High-density doped trimanganese tetroxide and preparation method thereof

A technology of trimanganese tetraoxide and high density, which is applied in the direction of manganate/permanganate, electrical components, battery electrodes, etc. It can solve the problems of complex production process, difficulty in ensuring uniformity, and low tap density, and achieve Good doping uniformity, good particle shape, stable doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

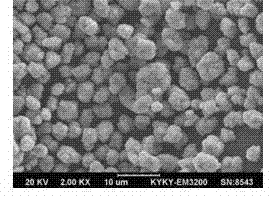

Image

Examples

preparation example Construction

[0017] The preparation method of high-density doped trimanganese tetraoxide of the present invention comprises the following steps:

[0018] (1) Grinding: mix metal manganese and doped oxides by molar ratio Mn:M x o y =3:0.01~0.3 is added to the mill, and the mixture is wet-ground to a certain particle size;

[0019] (2) Reaction: Add the ground slurry into the reactor, then add ammonium salt as a catalyst according to 0.5% to 10% of the total weight of manganese metal, and feed air or oxygen to control the reaction temperature at 70°C±10°C , control the pH value of 6.5-7.0, and carry out the catalytic oxidation reaction;

[0020] (3) Washing: Use washing equipment to perform one or more washings to remove the impurity elements doped in the trimanganese tetroxide;

[0021] (4) Drying: Use drying equipment to dry the manganese tetraoxide after washing to obtain a high-density, uniformly doped manganese tetraoxide product.

[0022] Wherein, in step (1): the metal manganese i...

Embodiment 1

[0028] (1) Grinding: Metal manganese flakes with a purity of 99.1% and aluminum oxide with a purity of 99.8% are mixed according to the molar ratio Mn:Al 2 o 3=3:0.07 for proportioning, the total weight is 1200Kg, put it into the ball mill, grind for 6 hours, and control the slurry D50 (particle size) to 0.93 um;

[0029] (2) Reaction: Add the ground slurry into the reactor, then add 50Kg of ammonium chloride, and start the air reaction. During the reaction process, the pH value is controlled to be 6.6±0.1, and the reaction temperature is 75°C±3°C. When the reaction pH is less than or equal to 6.4, it is judged as the end point, and the reaction lasts for 12 hours;

[0030] (3) Washing: Use a counter-current washing machine to wash the reacted slurry to control various impurities, especially Cl - , controlled below 200ppm;

[0031] (4) Drying: Use spray drying equipment to dry the washed slurry. The inlet temperature is controlled at 300°C±5°C, the outlet temperature is con...

Embodiment 2

[0034] (1) Grinding, manganese metal powder with a purity of 99.1%, aluminum oxide with a purity of 99.8%, and magnesium oxide with a purity of 99.6%, according to the molar ratio Mn:Al 2 o 3 :MgO=3:0.05:0.02 for proportioning, the total weight is 600Kg, add it to the ball mill, grind for 4 hours, and control the D50 (particle size) of the slurry to 0.92um;

[0035] (2) For reaction, add the ground slurry into the reactor, then add 30Kg of ammonium chloride, and start the air reaction. During the reaction process, the pH value is controlled to be 6.9±0.1, and the reaction temperature is 70°C±3°C. When the reaction pH is less than or equal to 6.4, it is judged as the end point, and the reaction lasts for 10 hours;

[0036] (3) Washing, using a counterflow washing machine to wash the reacted slurry to control various impurities, especially Cl - , controlled below 200ppm;

[0037] (4) Drying. Use spray drying equipment to dry the washed slurry. The inlet temperature is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com