Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Shorten flame length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

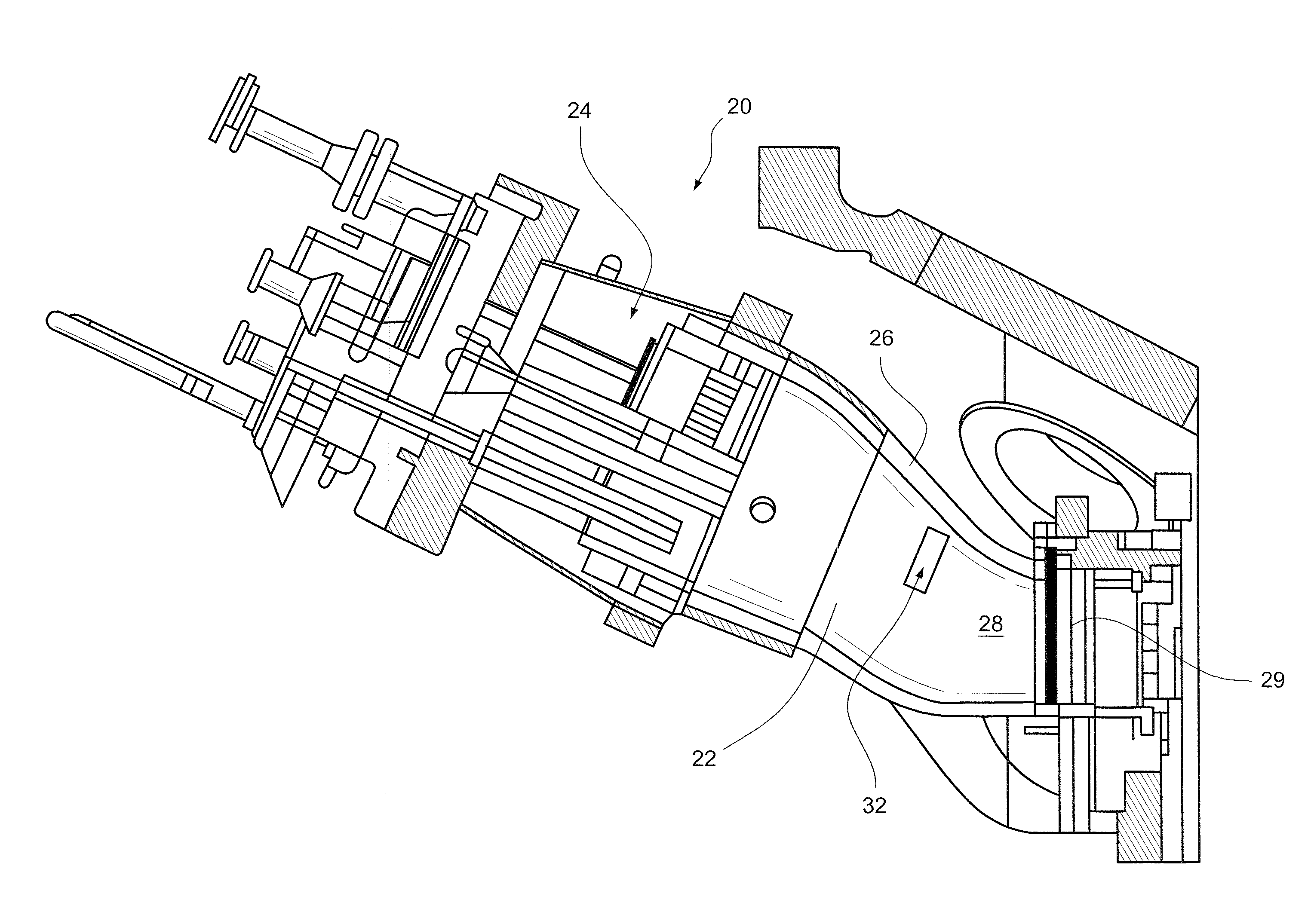

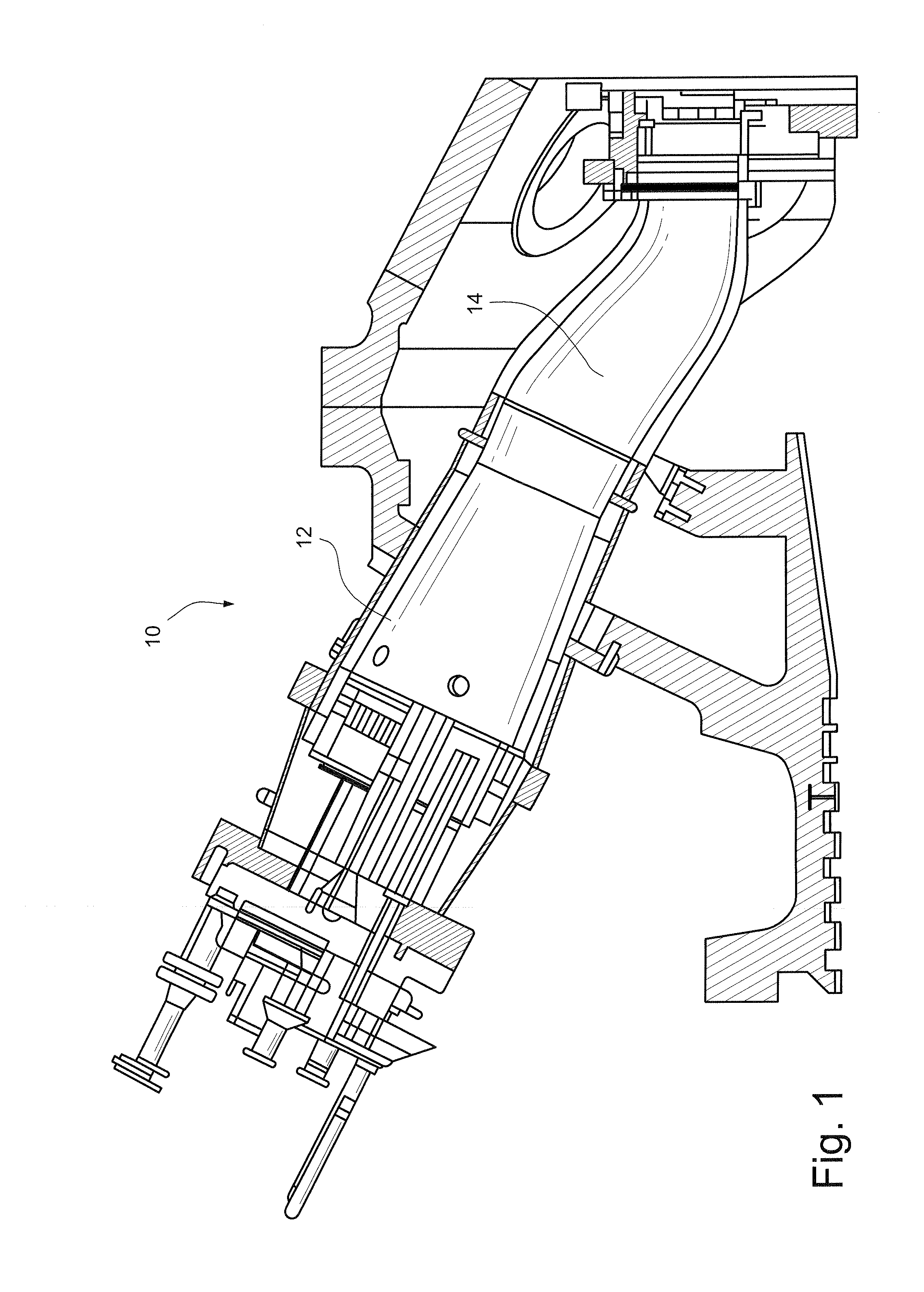

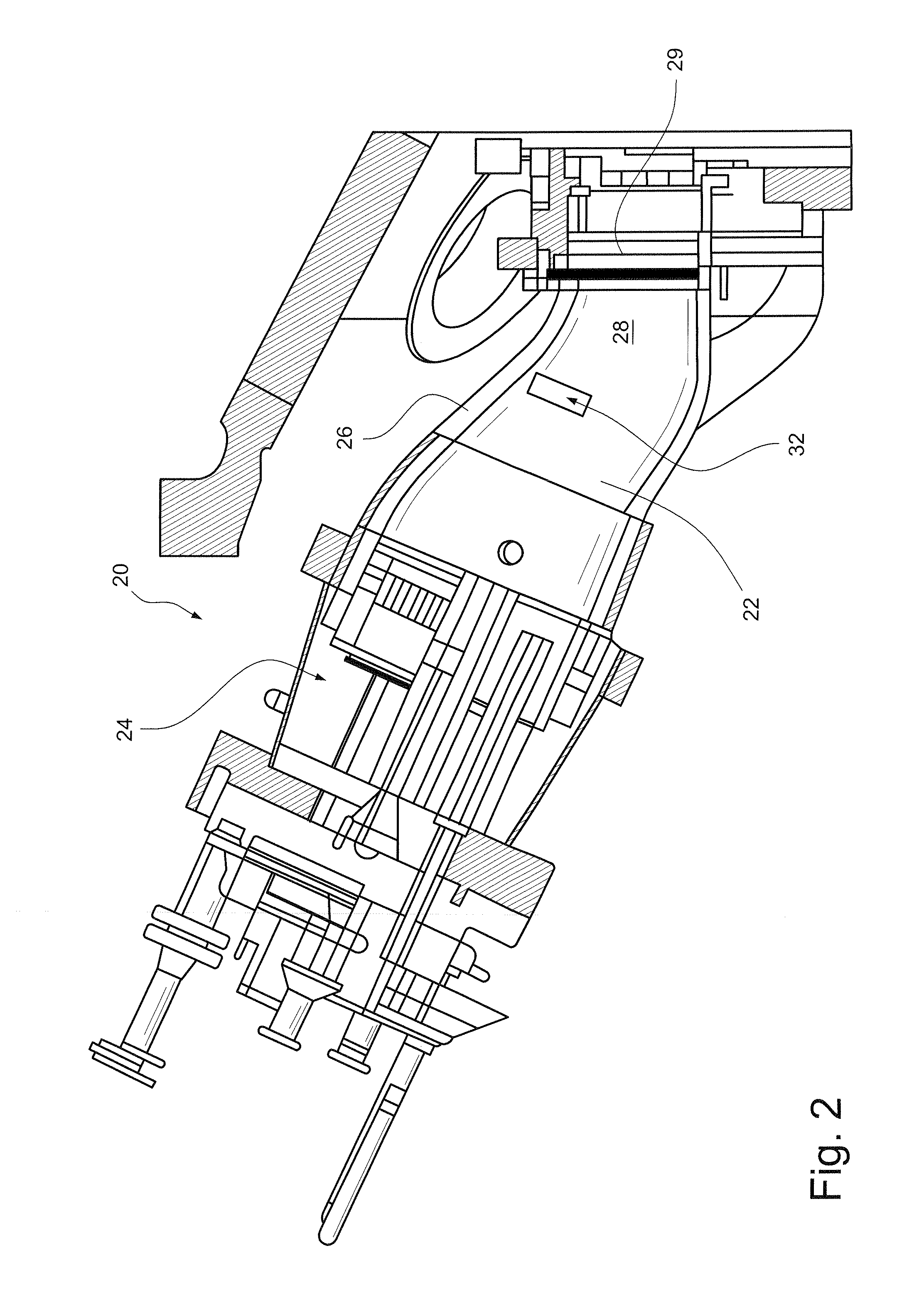

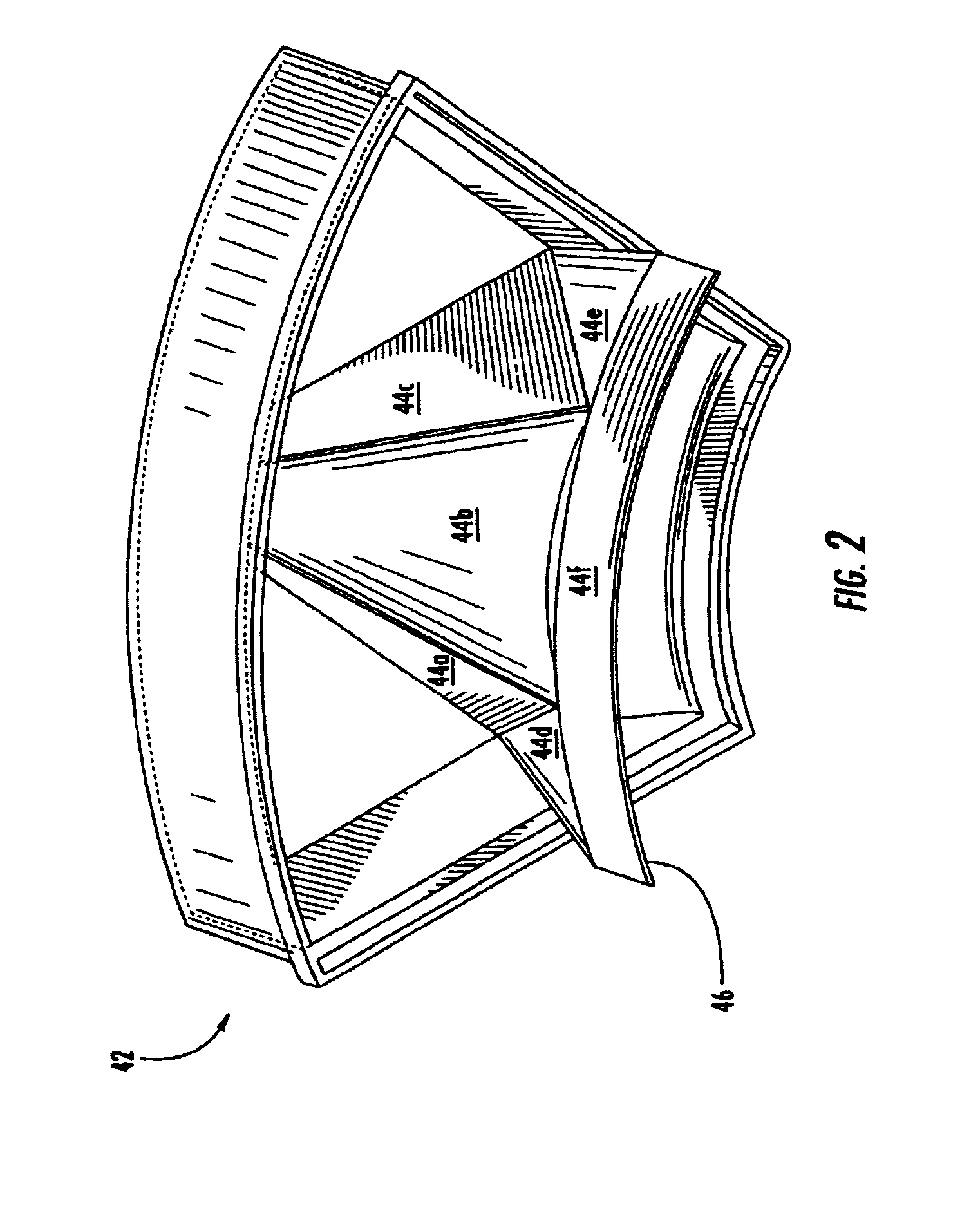

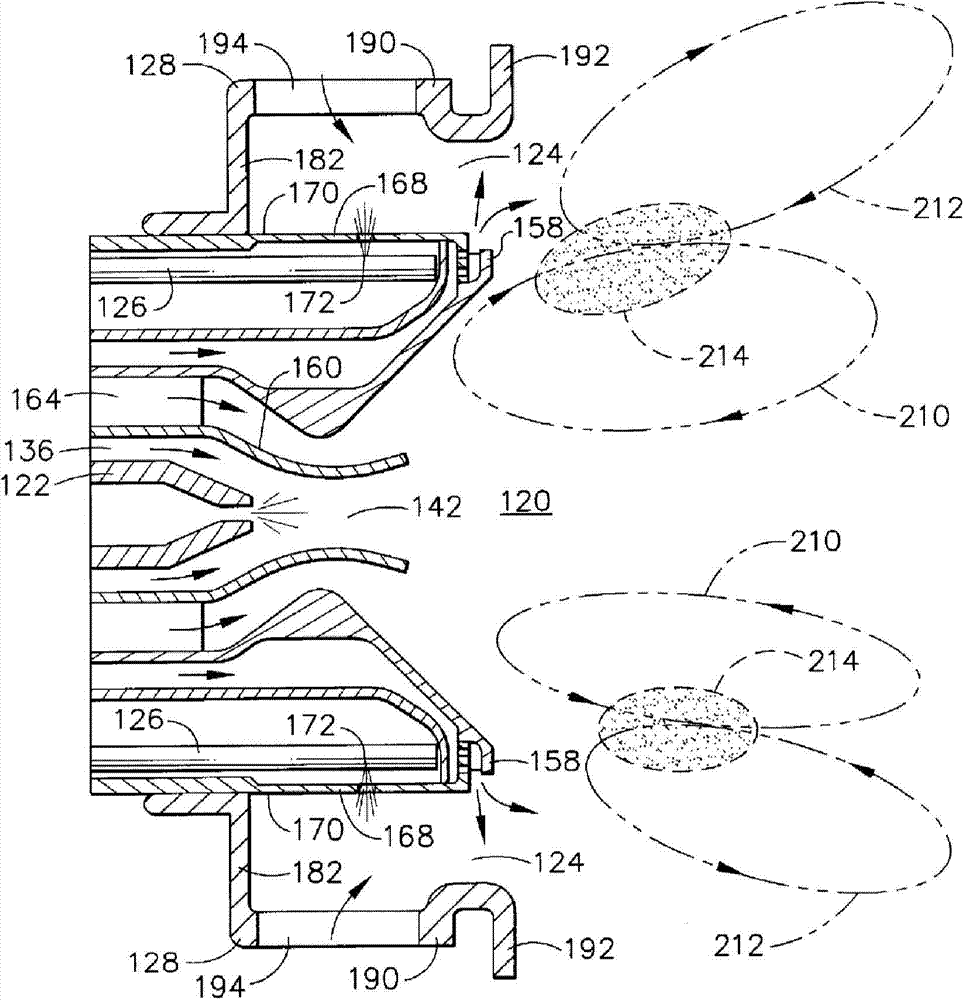

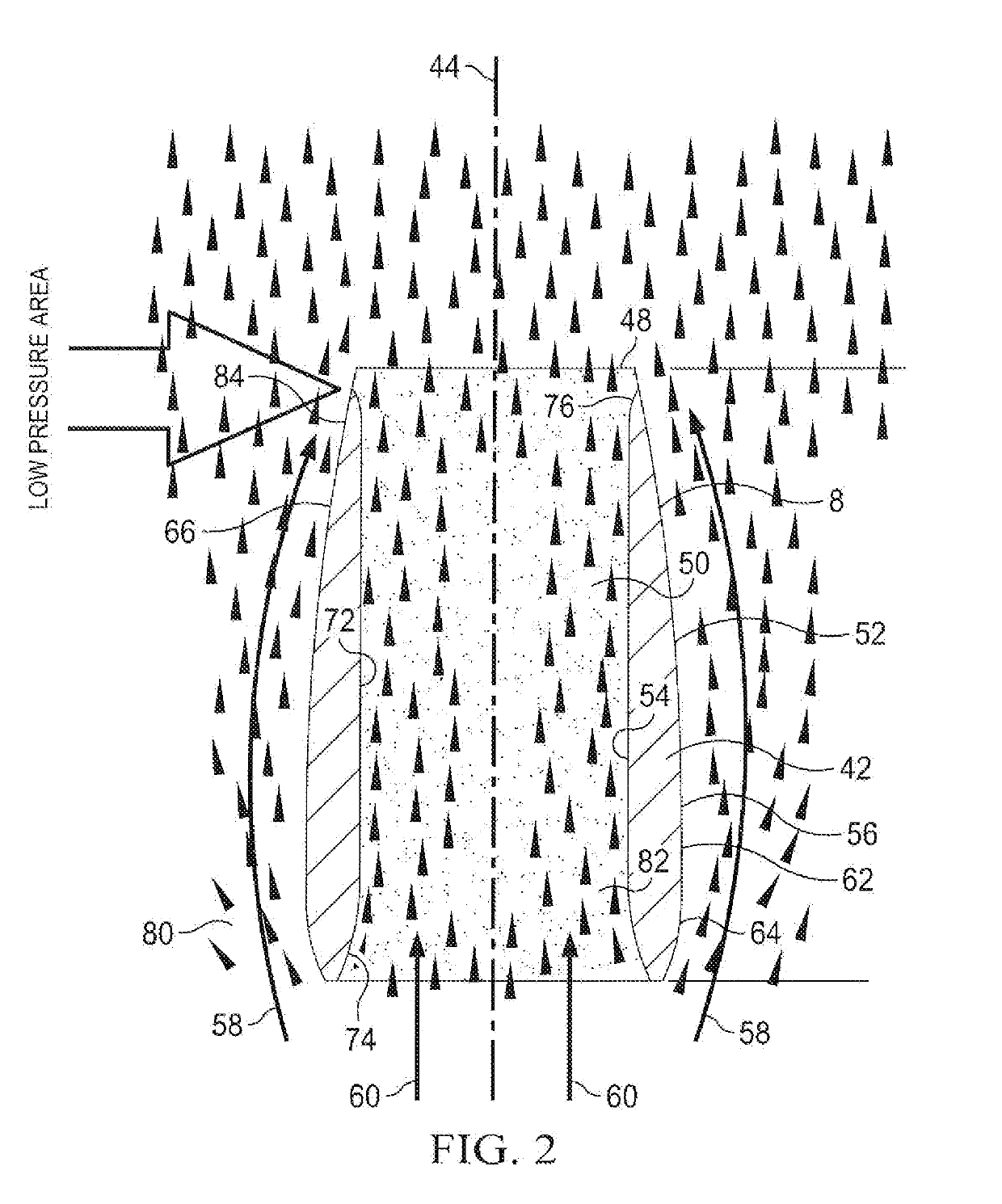

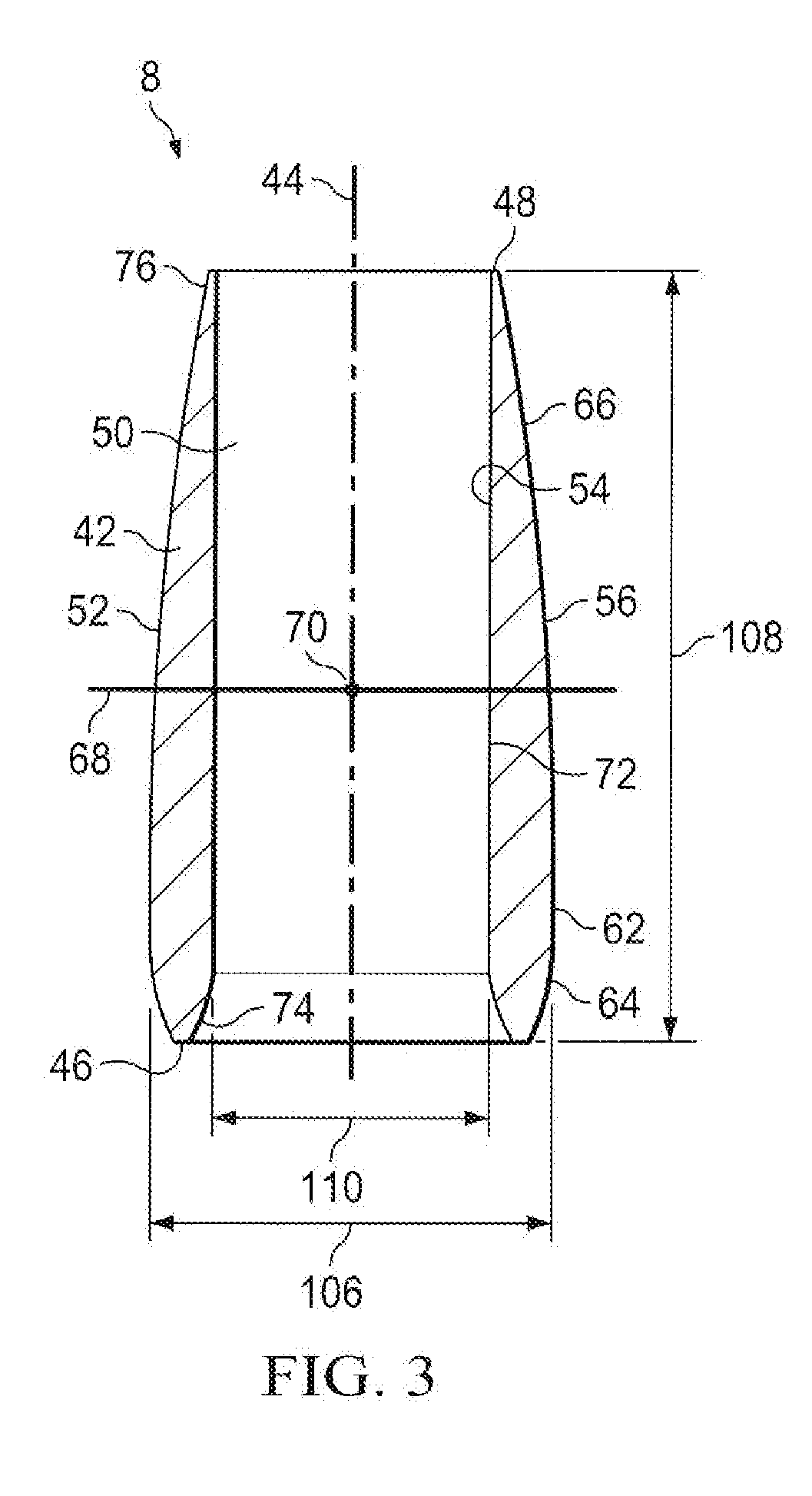

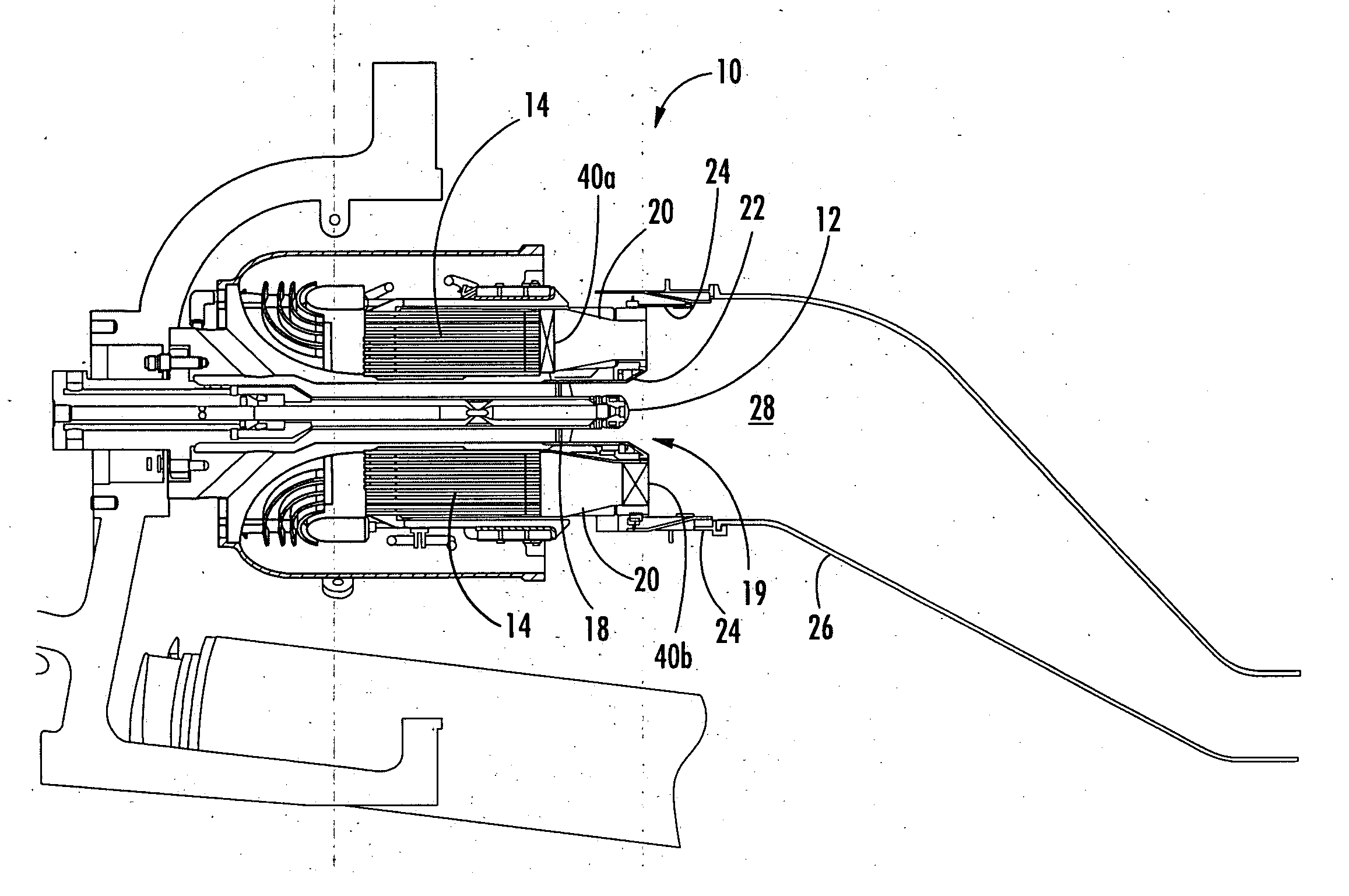

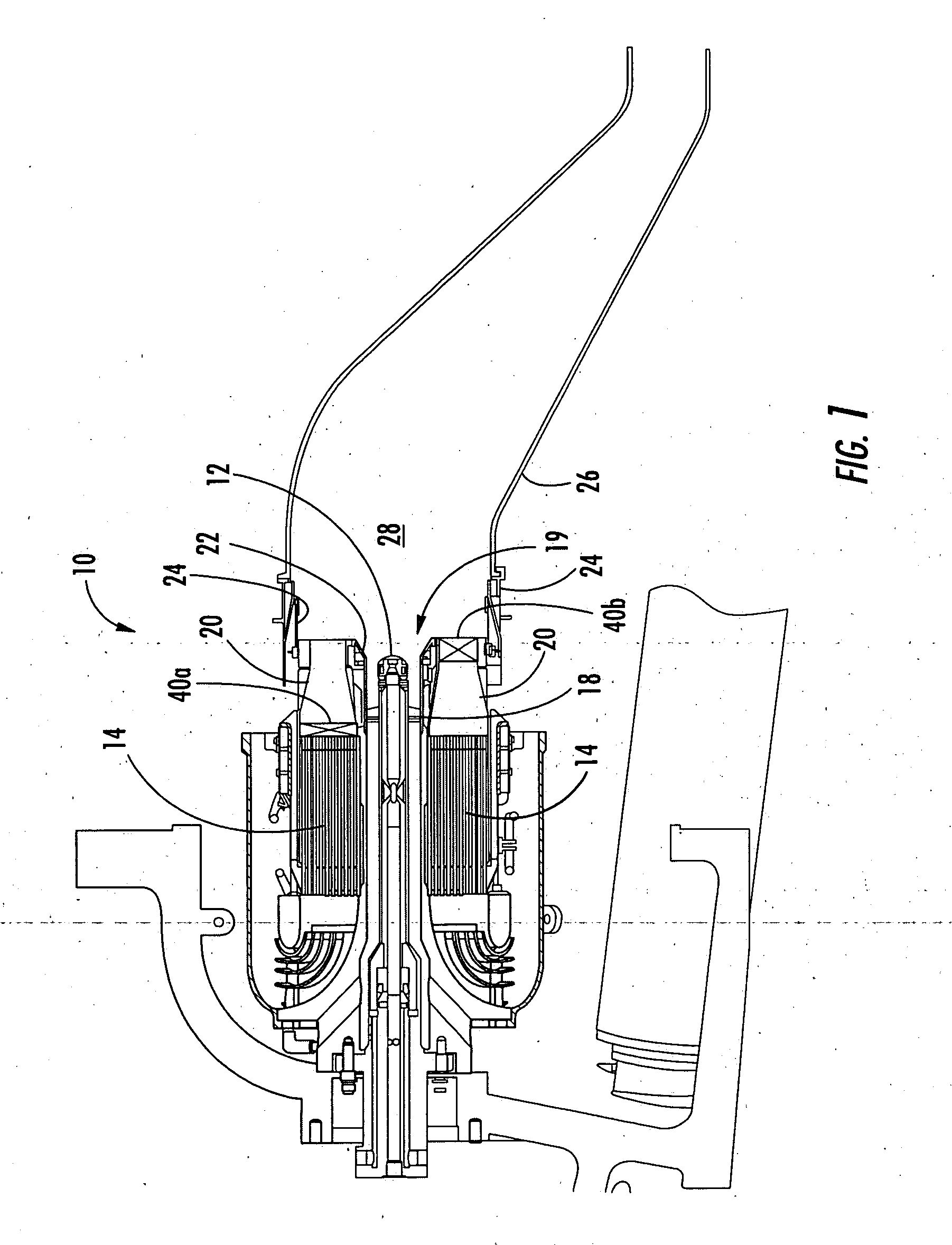

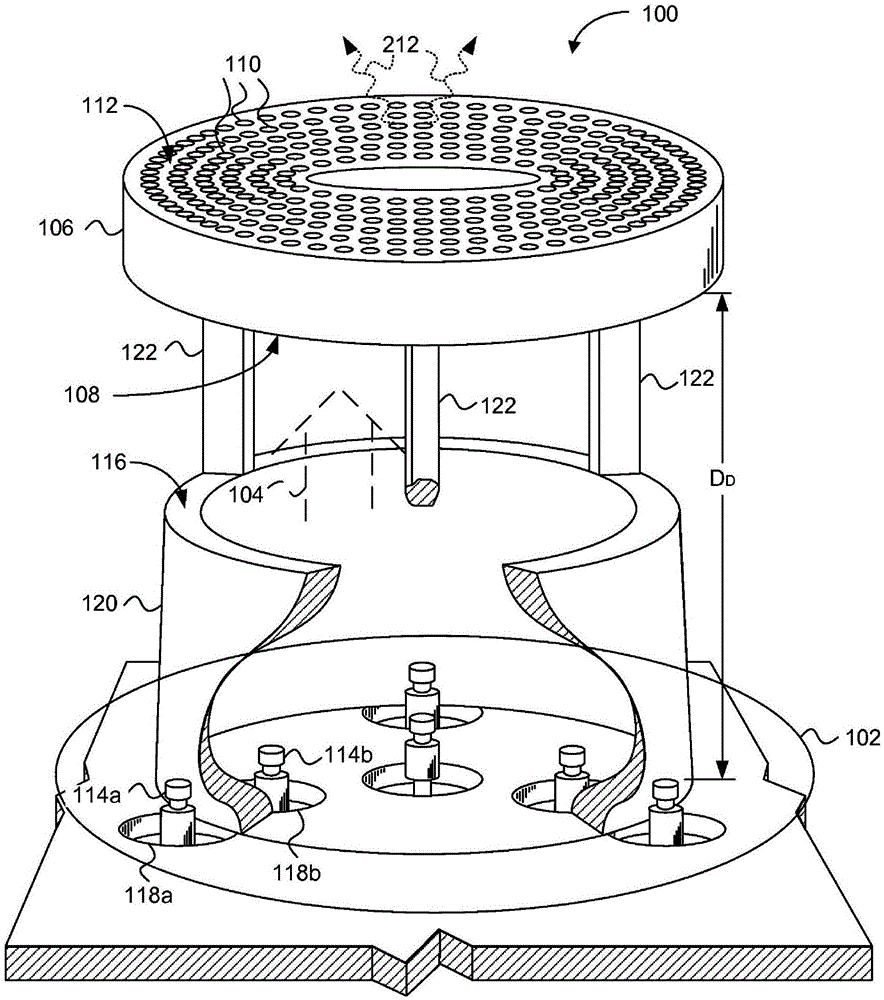

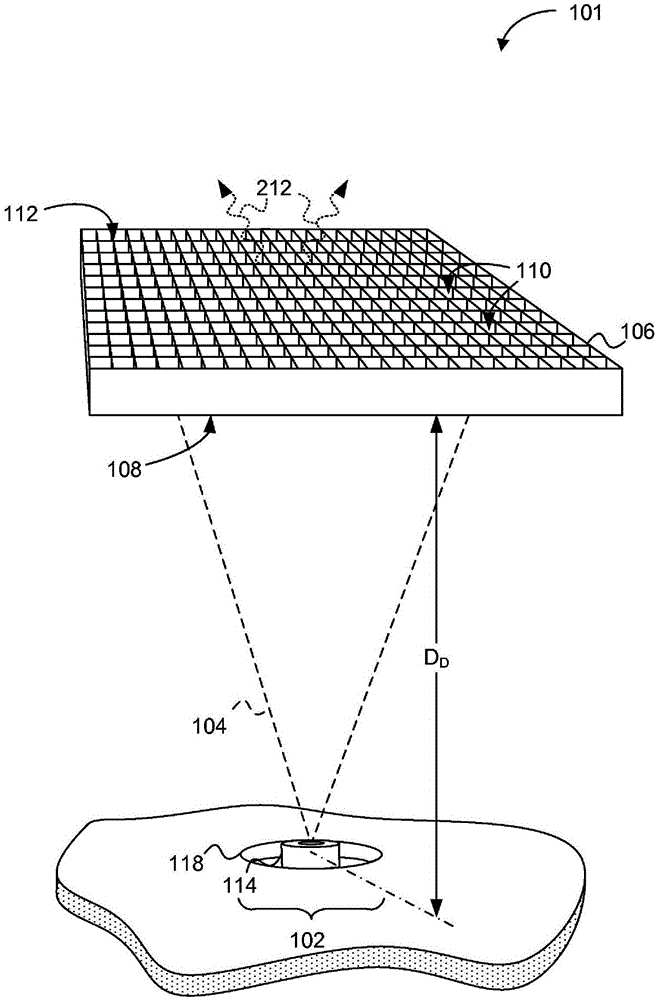

Integrated Combustor and Stage 1 Nozzle in a Gas Turbine and Method

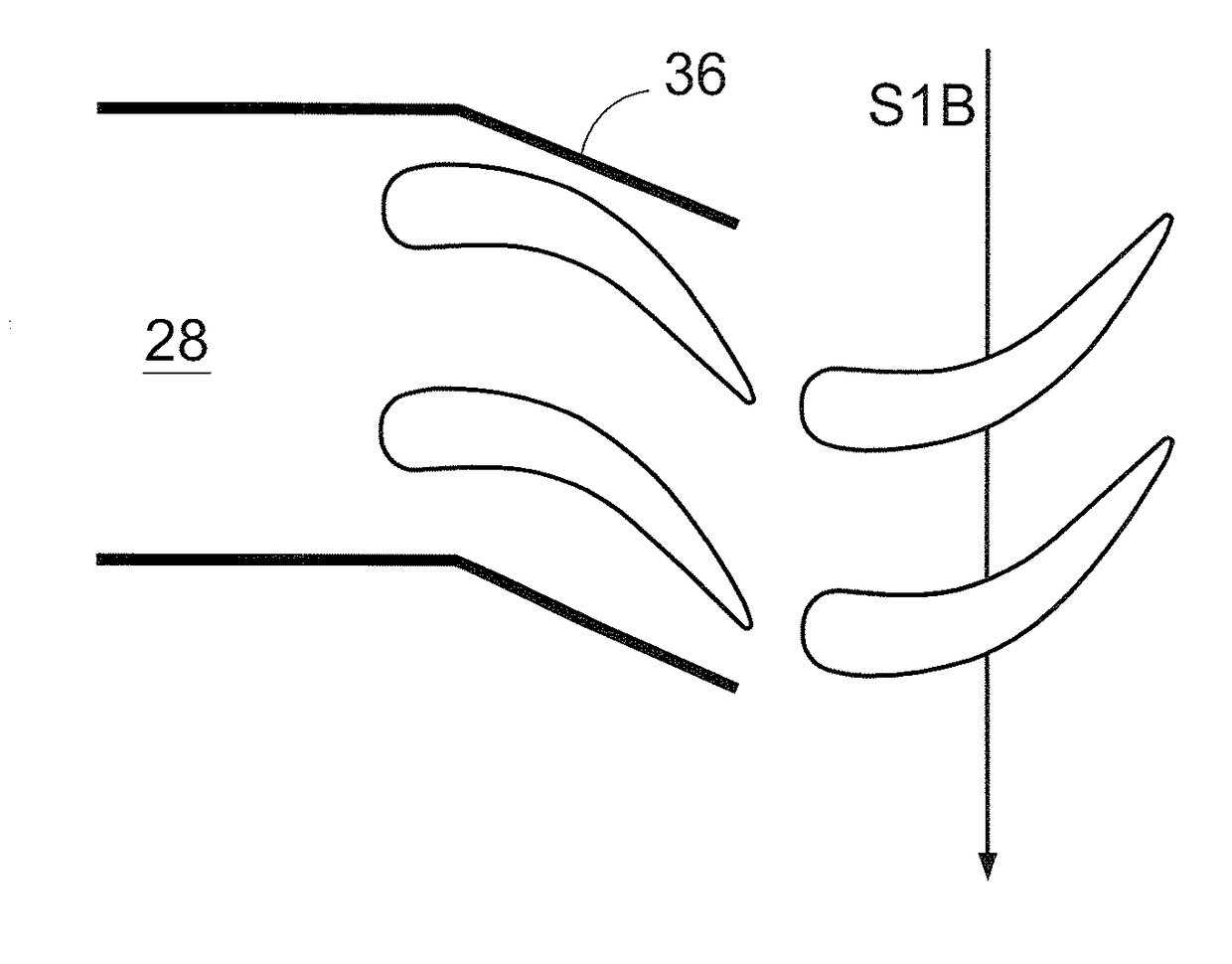

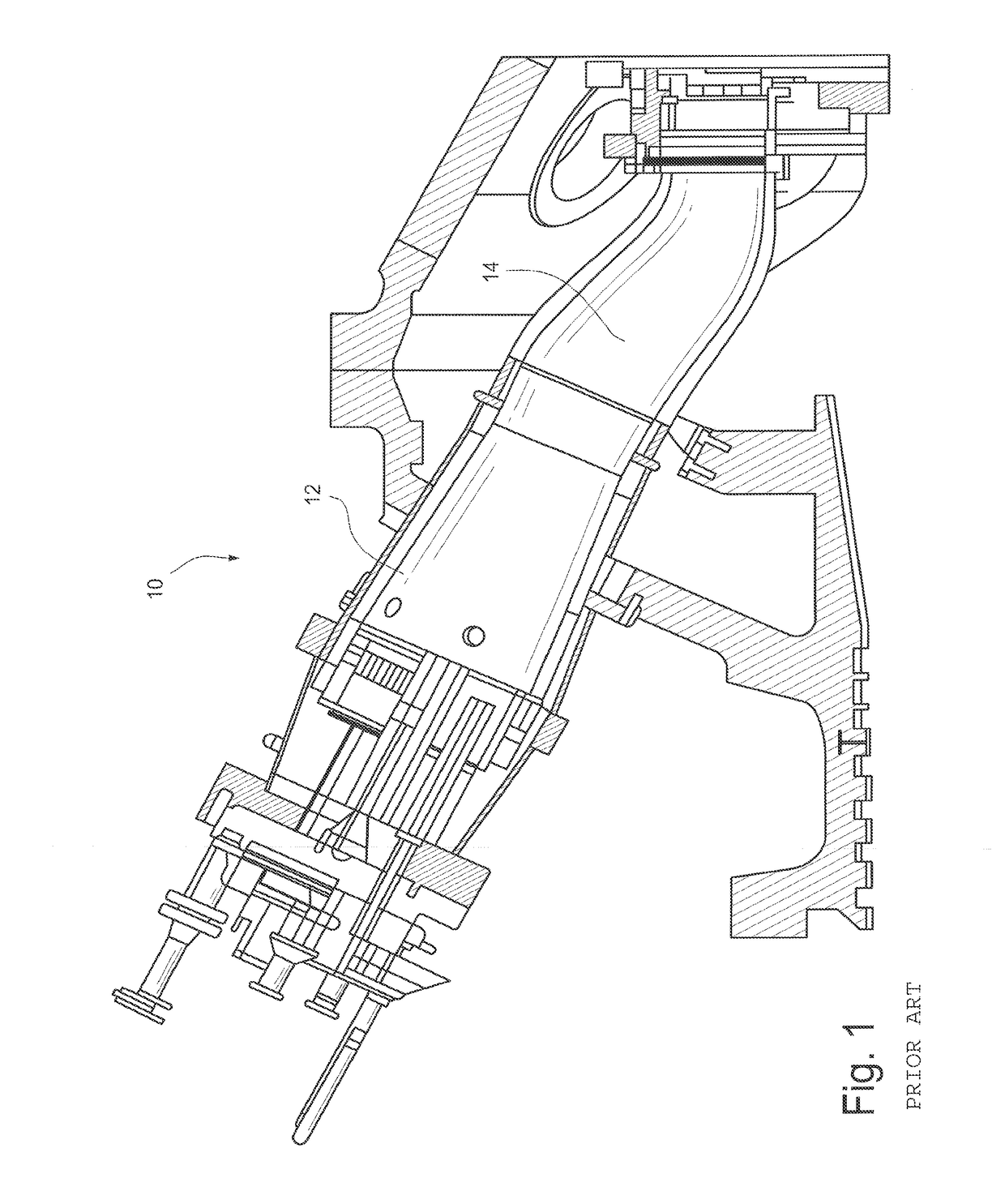

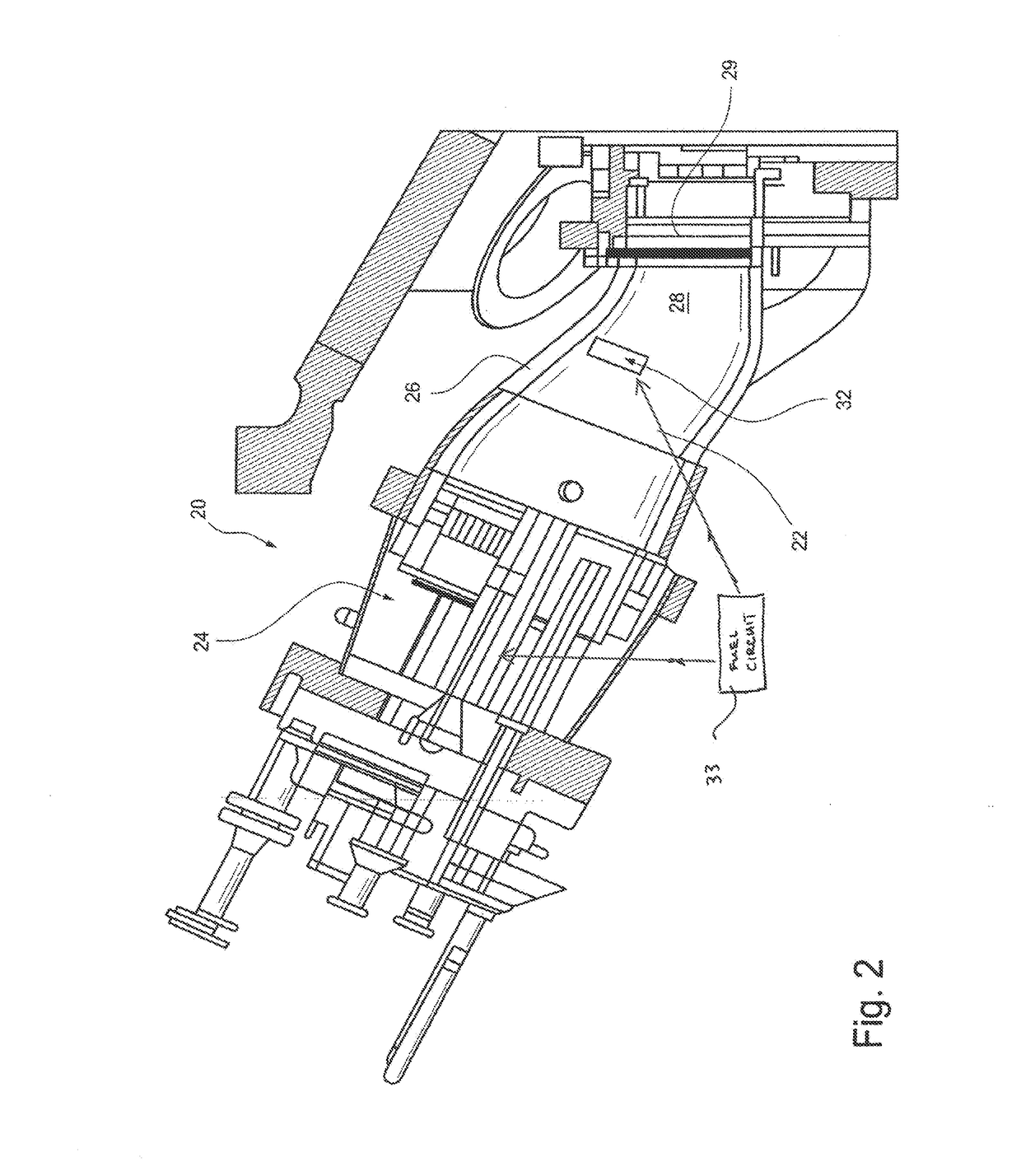

ActiveUS20100115953A1Shorten flame lengthContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberCombustor

An integrated combustor and stage one nozzle in a gas turbine includes a combustion chamber that receives premixed fuel and air from at least one fuel nozzle group at separate axial locations. The combustion chamber includes a liner and a transition piece that deliver hot combustion gas to the turbine. The stage one nozzle, the liner and the transition piece are integrated into a single part. At least one of the axial locations of the one or more fuel nozzle groups includes a plurality of small scale mixing devices that concentrate heat release and reduce flame length.

Owner:GENERAL ELECTRIC CO

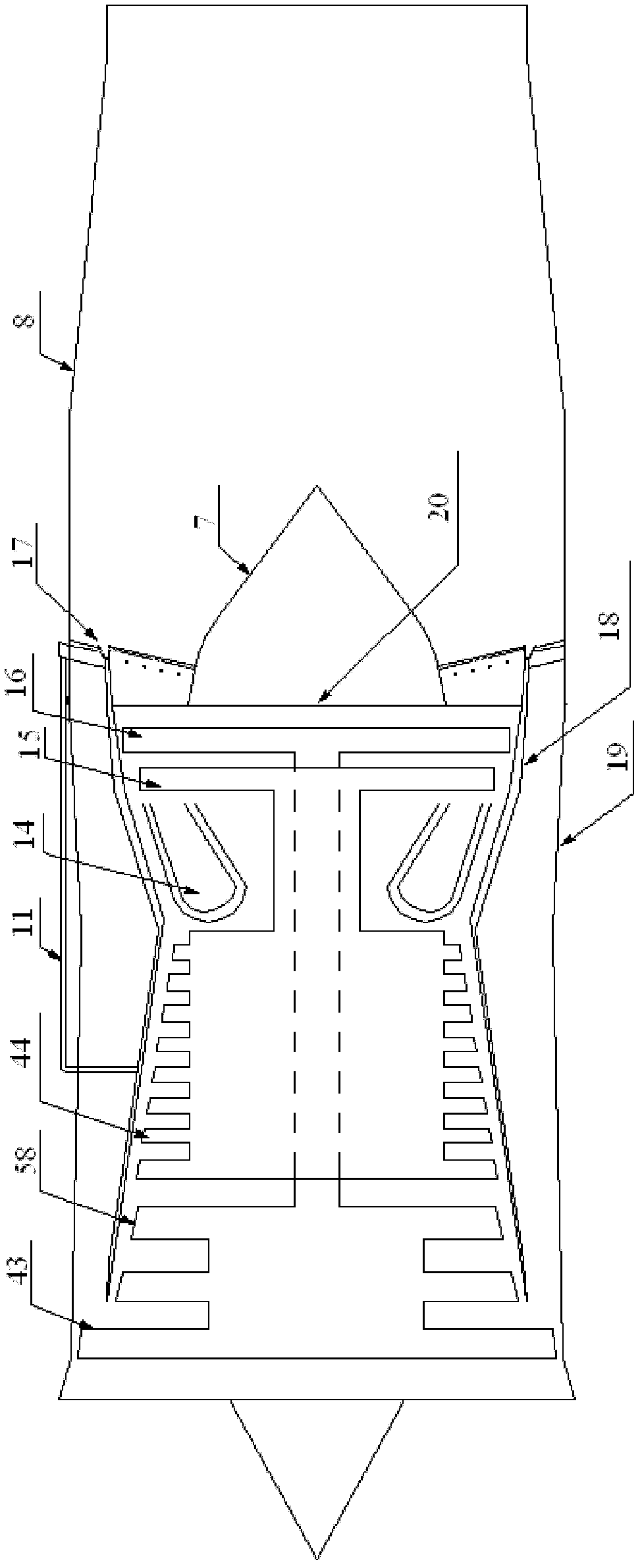

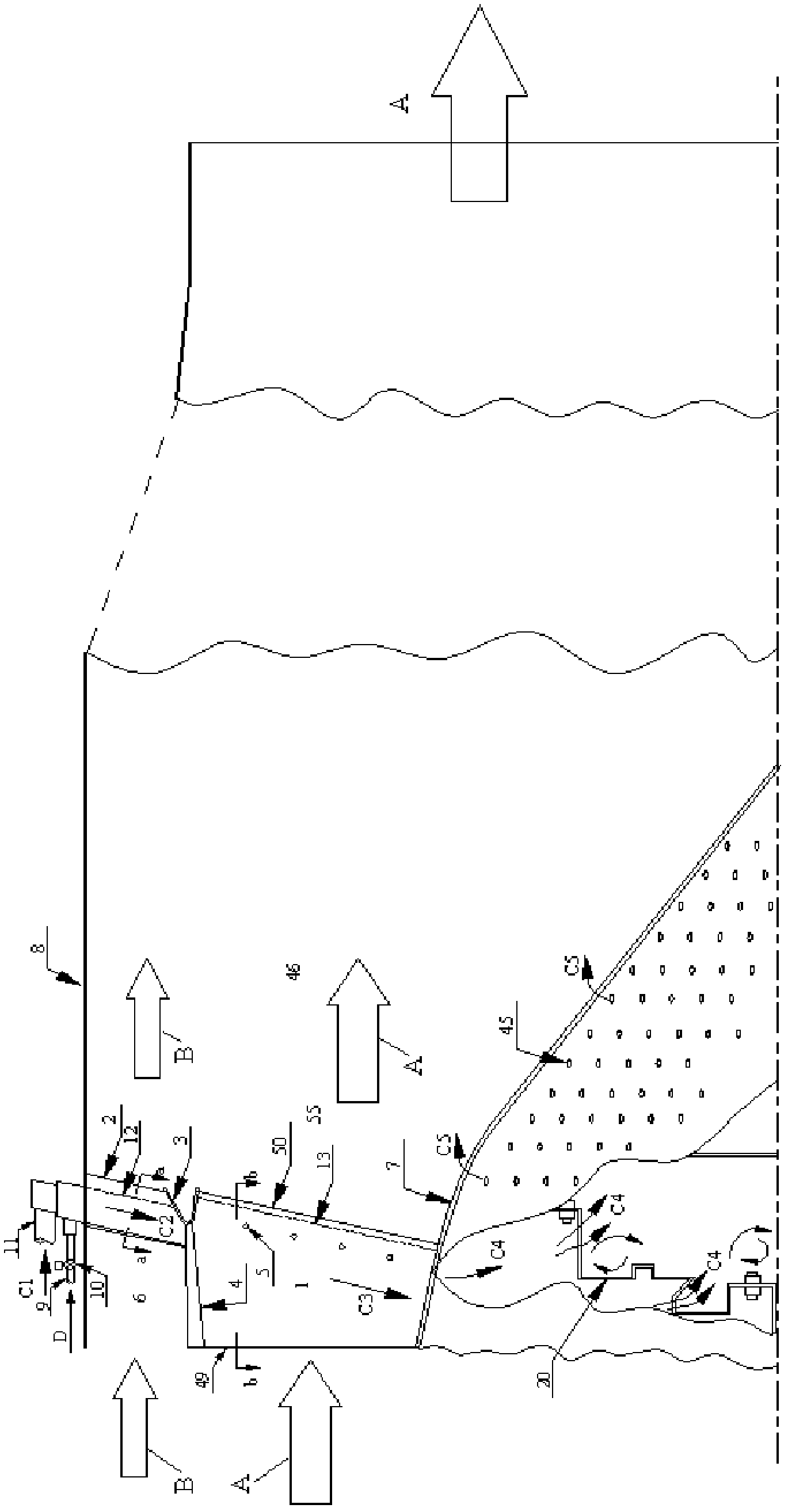

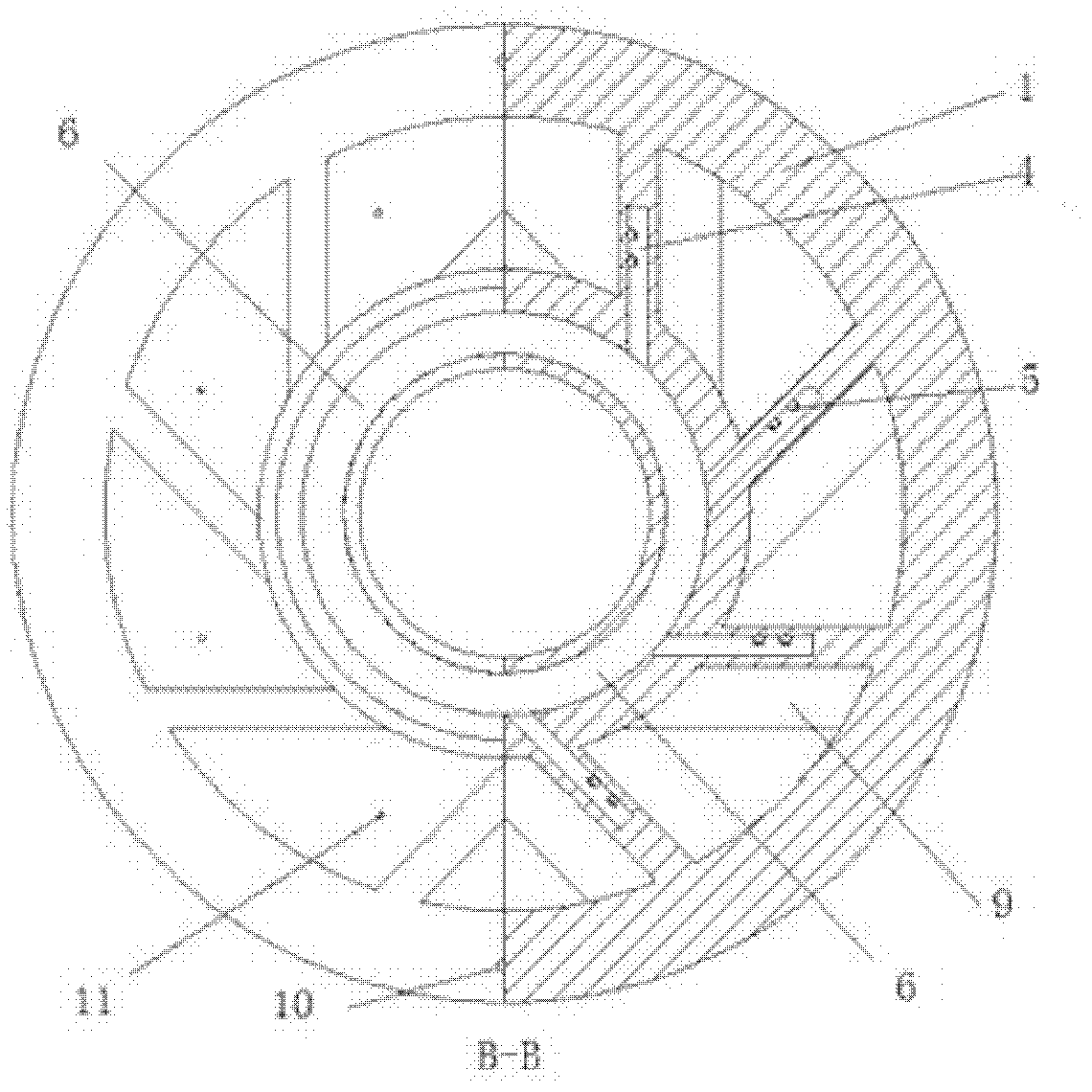

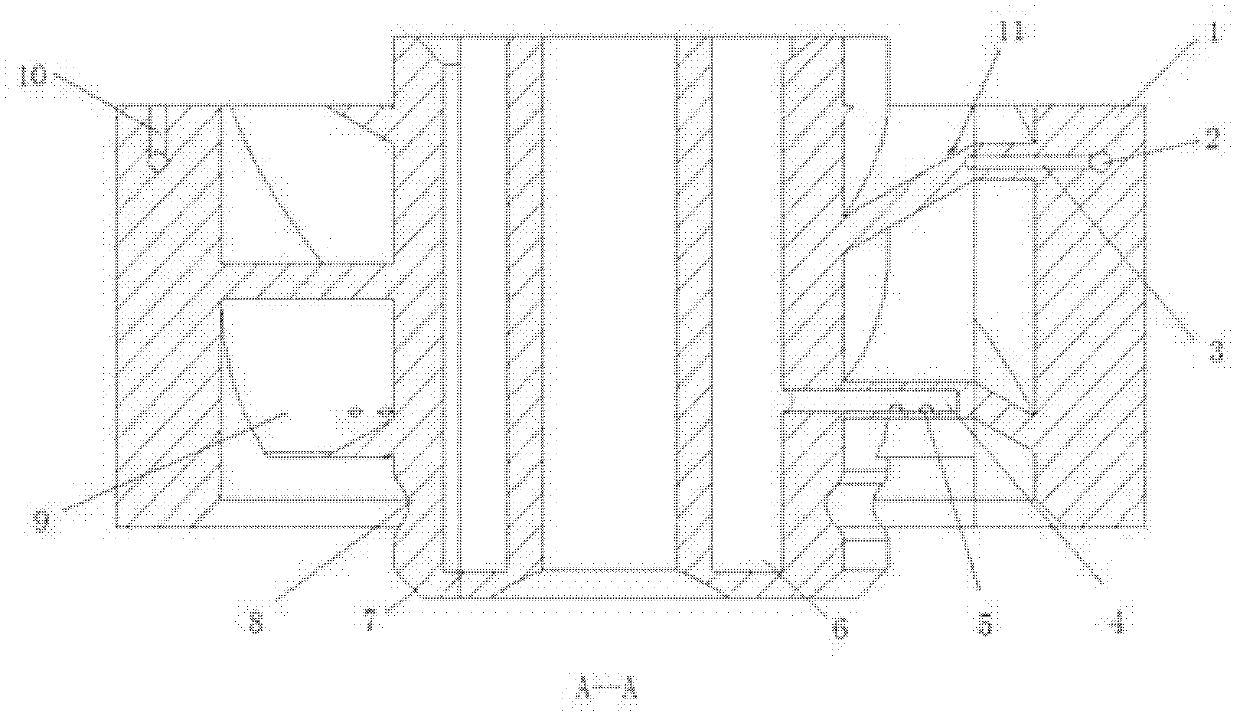

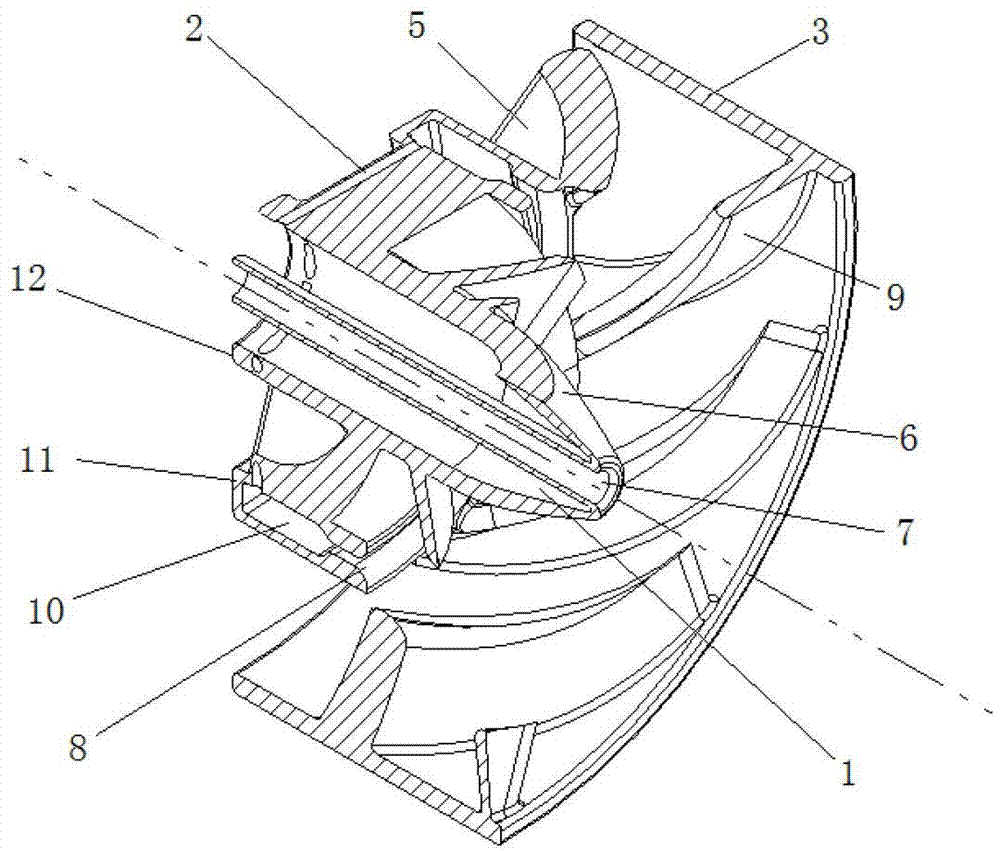

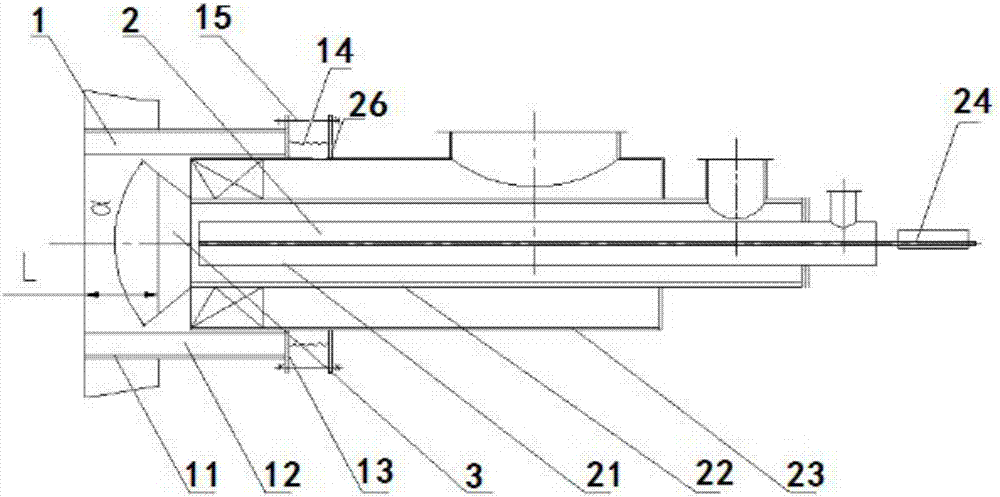

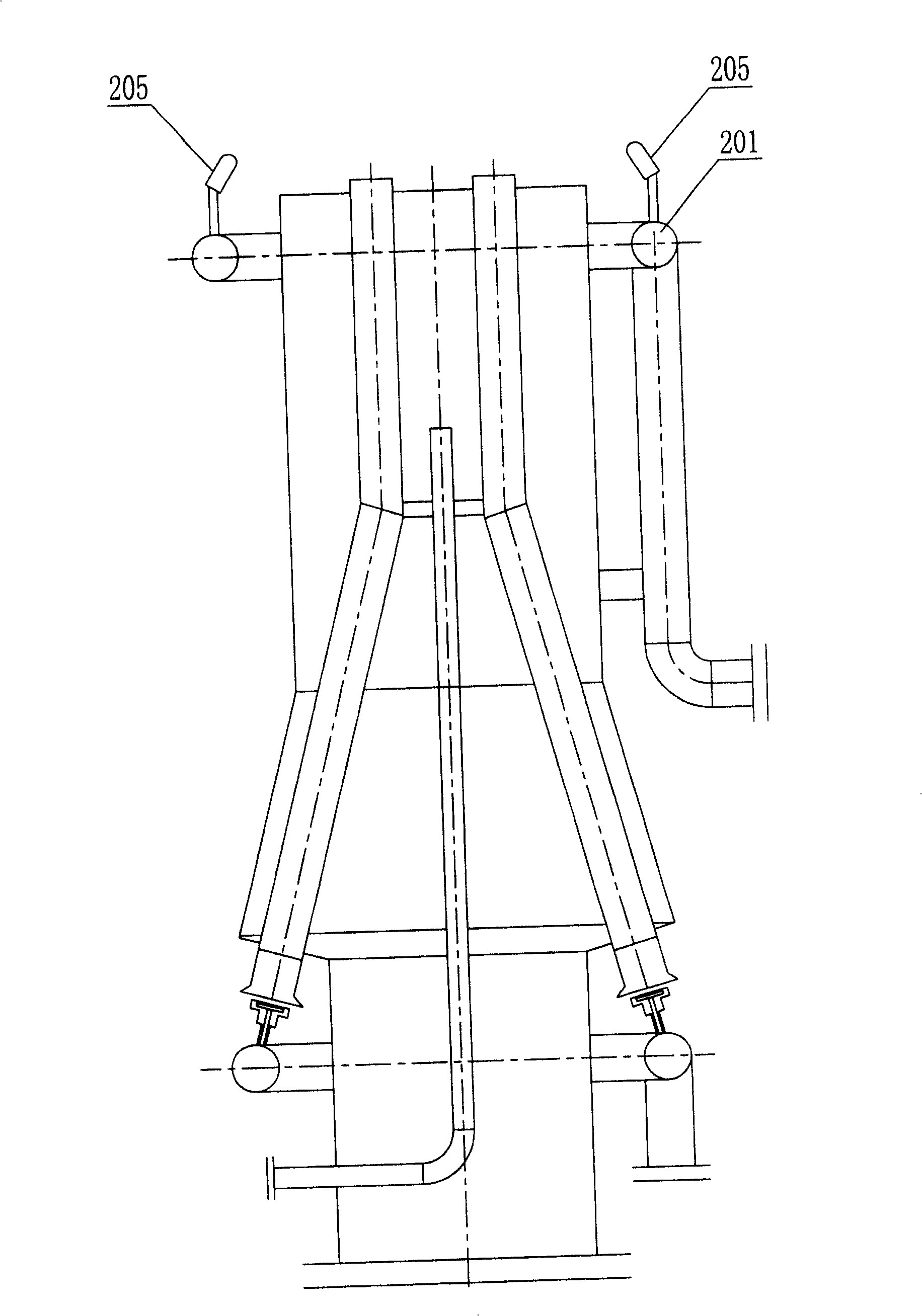

Afterburner integrated with stabilizer and worm wheel rear rectification support plate

InactiveCN102538010ASolve the technical problems of ablationImprove reliabilityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

