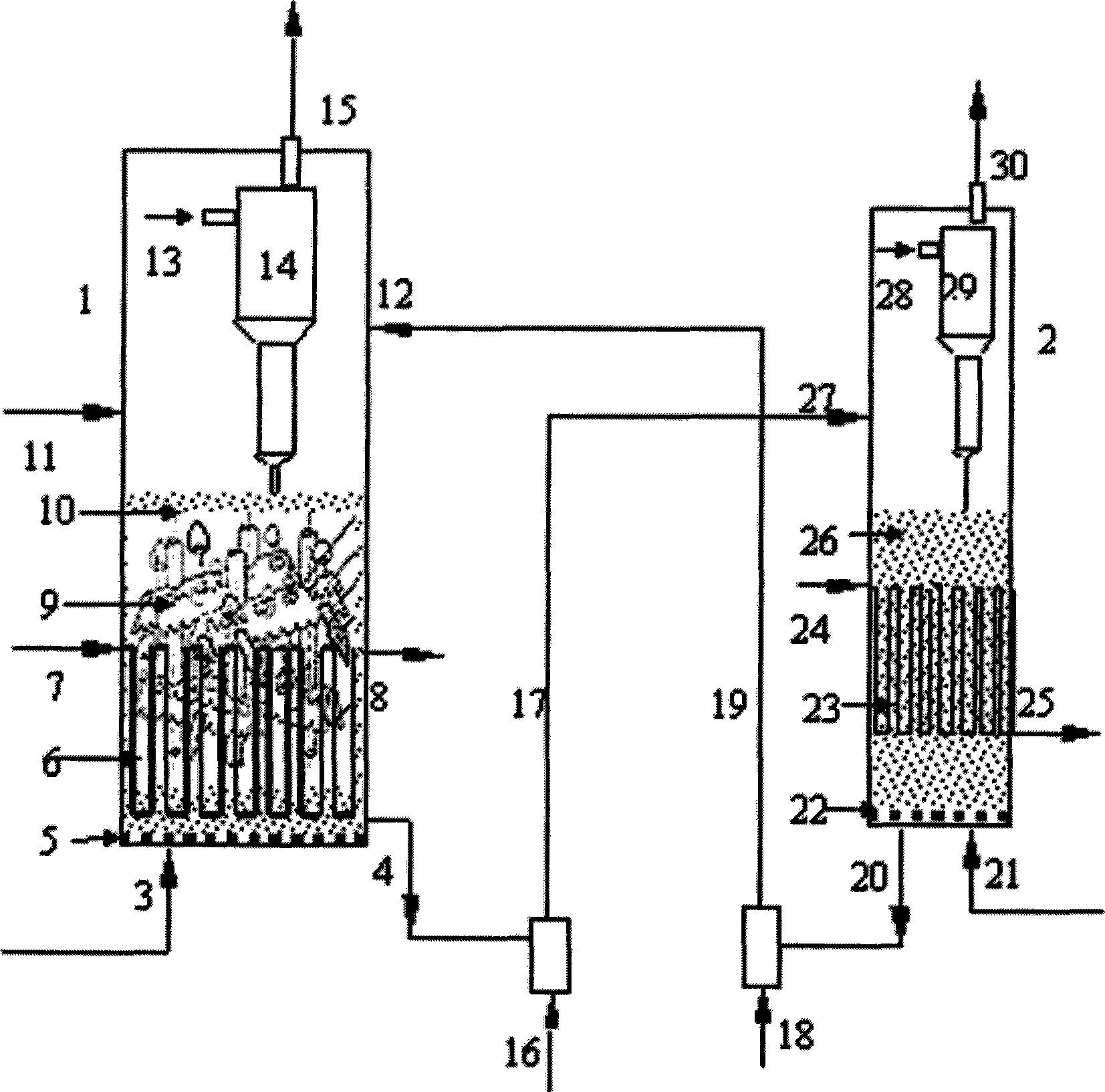

Continuous aromatization and catalyst regeneration device and method thereof

An aromatization fluidized bed and catalyst technology, applied in the field of catalyst regeneration and catalyst continuous regeneration device, can solve the problems of low strength, no detailed hydrocarbon aromatization and catalyst, no catalyst composition report, etc., and achieve cost Low cost, low maintenance cost, small equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The catalyst is prepared, wherein the metal content is 4.5% molybdenum, 3% gallium, and 0.1% ruthenium, the 0.5nm pores in the molecular sieve are controlled to be 70%, the molecular sieve content is 65%, and the Mohs hardness of the final catalyst is controlled to be greater than 6.5. The catalyst is loaded into the aromatization fluidized bed reactor, and the temperature of the aromatization reactor is raised to 750°C by exchanging heat with high-temperature helium at 800°C. Feed 100% methane feed gas, control methane space velocity to 1000ml / gcat / h, and operate pressure to 0.1MPa. When the catalyst activity drops to 95% of its highest active point, the pressure of the regeneration reactor (diameter, height being 2 / 3, 2 / 3 of the aromatization reactor) is guaranteed to be slightly positive pressure, and under anaerobic state, the 1 / 5 of the catalyst is transported to the catalyst regenerator through the transfer pipeline. After the transportation is completed, use met...

Embodiment 2

[0038] Prepare the catalyst, wherein the metal content is 1.2% molybdenum, 5% zinc, 1% tungsten, control the molecular sieve containing silicon, the 0.5nm pores of aluminum are 50%, the molecular sieve content is 70%, and the Mohs hardness of the final catalyst is controlled to be greater than 5 . The catalyst is loaded into the aromatization fluidized bed reactor, and the temperature of the aromatization reactor is raised to 500°C by exchanging heat with high-temperature argon at 700°C. Feed mixed feed gas of ethylene (50%) and ethane (50%), control the total space velocity to 4000ml / gcat / h, and operate the pressure to 0.1MPa. When the catalyst activity drops to 98% of its highest active point, the pressure of the regeneration reactor (diameter, height being 2 / 3 and 1 / 2 of the aromatization reactor) is guaranteed to be slightly positive pressure, and under anaerobic state, the 1 / 8 of the catalyst is delivered to the catalyst regenerator through the delivery pipeline. After ...

Embodiment 3

[0040] Prepare the catalyst, wherein the metal content is 0.02% platinum 6% gallium, 0.3% nickel, 0.7% iron, control silicon, the pore of 0.5nm in the molecular sieve of aluminum is 70%, the molecular sieve content is 55%, control the Mohs of the final catalyst The hardness is greater than 7. The catalyst is loaded into the aromatization fluidized bed reactor, and the temperature of the aromatization reactor is raised to 750°C by exchanging heat with 900°C high-temperature flue gas. Pass into acetylene (20%), methane (45%), H 2(10%) and CO (25%) mixed feed gas, the total space velocity is controlled to 300ml / gcat / h, and the operating pressure is 0.5MPa. When the catalyst activity drops to 95% of its highest active point, the pressure of the regeneration reactor (diameter, height being 1 / 3 of the aromatization reactor, 1) is guaranteed to be slightly positive pressure, and under anaerobic state, the pressure of 1 / The catalyst of 10 is transported to the catalyst regenerator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com