Loaded method of Non-metallocene catalyst loaded by composite carrier and polymerizing application

A composite carrier and non-metallocene technology, applied in the field of olefin polymerization, can solve the problems of poor polymer shape, no polymer granulation performance, low catalytic activity, etc., and achieve the effect of good particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] 1.1 Preparation of supported catalyst

[0136] 1.1.1 Activation of the carrier

[0137] Take ES70 type silica gel (product of Crosfield Company) and bake it under nitrogen atmosphere. The calcination conditions are: heating rate 5°C / Min, constant temperature at 200°C for 0.5h, constant temperature at 400°C for 0.5h, then constant temperature at 600°C for 4h, and finally natural cooling under nitrogen atmosphere. Recorded as ES70-650 carrier.

[0138] 1.1.2 Preparation of anhydrous magnesium chloride

[0139] Anhydrous magnesium chloride is obtained by calcining analytically pure magnesium chloride at 500°C for 3 hours in an air atmosphere.

[0140] 1.1.3 Preparation of composite carrier

[0141] Under an anhydrous and oxygen-free nitrogen atmosphere (both water and oxygen content are lower than 5ppm), weigh 1.064g of anhydrous magnesium chloride, add 30ml of tetrahydrofuran (THF), stir at 30°C for 16h, and then dropwise add 2.5ml of absolute ethanol (4A molecular s...

Embodiment 2

[0151] 2.1 Preparation of catalyst

[0152] The preparation process of the catalyst is similar to Example 1.1, take 507 mg of the composite carrier in 1.1.3, and only slowly add 5 ml of TiCl 4 hexane solution. Solution impregnation was carried out in 70 mg of non-metallocene olefin polymerization catalyst in 25 ml of toluene solution, and finally washed, filtered, dried and sucked dry.

