Method for catalytic conversion production of propylene and light aromatics

A catalytic conversion method and technology for catalytic conversion, which are applied in the field of catalytic conversion of hydrocarbons, can solve the problems of increasing the selectivity and yield of propylene in a catalytic cracking unit, and achieve the improvement of comprehensive conversion rate, high process flexibility, and energy efficiency. consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

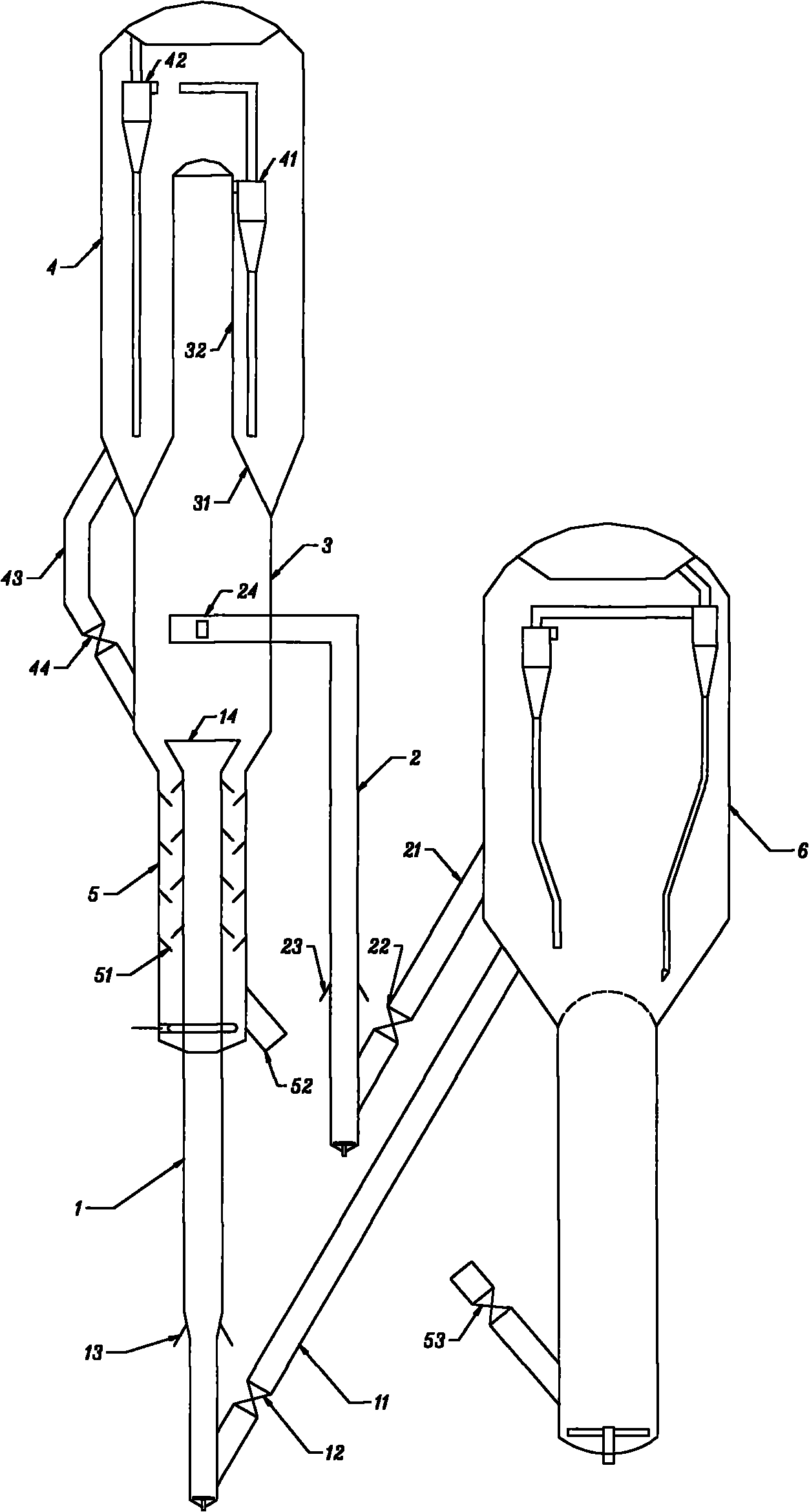

[0050] The trade name of the catalyst used is DMMC-1, produced by Qilu Catalyst Branch of Sinopec Co., Ltd. Use as attached figure 1 The medium-scale test device shown, wherein the heavy oil riser reactor has an inner diameter of 18 mm and a height of 6 meters, the fluidized bed reactor has an inner diameter of 64 mm and a height of 0.5 meters, and the auxiliary riser reactor has an inner diameter of 16 mm, The height is 5 meters. The diameter reduction ratio of the dilute phase pipe at the outlet of the fluidized bed reactor is 30%. The catalyst was aged at 800° C. with 100% steam for 10 hours, and the loading capacity of the catalyst in the composite reactor was 60 kg.

