Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Solve combustion instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

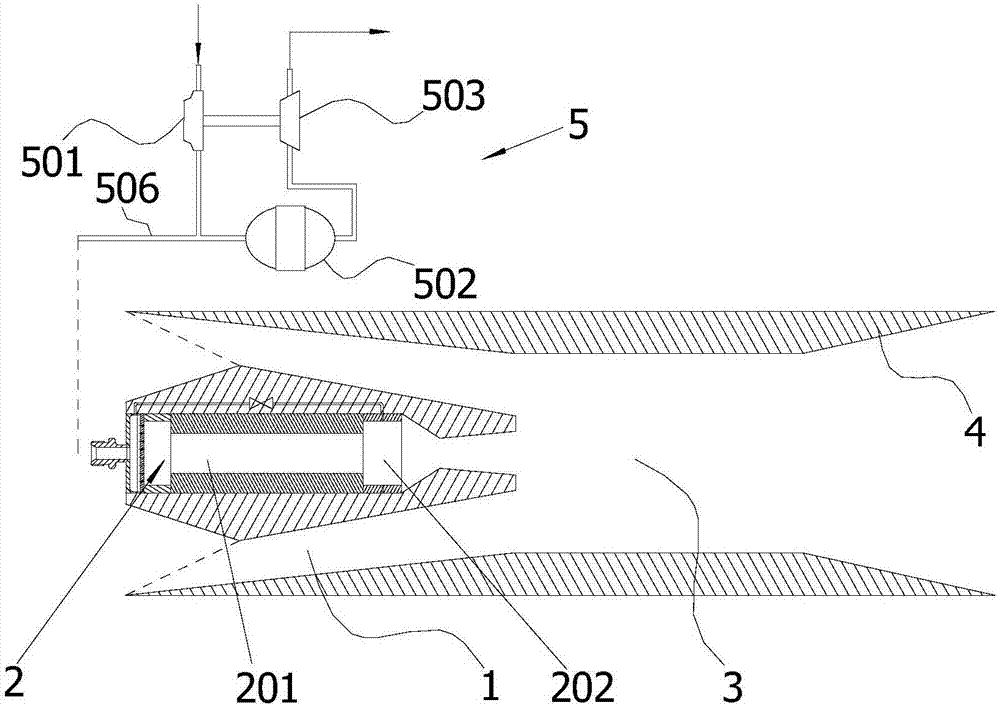

Solid-liquid hybrid rocket combined cycle propelling system and control method thereof

InactiveCN107503862AImprove overall gas energyIncrease thrustRocket engine plantsCombustion chamberPower equipment

The invention provides a solid-liquid hybrid rocket combined cycle propelling system, and relates to the technical field of aerospace power equipment. The solid-liquid hybrid rocket combined cycle propelling system comprises an air inlet, a solid-liquid hybrid rocket engine, a super combustion chamber, an exhaust nozzle and an oxidizing agent conveying device. The solid-liquid hybrid rocket engine, the super combustion chamber and the exhaust nozzle are successively communicated in sequence. A combustion chamber and an after-combustion chamber are successively arranged in the solid-liquid hybrid rocket engine. The air inlet is arranged on the circumferential outer side of the solid-liquid hybrid rocket engine and directly communicates with the super combustion chamber. The oxidizing agent conveying device is connected with the combustion chamber and the after-combustion chamber. The solid-liquid hybrid rocket combined cycle propelling system is simple in structure, safe, efficient and stable in combustion, ignition is easy, and the flow of an oxidizing agent and the thrust of the system can be flexibly adjusted. On the basis, the invention further provides a control method of the propelling system.