The invention discloses an afterburner integrated with a stabilizer and a worm wheel rear rectification support plate. A combustion part in the afterburner is integrated with a worm wheel rear load-bearing framework; the worm wheel rear rectification support plate is integrated with an inner culvert flame stabilizer, and cooling air is fed; a fuel oil supply pipe and a fuel oil nozzle are arranged in the rectification support plate; main fuel oil is transversely sprayed out from two sides of the support plate; and duty fuel oil is sprayed out from a groove on the rear surface of the stabilizer to form a duty flame. A pneumatic appearance of an outer culvert flame stabilizer is designed as a V-shaped bluff body, and the cooling air is fed into the outer culvert flame stabilizer; a fuel oil pipeline is arranged in the outer culvert flame stabilizer; the main fuel oil is transversely sprayed by a baffle plate nozzle; and the duty fuel oil is sprayed out from a groove on the rear surface of the outer culvert flame stabilizer. An annular flame stabilizer is arranged between the inner culvert flame stabilizer and the outer culvert flame stabilizer, so that functions of the stabilizer and a flame coupler are realized in a circumferential direction. The internal parts of the afterburner are integrated, so that the part utilization efficiency is improved, and the engine thrust-weight ratio is increased.

Owner:BEIHANG UNIV

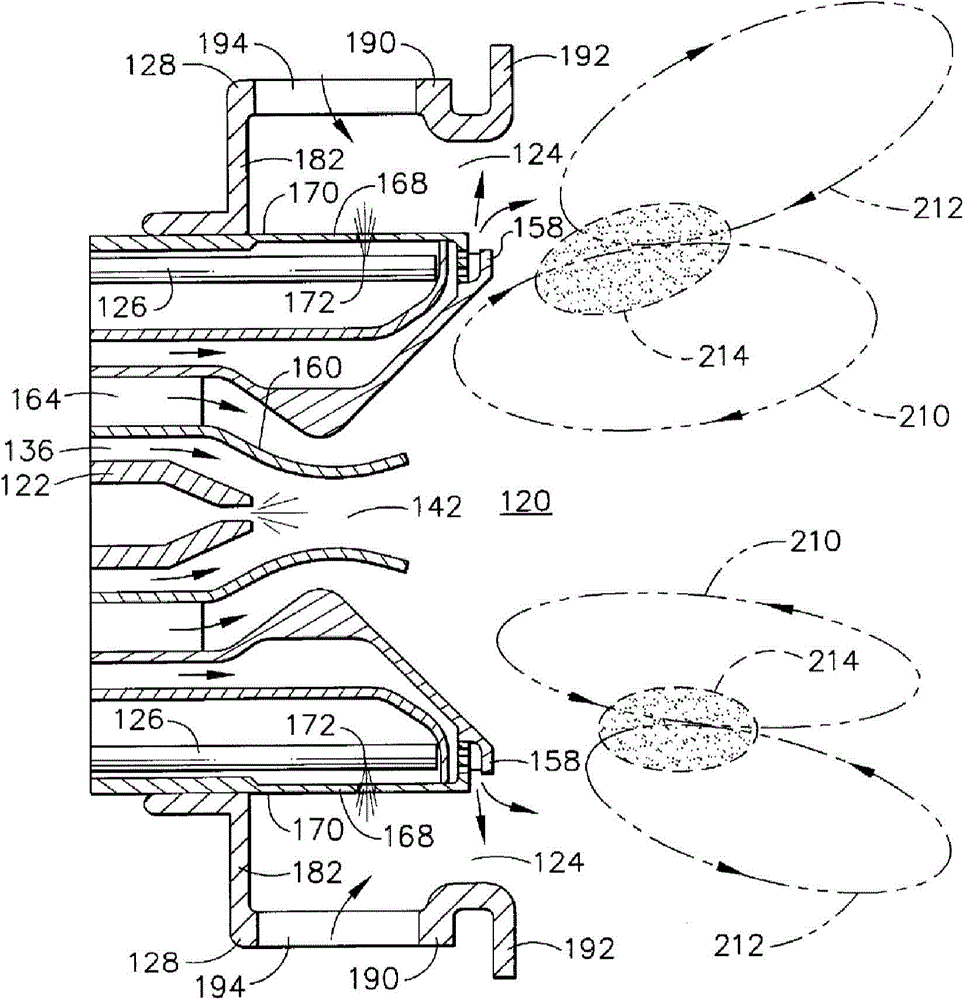

Catalytic combustion system and method

InactiveUS7096671B2Emission reductionShorten flame lengthContinuous combustion chamberTurbine/propulsion fuel supply systemsNitrogenNitrogen oxide

Aspects according to the invention relate to a catalytic combustor system for a turbine engine and an associated method. Catalytic combustors are used in connection with turbine engines because they can minimize the formation of oxides of nitrogen during combustion. Despite this emissions advantage, catalytic combustion systems can increase the level of CO in the turbine exhaust. According to aspects of the invention, vortex formation devices includes vortex generators, swirlers and mixers can be placed downstream of each catalytic module surrounding the pilot nozzle so as to form one or more vortices in the otherwise substantially laminar flow exiting the modules. The vortices can create a suction so that a portion of the flow exiting the pilot nozzles is mixed with the flow exiting the catalyst modules. The introduction of the higher temperature pilot flow can accelerate the catalytic reaction time, promoting burnout of the CO formed during combustion.