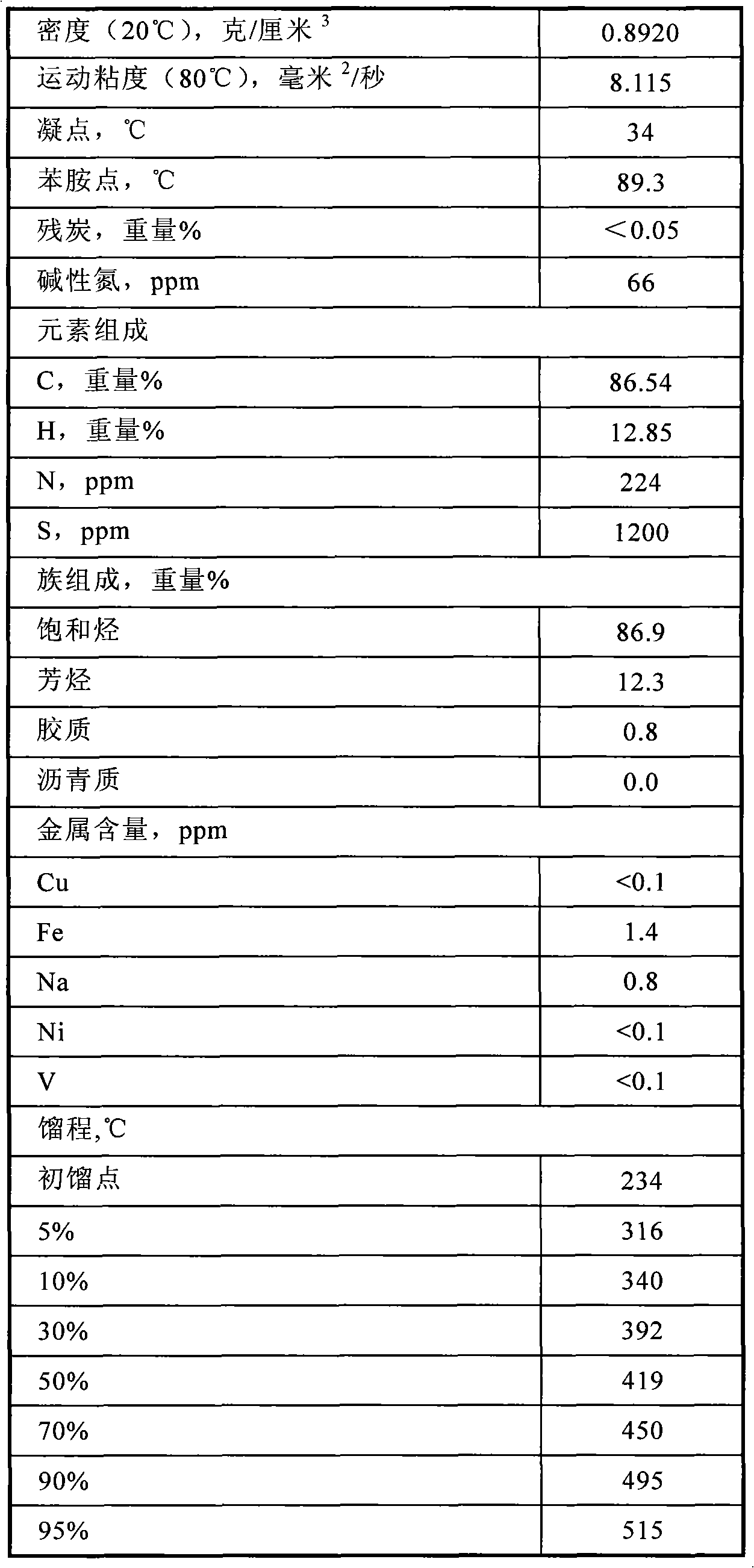

[0051] The heavy hydrocarbon oil raw material is introduced into the heavy oil cracking riser reactor and contacted with the catalyst for catalytic cracking reaction; the hydrocarbon oil raw material is not introduced into the auxiliary riser reactor, which is a catalyst delivery channel. The properties o...

Embodiment 2

[0053] The catalyst and reaction device used in Example 2 are the same as those in Example 1. The heavy hydrocarbon oil raw material is introduced into the heavy oil cracking riser reactor to contact the catalyst for catalytic cracking reaction, and the re-refined C4 component is introduced into the auxiliary riser reactor to carry out reaction. See Table 1 for the properties of the heavy oil raw material, Table 2 for the composition of back-refined C4, and Table 4 for the reaction conditions and yield.

Embodiment 3

[0055] The catalyst and reaction device used in Example 3 are the same as in Example 1. The heavy hydrocarbon oil feedstock is introduced into the heavy oil cracking riser reactor to contact with the catalyst to carry out the catalytic cracking reaction, and the recycled C4 component and light gasoline component are introduced into the auxiliary The reaction was carried out in a riser reactor. The catalyst-to-oil ratio in the examples refers to the weight ratio of catalyst to fresh feed. The properties of the heavy hydrocarbon oil feedstock are shown in Table 1, the composition of light gasoline is shown in Table 2, and the reaction operating conditions and results are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com