Owner:BEIHANG UNIV

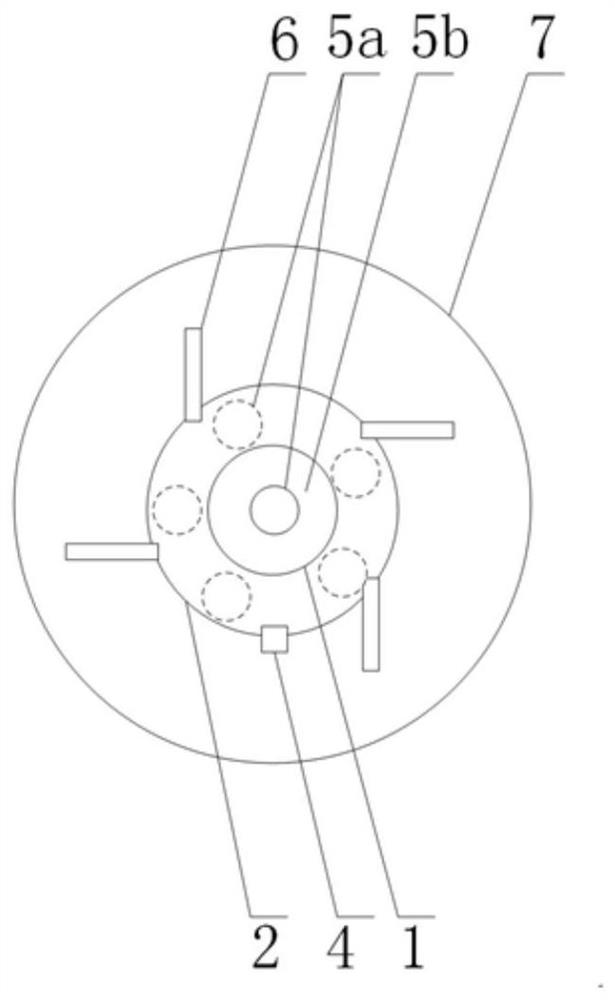

Combined cycle engine

ActiveCN105736178AImprove specific impulseImprove economyGas turbine plantsTurbine/propulsion air intakesDetonationTurbojet engine

The invention provides a combined cycle engine. The combined cycle engine comprises a supersonic air inlet mechanism, a continuous rotation detonation engine body and a turbojet engine body, wherein the supersonic air inlet mechanism is provided with a first gas inlet which communicates with the outside and is opened in the axial direction, and the continuous rotation detonation engine body and the turbojet engine body are fixedly connected to the lower portion of the supersonic air inlet mechanism. The continuous rotation detonation engine body and the turbojet engine body both communicate with the supersonic air inlet mechanism in a controlled mode in order to work in the mode that external gas is introduced into the continuous rotation detonation engine body and the turbojet engine body through the first gas inlet in the controlled mode. According to the combined cycle engine, mode transition can be completed within an operating envelope range, the stable thrust is provided for an aircraft, and then the aircraft hypersonically flies at 5.0 Mach or above in the atmosphere and can land and take off horizontally; in addition, the specific impulse of the engine is improved on the basis of adopting the continuous rotation detonation technique, the combustion heat efficiency is improved, and the economy and the reliability of the engine are improved.