Owner:SIEMENS ENERGY INC

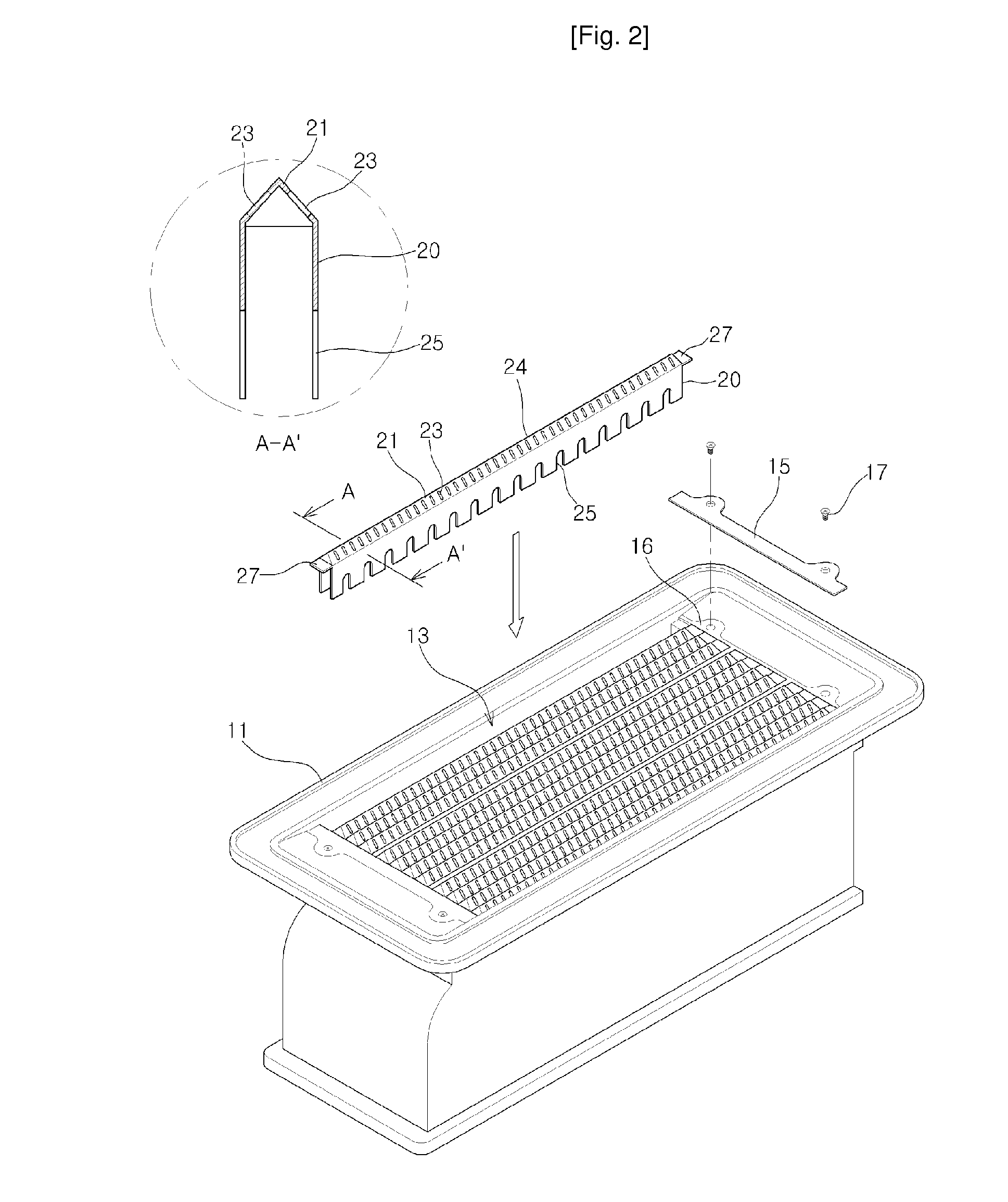

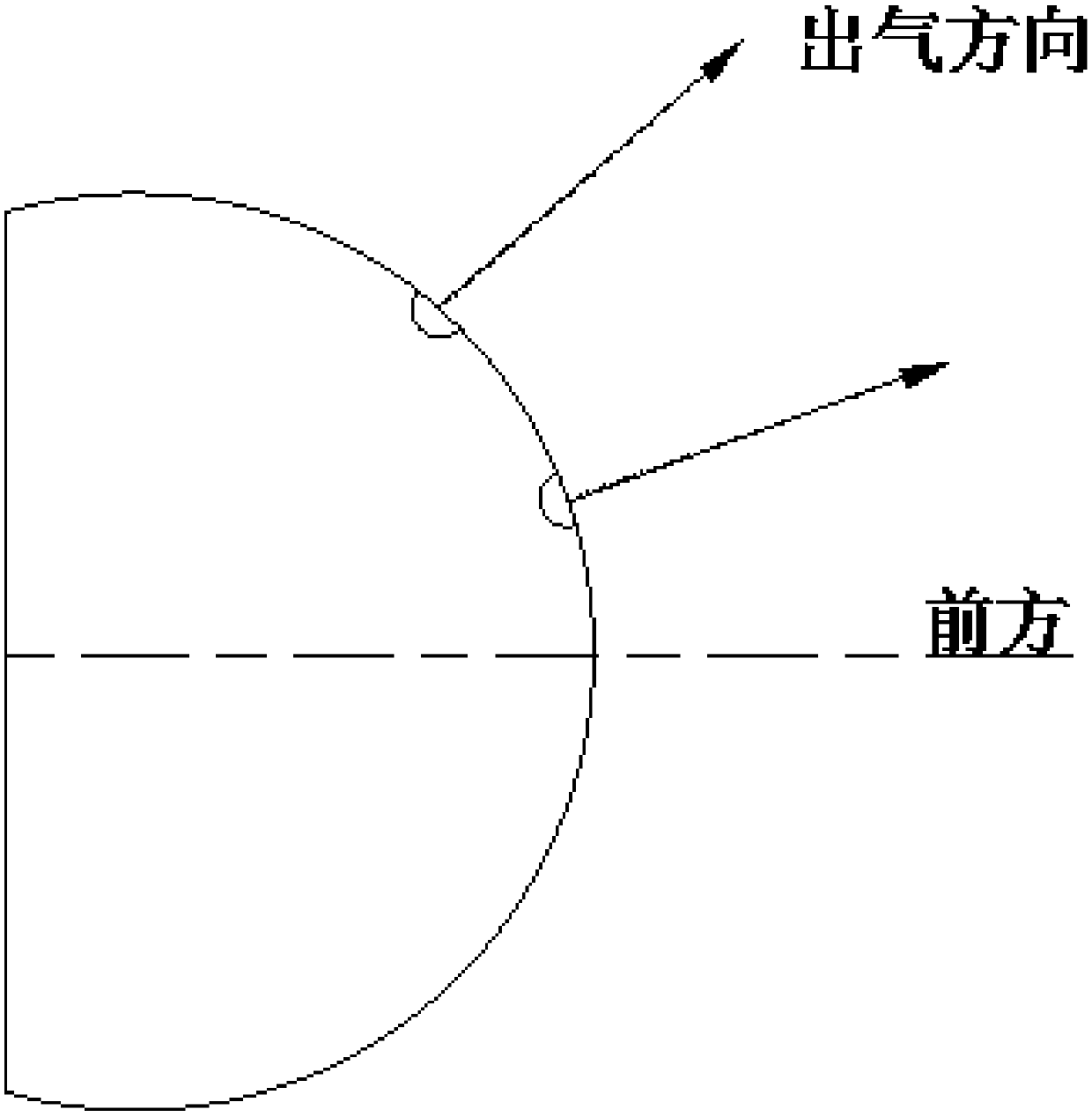

Flame structure of gas burner

InactiveUS20090291402A1Reduce in sizeCombustion load be increasePilot flame ignitersGaseous fuel burnerGas burnerFlame structure

A fire hole part structure of a gas burner, which is constructed to be manufactured at a low cost, can improve flame stability, and can prevent incomplete combustion due to the length of flame. The structure is provided to a premixing ignition burner, which is installed to apply heat to a heat exchanger of a boiler, and includes fire hole pieces which are installed parallel to one another in mounting openings of a burner body, and each of which is defined with fire holes at regular intervals. An upper wall of at least one of the fire hole pieces is bent or curved to extend in at least two directions, and the fire holes are defined through respective surface portions of the upper wall, which extend in different directions, to face different directions.

Owner:KYUNGDONG NAVIEN

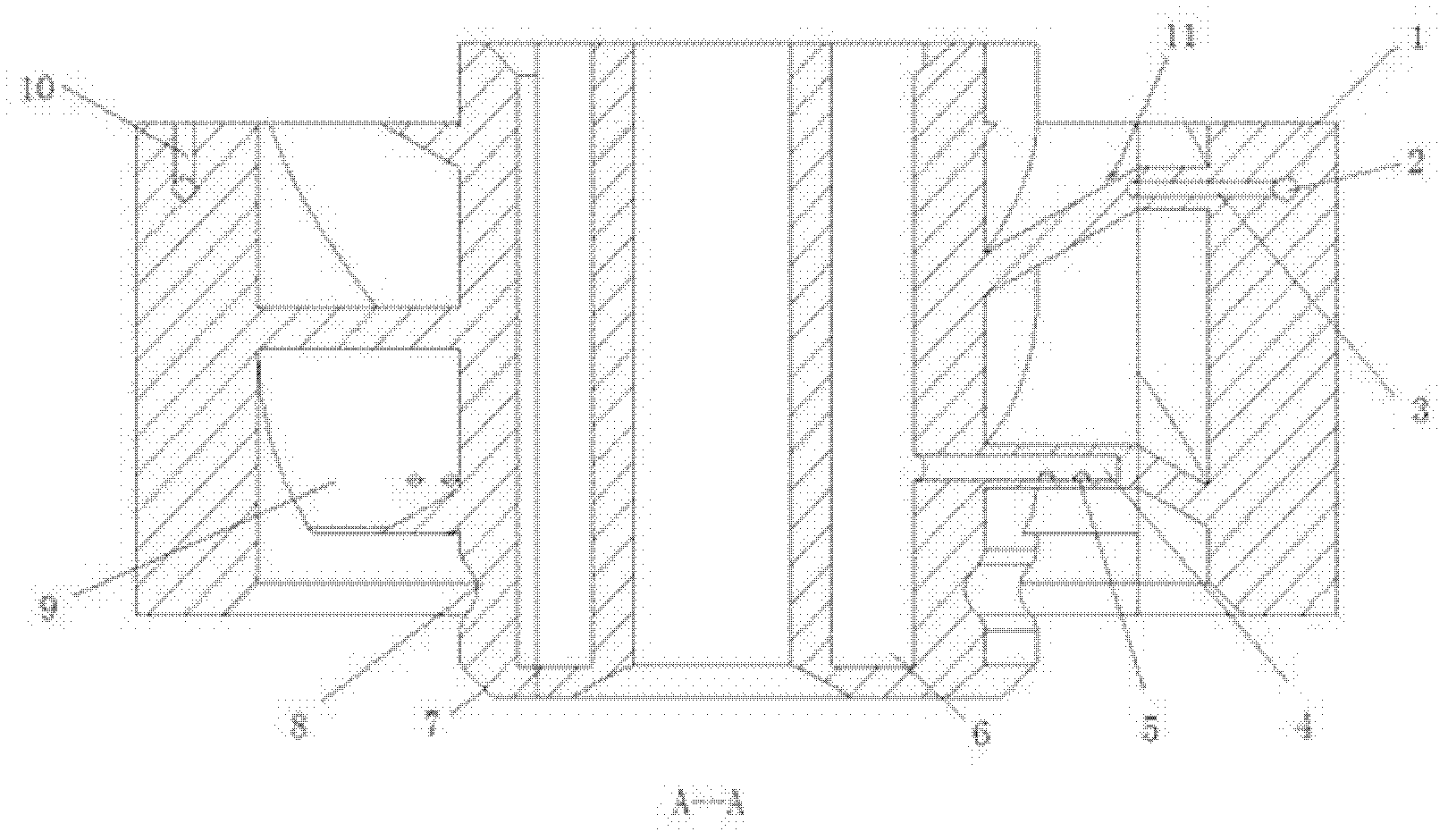

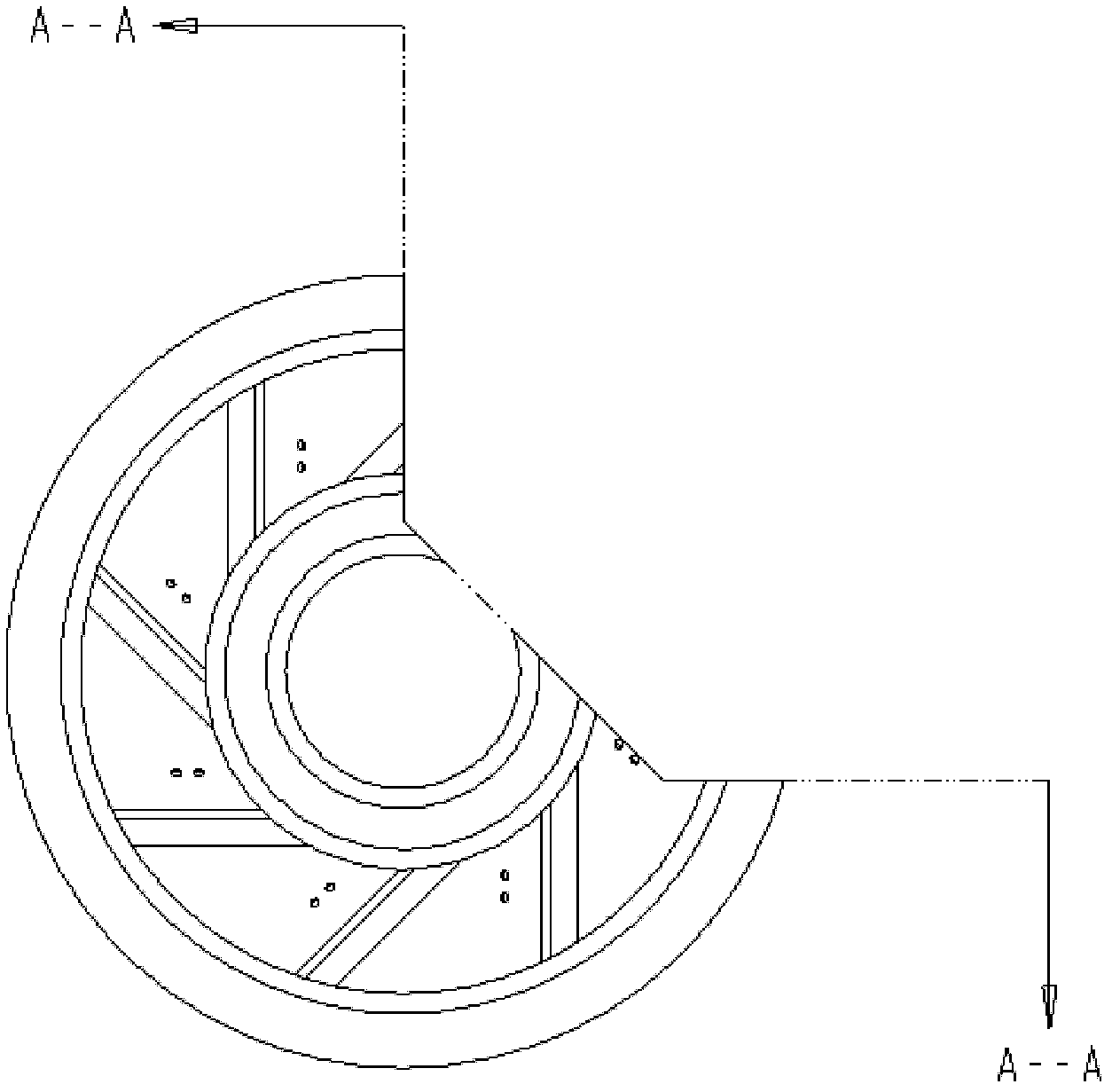

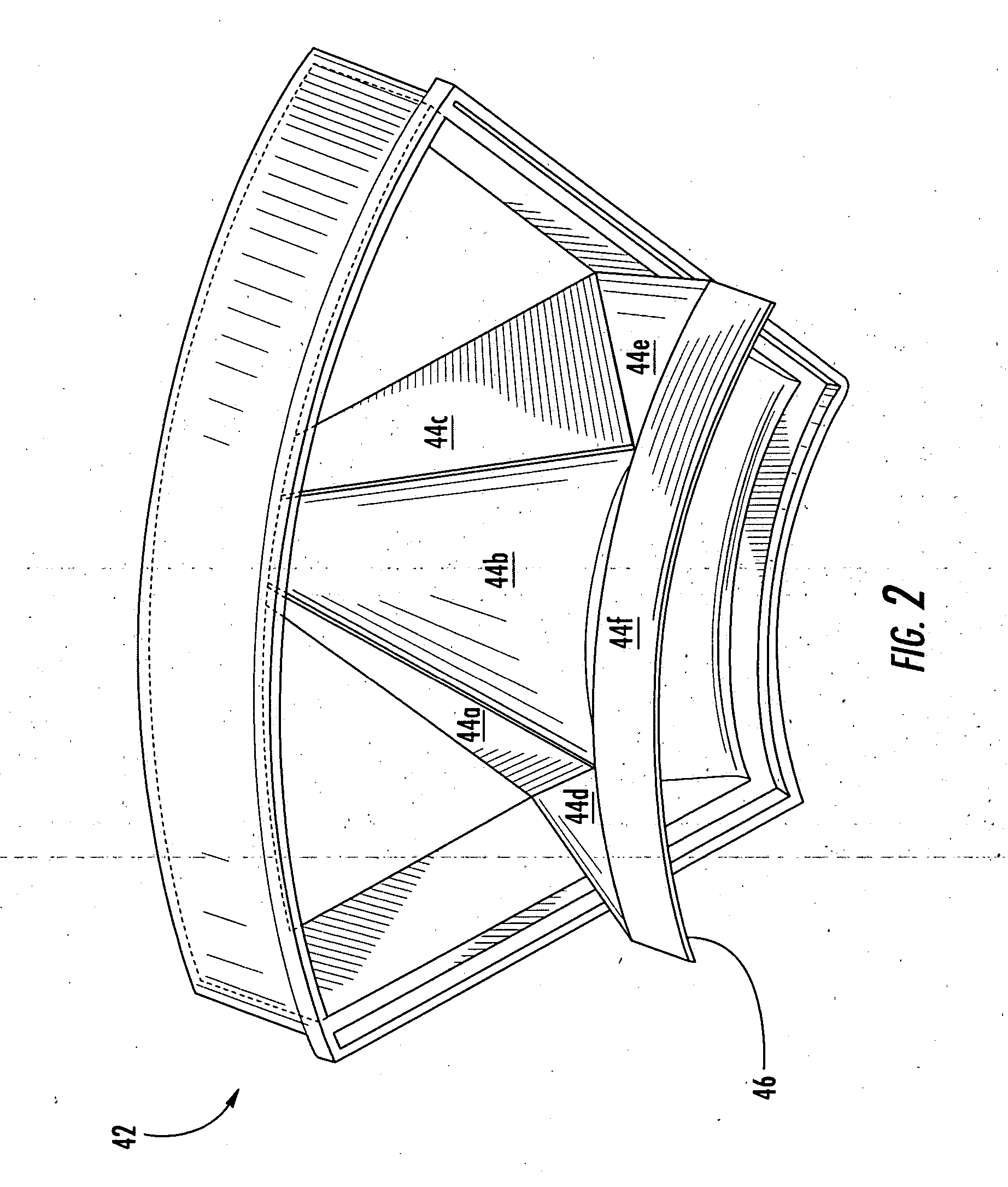

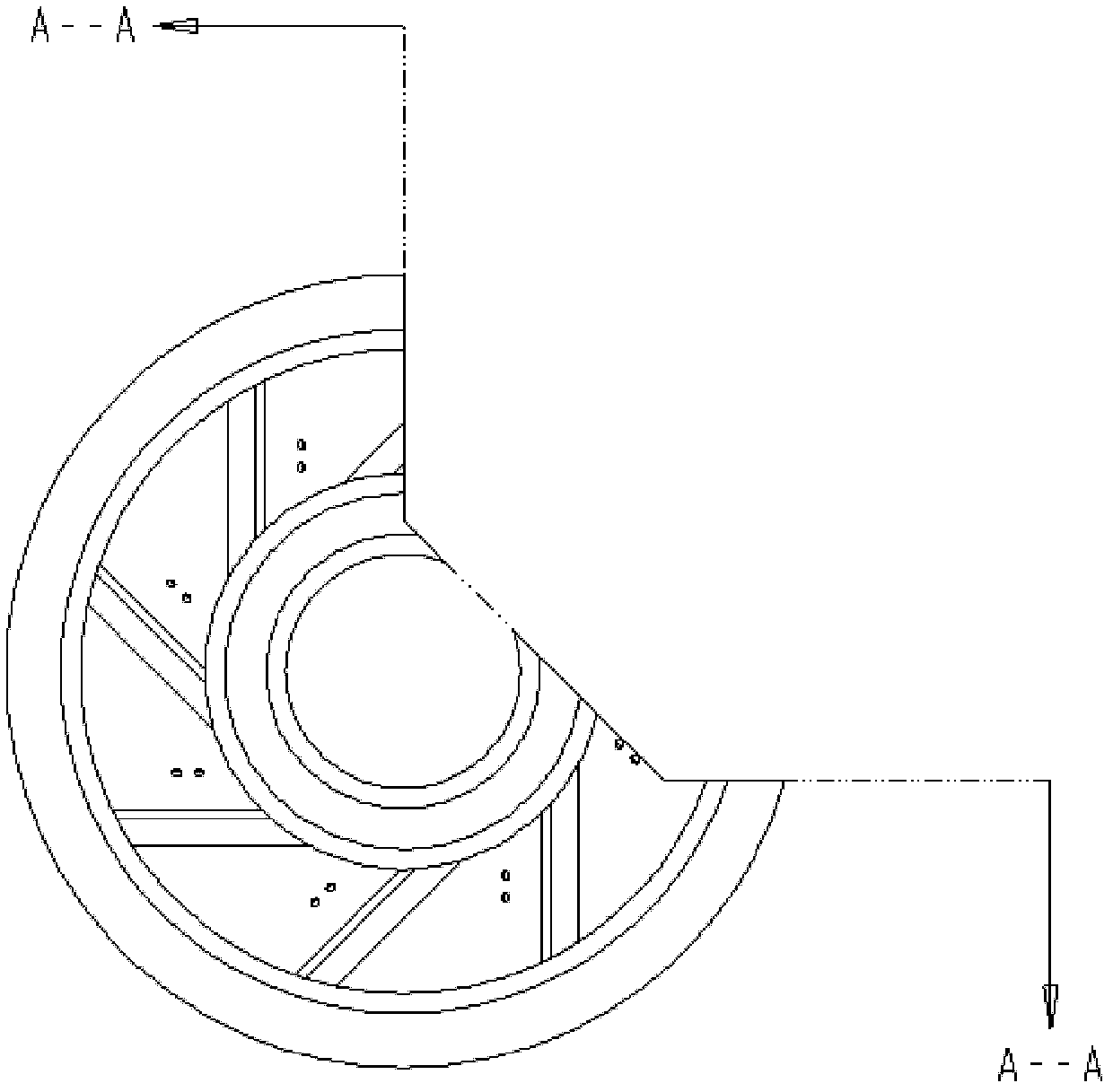

Combustion chamber adopting swirl vane tail edge pre-film atomization mode

ActiveCN104329689AAvoid cokingGreat momentumContinuous combustion chamberCombustion chamberGas mixing

The invention provides a combustion chamber adopting a swirl vane tail edge pre-film atomization mode. The combustion chamber comprises a combustion chamber flame tube, a center level oil and gas mixing assembly and a main combustion level oil and gas mixing assembly which is arranged at the front end of the combustion chamber flame tube and the periphery of the center level oil and gas mixing assembly. The main combustion level oil and gas mixing assembly comprises a main combustion level swirl channel, N wedge-shaped swirl vanes and M vane interior oil paths; the N wedge-shaped swirl vanes are slantly fixed to the interior of the main combustion level swirl channel, and the M vane interior oil paths are arranged in at least one part of wedge-shaped swirl vanes respectively; the front end of each vane interior oil path is connected with a main combustion level oil cavity, and the tail end of the each vane interior oil path extends to the tail edge of the corresponding wedge-shaped swirl vane; the M is smaller than or equal to the N. The swirl vanes are wedge-shaped; velocity gradients are formed at the tail edges of the swirl vanes; a fuel liquid film flowing out of the tail edges of the swirl vanes is rapidly shorn and atomized under the action of the velocity gradients; the oil and gas blending distance is short, and the flame length and the length of the flame tube are shortened.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

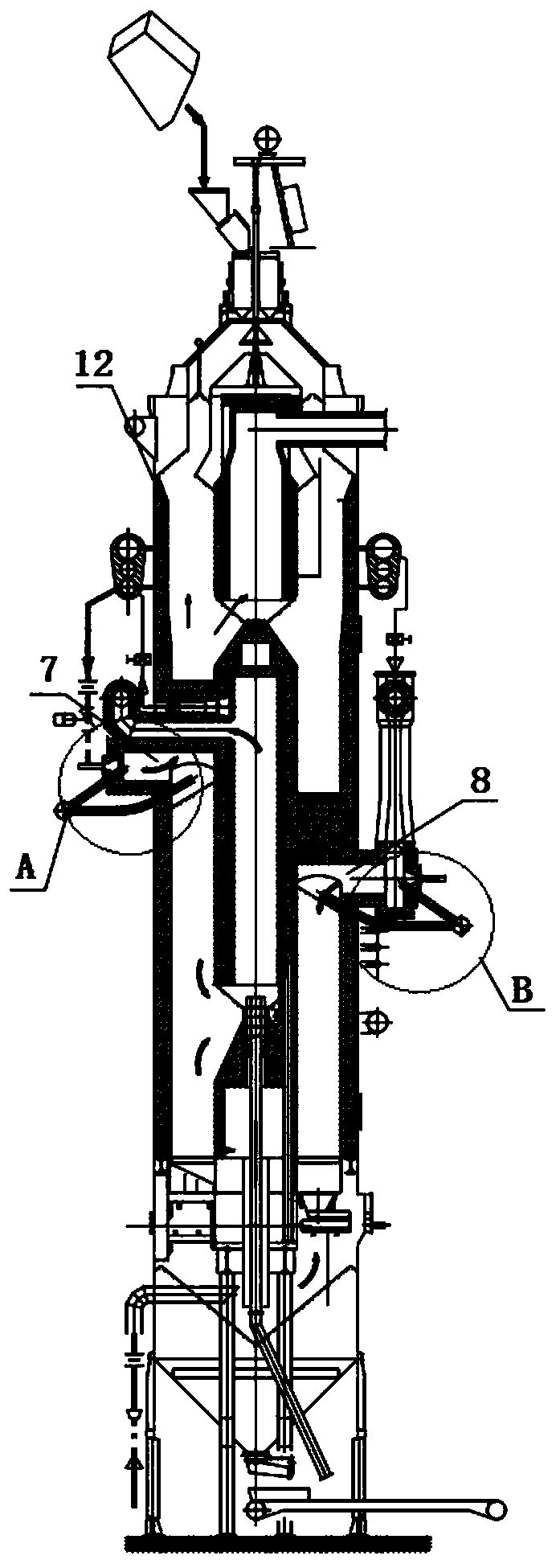

Apparatus and process for producing perlite

InactiveUS6244860B1Improve throughputLower energy requirementsMuffle furnacesAluminium silicatesCombustorPulp and paper industry

In an apparatus for producing perlite granules, having an expansion tube and one or more burners arranged at one end of the expansion tube, the combustion air is blown into the flame through one or more combustion air nozzles. An additional subsonic nozzle is arranged in at least one combustion air nozzle. In a process for expanding raw perlite in the updraft from a flame, with the introduction of oxygen or oxygen-enriched air into this flame, the oxygen or oxygen-enriched air is introduced axially into the flame through subsonic nozzles.

Owner:MESSER GRIESHEIM GMBH

Burner for gas boiler

InactiveUS20100294214A1Improve flame holding effectReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The present invention relates to a burner for gas boiler that produces stable combustion without lifting of flame by stably guiding gas and primary and secondary air to the inside of an upper plate and having a first slope having main fire holes to improve efficiency of ignition and combustion in a burner main body, in which a gas mixture channel is formed by a guide plate disposed at the center of the burner main bodyburner bodyor stable mixing of gas and the primary air.