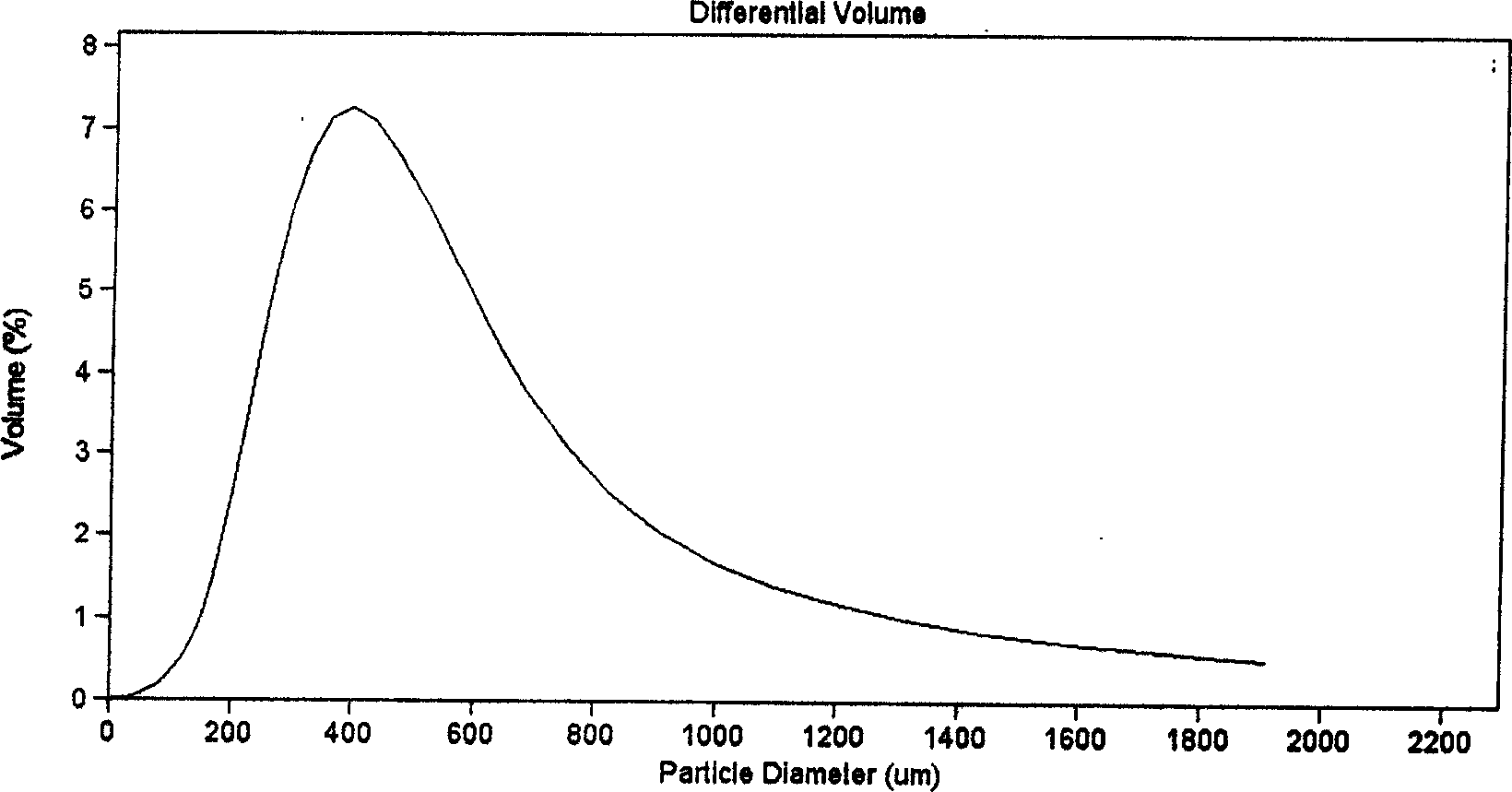

[0153] 2.2 Aggregation

[0154] 12 mg of supported catalyst, 3 ml of concentrated MAO, and 250 ml of hexane solvent were simultaneously added into a 0.5 L autoclave, and ethylene polymerization was carried out at an ethylene pressure of 3.0 MPa. The stirring speed is 540rpm, the reaction temperature is 60°C, and the reaction time is 1.5h.

[0155] Yield: 61.52 g.

[0156] (Remove) 35.3mg of supported catalyst, 3ml of concentrated MAO and 580ml of hexane solvent were simultaneously added to a 2L autoclave, and ethylene polymerization was carried out at an ethylene pressure of 2.0MPa. The s...

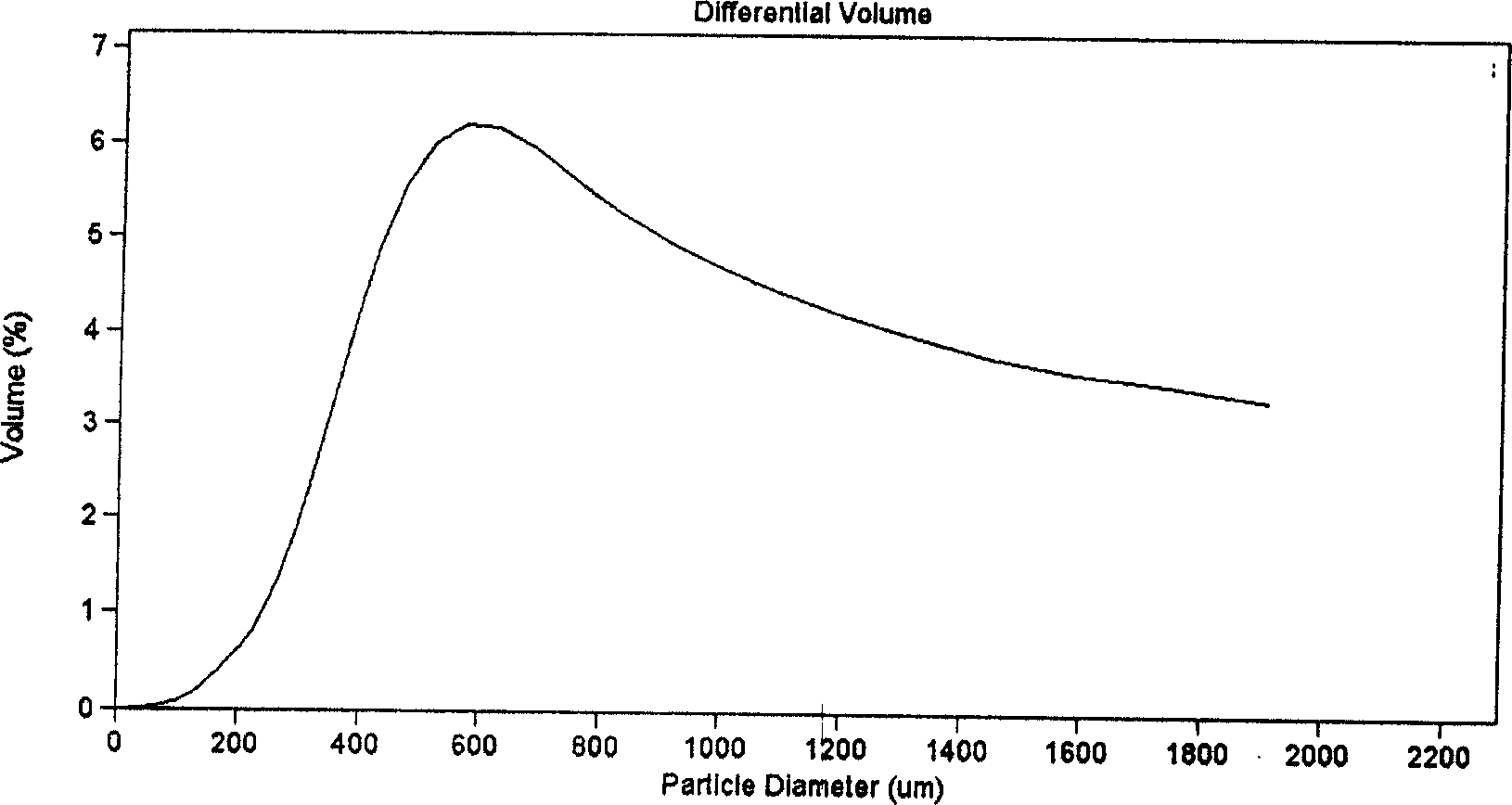

Embodiment 3

[0162] Take ES-70 silica gel and keep it at 300°C for 6 hours, and record it as ES70-300 carrier.