Owner:清航空天(浙江)科技有限公司

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

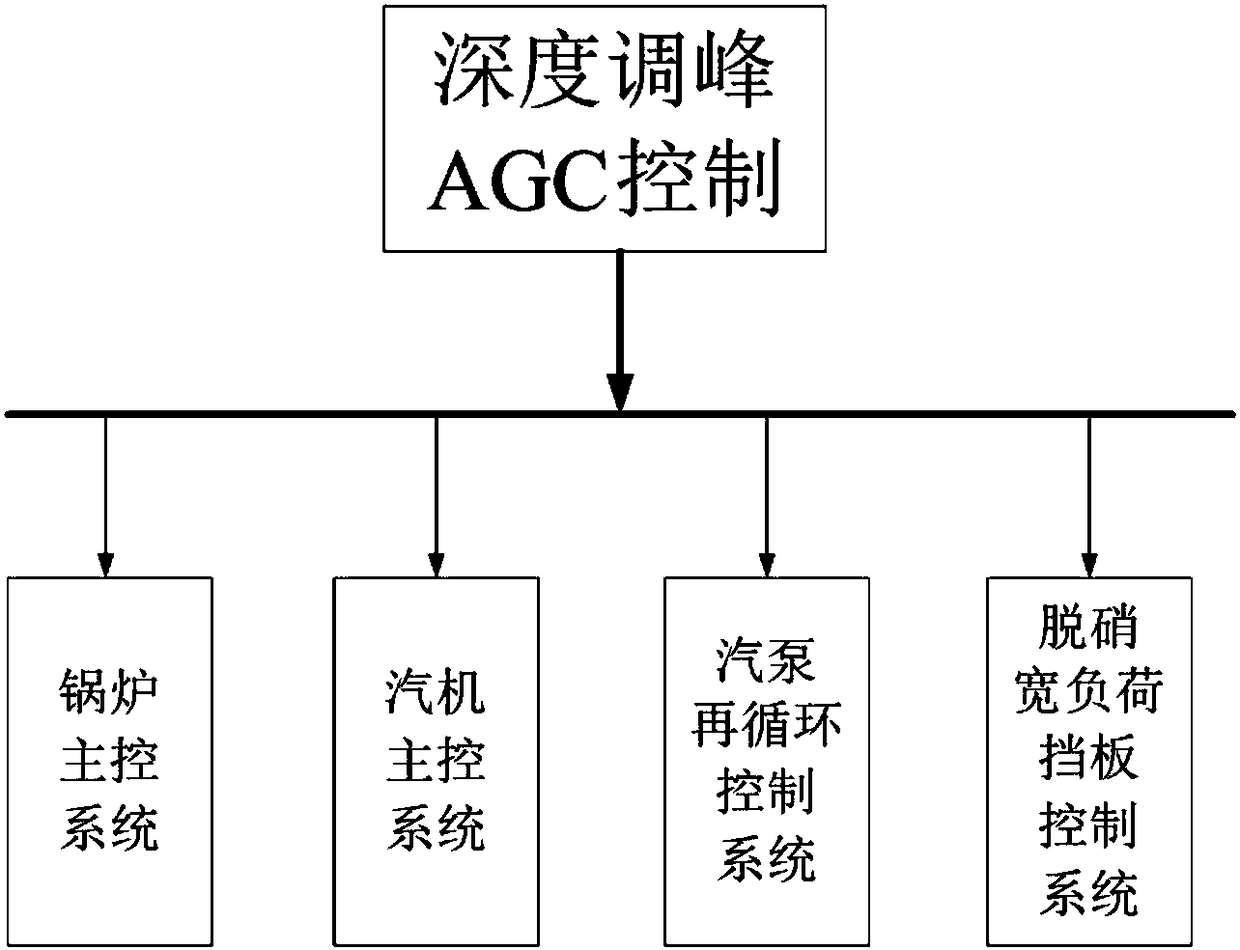

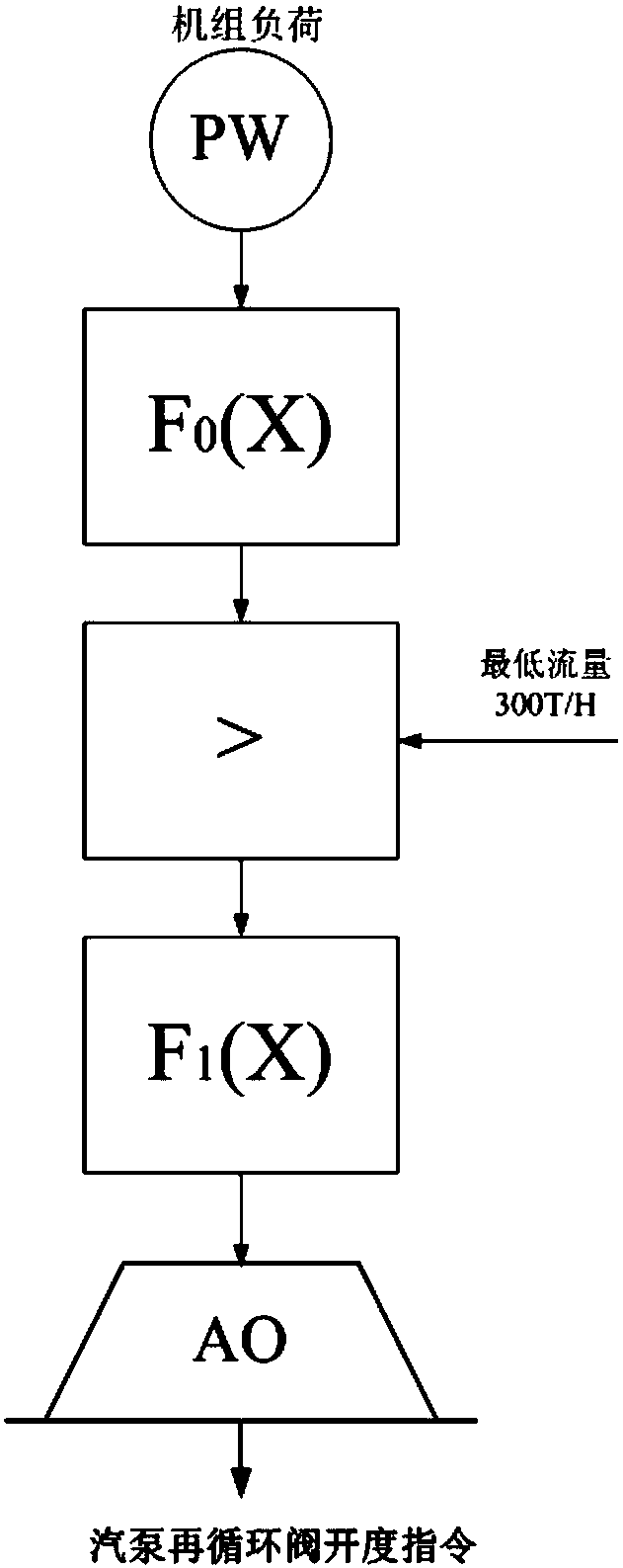

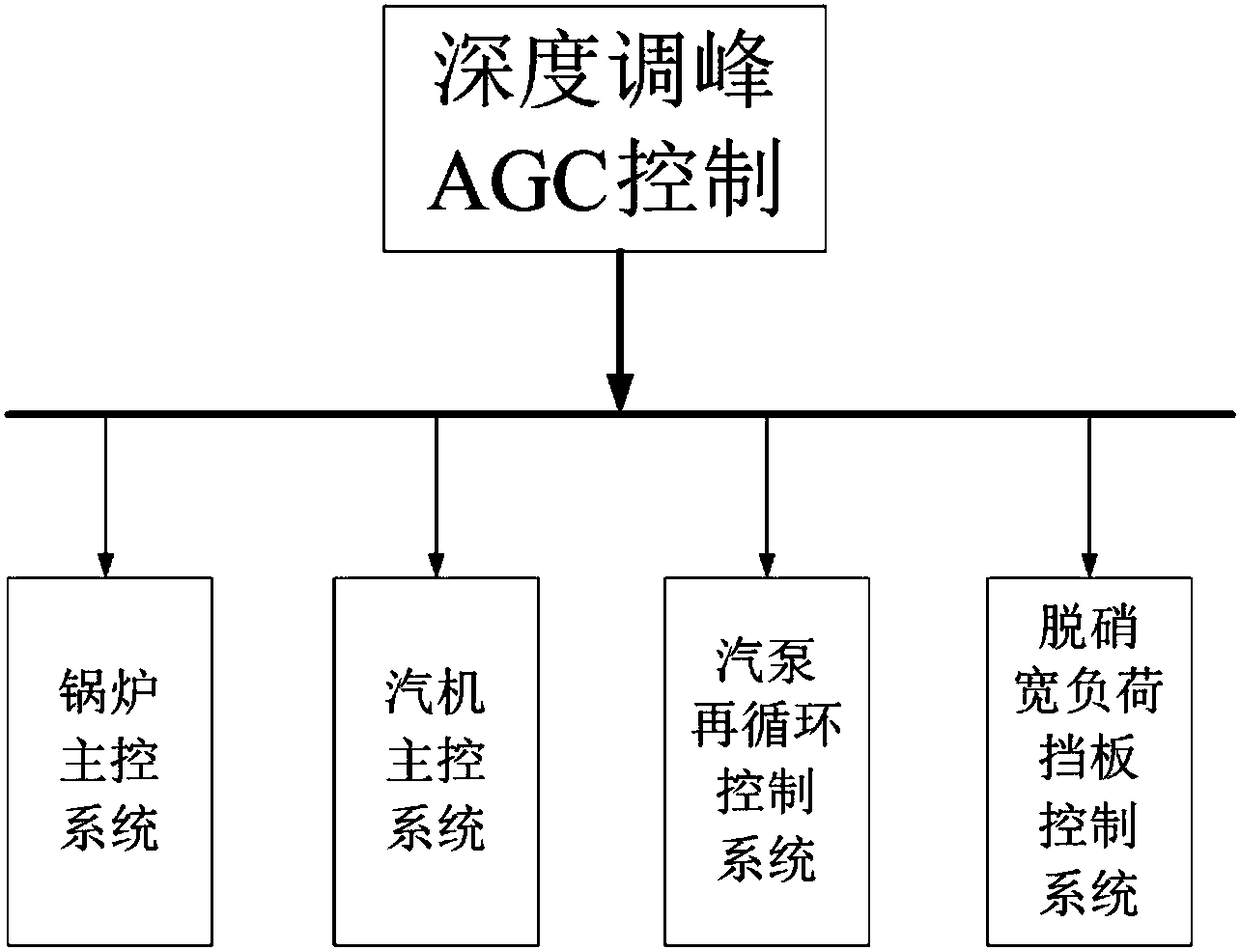

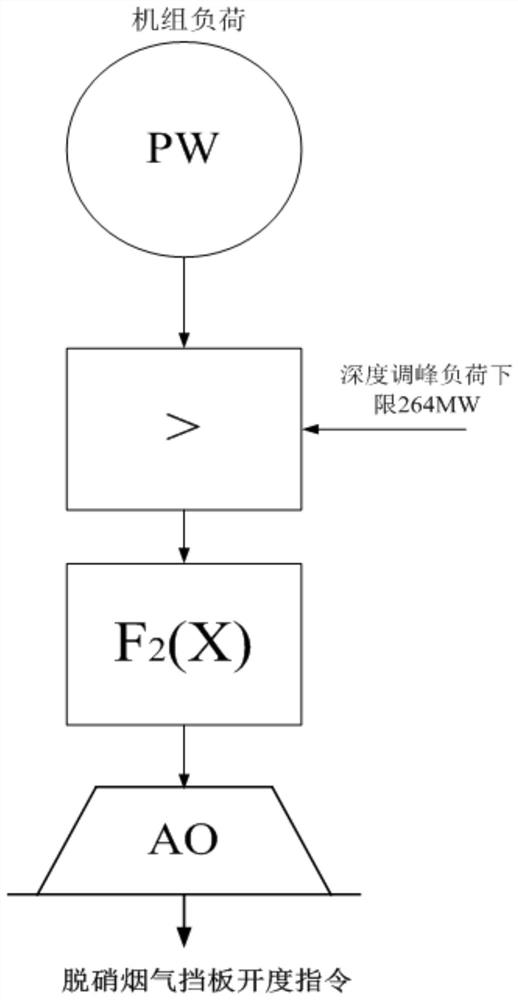

AGC control system for 660MW supercritical unit under deep peak regulation

ActiveCN108490794AIncrease adjustment depthAvoid cavitationAdaptive controlAutomatic controlParameter control

The invention discloses an AGC control system for a 660MW supercritical unit under deep peak regulation, belonging to the technical field of AGC control. When the load of the unit is in a deep peak regulation interval, minimum flow limitation is carried out on the flow of a gas pump; when the flow of a single gas pump is smaller than 425T / H, and a re-circulating valve of the gas pump is involved in gas pump inlet flow regulation, is slowly started and is maintained to work over a minimum output; meanwhile, the smoke temperature is increased at a boiler side, and a denitration wide load baffleis slowly turned down along the load of the unit so as to maintain the smoke