Owner:KYUNGDONG NAVIEN

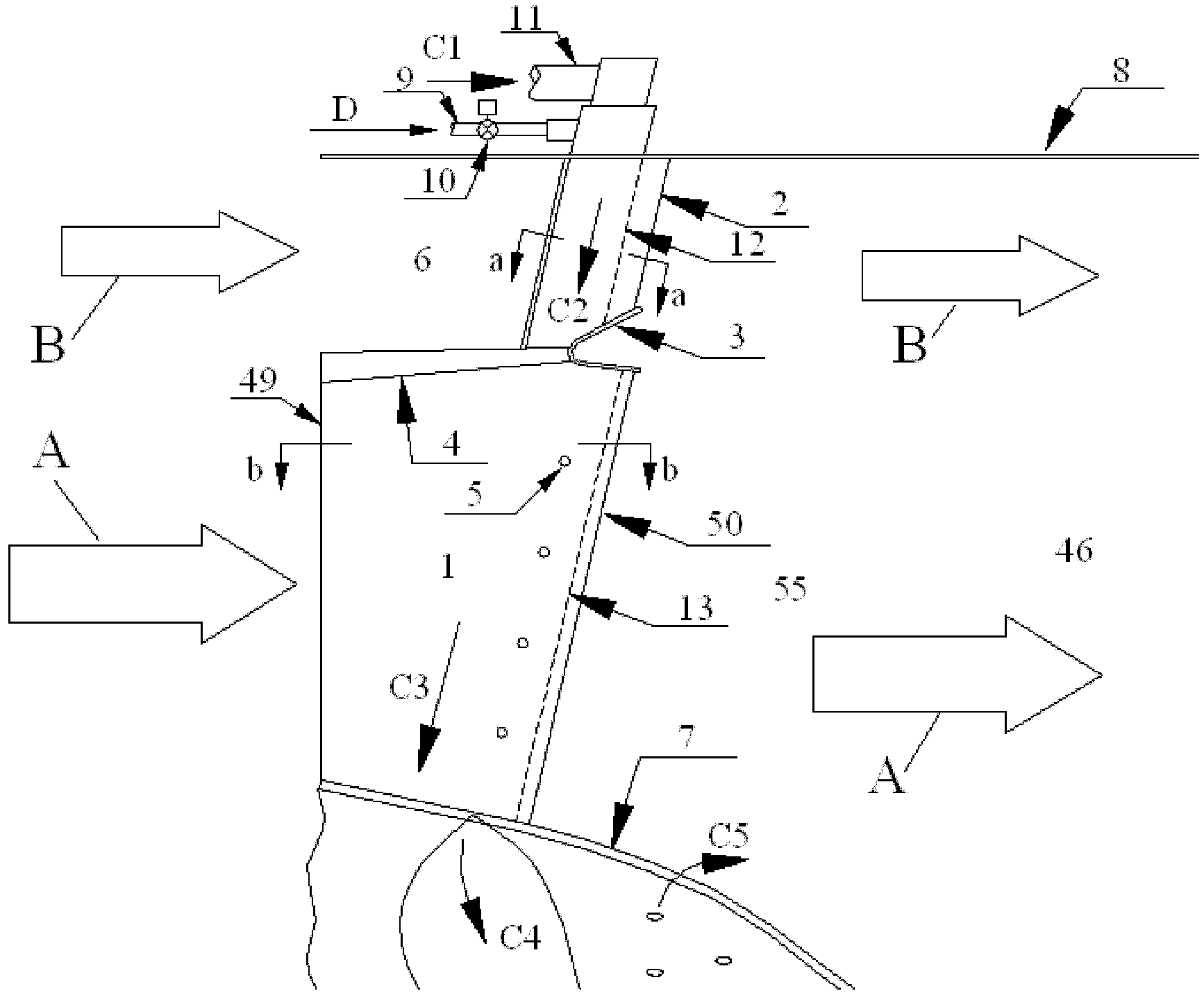

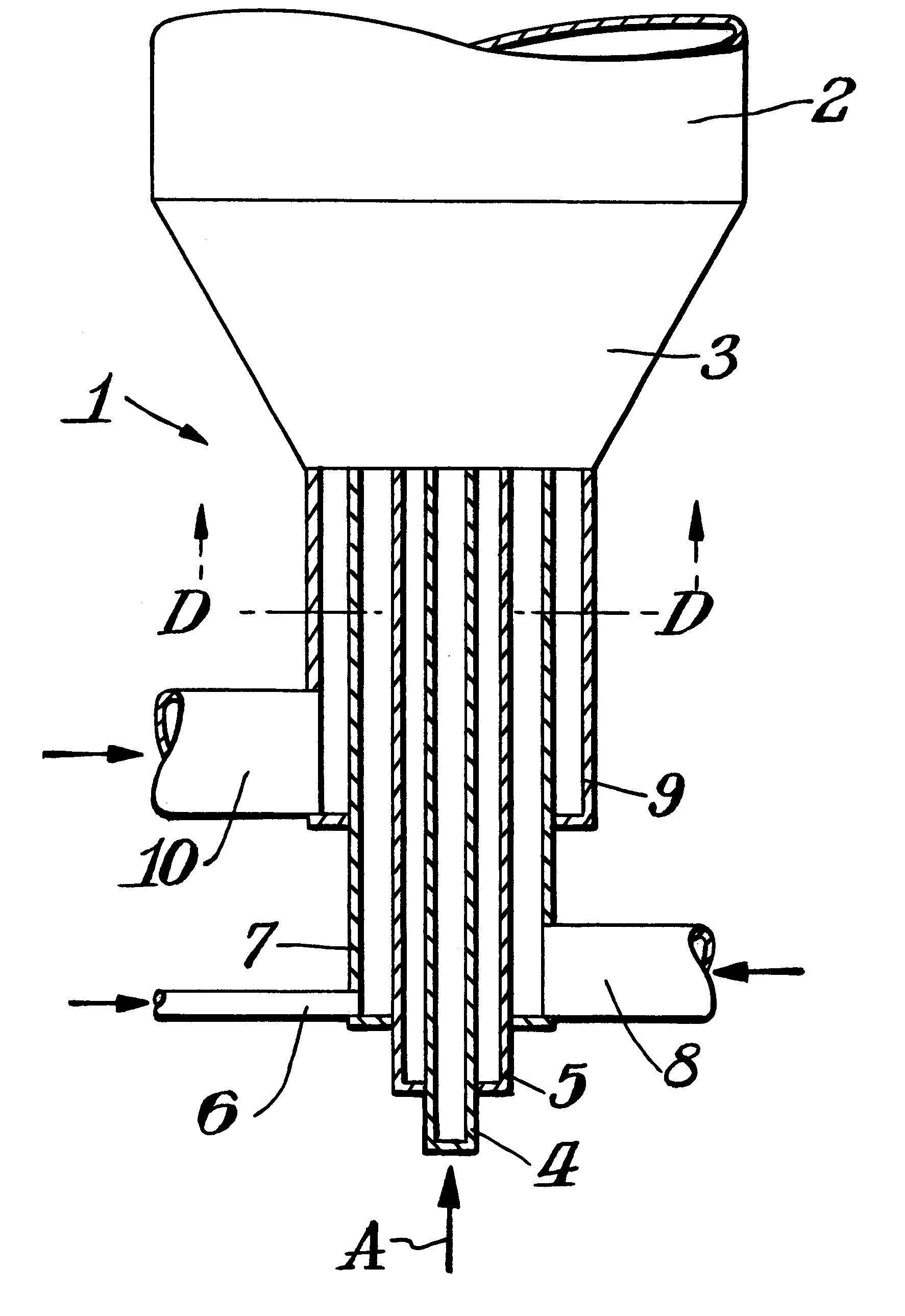

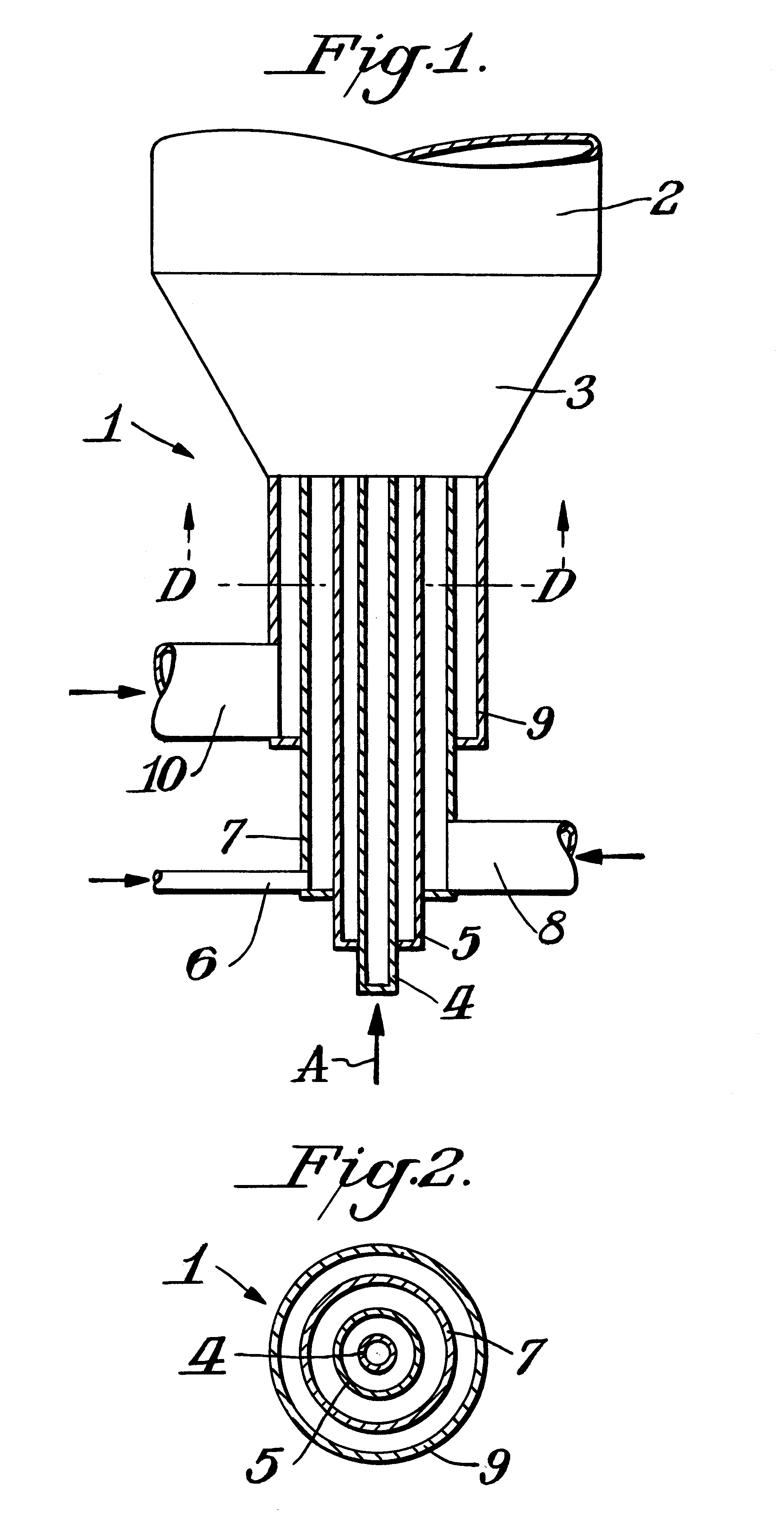

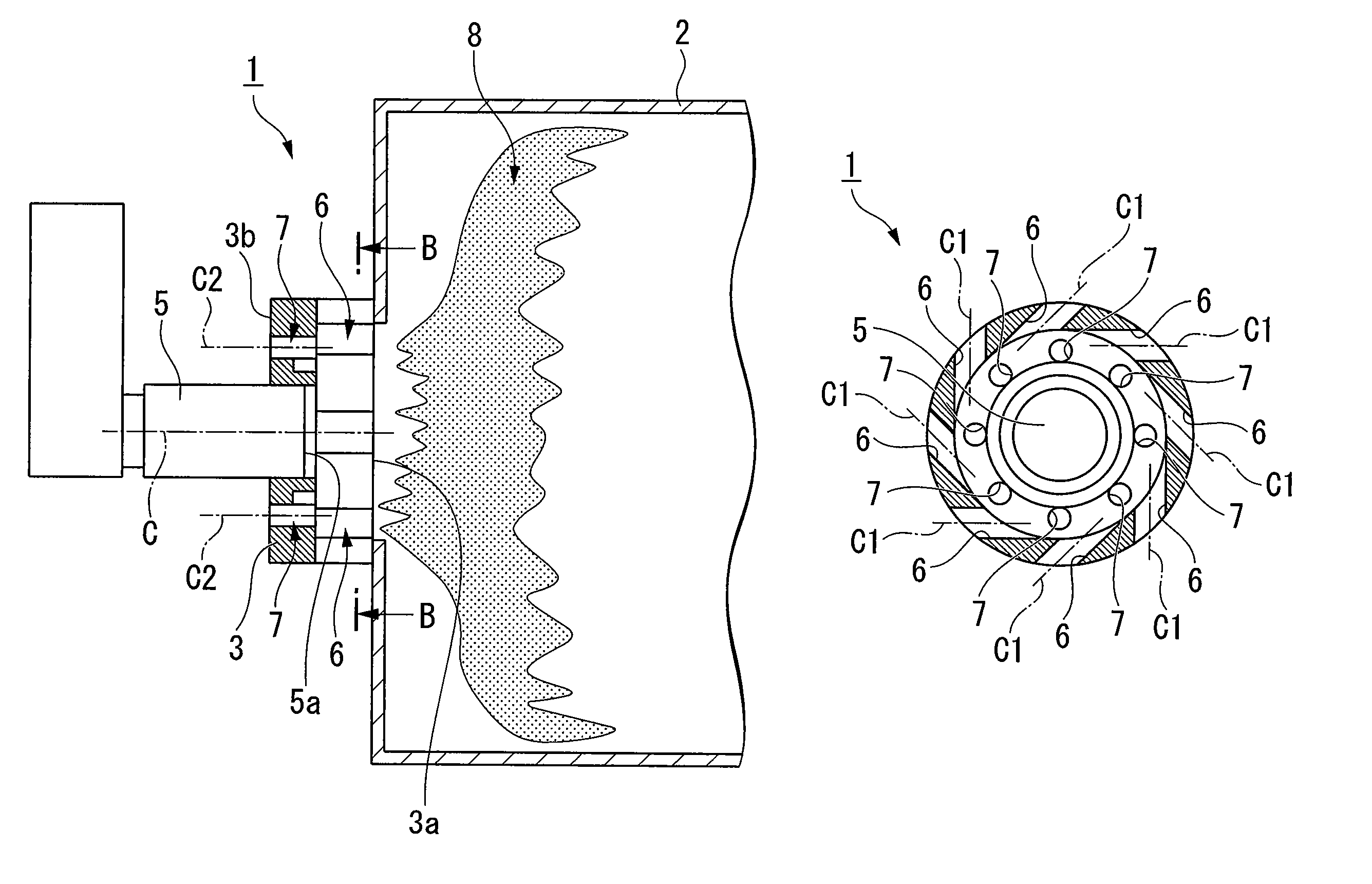

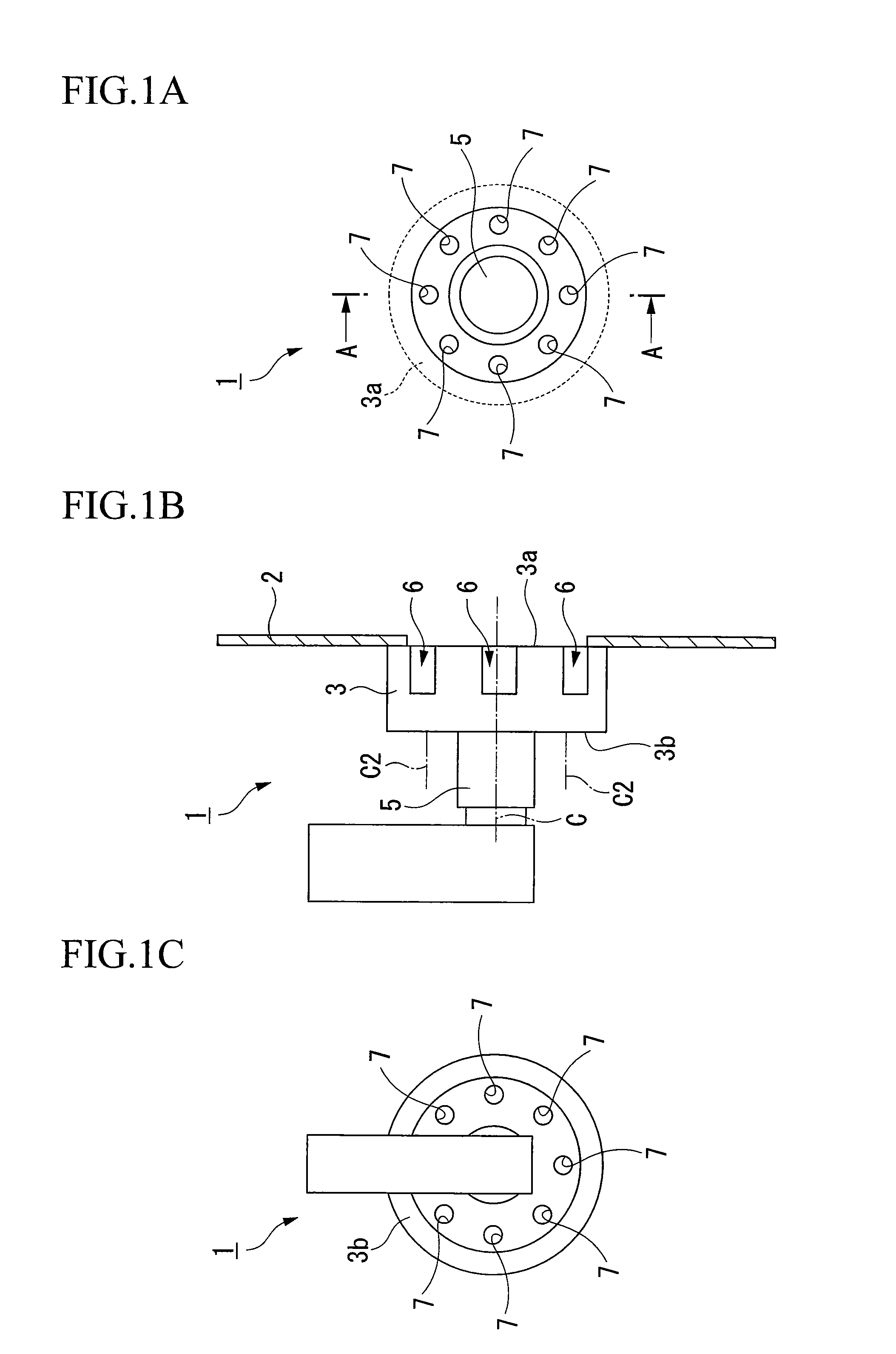

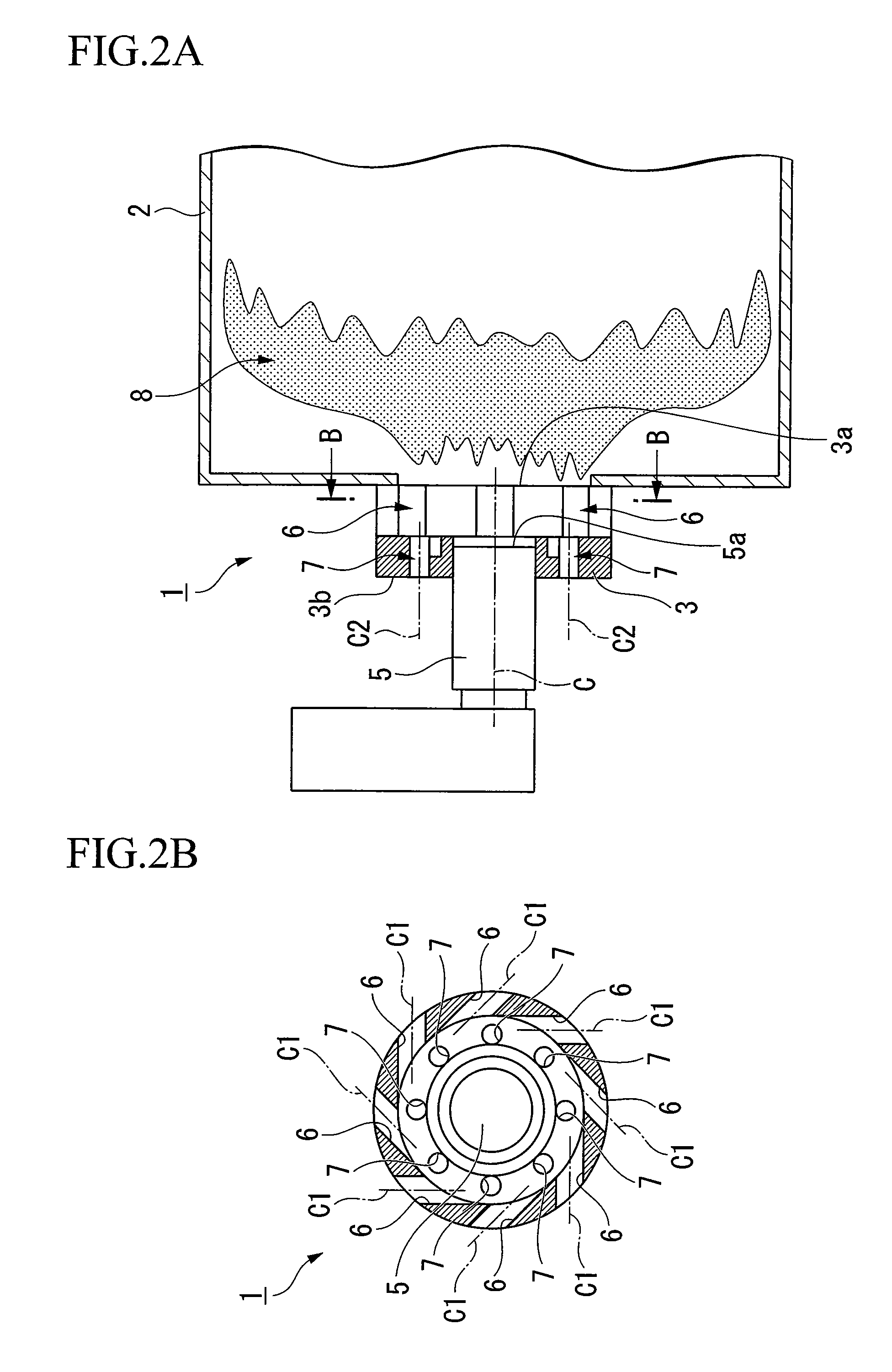

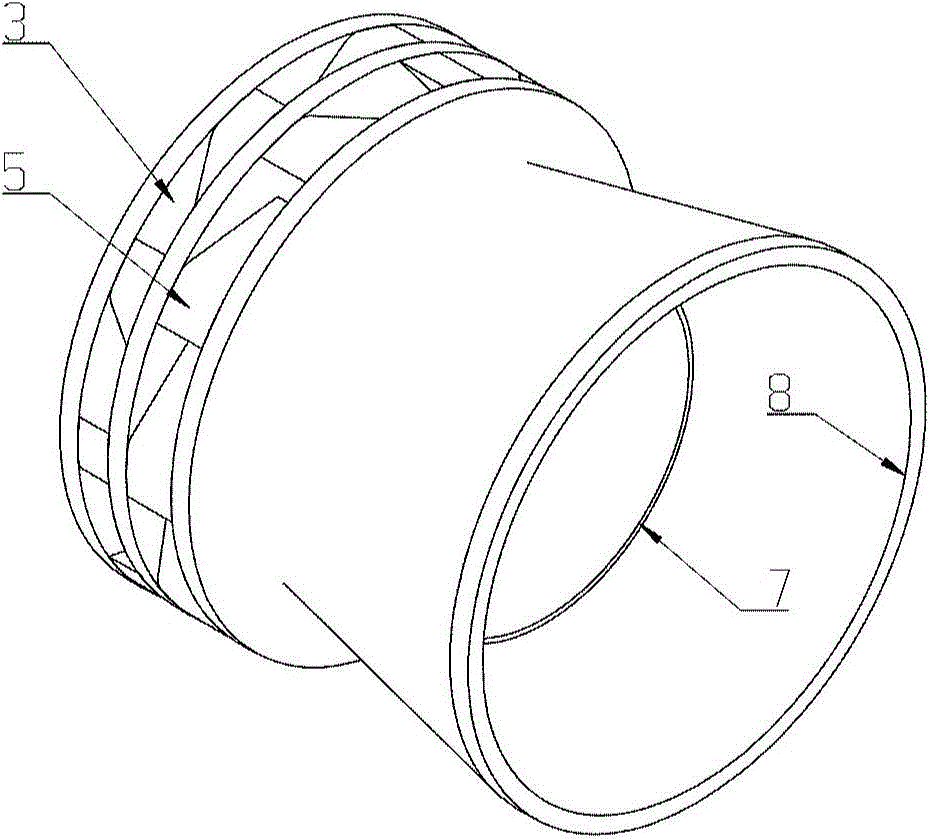

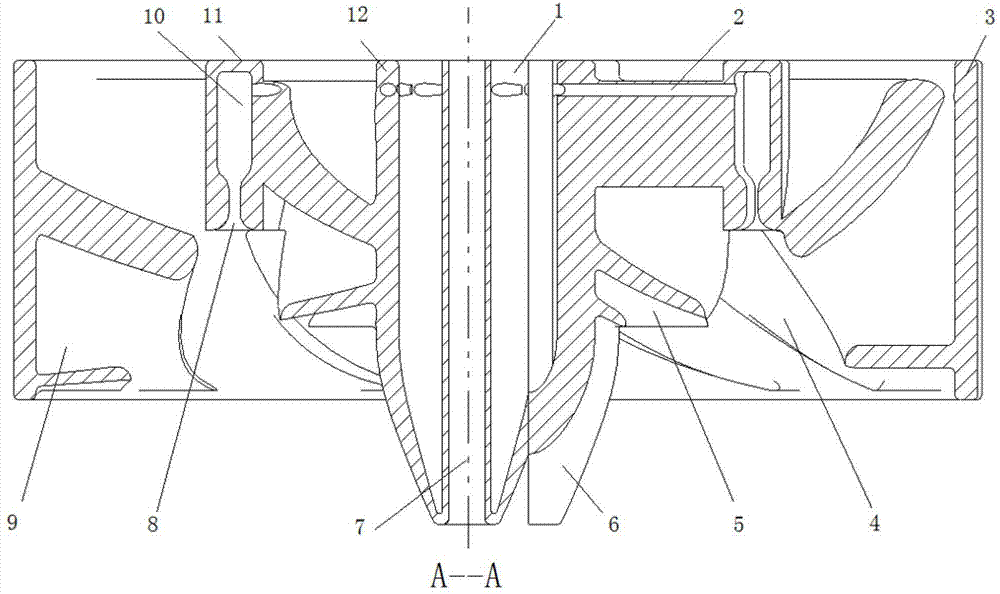

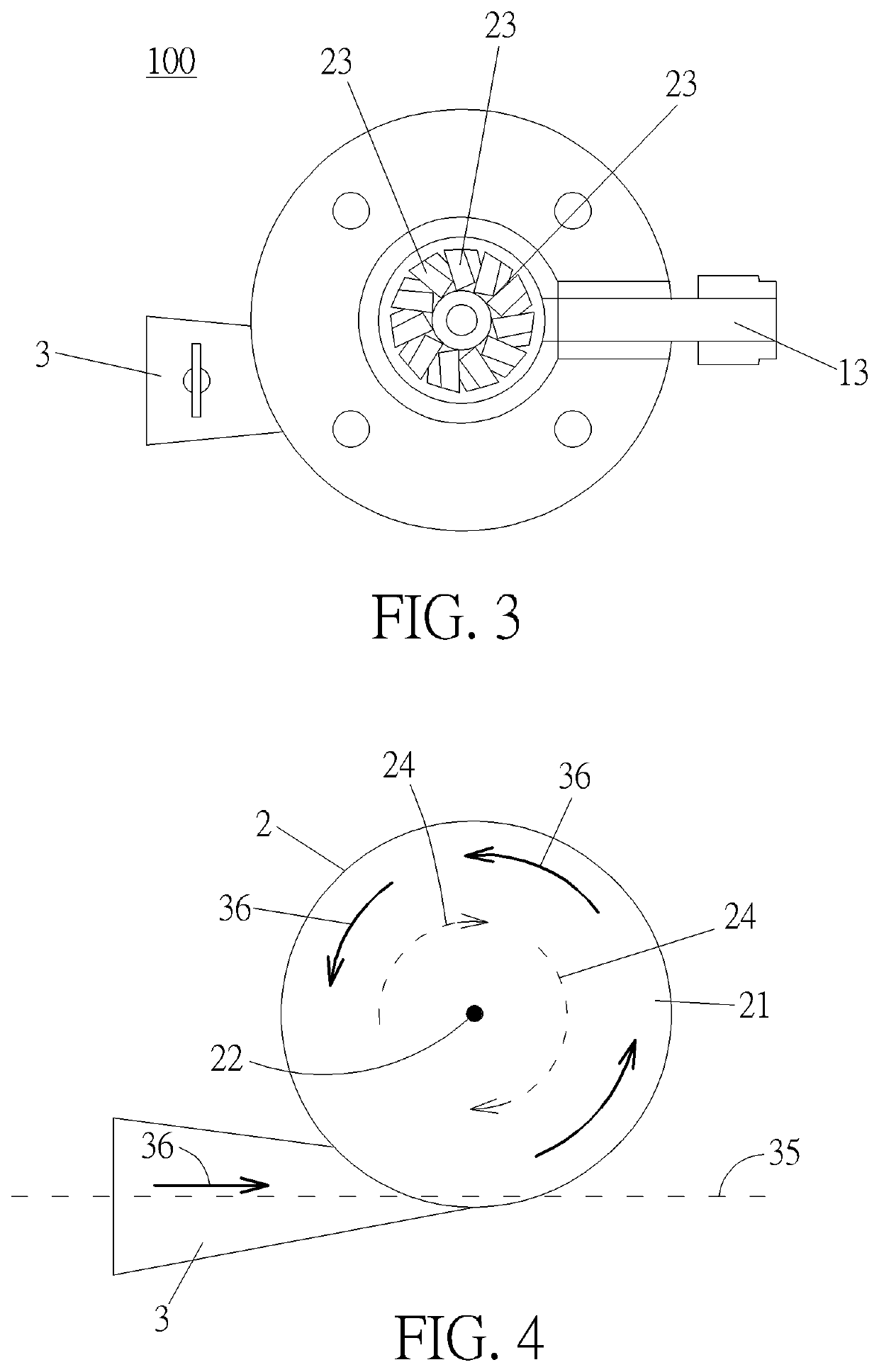

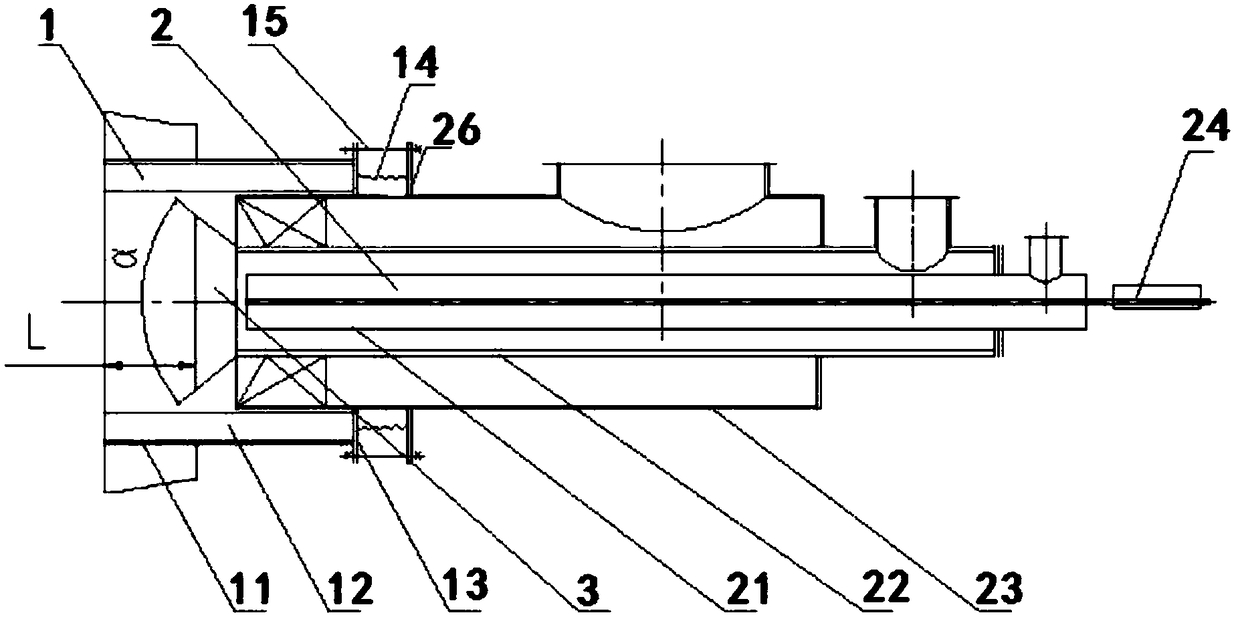

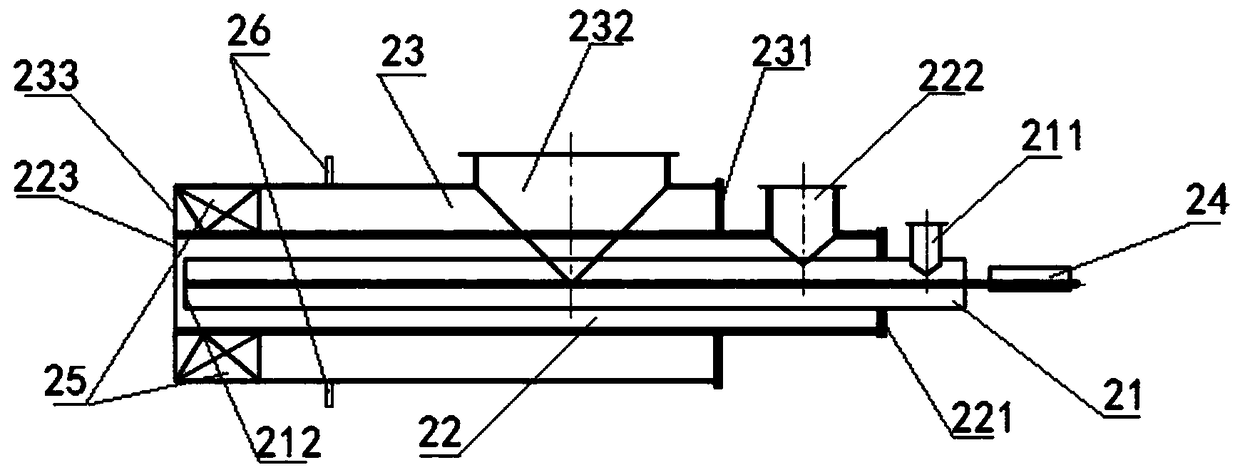

Burner for combustion chamber and combustion method

ActiveUS7913494B2Shorten flame lengthImprove combustion efficiencyBurnersContinuous combustion chamberCombustorEngineering

A burner 1 for combustion chamber is provided with a cylindrical mixing portion 3 that mixes air for combustion (oxidizing agent) and fuel in the interior thereof and has one end 3a that opens to a combustion portion 2; a spray nozzle (fuel spraying portion) 5 that sprays fuel in the mixing portion 3, being disposed on another end 3b of the mixing portion 3; first blowing ports 6 that introduce the air for combustion to the mixing portion 3 to form a swirling flow with the fuel, being disposed to open to the inner wall of the mixing portion 3; and second blowing ports 7 that additionally introduce the air for combustion to the mixing portion 3, opening in a direction different from the first blowing ports 6 and being disposed further to the other end 3b side of the mixing portion 3 than the swirling flow. The burner for combustion chamber and combustion method of the present invention can shorten the flame length in the central axial direction by improving the combustion efficiency even during low loading and shorten the overall length of the burner for combustion chamber in the central axial direction.

Owner:IHI CORP

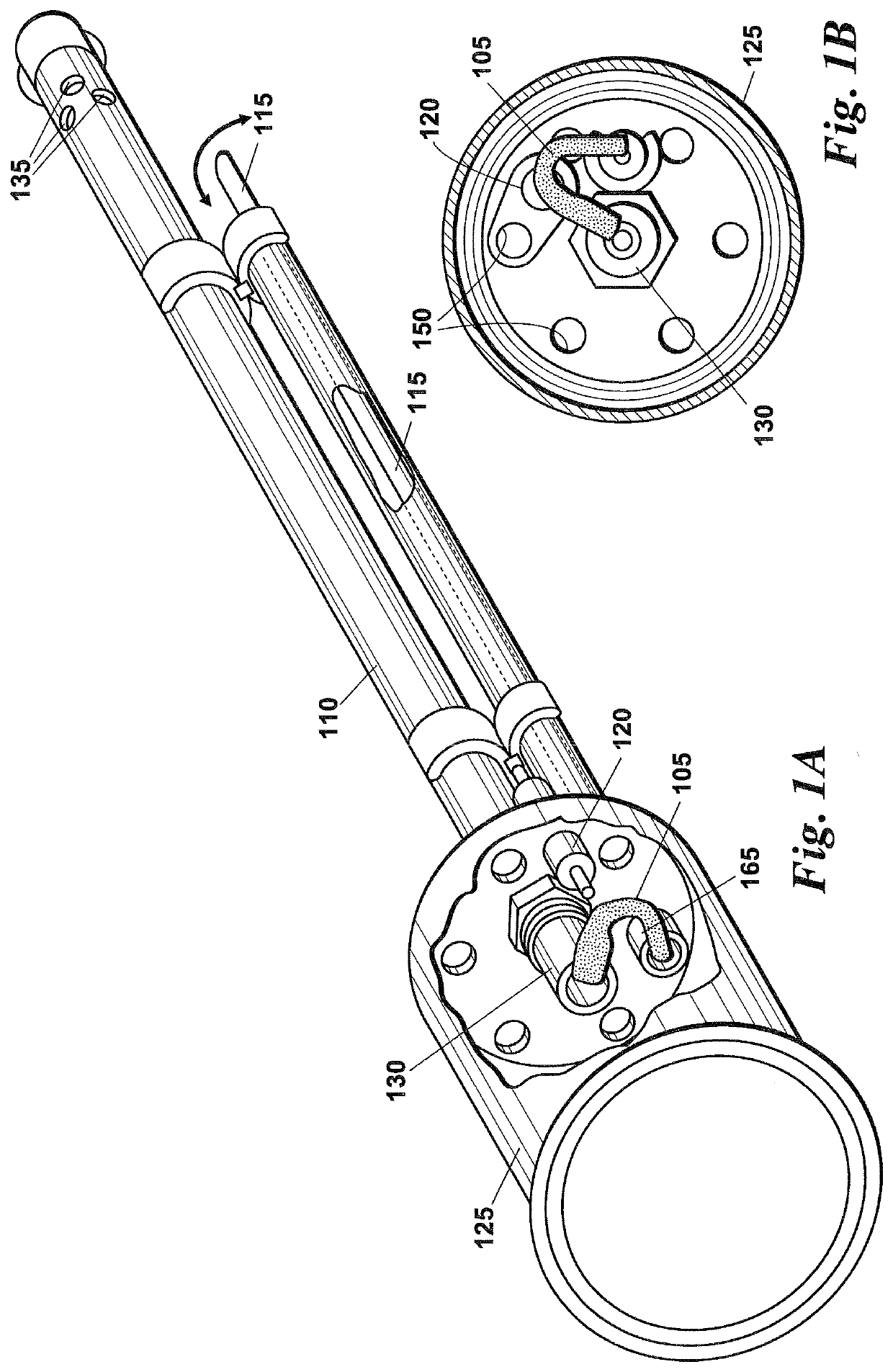

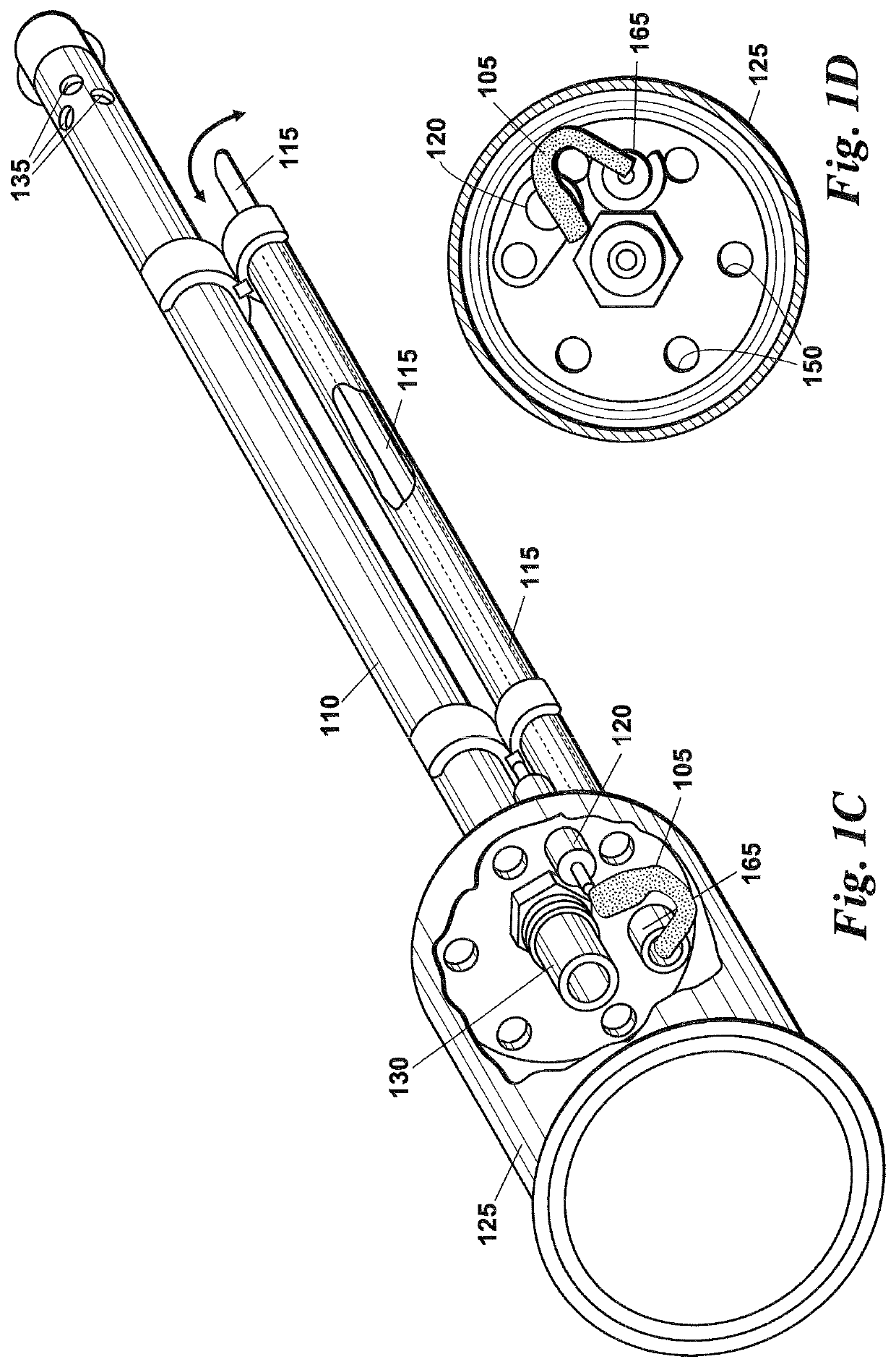

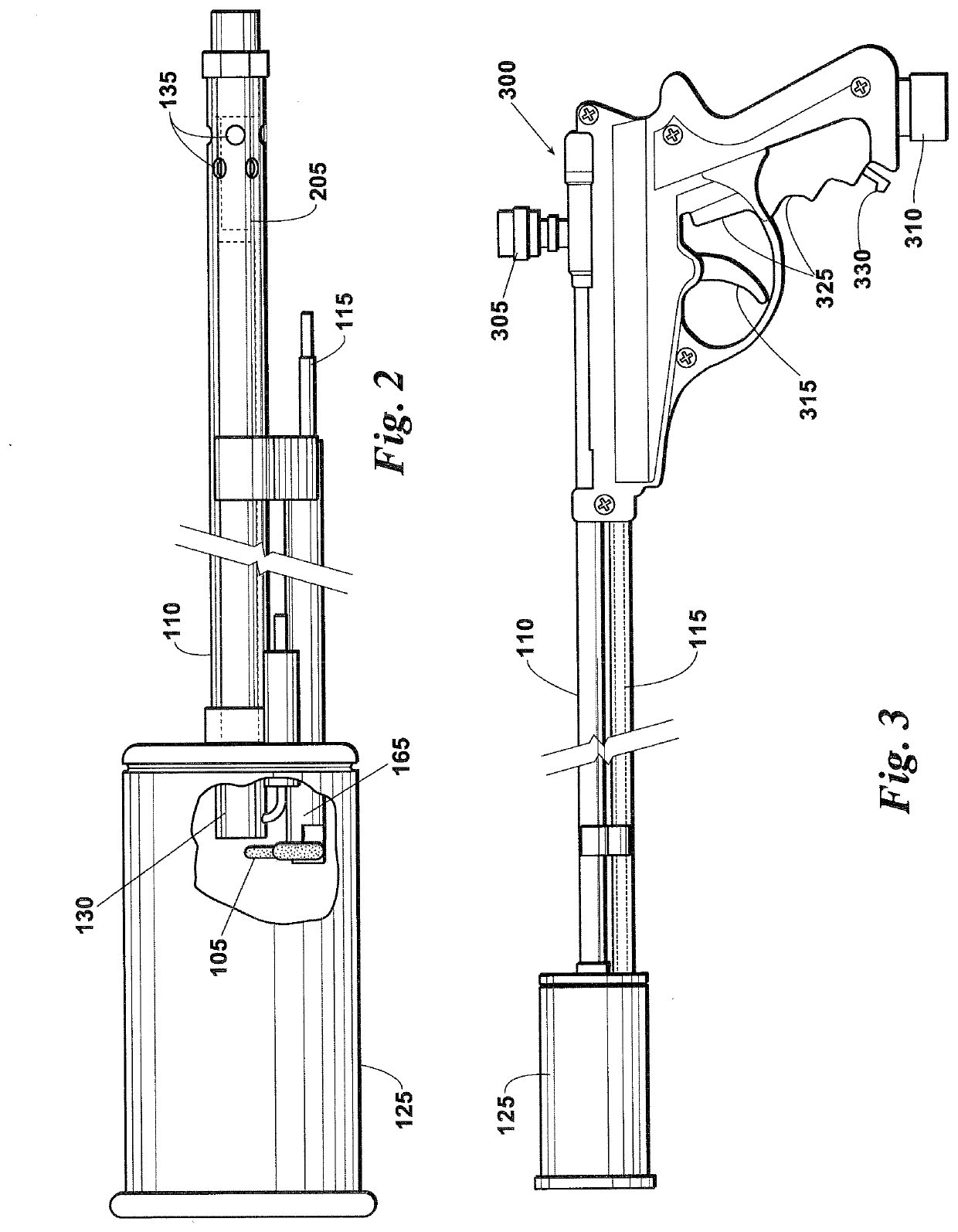

Gas powered torch

ActiveUS20200132298A1Started quickly and easilyReliable ignitionElectric spark ignitersGaseous fuel burnerLiquid propaneDirect combustion

Various embodiments utilize a novel approach to igniting the natural gas flame that is emitted from the end of the torch. According to one embodiment a rotary diverter within the ignition bell of the GrillGun is used to shunt a portion of the higher velocity gas flow to an area in the bell where the ignition spark is out of the direct burning gas stream. According to another embodiment the ignition bell has a plate that largely covers its open end that reduces the length of the flame that is emitted and focuses it. Still another embodiment has a check valve that operates to stop the flow of gas to the gas conduit when the GrillGun is dropped or tipped over or liquid propane is otherwise presented into the check valve by any other means.

