Cracking-gas fuel injection device for chemical regenerative cycle

A technology of fuel injection device and chemical regenerative cycle, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problem of no swirl vanes, and achieve the effect of preventing flow field fluctuations, compact structure, and overcoming combustion instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in more detail below in conjunction with accompanying drawing example:

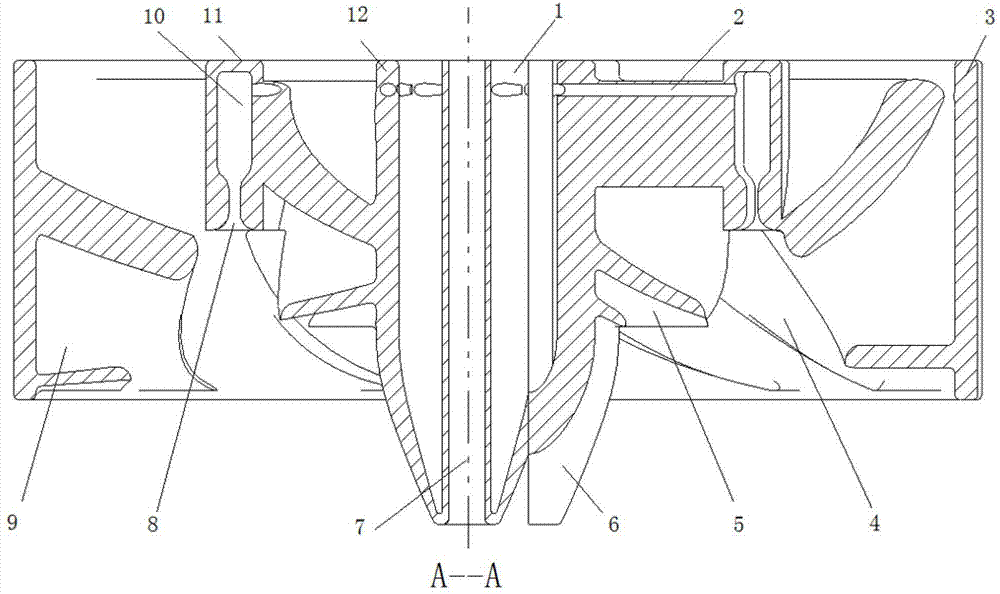

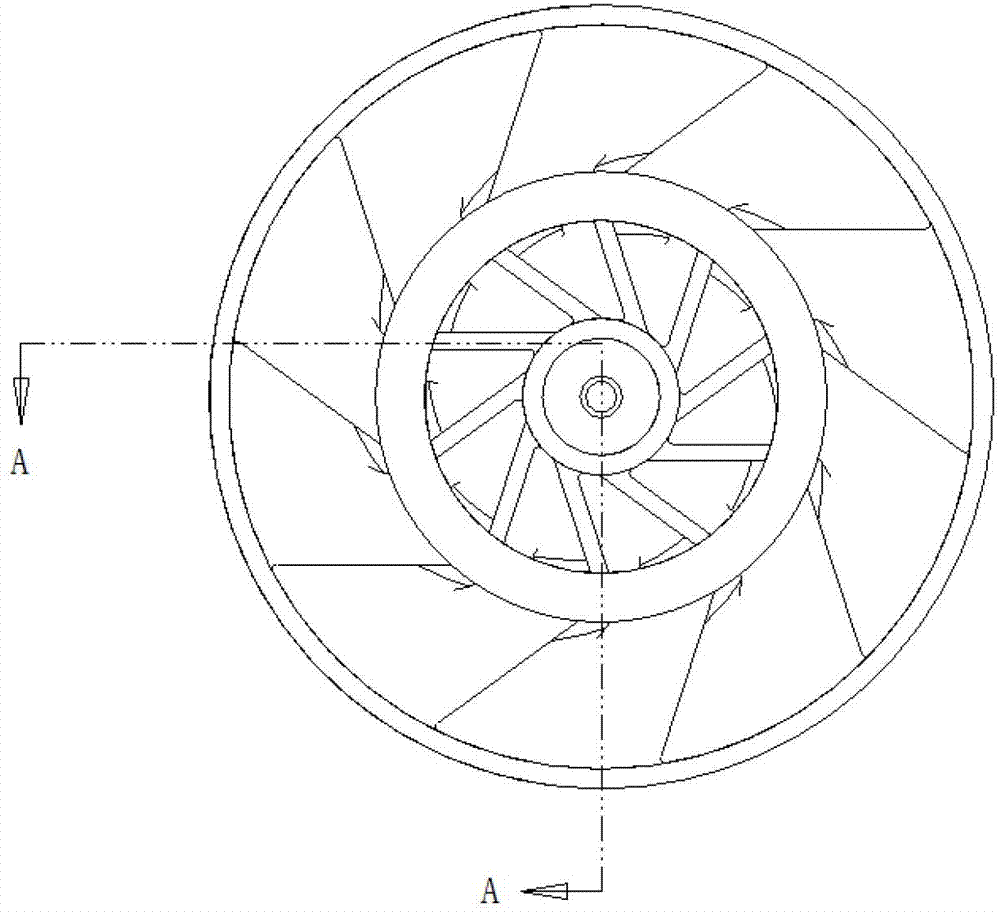

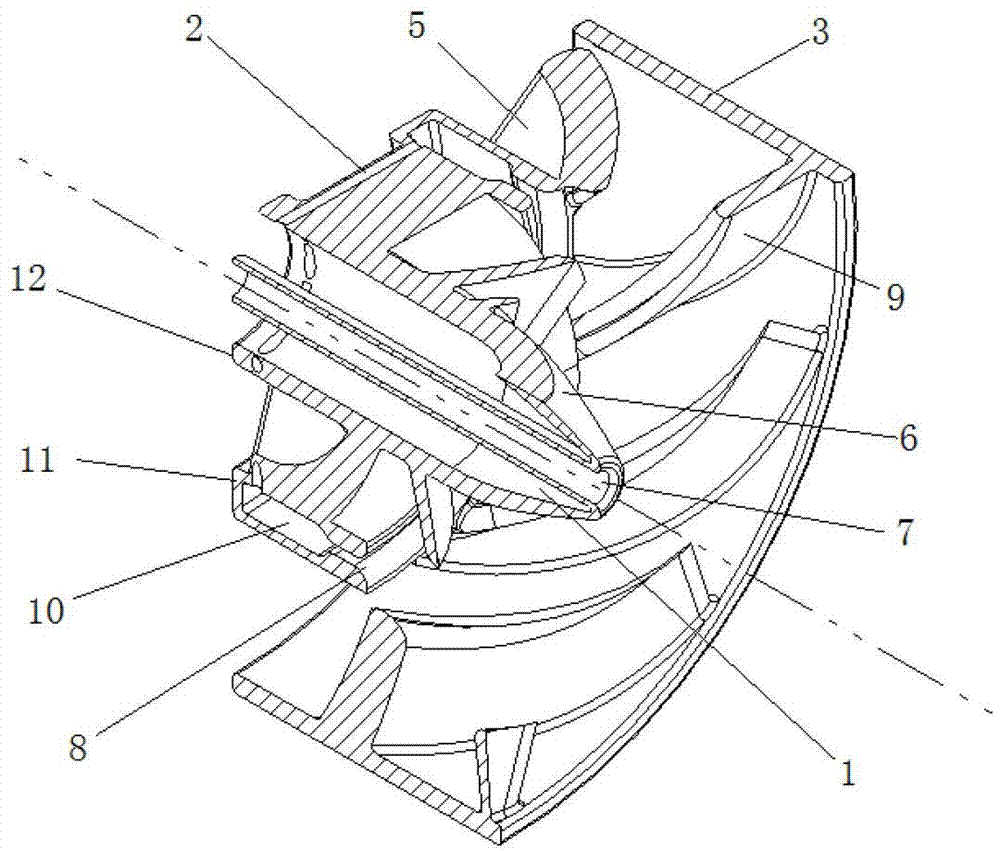

[0026] combine Figure 1~6 , the swirler includes a fuel supply channel 1, a gas channel 2 in the blade, an outer hub of the swirler 3, a diverging channel 4, an inner swirl blade 5, a central body cap 6, a central through hole 7, Coanda Nozzle 8, swirler blade 9, pyrolysis gas ring chamber 10, swirler middle hub 11, swirler inner hub 12. In addition, it also includes a schematic curve 13 of cracked gas fuel flow and a general schematic curve 14 of the expanding channel.

[0027] figure 1 and figure 2 Together, the working principle of the cracked gas fuel ring injection port is explained. The cracked gas first enters the nozzle through the fuel supply channel 1, and then enters the cracked gas ring cavity 10 through the vane gas channel 2 after encountering the blockage of the central body cap 6. During the process, a certain steady flow is carried out, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com