temperature of the unit under a low load; and when the load of the unit is in a deep peak regulation interval, AGC speed isautomatically reduced through judgment, meanwhile, PID self-adaption and variable parameter control of boiler main control and steam engine main control can be realized through AGC, so that the automatic control quality is improved. According to the AGC control system, the following of the re-circulating valve and the denitration wide load baffle of a steam feed pump along the automatic load control of the unit, the AGC automatic control under deep peak regulation, the steam engine main control PID self-adaption control and the boiler main control PID self-adaption control can be realized.

Owner:MAANSHAN DANGTU POWER GENERATION

AGC (automatic gain control) control method for 660MW supercritical unit under deep peak-load regulation

The invention belongs to the technical field of AGC (automatic gain control) control and discloses an AGC control method for a 660MW supercritical unit under deep peak-load regulation. The method includes: when a unit load enters a deep peak-load regulation range, subjecting flow of steam pumps to minimum flow limitation; when the flow of each single steam pump is smaller than 435T / H, enabling a steam pump recirculation valve to participate in steam pump inlet flow regulation, slowly opening, and keeping each steam pump operating above minimum output; increasing smoke temperature on a boiler side, and slowly closing a denitrification wide load baffle along with the unit load to keep smoke temperature under a low unit load condition; after the unit load enters the deep peak-load regulationrange, automatically reducing the rate through AGC rate judgment, and enabling boiler master control and steam engine master control PID self-adaption variable-parameter control through AGC control, so that automatic control quality can be improved. Automatic control of the steam feed pump recirculation valve and the denitrification wide load baffle along with the unit load, AGC automatic controlunder deep peak-load regulation, steam engine master control PID self-adaption control and boiler master control PID self-adaption control are realized.