Owner:HEALEY ROBERT W

Steam combustion-supporting type torch burner

ActiveCN1959211AHigh smoke suppression effectExtend your lifeIncinerator apparatusGaseous fuel burnerCombustorTorch

A torch burner of steam combustion-assisting type consists of cylinder body, central jet pipe of steam, steam ring pipe, nozzle and jet pipe of steam-air. It is featured as setting nozzle jacketed on steam ring pipe far from top of cylinder body, aligning nozzle to entrance of jet pipe of steam-air and setting steam jet component far from high temperature region at top of burner.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

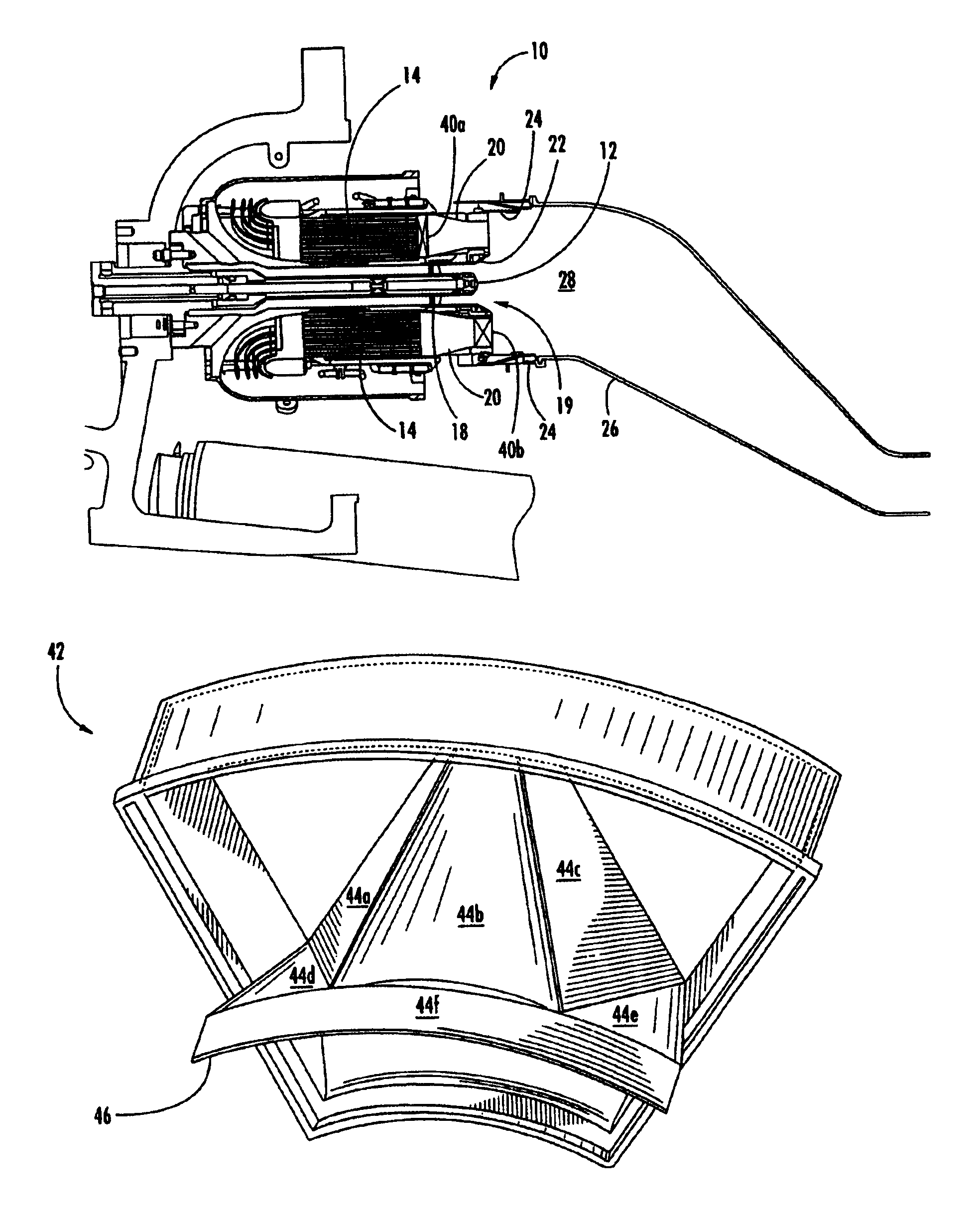

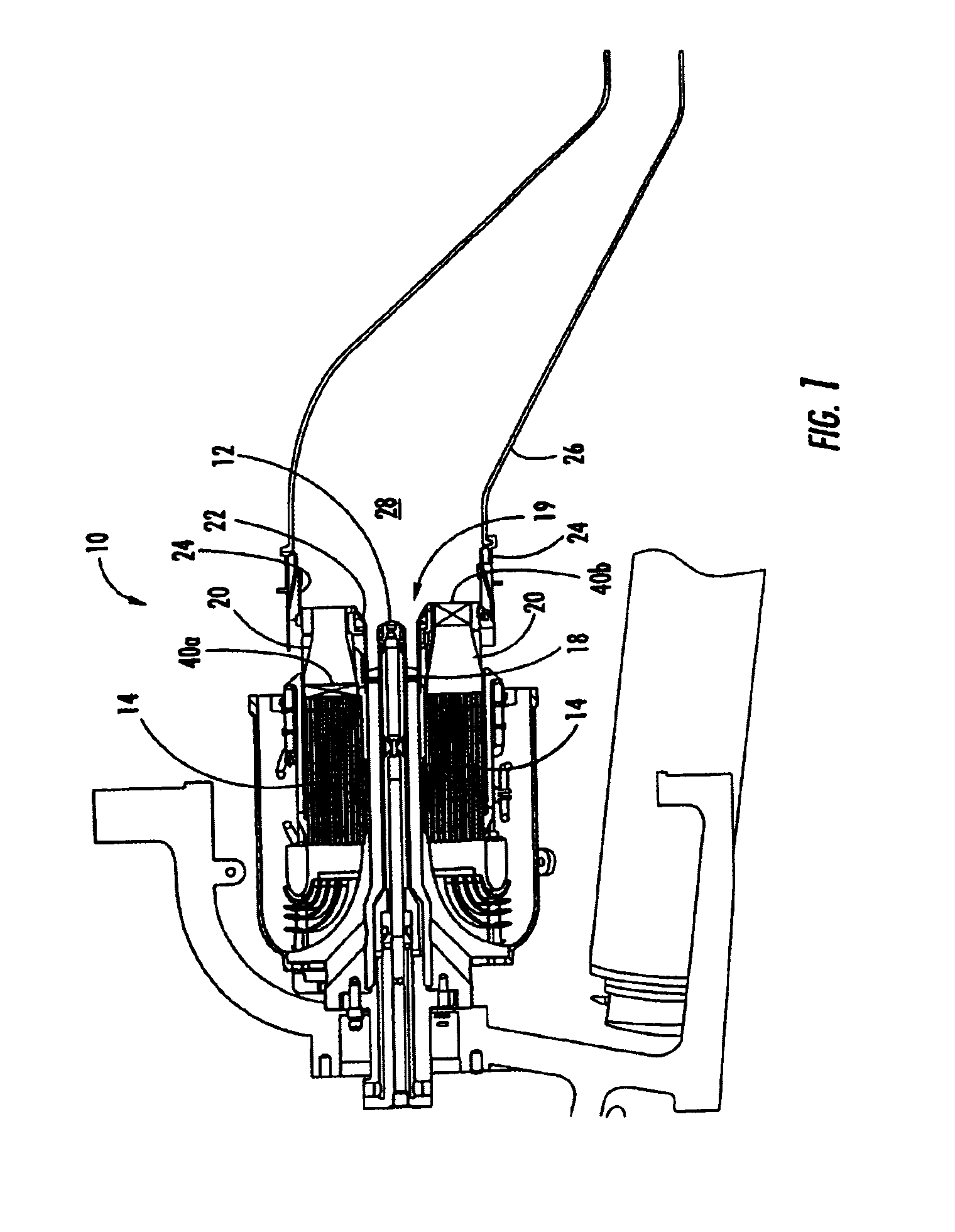

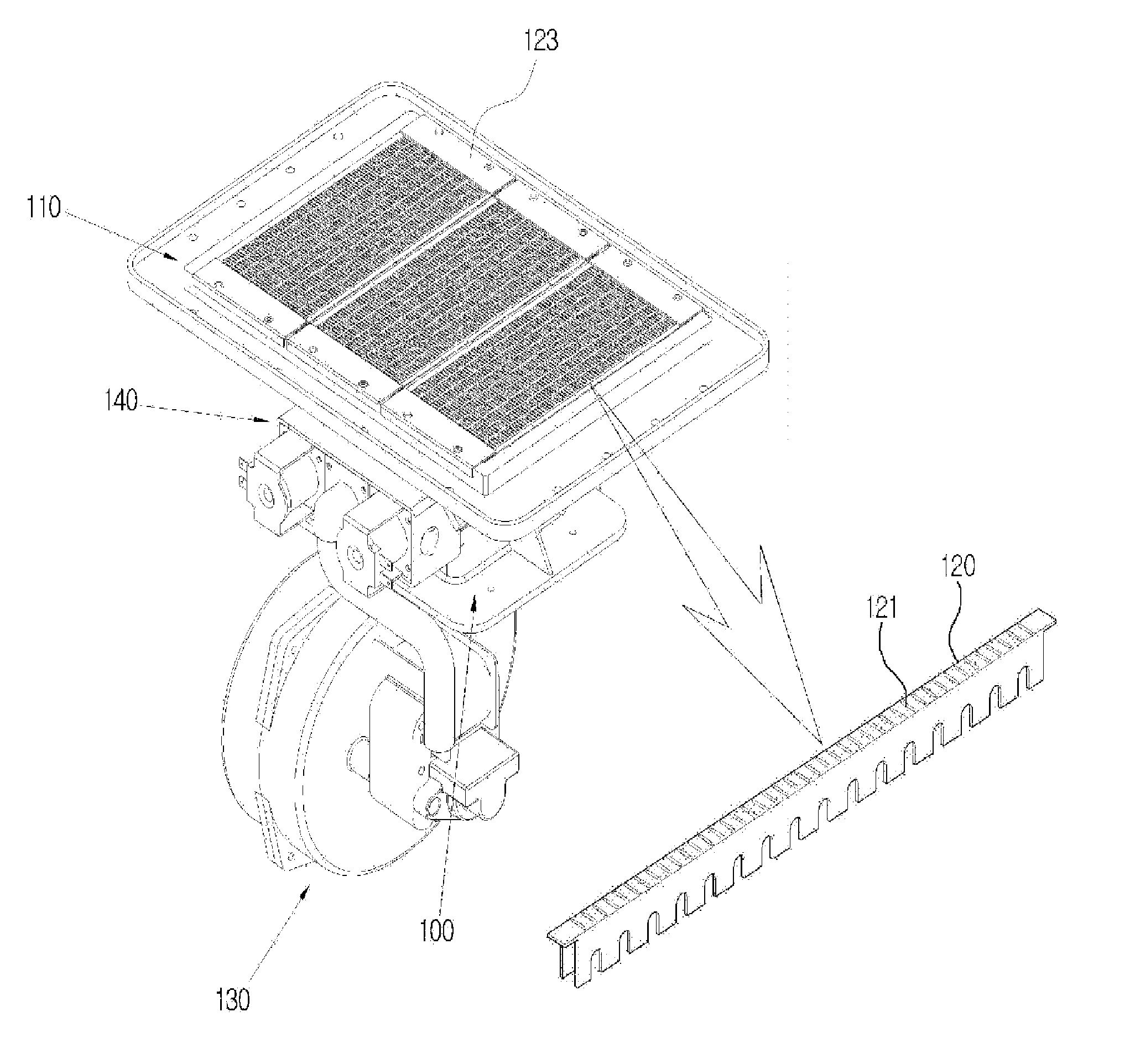

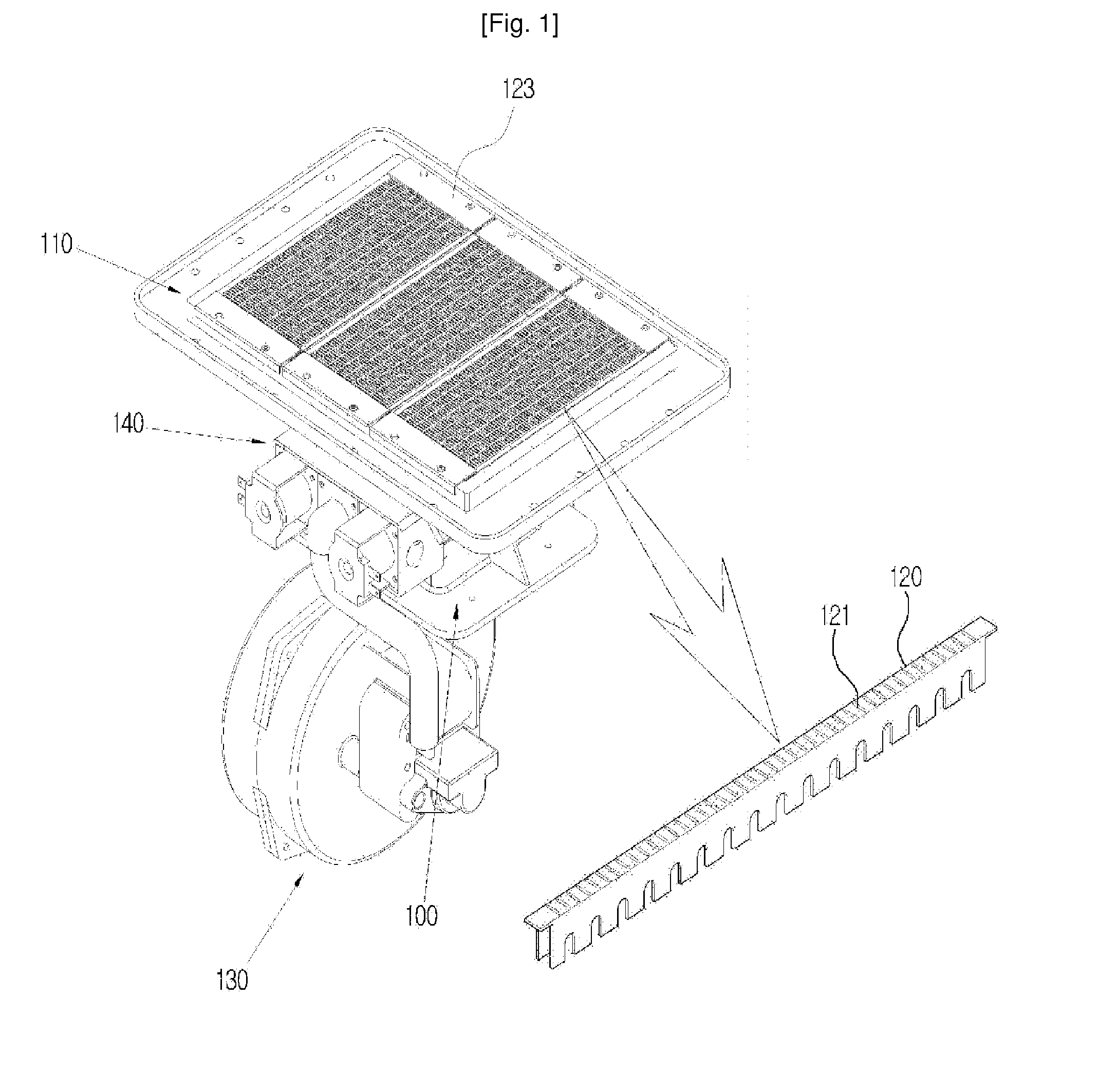

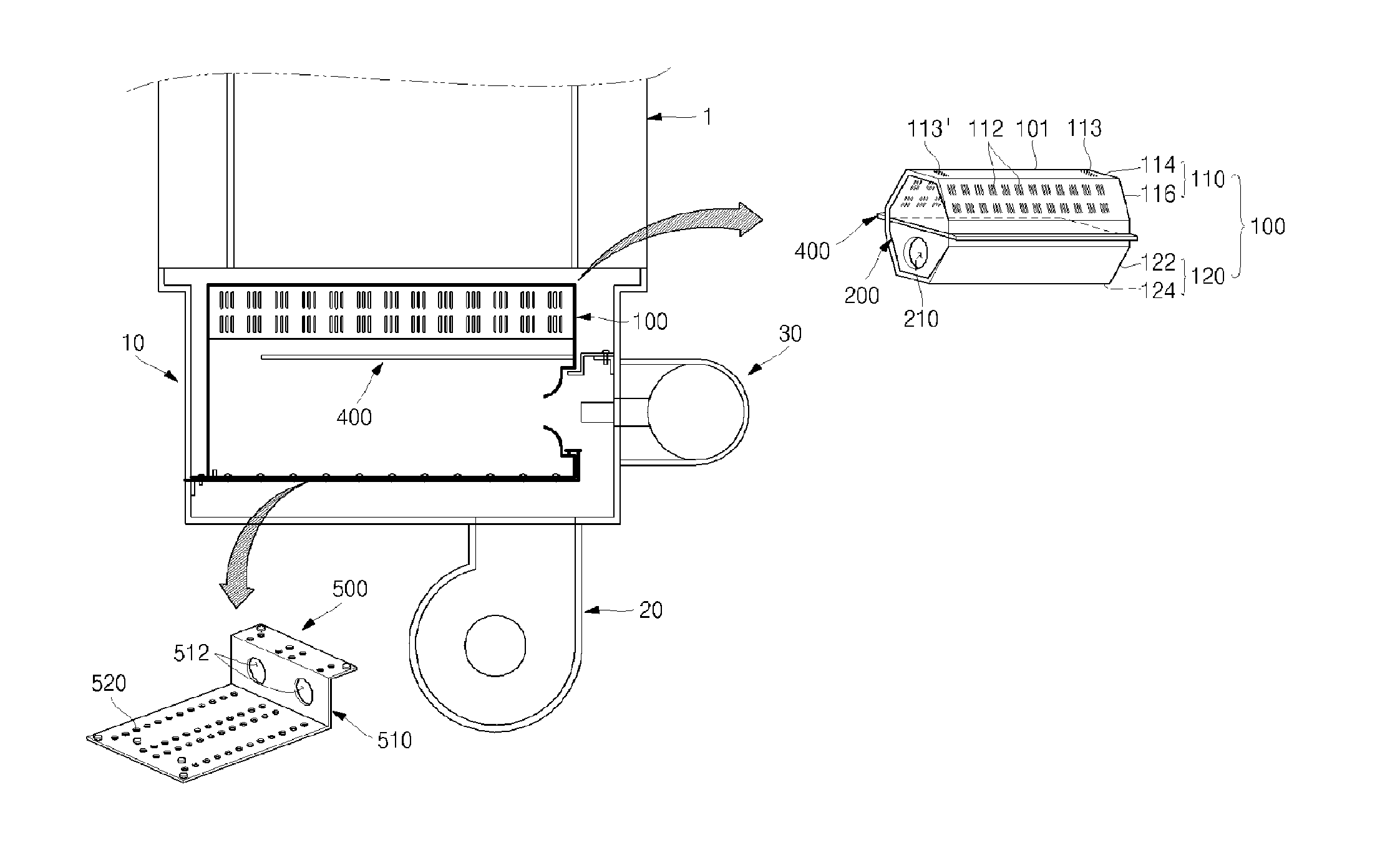

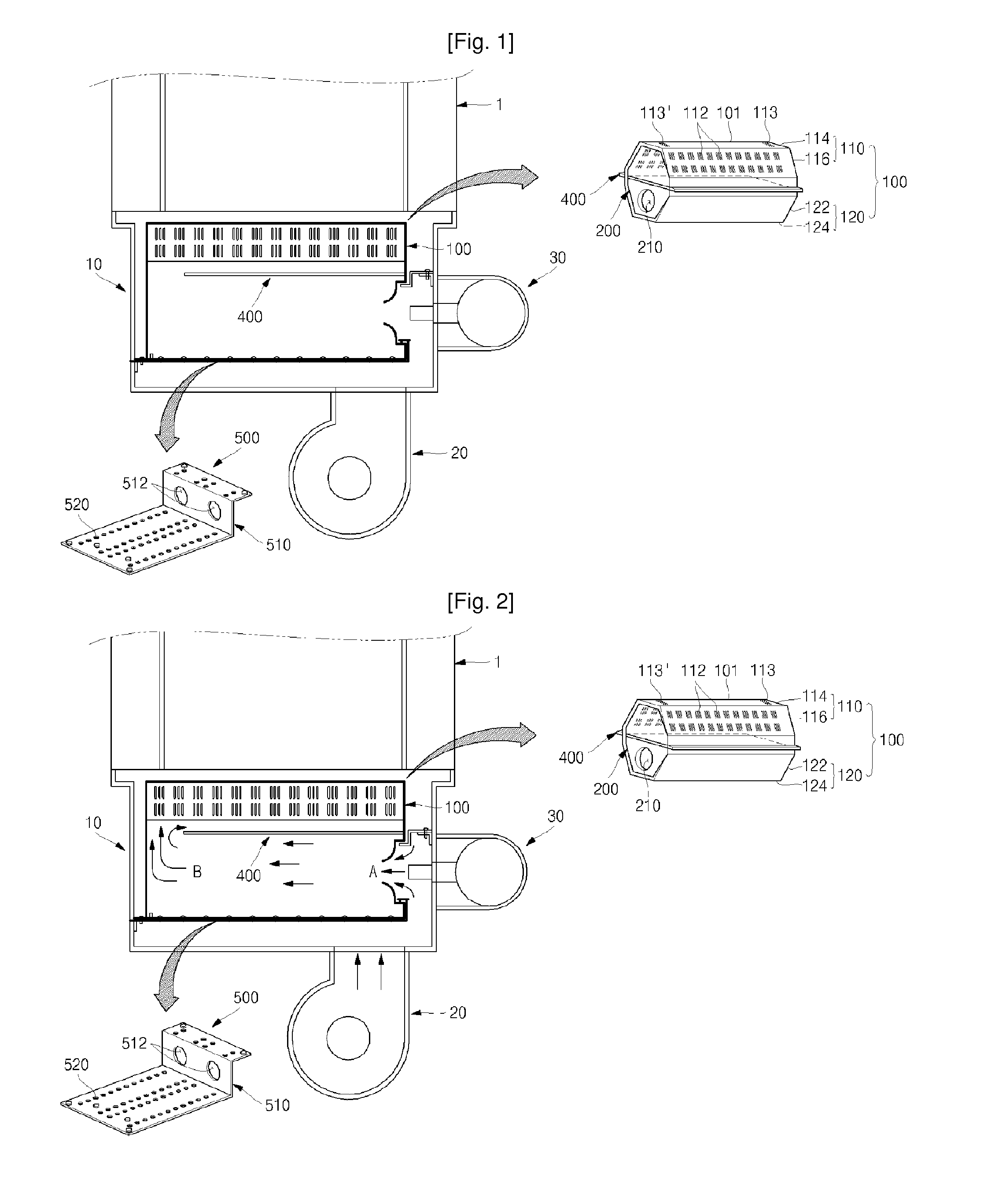

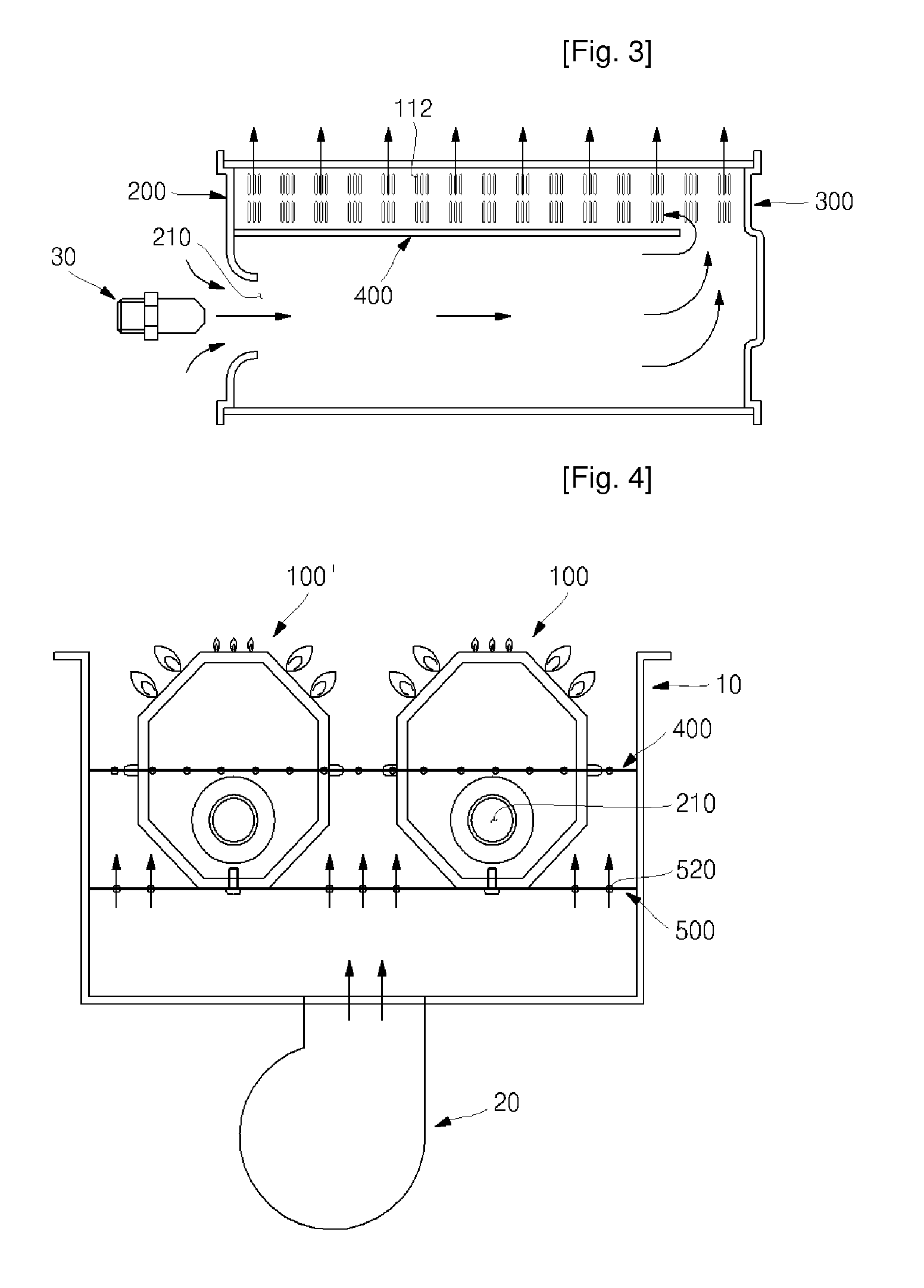

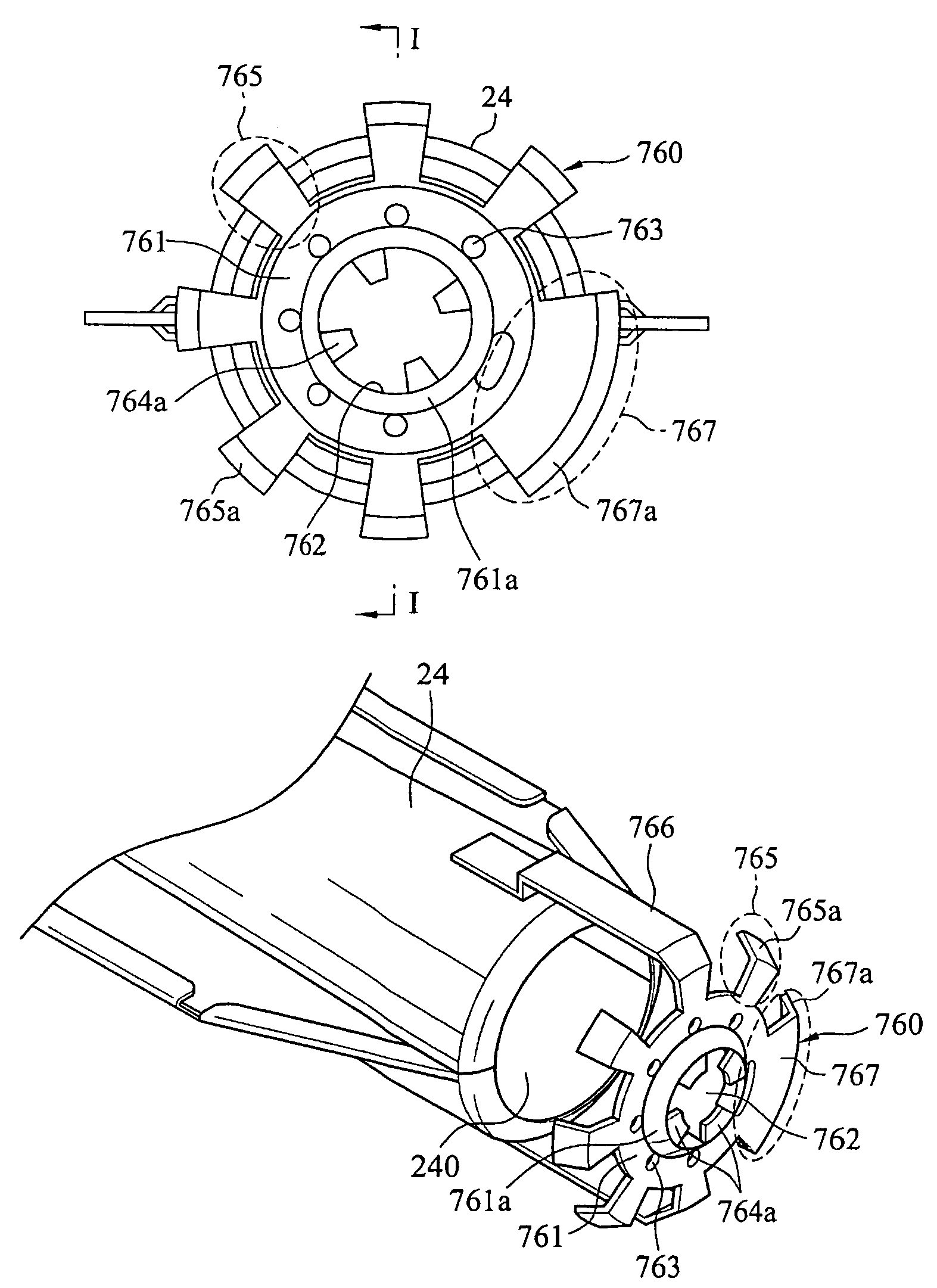

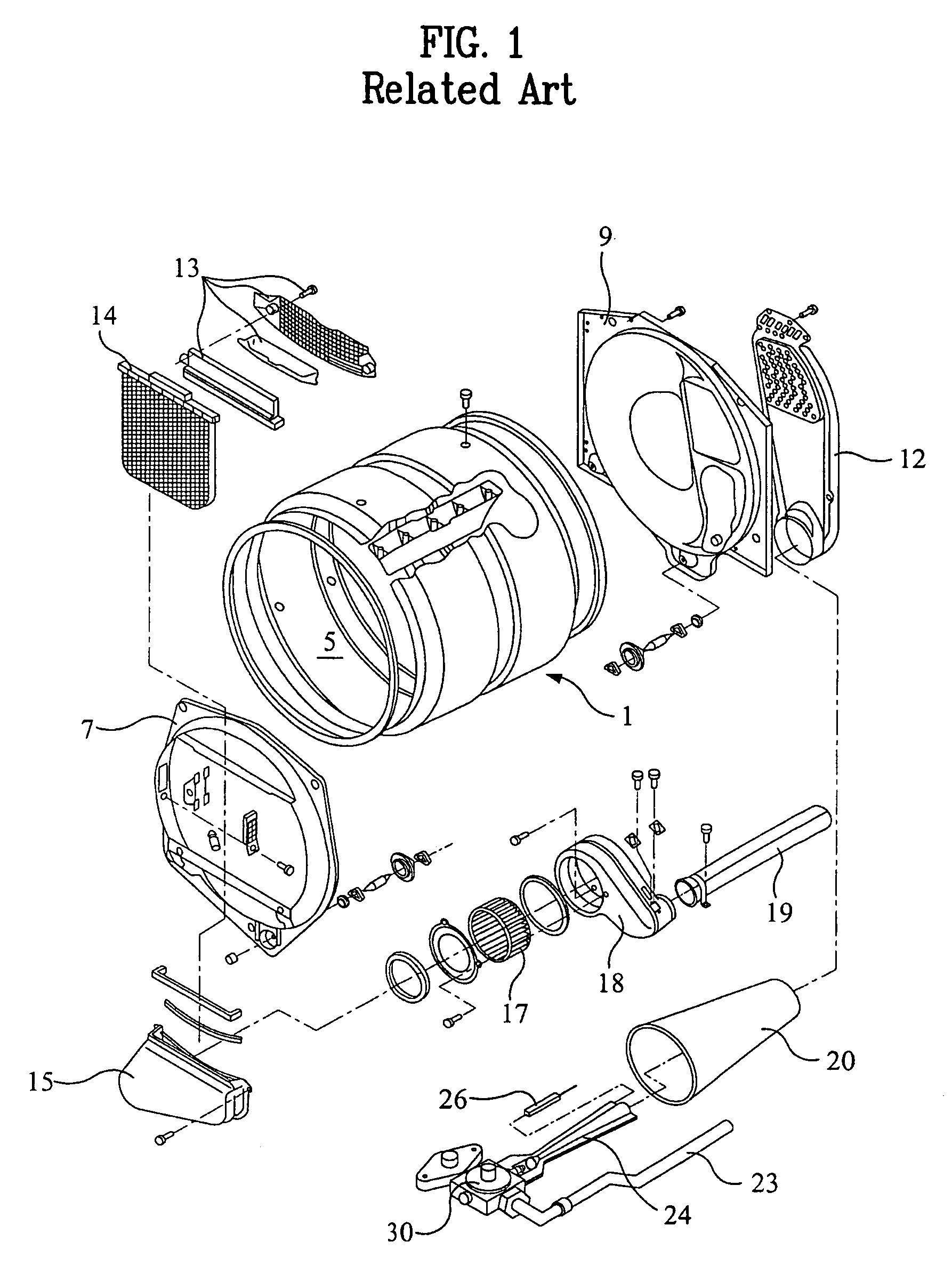

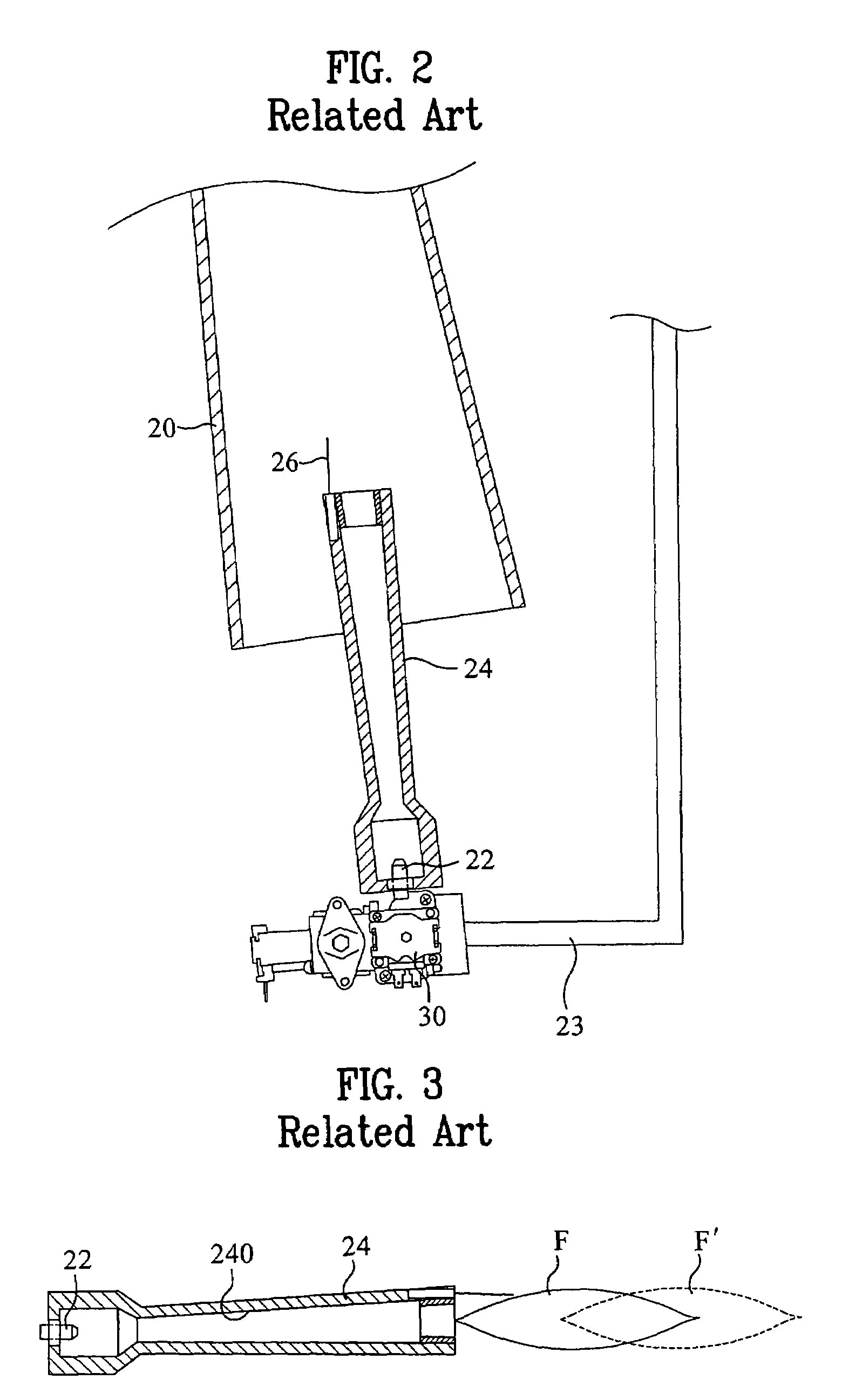

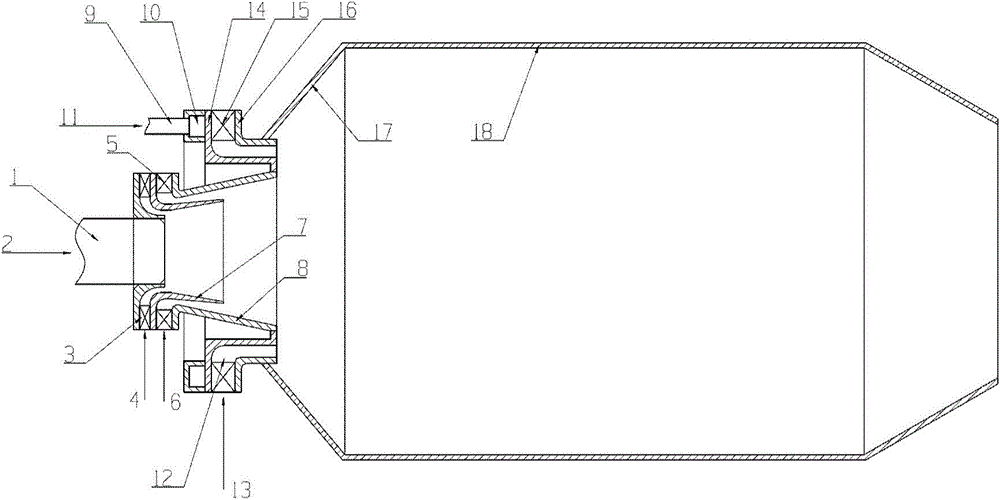

Laundry dryer having gas combustion apparatus

ActiveUS7172413B2Avoid adjustmentShorten flame lengthElectric spark ignitersSpray nozzlesCombustionProcess engineering

A gas combustion apparatus of a laundry dryer is provided, by which an initial ignition power is improved to enhance an ignition property. The gas combustion apparatus includes a gas supply; a mixing pipe, having a mixing passage extending from an inlet end to an outlet end, for mixing the supplied gas with primary air, the primary air and gas entering the mixing passage at the inlet end and a gas-and-air mixture exiting the mixing passage at the outlet end; and a flame holder, disposed at the outlet end of the mixing pipe, for separating the gas-and-air mixture exiting the mixing pipe into a complex plurality of jetted streams.

Owner:LG ELECTRONICS INC

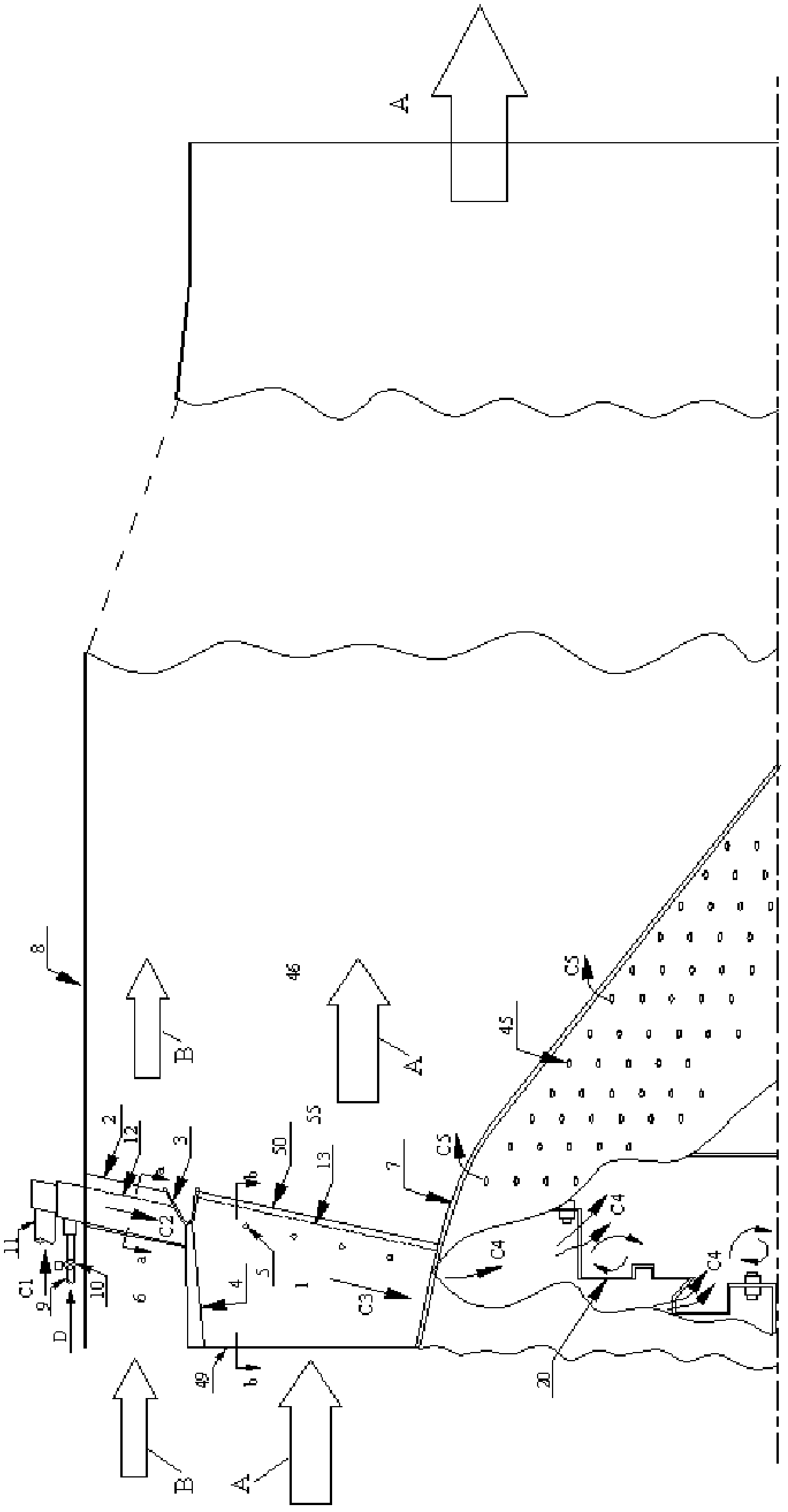

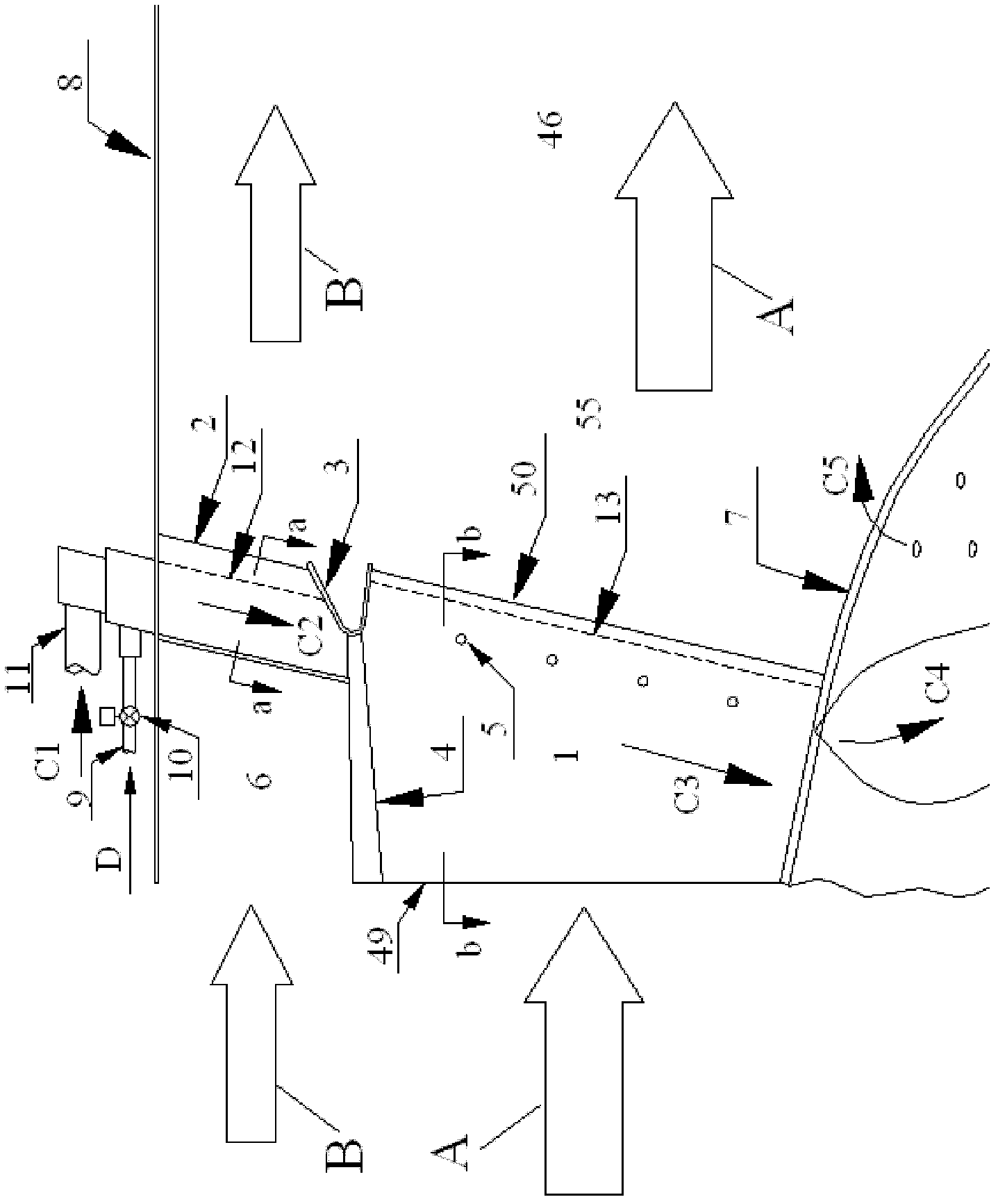

Process method for preparing active calcium oxide through oxygen-enriched calcination

InactiveCN110627384AHigh activityLow ignition pointCalcium/strontium/barium oxides/hydroxidesDecompositionHeat transfer efficiency

The invention discloses a process method for preparing active calcium oxide by oxygen-enriched calcination. The process method the following steps of firstly crushing and sieving raw limestone to enable the particle size of the raw limestone to be 10-55 mm, conveying the raw limestone into a stock bin with a circular cross section, wherein the stock bin is arranged at an upper part of a vertical preheater; then, uniformly conveying the raw materials in the stock bin into the vertical preheater through a blanking pipe, and preheating the raw materials by using high-temperature kiln gas and cooling gas of a vertical cooler; then, feeding the materials into a rotary kiln, and importing oxygen-enriched air from a kiln head to perform oxygen-enriched calcination; and then, feeding the calcium oxide obtained after calcination and decomposition into the vertical cooler to be cooled by air, namely, obtaining the active calcium oxide. According to the process method disclosed by the invention,through the integration of the processes of graded preheating, oxygen-enriched calcination, graded cooling, dynamic temperature monitoring and the like, and the raw materials are preheated by combining the high-temperature kiln gas and the high-temperature gas discharged from the cooler, the heat transfer efficiency of the system is greatly improved, the activity of calcium oxide is obviously improved, the energy consumption is reduced, and the energy conservation and emission reduction are realized.

Owner:HUBEI UNIV

Integrated combustor and stage 1 nozzle in a gas turbine and method

ActiveUS9822649B2Shorten flame lengthContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

