Method for preparing hydrogen from biomass

A biomass and raw material technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as high energy consumption, high gasification temperature, and high equipment requirements, and achieve low equipment investment, high purity, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

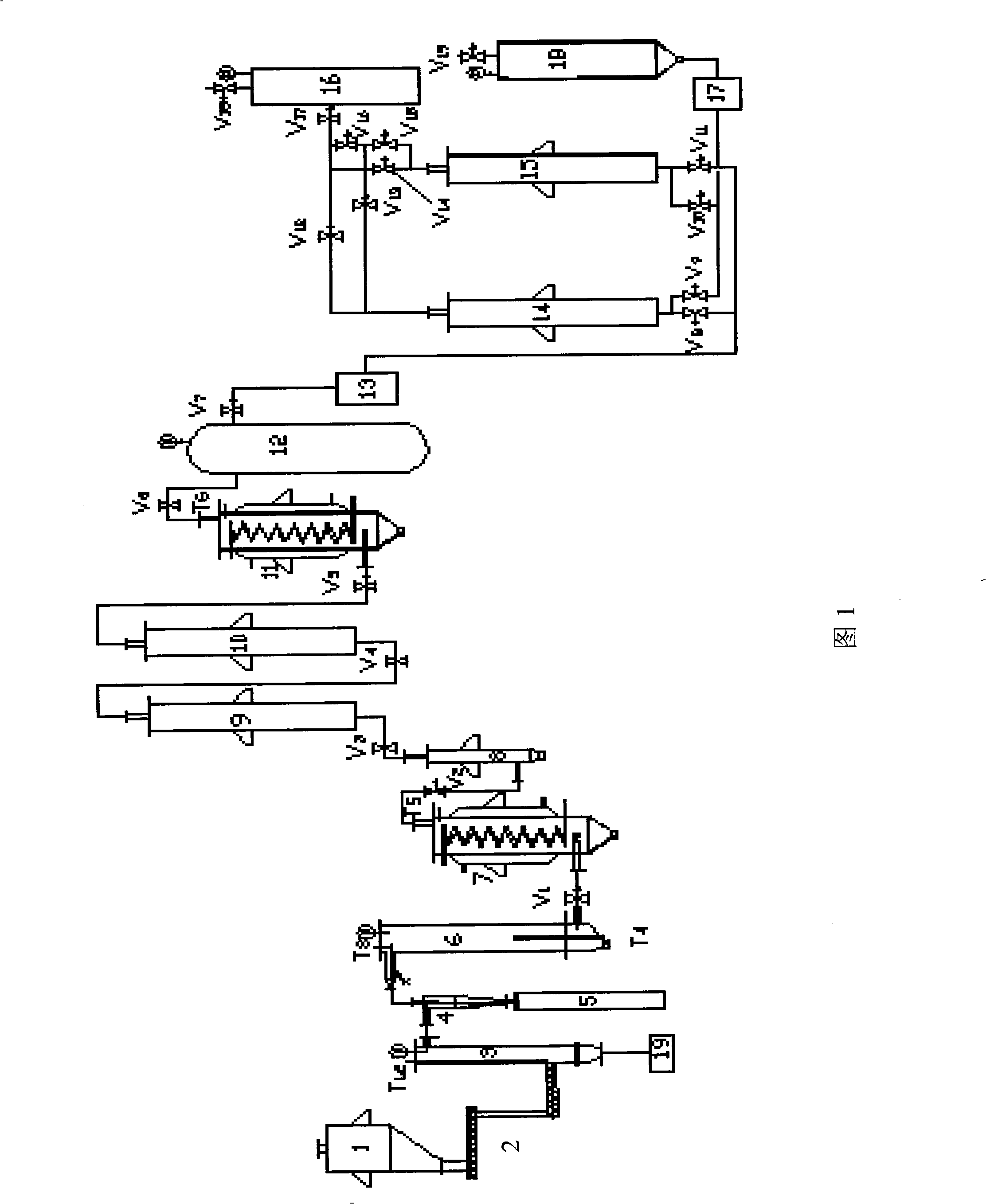

[0051] Explain in conjunction with accompanying drawing 1:

[0052] The raw material biomass less than 50 meshes is added into the hopper, and enters into the normal pressure bubbling fluidized bed rapid pyrolysis reactor 3 through the double screw feeder 2 for rapid pyrolysis. The pyrolysis temperature is 470°C, and the pyrolysis reaction pressure is (gauge pressure) 40mmH 2 O, the amount of raw material added is 100g / h. The fluidization gas from the fluidization gas generator enters the cavity of the reactor and then enters the reactor 3 through the distribution plate to fluidize the biomass and quartz sand. The steam catalytic reforming reaction temperature is 850°C, and the catalyst used is 7% Fe by mass fraction 2 o 3 ; Mass fraction 18% NiO; Mass fraction 75% dolomite catalyst, particle size is 2mm, catalytic pressure is 40mmH 2O (gauge pressure), the medium temperature shift reaction temperature is 450°C, and the low temperature shift reaction temperature is 300°C. ...

