Method for regeneration and resource utilization of waste honeycombed denitrification catalyst

A technology for denitration catalyst and waste catalyst, which is applied in the field of waste honeycomb denitration catalyst regeneration and resource utilization, can solve problems such as failure to realize commercial operation, and achieve the effects of reducing operating costs, good regeneration effect, and significant environmental benefits.

Inactive Publication Date: 2014-01-15

YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

View PDF4 Cites 46 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the embodiments of the present invention is to provide a method for the regeneration and resource utilization of waste cellular denitrification catalysts, aiming to solve the problem that catalyst regeneration technology is a new issue in our country. It has not yet realized commercial operation and is facing promising industry development and market. space problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

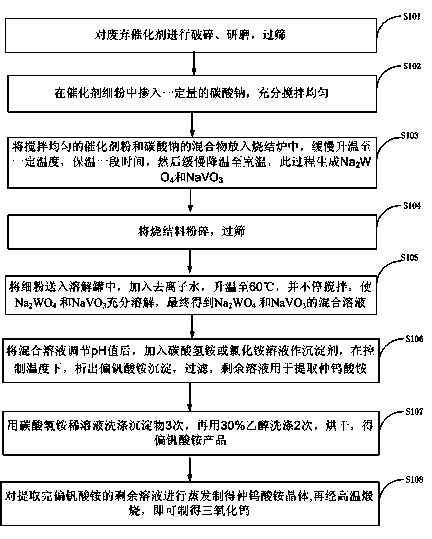

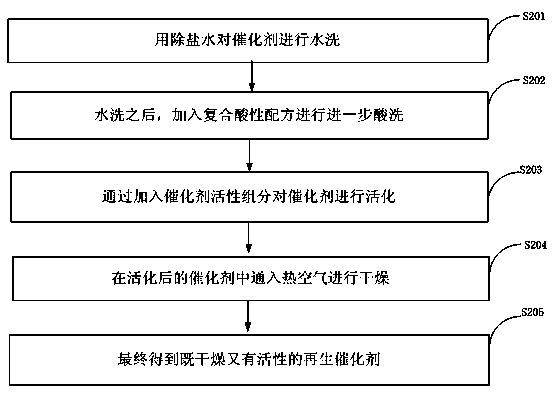

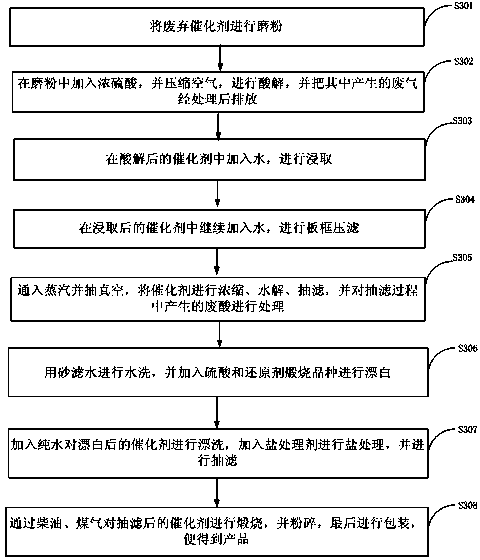

The invention discloses a method for regeneration and resource utilization of a waste honeycombed denitrification catalyst. The method comprises the following steps of: crushing, grinding and sieving the waste catalyst; loading a mixture of the powdered catalyst and sodium carbonate into a sintering furnace to produce Na2WO4 and NaVO3, dissolving completely, adjusting the pH value to separate ammonium metavanadate precipitates, filtering, applying the remaining liquid to ammonium paratungstate extraction, washing the precipitates and oven-drying to obtain ammonium metavanadate, and making ammonium paratungstate crystals and tungsten trioxide. The regeneration method of the SCR catalyst comprises the following steps of: performing water-washing, pickling, activation and drying on the catalyst. The method for producing titanium pigment from the waste catalyst as raw material comprises the following steps of: performing pulverization, acidolysis and extraction on the waste catalyst, performing plate-frame pressure filtration; performing concentration, hydrolysis and suction-filtration on the catalyst, washing and blanching with sand leaching water, calcining, grinding and packaging. The method disclosed by the invention can effectively restore the activity of a deactivated catalyst and prolong the service life of the deactivated catalyst, which not only reduce the operating cost of a thermal power plant but also save the valuable rare earth resources.

Description

technical field [0001] The invention belongs to the field of catalyst regeneration, and in particular relates to a method for regeneration and resource utilization of a waste honeycomb denitration catalyst. Background technique [0002] Generally speaking, the SCR denitrification catalyst will partially fail after 3 years of use. In order to ensure that the denitrification efficiency target is met, 1 / 3 of it will be replaced every year. 3 of spent catalysts. If these spent catalysts are regenerated, huge economic and environmental benefits will be produced. Since 80% of the denitrification catalysts used in my country's thermal power plants are honeycomb catalysts, there is a great market potential for recycling invalid honeycomb catalysts. [0003] Since entering the "Twelfth Five-Year Plan", the country has put forward higher requirements for environmental protection and green development of energy economy, and has issued a series of plans, policies and standards for the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G31/00C01G41/02B01J38/60B01D53/96B01D53/56

CPCY02P20/584

Inventor 裴叶舜裴小罗姚力智齐政鸿徐毅

Owner YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com