An integrated combustor and stage one nozzle in a gas turbine includes a combustion chamber that receives premixed fuel and air from at least one fuel nozzle group at separate axial locations. The combustion chamber includes a liner and a transition piece that deliver hot combustion gas to the turbine. The stage one nozzle, the liner and the transition piece are integrated into a single part. At least one of the axial locations of the one or more fuel nozzle groups includes a plurality of small scale mixing devices that concentrate heat release and reduce flame length.

Owner:GENERAL ELECTRIC CO

LOW NOx BURNER AND FLOW MOMENTUM ENHANCING DEVICE

ActiveUS20190309942A1Speed up the flowReduce peak flame temperatureCasings/liningsGaseous fuel burnerThermodynamicsCombustor

A flow momentum enhancing device having an airfoil shape is used in a new or refurbished burner to increase the momentum of the burner combustion air stream and create a reduced pressure region which pulls inert products of combustion into the combustion process. The inert products of combustion mix with the burner air and / or fuel streams to lower the peak flame temperature of the burner and provide reduced NOx production.

Owner:ZEECO

Burner spray head, burner with spray head and clothes dryer

PendingCN110864285AImprove combustion efficiencyBurn fullyGaseous fuel burnerCombustorCombustible gas

The invention discloses a burner spray head, a burner with the spray head and a clothes dryer. The spray head comprises a body, the body comprises a spray head portion provided with a spray head cavity, the spray head portion comprises spray head periphery walls, the spray head periphery walls comprise the first periphery wall and the second periphery wall, the second periphery wall is molded intoat least part of a conical surface shape, the first periphery wall and the second periphery wall are provided with a plurality of spray holes, and the spray holes communicate with the spray head cavity and the outside world. According to the embodiment of the invention of the burner spray head, the flame length can be reduced, the combustible gas combustion efficiency is improved, carbon monoxideemission is reduced, and more use requirements can be met.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

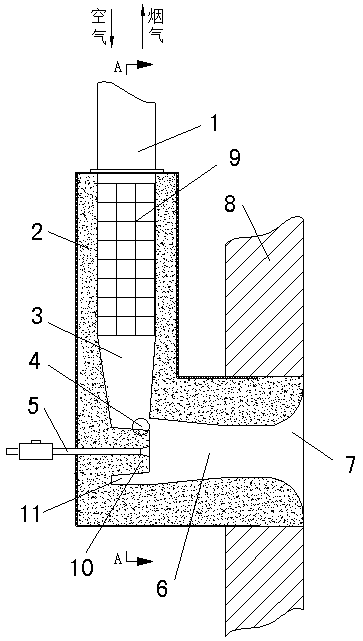

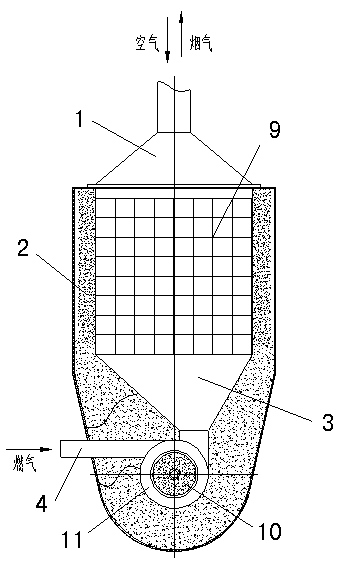

Double-rotational-flow single-heat-storage flat flame burner

PendingCN110887042AImprove combustion efficiencyImprove mixing uniformityHeat storage plantsGaseous fuel burnerThermodynamicsFlue gas

The utility model discloses a double-rotational-flow single-heat-storage flat flame burner including a shell. An air flue gas cavity and a combustion cavity which are communicated are arranged in theshell, an upper part of the air flue gas cavity is connected with an air flue gas pipeline, a bottom end of the air flue gas cavity is tangent to the circumference of the combustion cavity, a fuel gasinlet channel is arranged at a bottom of the air flue gas cavity on the shell, the fuel gas inlet channel is tangent to the circumference of the combustion cavity, and an ignition burner extending into the combustion cavity is arranged on the shell. According to the burner, the rotational flow of gas in an inner cavity of the burner is achieved through a built structure in the burner, accessoriessuch as a rotational flow piece which is generally used are reduced, and the manufacturing and maintaining cost of the burner is reduced. By means of the double-helix structure design in the burner,air and fuel gas flow into the combustion cavity in a double-rotation mode, the rotating speed of airflow in the combustion cavity is increased, meanwhile, air and fuel gas are better mixed evenly, the combustion efficiency of the fuel gas is improved, the flame length in the furnace cavity is reduced, the interior of the furnace cavity is evenly heated, and the design size of a furnace body can be reduced.