Embodiment 2

[0054] Explain in conjunction with accompanying drawing 1:

[0055] The raw material biomass less than 50 meshes is added into the hopper, and enters into the normal pressure bubbling fluidized bed rapid pyrolysis reactor 3 through the double screw feeder 2 for rapid pyrolysis. The pyrolysis temperature is 550°C, and the pyrolysis reaction pressure is (gauge pressure) 65mmH 2 O, the amount of raw material added is 100g / h. The fluidization gas from the fluidization gas generator enters the cavity of the reactor and then enters the reactor 3 through the distribution plate to fluidize the biomass and quartz sand. The steam catalytic reforming reaction temperature is 800°C, and the catalyst used is 7% Fe by mass fraction 2 o 3 ; Mass fraction 18% NiO; Mass fraction 75% dolomite catalyst, particle size is 2mm, catalytic pressure is 40mmH 2 O (gauge pressure), the medium temperature shift reaction temperature is 450°C, and the low temperature shift reaction temperature is 300°C....

Embodiment 3

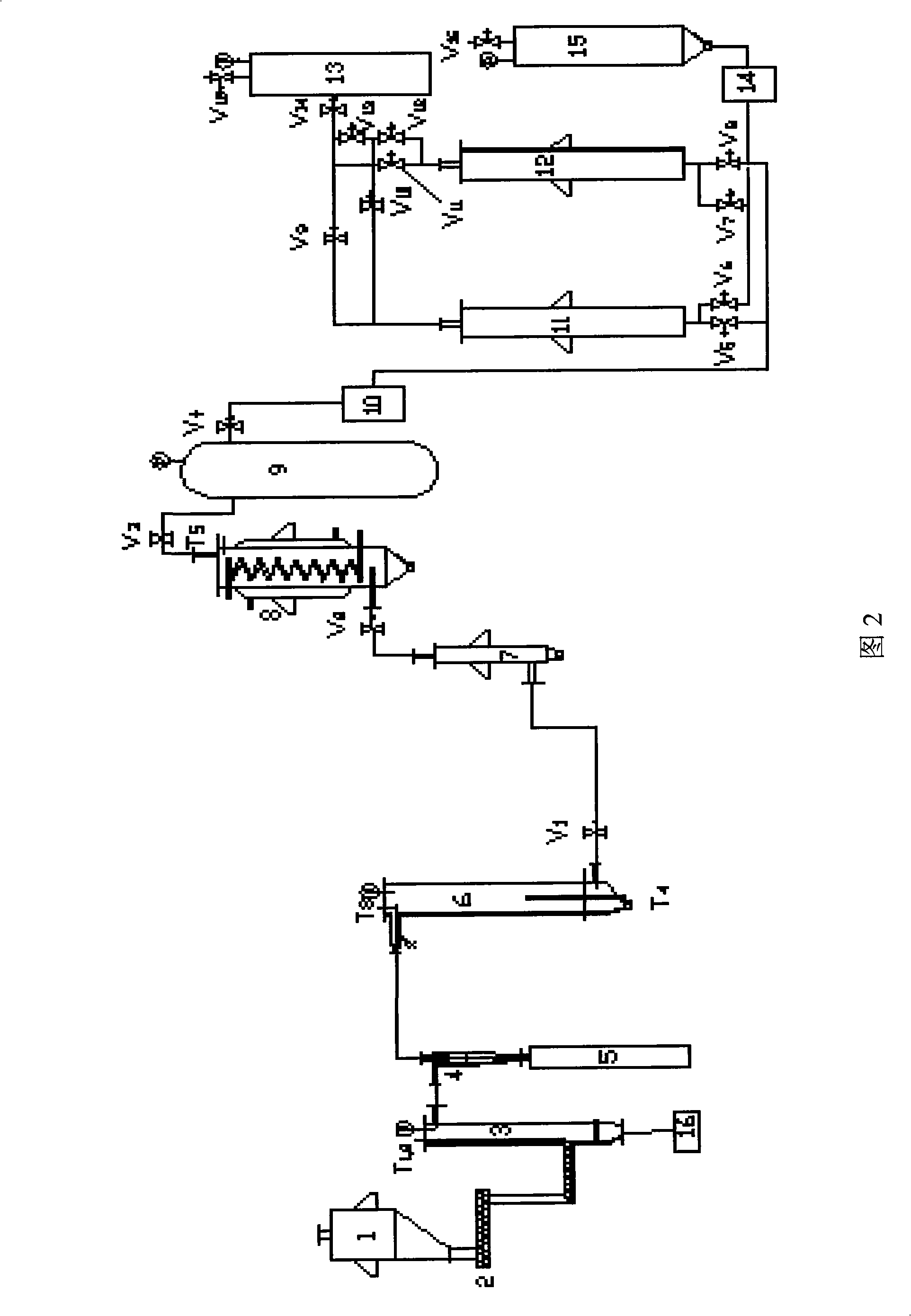

[0057] The raw material biomass less than 50 meshes is added into the hopper, and enters into the normal pressure bubbling fluidized bed rapid pyrolysis reactor 3 through the double screw feeder 2 for rapid pyrolysis. The pyrolysis temperature is 600°C, and the pyrolysis reaction pressure is (gauge pressure) 60mmH 2 O, the amount of raw material added is 100g / h. The fluidization gas from the fluidization gas generator enters the cavity of the reactor and then enters the reactor 3 through the distribution plate to fluidize the biomass and quartz sand. The steam catalytic reforming reaction temperature is 900°C, the catalyst used is a mixture of YWC-95 and CaO, wherein the content of YWC-95 is 97%, the particle size is 1mm, the content of CaO is 3%, and the size is less than or equal to 100 mesh , the catalytic pressure is 45mmH 2 O (gauge pressure). Water vapor and raw material mass ratio are 4, and the content (volume percentage) of hydrogen in crude gas after reaction reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com