zinc carbonate into the stirring tank, and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com