Owner:山东万方窑炉工程科技有限责任公司

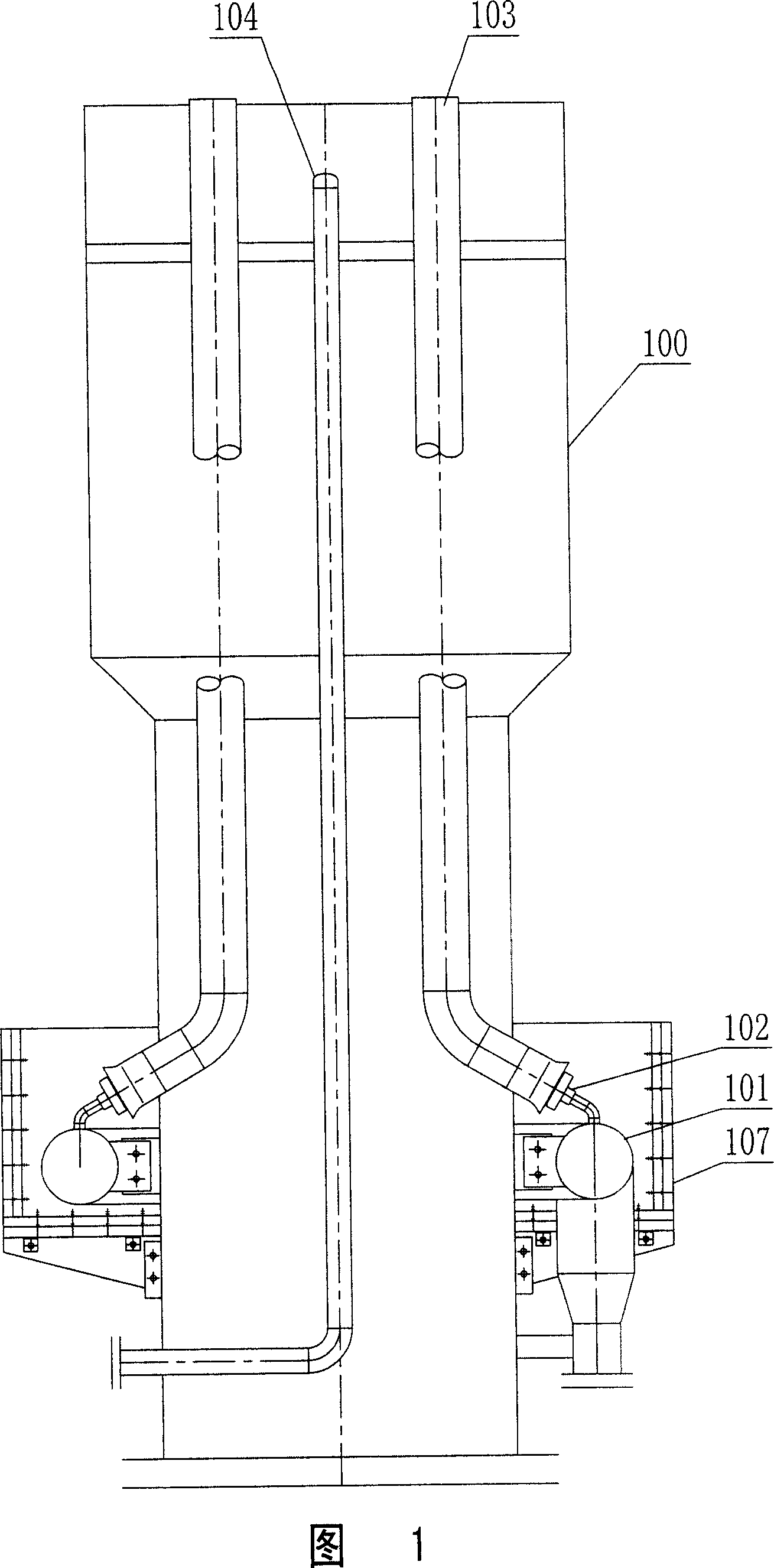

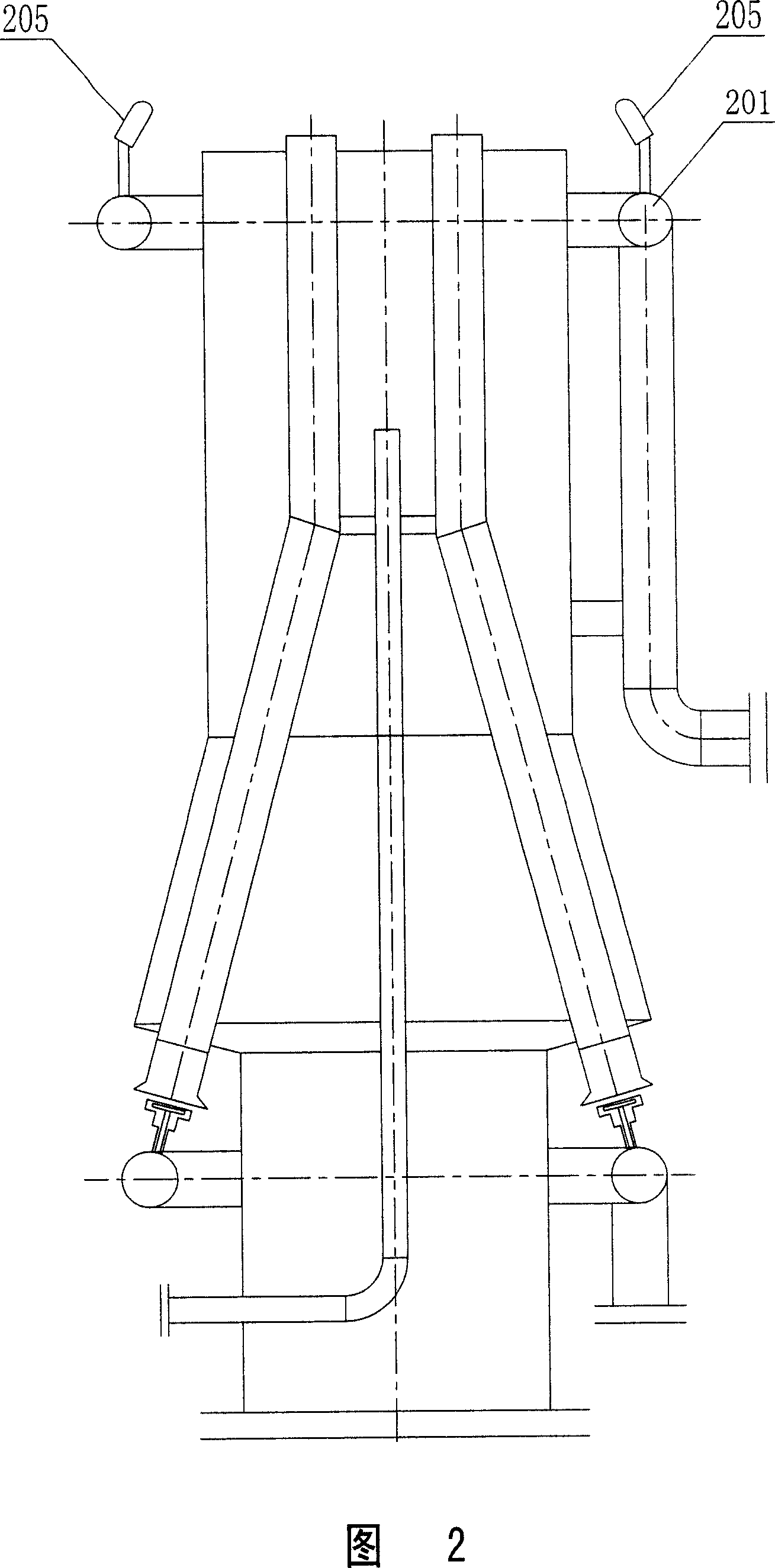

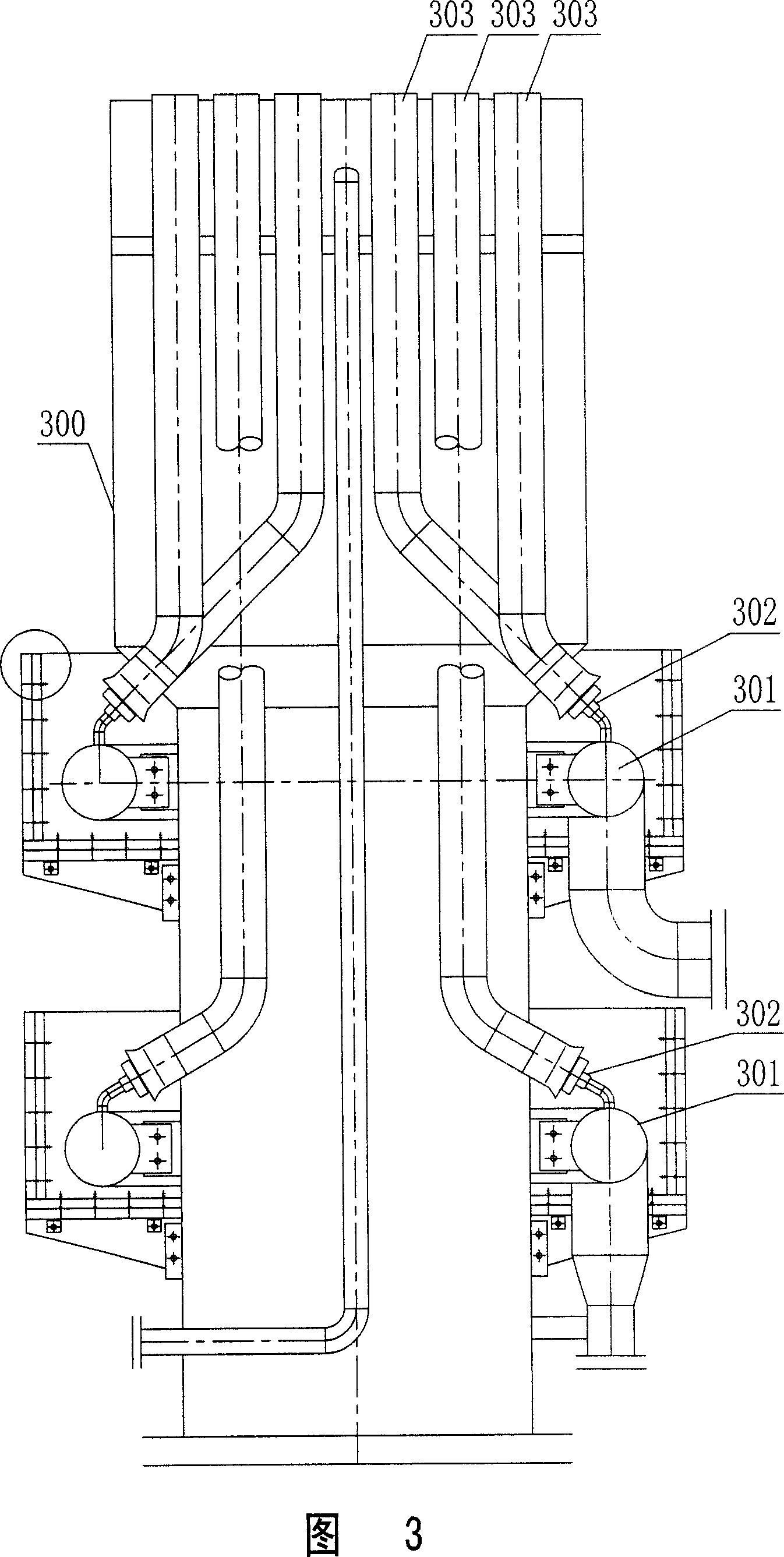

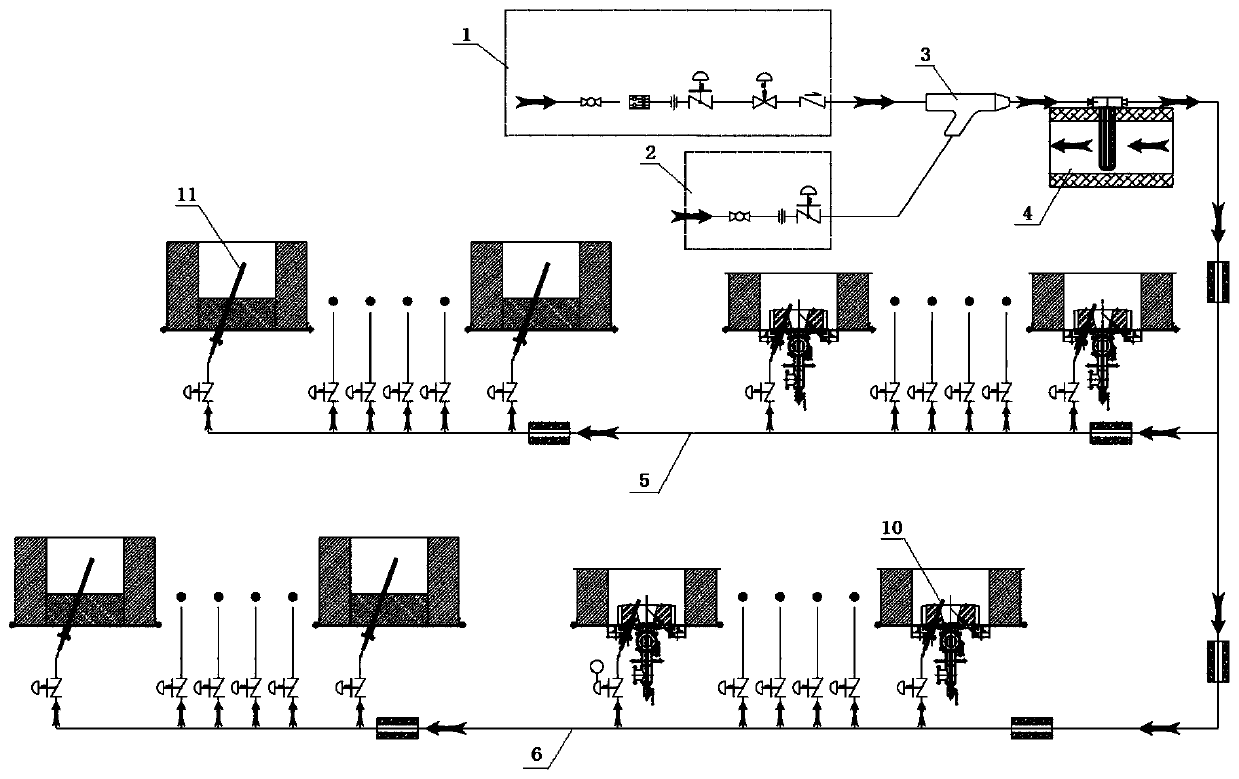

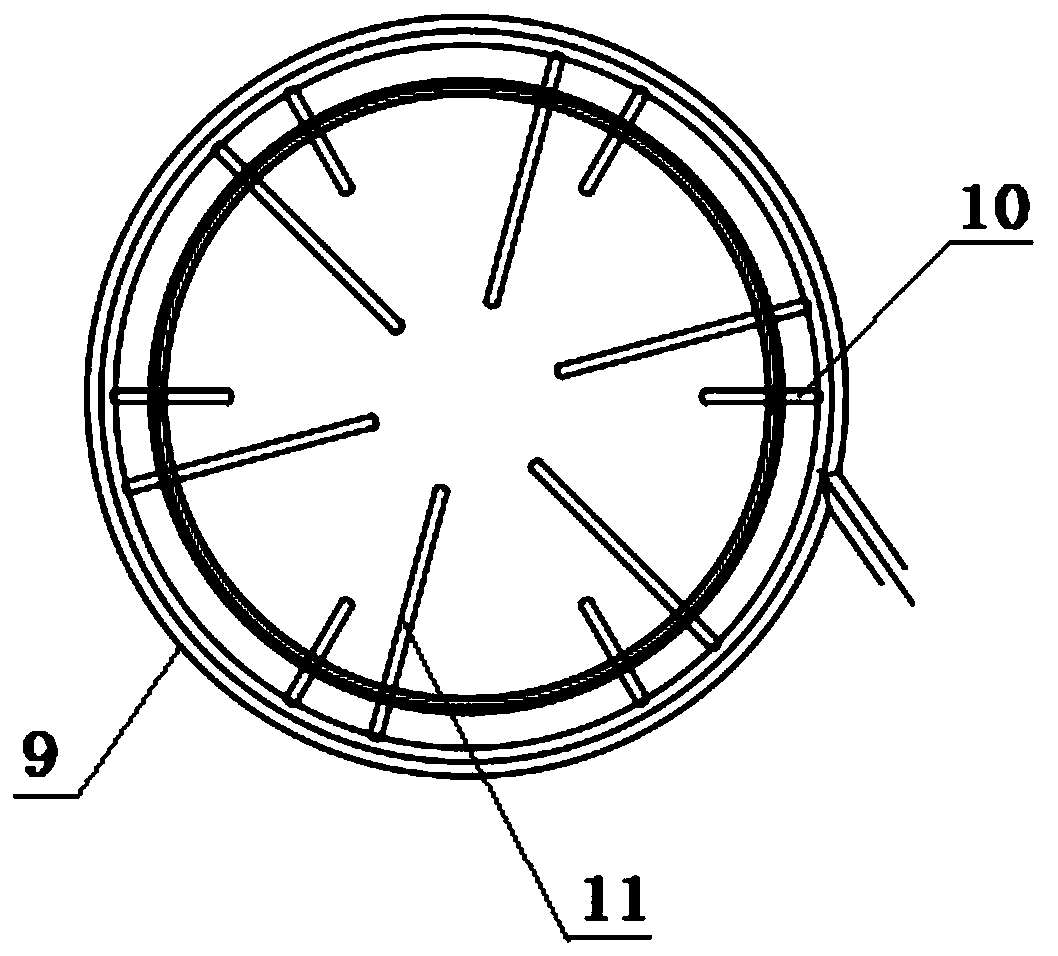

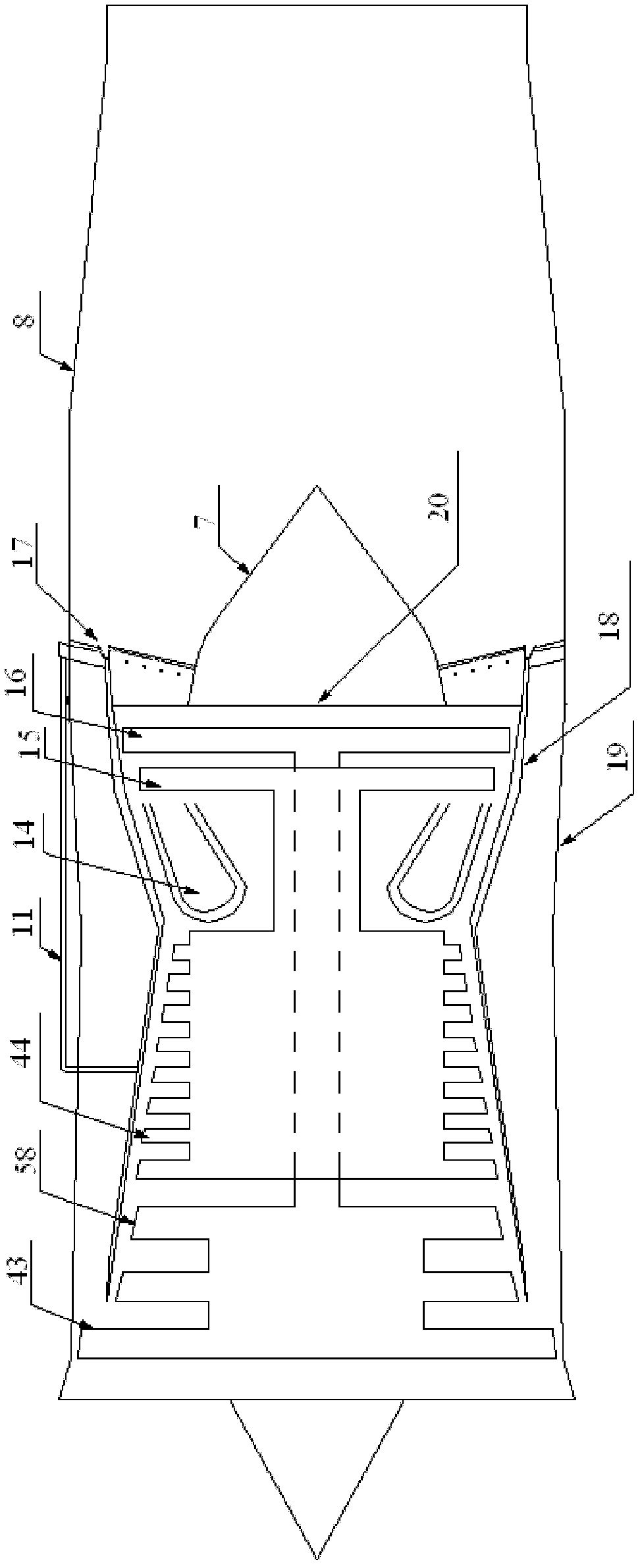

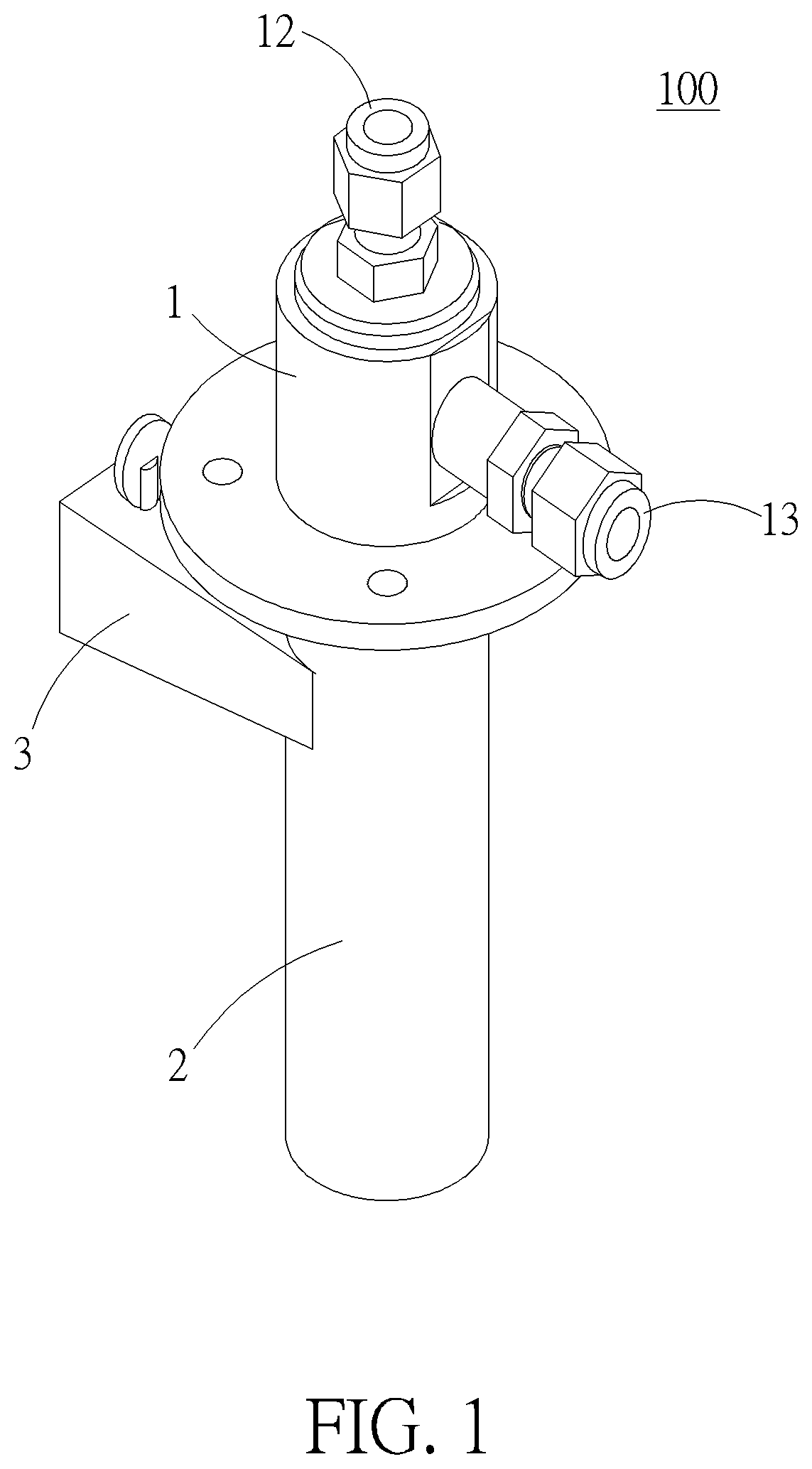

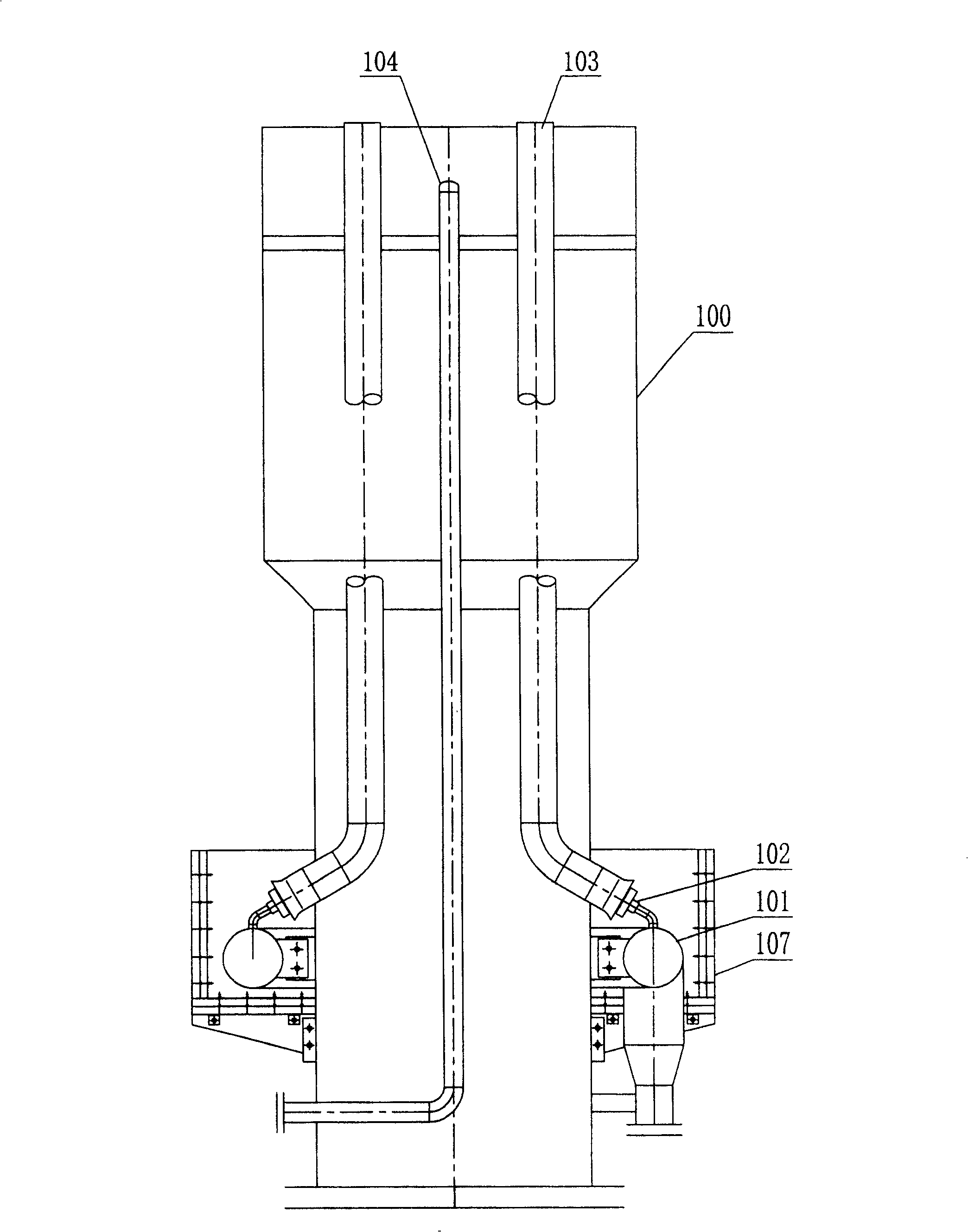

Sleeve kiln local oxygenation system

PendingCN111442649AReduce usageImprove combustion efficiencyMaintainance of heating chambersWaste heat treatmentCombustion chamberOxygen enhanced

The invention discloses a sleeve kiln local oxygenation system. The sleeve kiln local oxygenation system comprises an oxygen generation unit, an ejection unit, a heat exchange unit and an oxygenationunit, wherein the oxygen generation unit is used for producing pure oxygen, the inlet end of the ejection unit is connected with the oxygen generation unit, the inlet end of the heat exchange unit isconnected with the outlet end of the ejection unit, the heat exchange unit is arranged on a hot gas pipeline from an upper inner sleeve outlet flue of the sleeve kiln to the heat exchanger, the inletend of the oxygenation unit is connected with the outlet end of the heat exchange unit, the oxygenation unit is arranged outside a combustion chamber, the oxygenation unit comprises an oxygenation annular pipe, a plurality of oxygenation spray guns and a plurality of oxygenation spray pipes are arranged on the oxygenation annular pipe in the circumferential direction, the oxygenation spray guns are arranged on a combustion chamber panel, and the oxygenation spray pipes are arranged below an arch bridge. According to the sleeve kiln local oxygenation system, after local oxygen-enriched combustion, the combustion efficiency is improved, the combustion-supporting air volume and the use amount of fuel can be properly reduced, a better energy-saving effect can be achieved, the ignition temperature of the fuel in an oxygen-enriched state can be reduced, the combustion speed is increased, the combustion process is violent, the combustion reaction is sufficient and complete, and a better heatexchange effect is achieved.

Owner:JIANGSU ZHONGSHENGYUAN TECH CO LTD

Afterburner integrated with stabilizer and worm wheel rear rectification support plate

InactiveCN102538010BSolve the technical problems of ablationImprove reliabilityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

The invention discloses an afterburner integrated with a stabilizer and a worm wheel rear rectification support plate. A combustion part in the afterburner is integrated with a worm wheel rear load-bearing framework; the worm wheel rear rectification support plate is integrated with an inner culvert flame stabilizer, and cooling air is fed; a fuel oil supply pipe and a fuel oil nozzle are arranged in the rectification support plate; main fuel oil is transversely sprayed out from two sides of the support plate; and duty fuel oil is sprayed out from a groove on the rear surface of the stabilizer to form a duty flame. A pneumatic appearance of an outer culvert flame stabilizer is designed as a V-shaped bluff body, and the cooling air is fed into the outer culvert flame stabilizer; a fuel oil pipeline is arranged in the outer culvert flame stabilizer; the main fuel oil is transversely sprayed by a baffle plate nozzle; and the duty fuel oil is sprayed out from a groove on the rear surface of the outer culvert flame stabilizer. An annular flame stabilizer is arranged between the inner culvert flame stabilizer and the outer culvert flame stabilizer, so that functions of the stabilizer and a flame coupler are realized in a circumferential direction. The internal parts of the afterburner are integrated, so that the part utilization efficiency is improved, and the engine thrust-weight ratio is increased.

Owner:BEIHANG UNIV

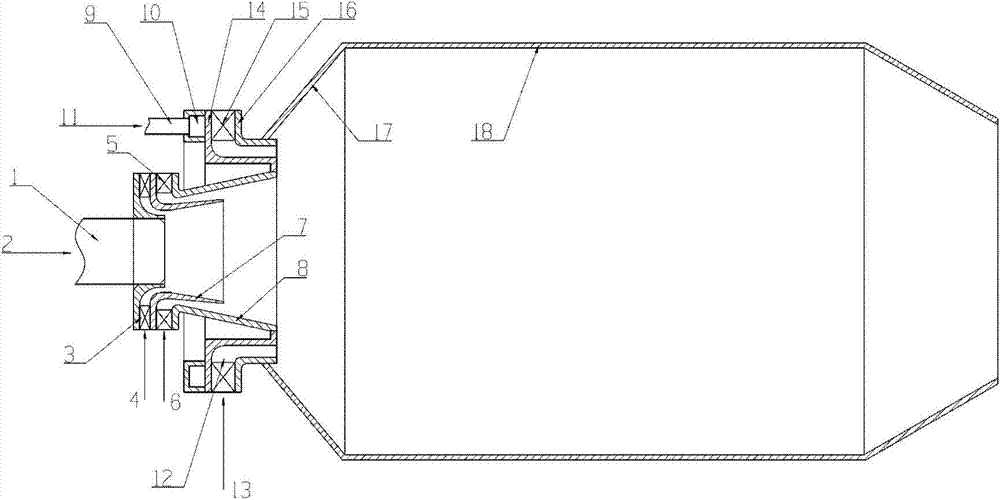

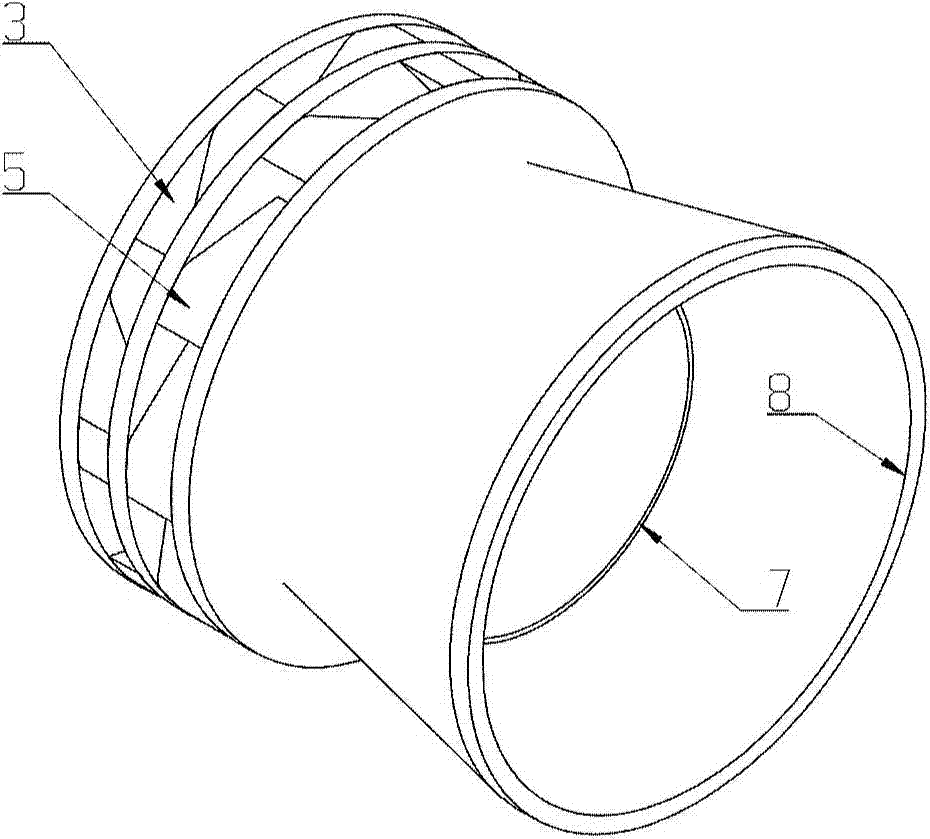

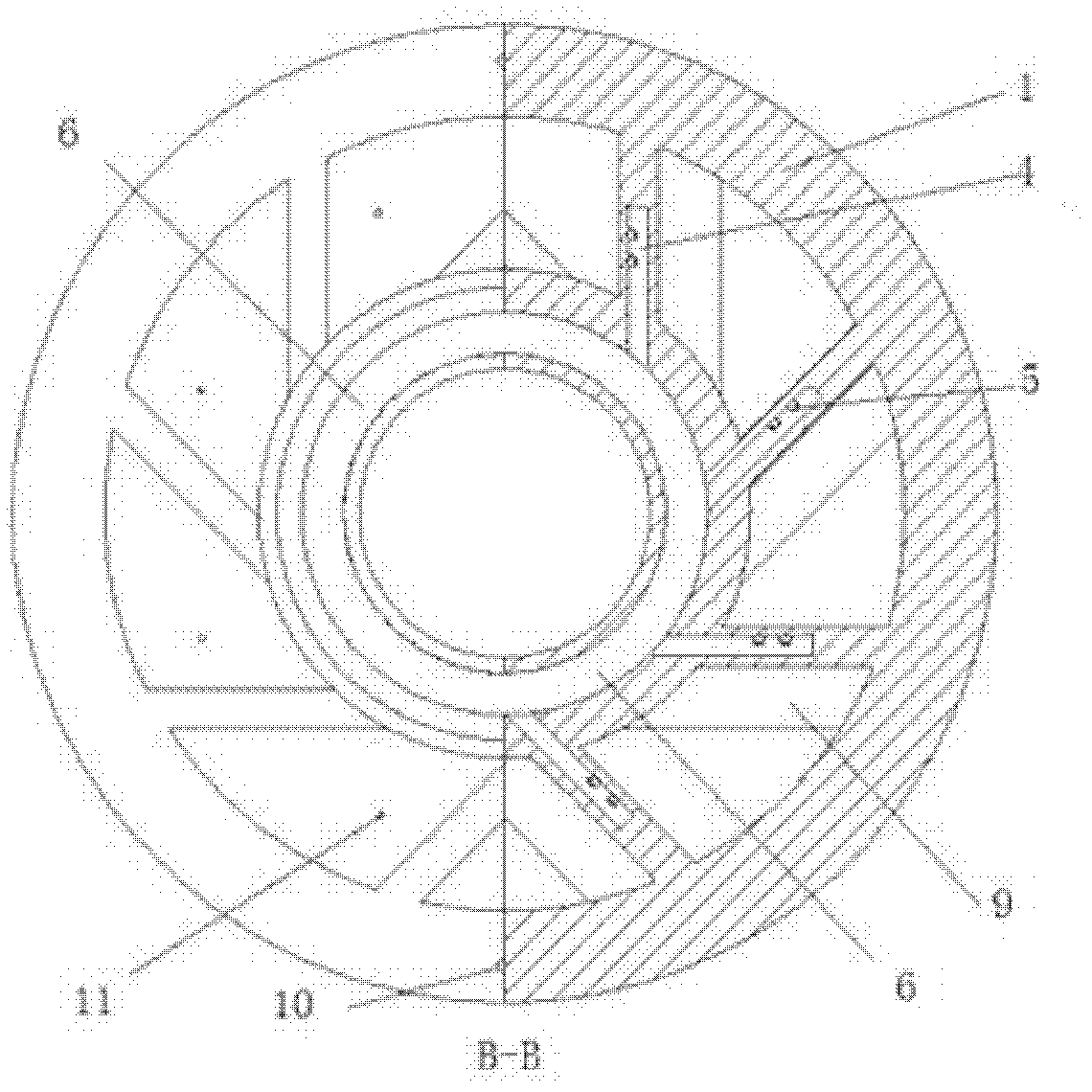

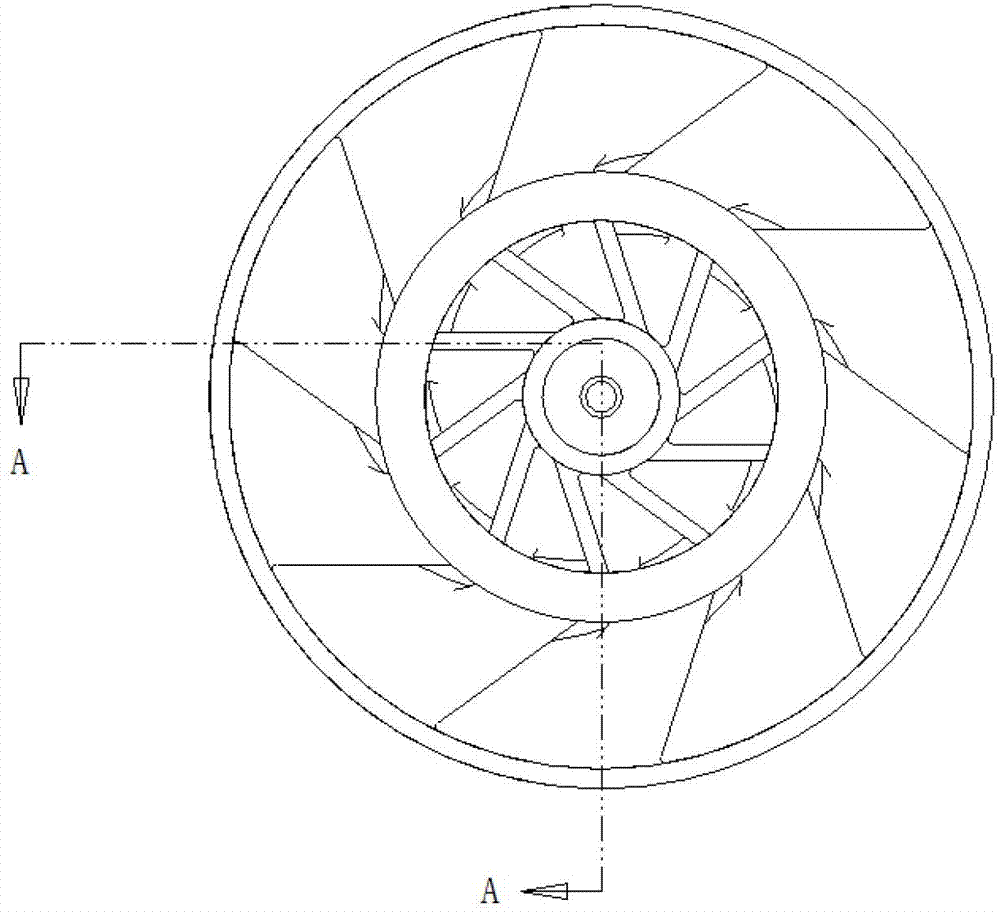

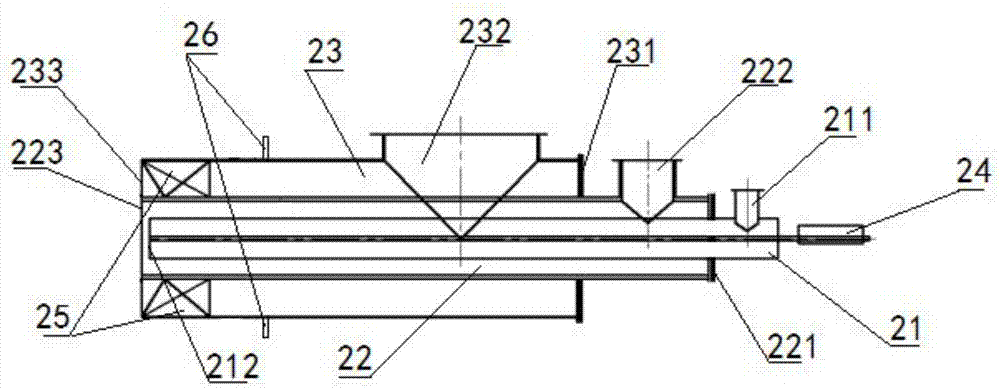

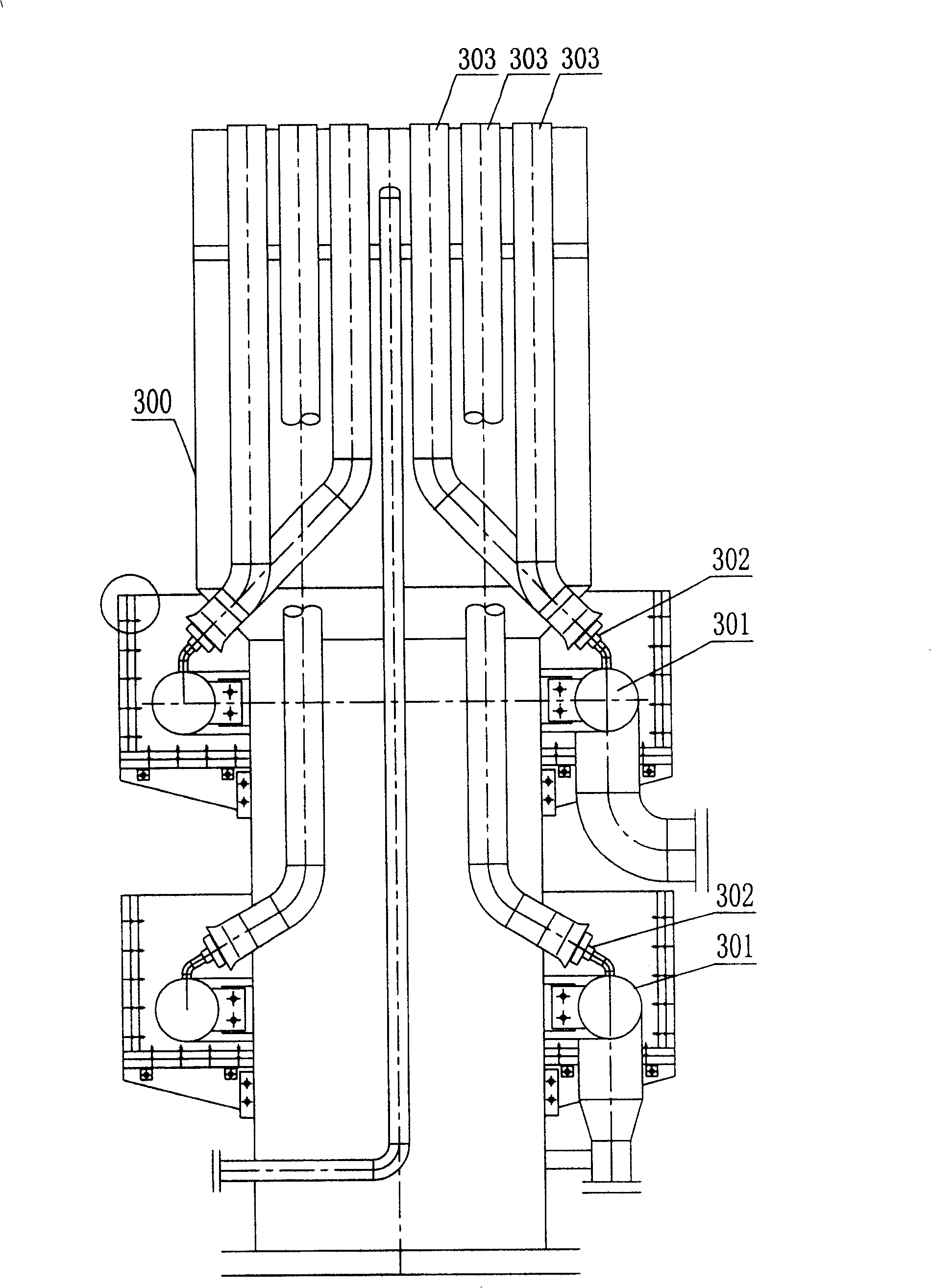

Dual-fuel swirling atomizing nozzle for chemical regenerative cycle

InactiveCN102538014AFully atomizedImprove atomization effectContinuous combustion chamberCombustion chamberLiquid fuel

The invention aims to provide a dual-fuel swirling atomizing nozzle for chemical regenerative cycle, which comprises an outer swirler hub, a main oil way, a main cracked gas channel and swirler blades. An oil inlet is arranged on the outer swirler hub and communicated with the main oil way, the main oil way is communicated with oil spraying pores on windward sides of the swirler blades through branch channels of the oil way, and the main cracked gas channel is communicated with cracked gas nozzles on lee sides of the swirler blades through branch cracked gas channels. By the aid of the dual-fuel swirling atomizing nozzle, cracked gas fuels and air can be effectively mixed, flame is further shortened, and combustion efficiency and the integral performance of a gas turbine are improved. A swirler is combined with the nozzle, so that the head structure of a combustion chamber is more compact, and arrangement and installation of the combustion chamber are facilitated. Liquid fuels and the cracked gas fuels are independently supplied, so that the proportion of input fuels under various working conditions can be precisely controlled and mastered, and adaptability and economy of a combustion engine under the various working conditions are improved.

Owner:HARBIN ENG UNIV

Catalytic combustion system and method

InactiveUS20060026964A1Emission reductionShorten flame lengthContinuous combustion chamberTurbine/propulsion fuel supply systemsNitrogenExhaust fumes

Aspects according to the invention relate to a catalytic combustor system for a turbine engine and an associated method. Catalytic combustors are used in connection with turbine engines because they can minimize the formation of oxides of nitrogen during combustion. Despite this emissions advantage, catalytic combustion systems can increase the level of CO in the turbine exhaust. According to aspects of the invention, vortex formation devices includes vortex generators, swirlers and mixers can be placed downstream of each catalytic module surrounding the pilot nozzle so as to form one or more vortices in the otherwise substantially laminar flow exiting the modules. The vortices can create a suction so that a portion of the flow exiting the pilot nozzle is mixed with the flow exiting thee catalyst modules. The introduction of the higher temperature pilot flow can accelerate the catalytic reaction time, promoting burnout of the CO formed during combustion.

Owner:SIEMENS ENERGY INC

A combustion chamber adopting the pre-film atomization method of the trailing edge of the swirl blade

ActiveCN104329689BShort blending distanceShorten flame lengthContinuous combustion chamberCombustion chamberTrailing edge

The invention provides a combustion chamber adopting a swirl vane tail edge pre-film atomization mode. The combustion chamber comprises a combustion chamber flame tube, a center level oil and gas mixing assembly and a main combustion level oil and gas mixing assembly which is arranged at the front end of the combustion chamber flame tube and the periphery of the center level oil and gas mixing assembly. The main combustion level oil and gas mixing assembly comprises a main combustion level swirl channel, N wedge-shaped swirl vanes and M vane interior oil paths; the N wedge-shaped swirl vanes are slantly fixed to the interior of the main combustion level swirl channel, and the M vane interior oil paths are arranged in at least one part of wedge-shaped swirl vanes respectively; the front end of each vane interior oil path is connected with a main combustion level oil cavity, and the tail end of the each vane interior oil path extends to the tail edge of the corresponding wedge-shaped swirl vane; the M is smaller than or equal to the N. The swirl vanes are wedge-shaped; velocity gradients are formed at the tail edges of the swirl vanes; a fuel liquid film flowing out of the tail edges of the swirl vanes is rapidly shorn and atomized under the action of the velocity gradients; the oil and gas blending distance is short, and the flame length and the length of the flame tube are shortened.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