[0163] The preparation of the catalyst is similar to Example 1.1. Among them, only 530 mg of ES70-650 was replaced with 1.0 g of ES70-300 carrier to obtain a composite carrier. Then take 0.5g of it, use 10mlTiCl 4 hexane solution treatment. Finally, 48 mg of the catalyst was weighed and dissolved in 30 ml of toluene, and the catalyst was supported by a solution impregnation method.

[0164] The polymerization process was carried out similarly to Example 1.2. With 13.6mg of supported catalyst, 3ml of concentrated MAO and 250ml of hexane solvent, ethylene polymerization was carried out at ethylene pressure of 2.0MPa, stirring speed of 510rpm and 50°C. The reaction time is 1h.

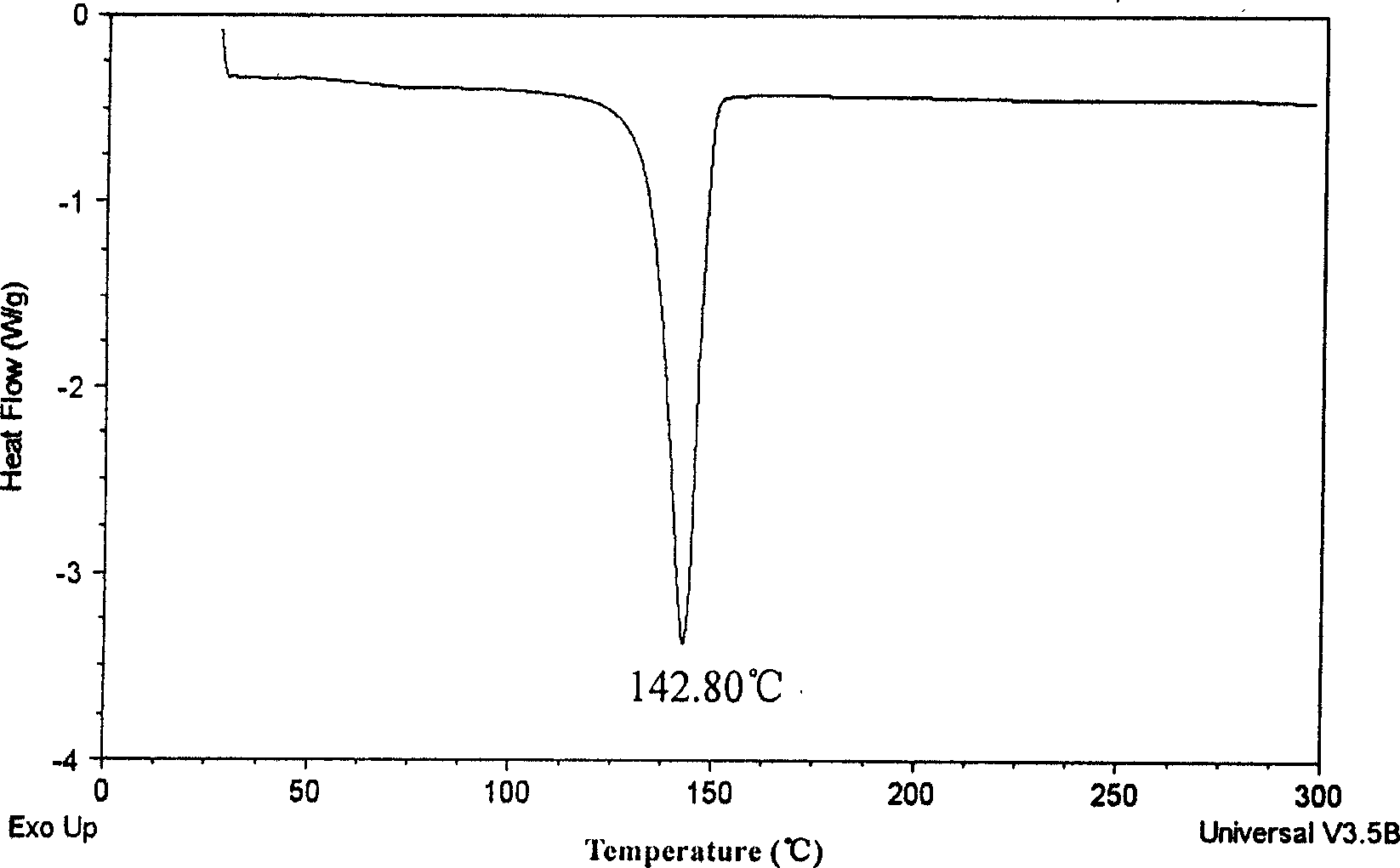

[0165] Yield: 25.18 g, polyethylene melting point 142.33°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com