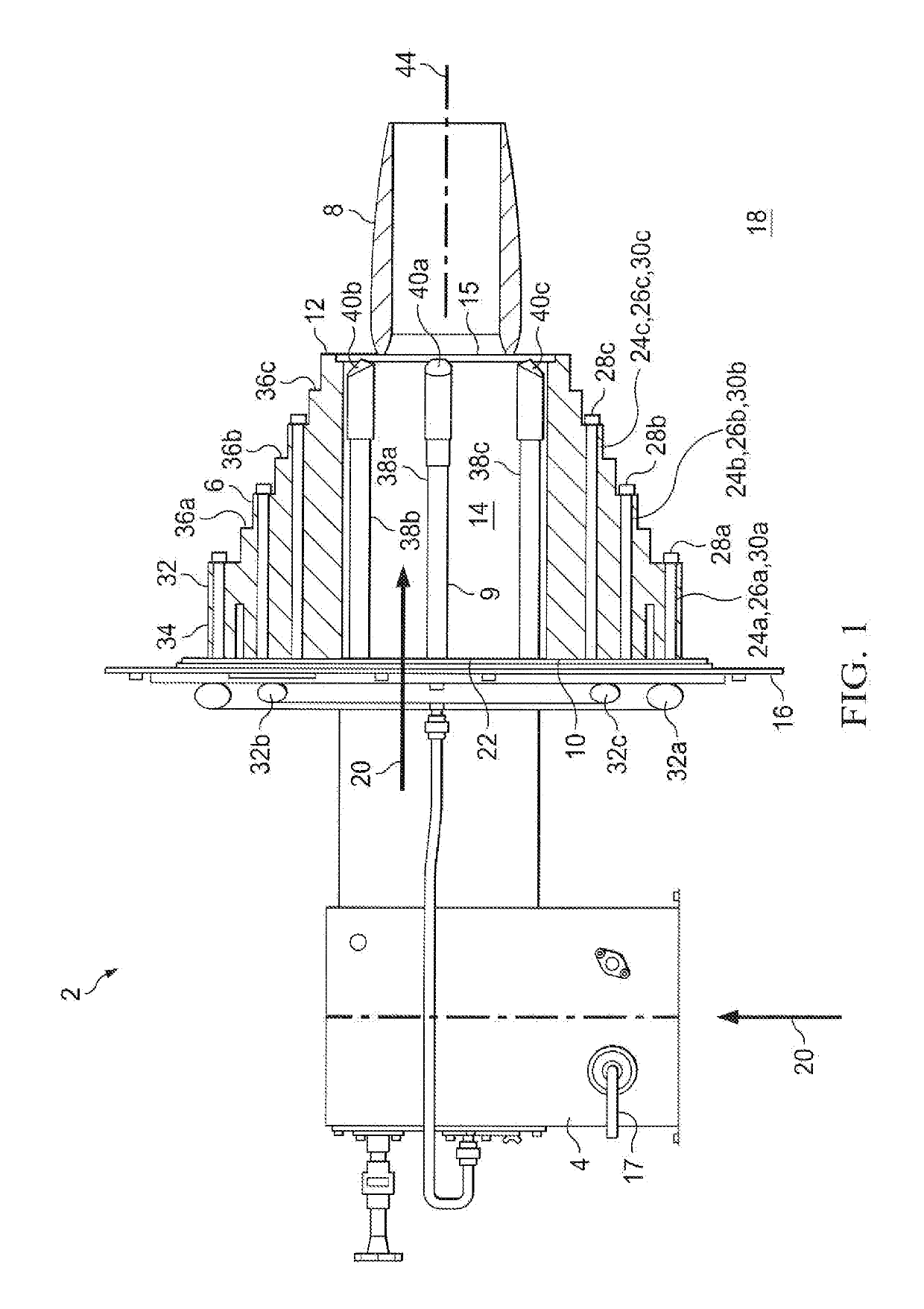

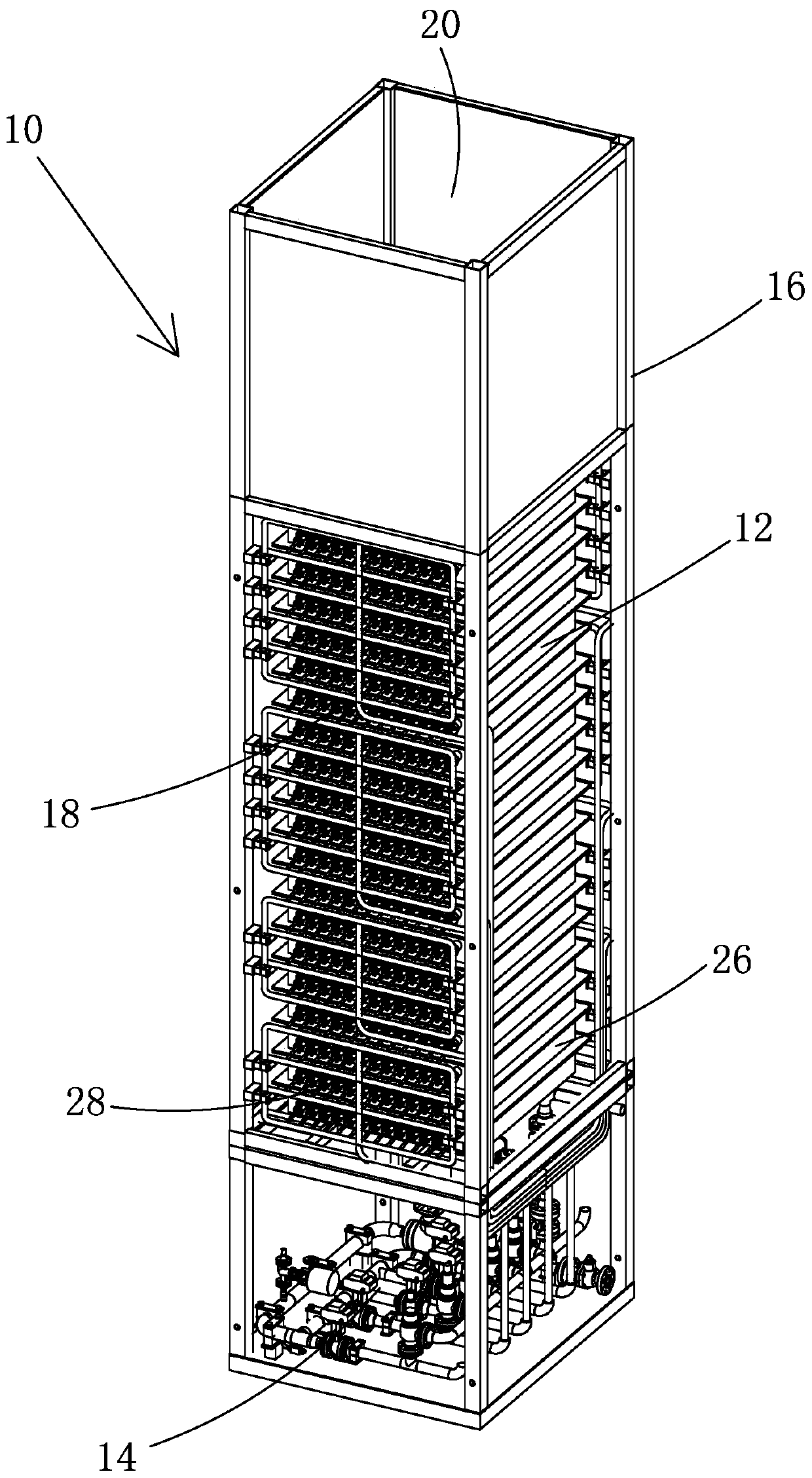

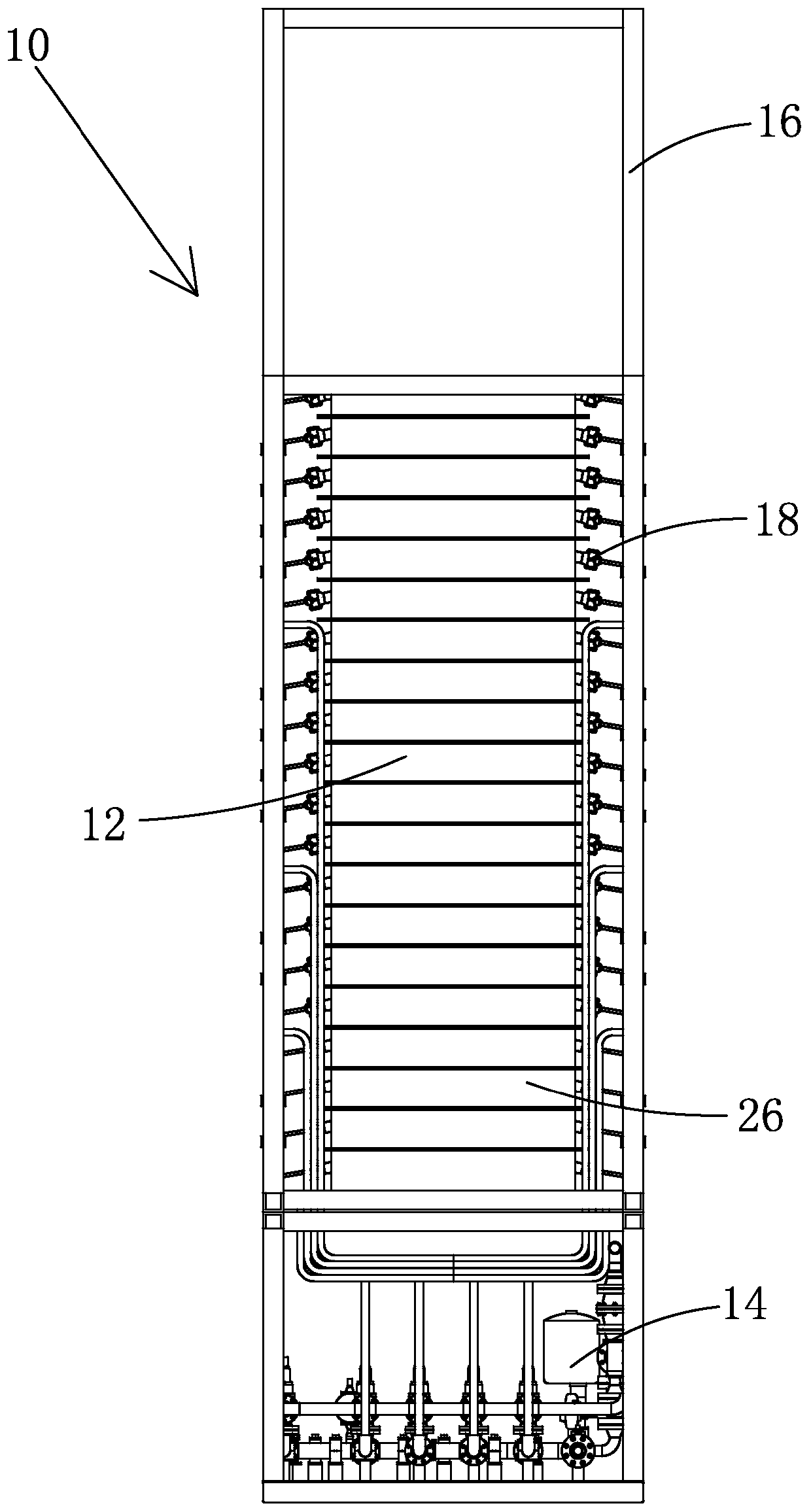

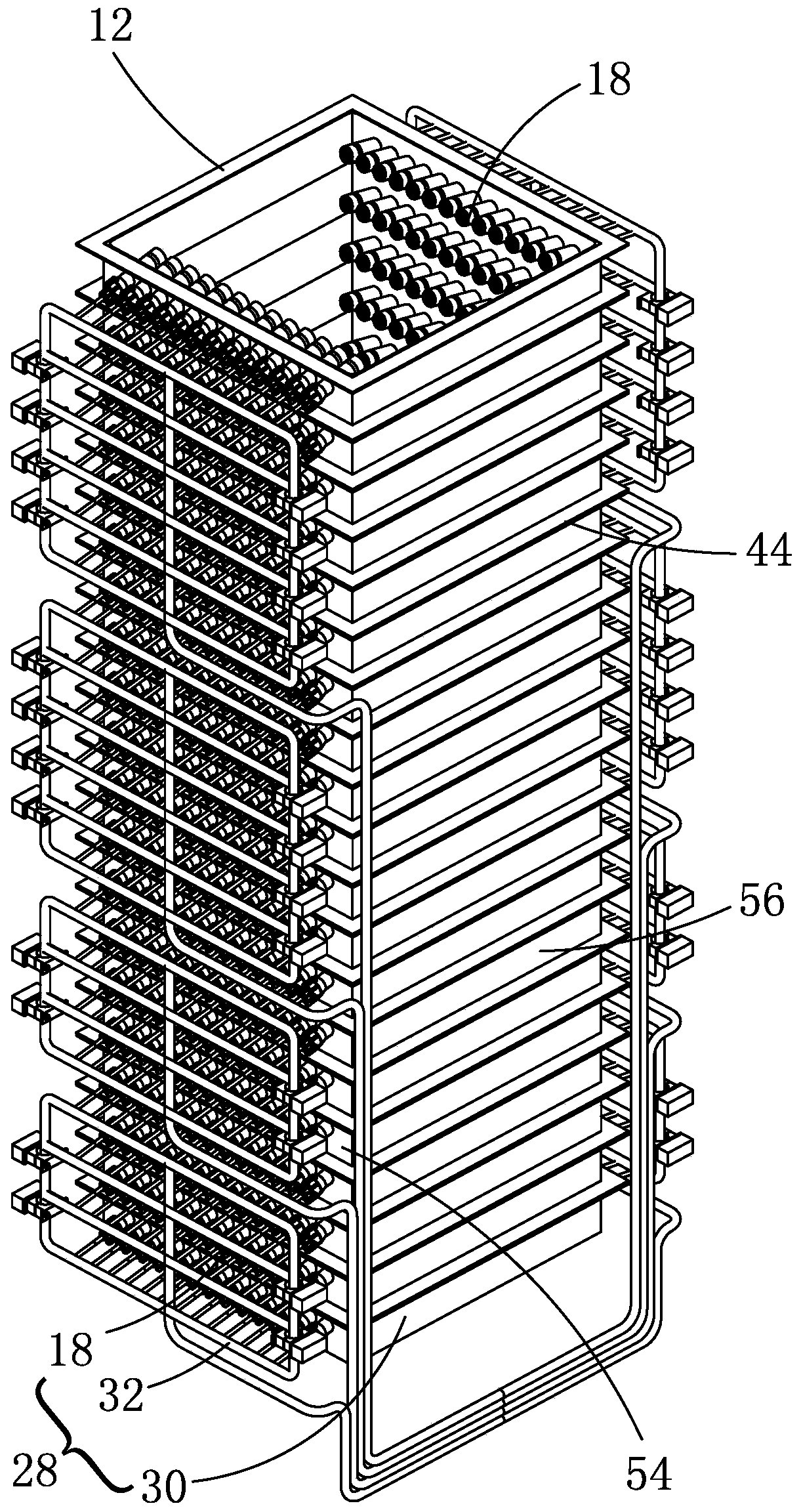

Assembling method of injector combustion device

The invention provides an assembly method of an injection-type combustion device. The injection-type combustion device comprises an outer frame. The assembly method comprises the steps that several combustor assemblies are put in the outer frame and mutually fixed, wherein each combustor assembly comprises a protection hood part, several Venturi combustors supported on the protection hood part anda gas supply pipeline communicated with the Venturi combustors, the protection hood part, the Venturi combustors and the gas supply pipeline of each combustor assembly are installed together before being put into the outer frame, and after the combustor assemblies are mutually fixed, the protection hood parts of the combustor assemblies jointly form a protection hood of the injection-type combustion device; the protection hood part of each combustor assembly is fixed to the outer frame.

Owner:SHENZHEN WISDOM ENERGY TECH CO

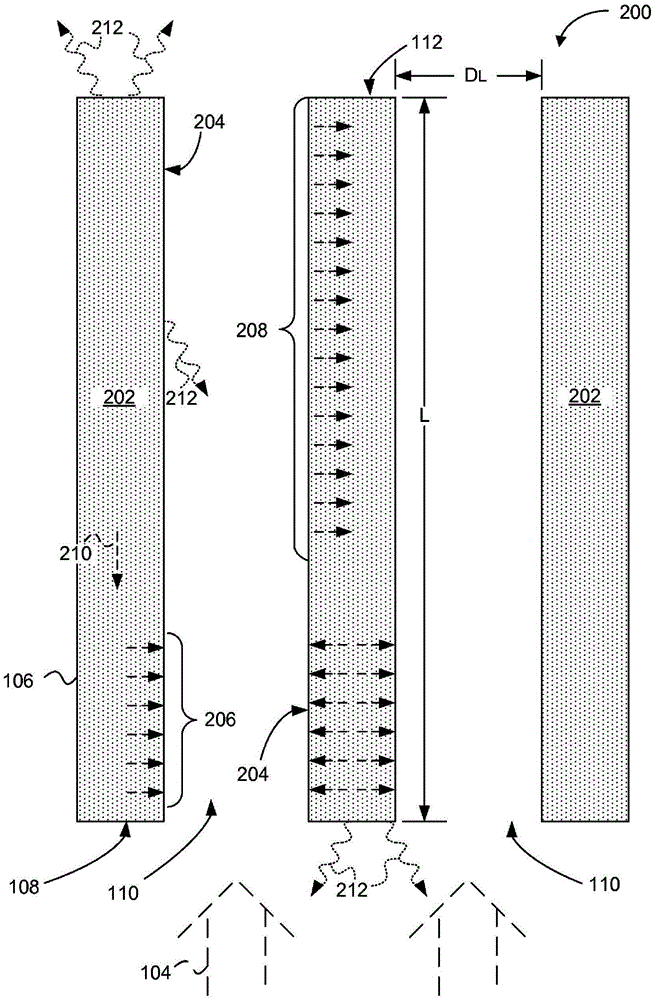

Porous flame holder for low nox combustion

ActiveCN105556210AAdvantages Fuel EfficiencyMerit YieldIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorNitrogen

A burner includes a porous flame holder configured to support a combustion reaction to achieve a very low output of oxides of nitrogen (NOx).

Owner:美一蓝技术公司

Dual-fuel swirling atomizing nozzle for chemical regenerative cycle

InactiveCN102538014BFully atomizedImprove atomization effectContinuous combustion chamberCombustion chamberLiquid fuel

The invention aims to provide a dual-fuel swirling atomizing nozzle for chemical regenerative cycle, which comprises an outer swirler hub, a main oil way, a main cracked gas channel and swirler blades. An oil inlet is arranged on the outer swirler hub and communicated with the main oil way, the main oil way is communicated with oil spraying pores on windward sides of the swirler blades through branch channels of the oil way, and the main cracked gas channel is communicated with cracked gas nozzles on lee sides of the swirler blades through branch cracked gas channels. By the aid of the dual-fuel swirling atomizing nozzle, cracked gas fuels and air can be effectively mixed, flame is further shortened, and combustion efficiency and the integral performance of a gas turbine are improved. A swirler is combined with the nozzle, so that the head structure of a combustion chamber is more compact, and arrangement and installation of the combustion chamber are facilitated. Liquid fuels and the cracked gas fuels are independently supplied, so that the proportion of input fuels under various working conditions can be precisely controlled and mastered, and adaptability and economy of a combustion engine under the various working conditions are improved.

Owner:HARBIN ENG UNIV

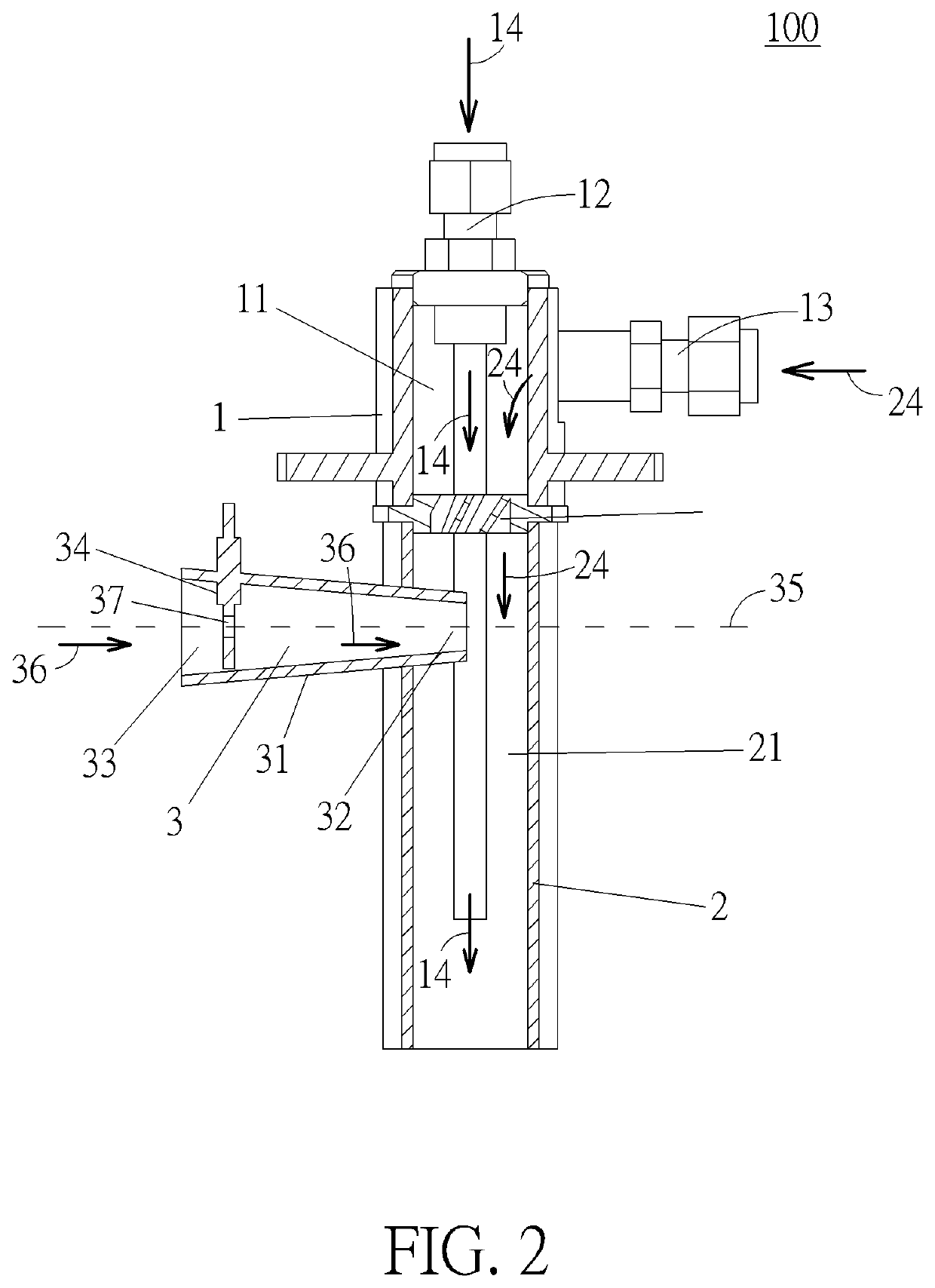

Cracking-gas fuel injection device for chemical regenerative cycle

InactiveCN102721082BShorten the lengthCompact structureContinuous combustion chamberInlet channelCombustion chamber

Owner:三亚哈尔滨工程大学南海创新发展基地

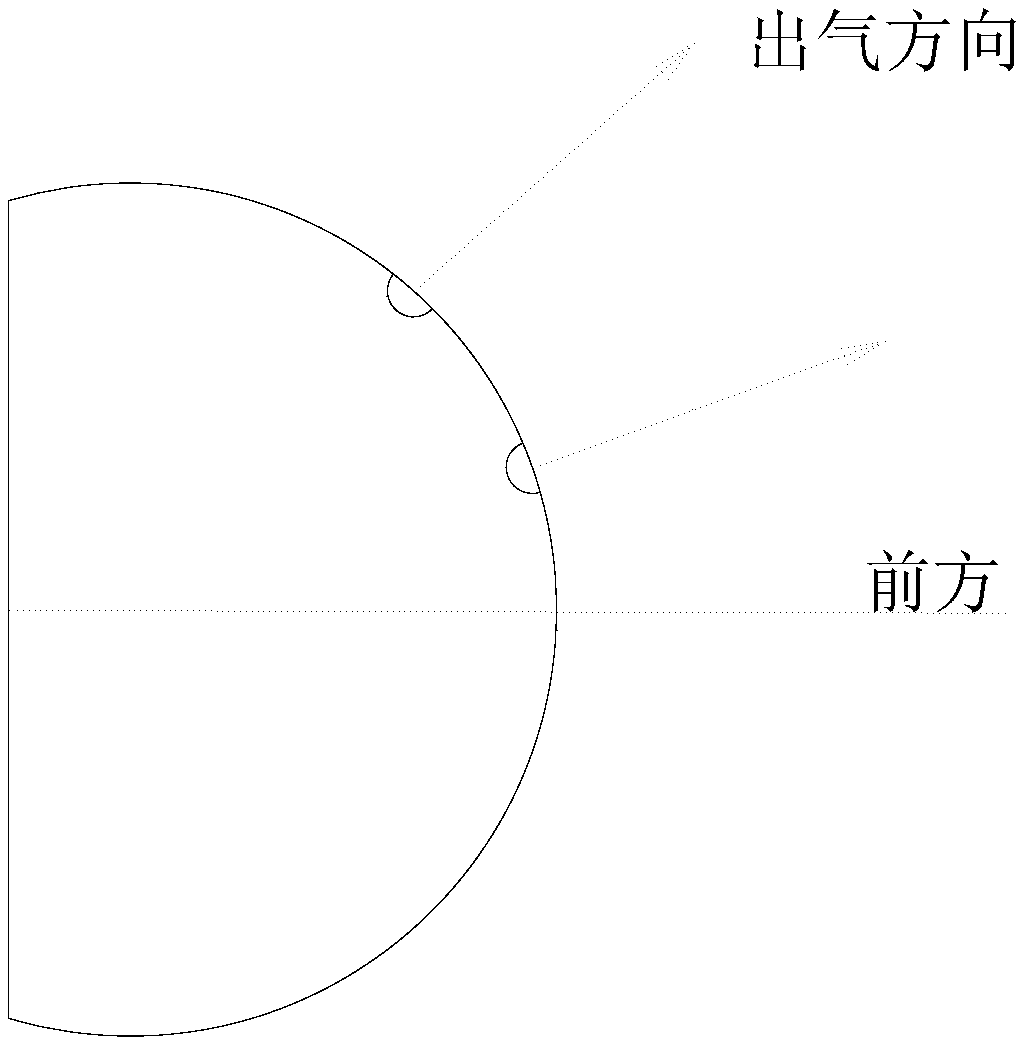

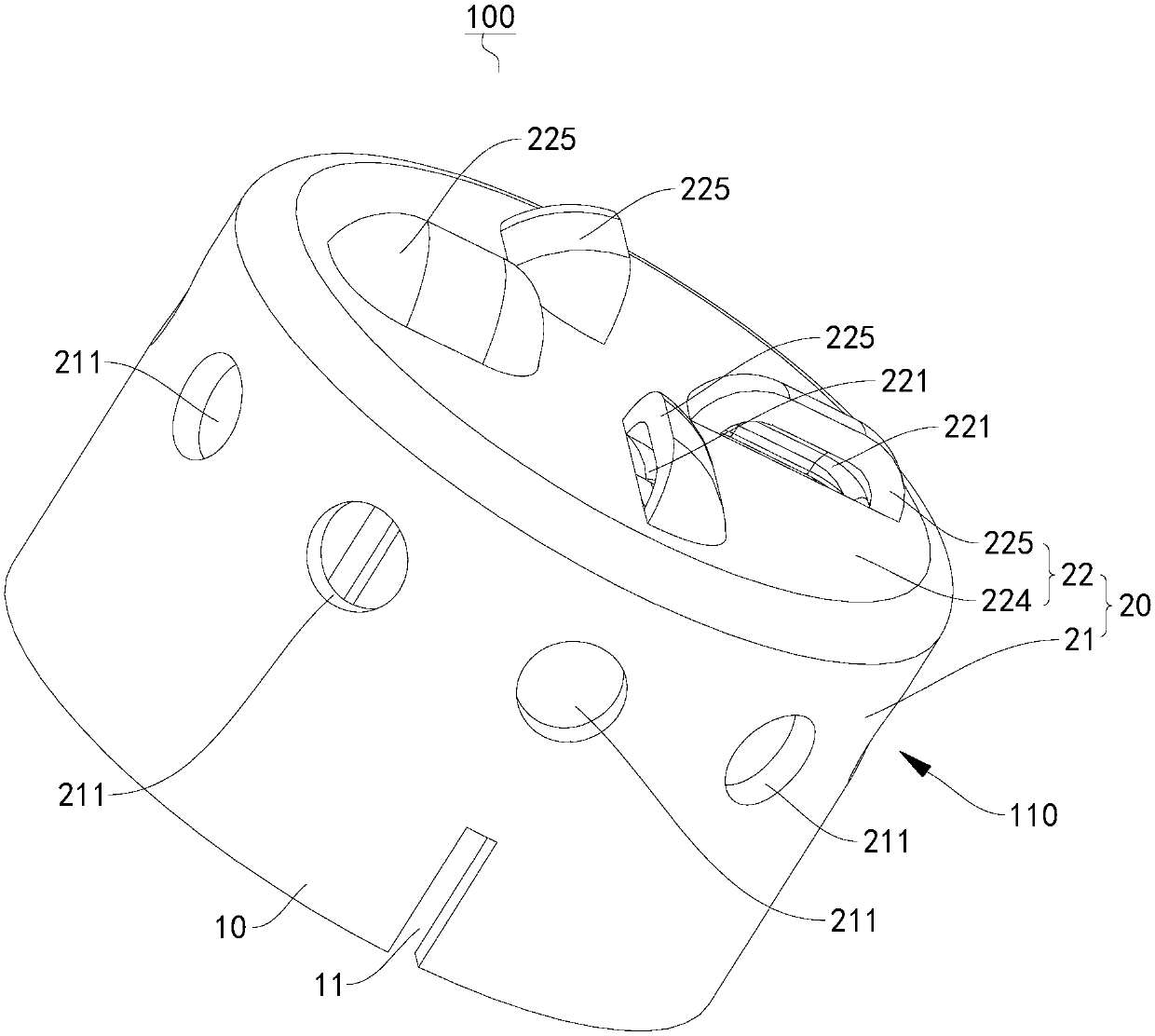

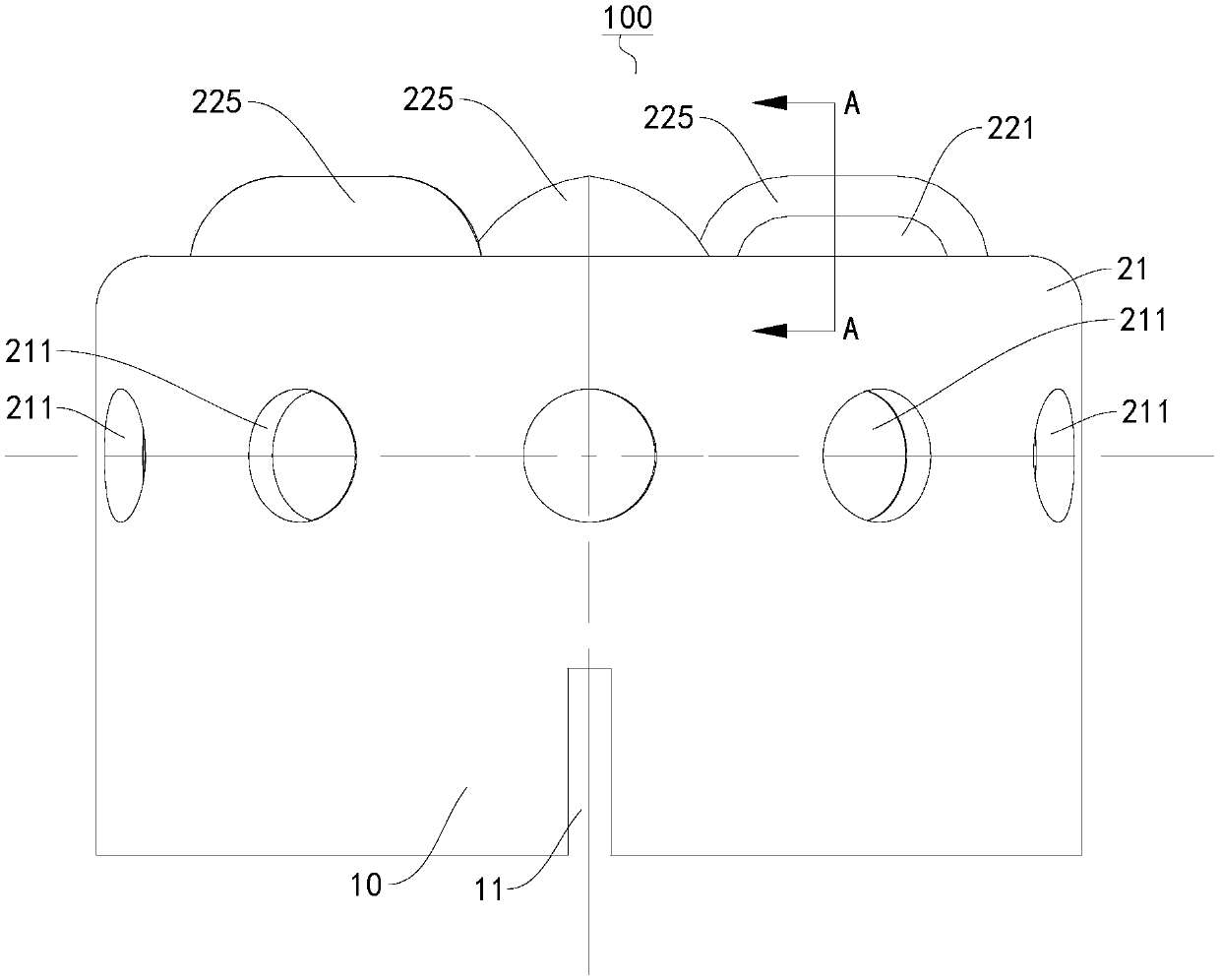

Nozzle of combustor, combustor with nozzle and clothes dryer

PendingCN110864286AShorten flame lengthImprove combustion efficiencyTextiles and paperGaseous fuel burnerEngineeringMechanics

The invention discloses a nozzle of a combustor, the combustor with the nozzle and a clothes dryer. The nozzle comprises a body, the body comprises a nozzle part with a nozzle cavity, the nozzle partcomprises a nozzle circumferential wall and a nozzle end wall covering the outlet end of the nozzle circumferential wall, multiple first spray holes are distributed in the end wall of the nozzle in the circumferential direction, the first spray holes communicate the nozzle cavity with the exterior, and the first spray holes are configured to enable gas flowing out of the first spray holes to formrotational flow. The nozzle of the combustor can reduce the flame length, the combustion efficiency of combustible gas can be improved, combustion is sufficient, emissions of carbon monoxide can be reduced, safety is higher, energy saving and environment friendliness are achieved, more use needs are met, and adaptation is better.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Coal powder turbulent burner

ActiveCN107575860AImprove combustion stabilityExtend the mixing timePulverulent fuel combustion burnersCombustorFlue gas

The invention discloses a coal powder turbulent burner comprising a pre-burning chamber and a burner body. The burner body comprises a central air pipe, a primary air pipe and a secondary air pipe. The front end of the burner body extends into the pre-burning chamber. By arranging a truncated-cone-type blunt body diverging in the airflow direction at a primary air outlet of the primary air pipe, the mixing time of secondary air airflow of the secondary air pipe and coal powder airflow is prolonged, the length of a flame formed by burning of coal powder at an opening of the primary air pipe isdecreased, and low-nitrogen burning is facilitated; meanwhile, by arranging the truncated-cone-type blunt body, the secondary air airflow of the secondary air pipe forms a strong backflow area at a secondary air outlet, the burning temperature in the pre-burning chamber is decreased, and the coking phenomenon in the pre-burning chamber is effectively avoided; and the truncated-cone-type blunt bodyand the pre-burning chamber are matched in use, therefore, the truncated-cone-type blunt body can suck high-temperature flue gas in a furnace in a rolling mode, the anti-interference capability of the pre-burning can be improved during burning, and accordingly the steady burning performance of the coal powder is improved.

Owner:HARBIN INST OF TECH

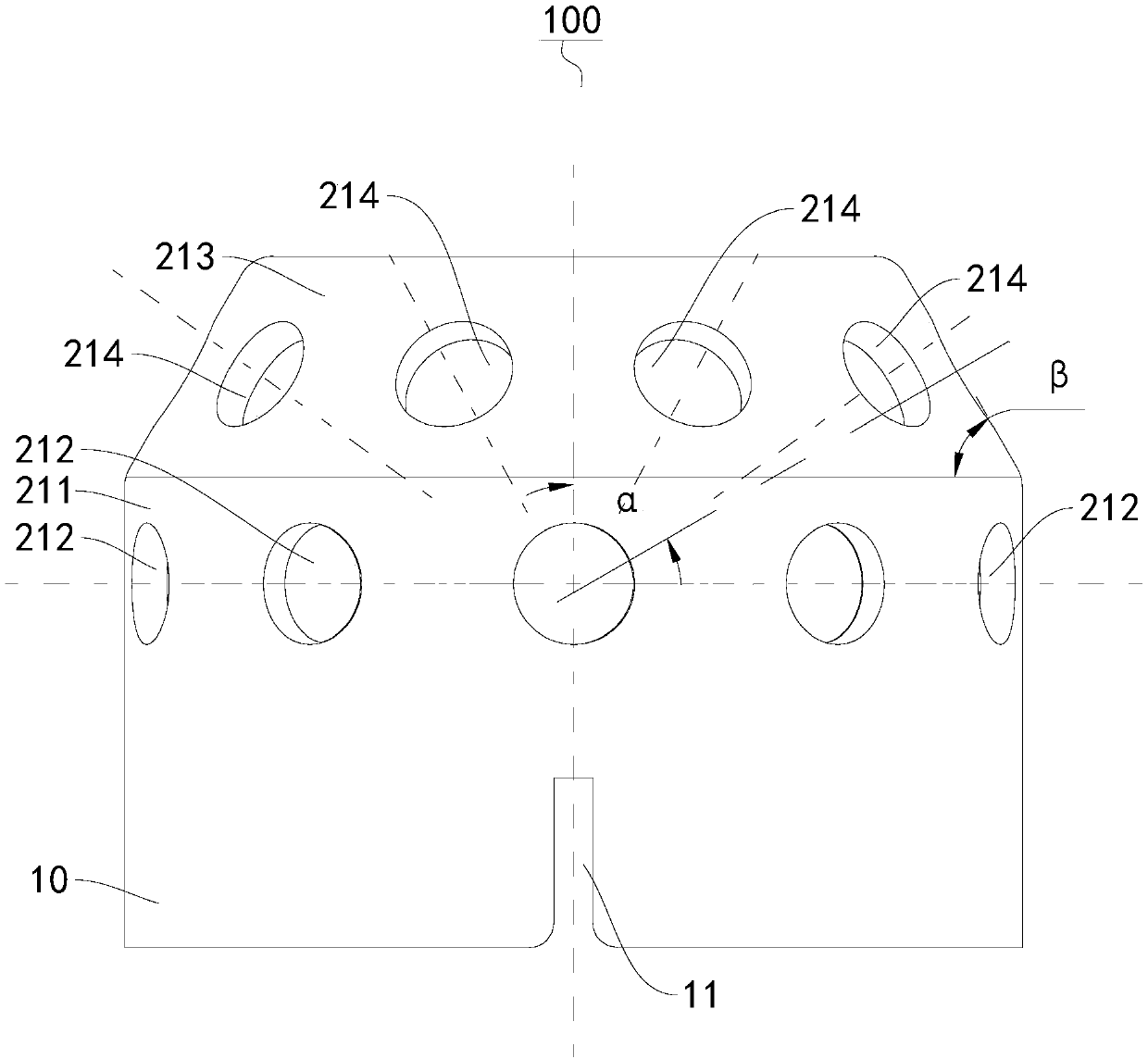

Fuel gas nozzle

ActiveUS20200200391A1Improve the mixing effectShorten flame lengthFuel supply regulationContinuous combustion chamberEngineeringMechanics

A fuel gas nozzle used in a microturbine includes a first chamber, a second chamber connected to the first chamber, a pilot fuel gas pipe, a main fuel gas pipe and an intake pipe. An intake zone and a mixing zone are respectively formed in the first chamber and the second chamber and are communicated with each other. The pilot fuel gas pipe is for introducing a first fuel gas into a downstream of the second chamber. The main fuel gas pipe is for introducing a second fuel gas into the mixing zone via the intake zone. The intake pipe is for introducing an air into the mixing zone. A centerline of the intake pipe is not intersected with a centerline of the second chamber, so as to induce a vortex flow field of the air flowing into the mixing zone for mixing the air and the second fuel gas.

Owner:NAT CHUNG SHAN INST SCI & TECH

A pulverized coal swirl burner

ActiveCN107575860BImprove combustion stabilityExtend the mixing timePulverulent fuel combustion burnersCombustorFlue gas

Owner:HARBIN INST OF TECH

Steam combustion-supporting type torch burner

ActiveCN100453906CHigh smoke suppression effectExtend your lifeIncinerator apparatusGaseous fuel burnerCombustorTorch

A torch burner of steam combustion-assisting type consists of cylinder body, central jet pipe of steam, steam ring pipe, nozzle and jet pipe of steam-air. It is featured as setting nozzle jacketed on steam ring pipe far from top of cylinder body, aligning nozzle to entrance of jet pipe of steam-air and setting steam jet component far from high temperature region at top of burner.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com