Owner:MAANSHAN DANGTU POWER GENERATION

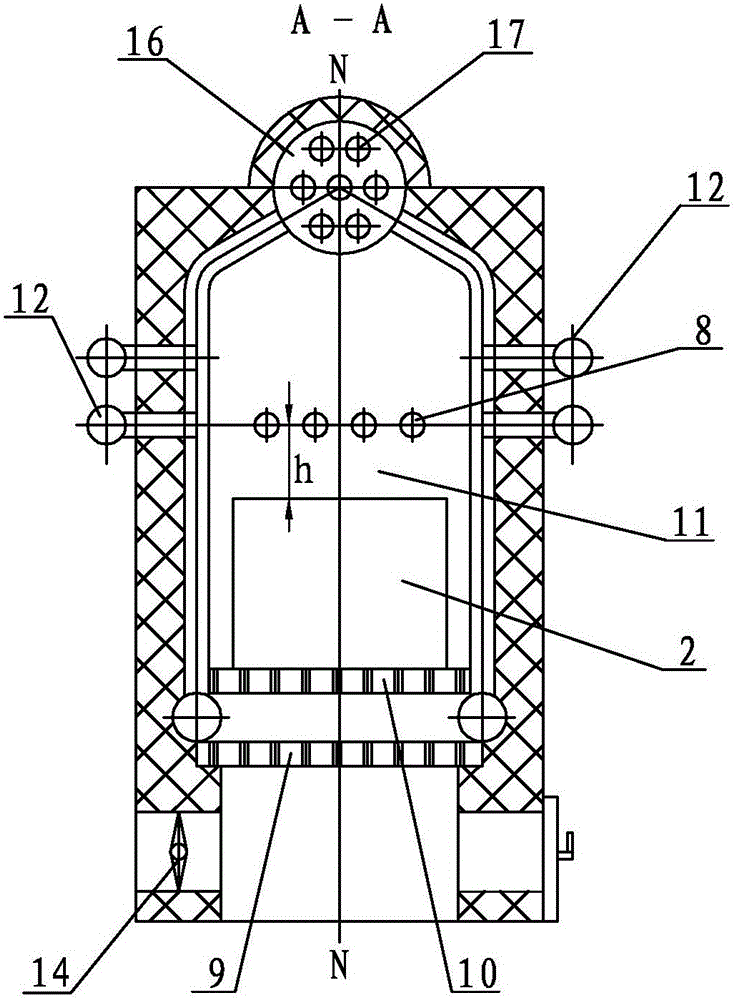

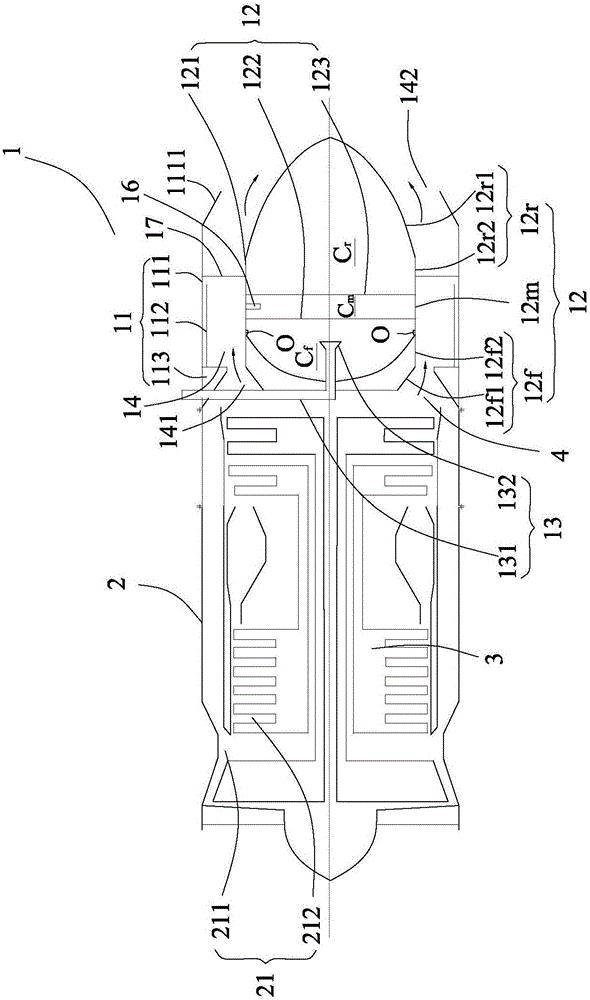

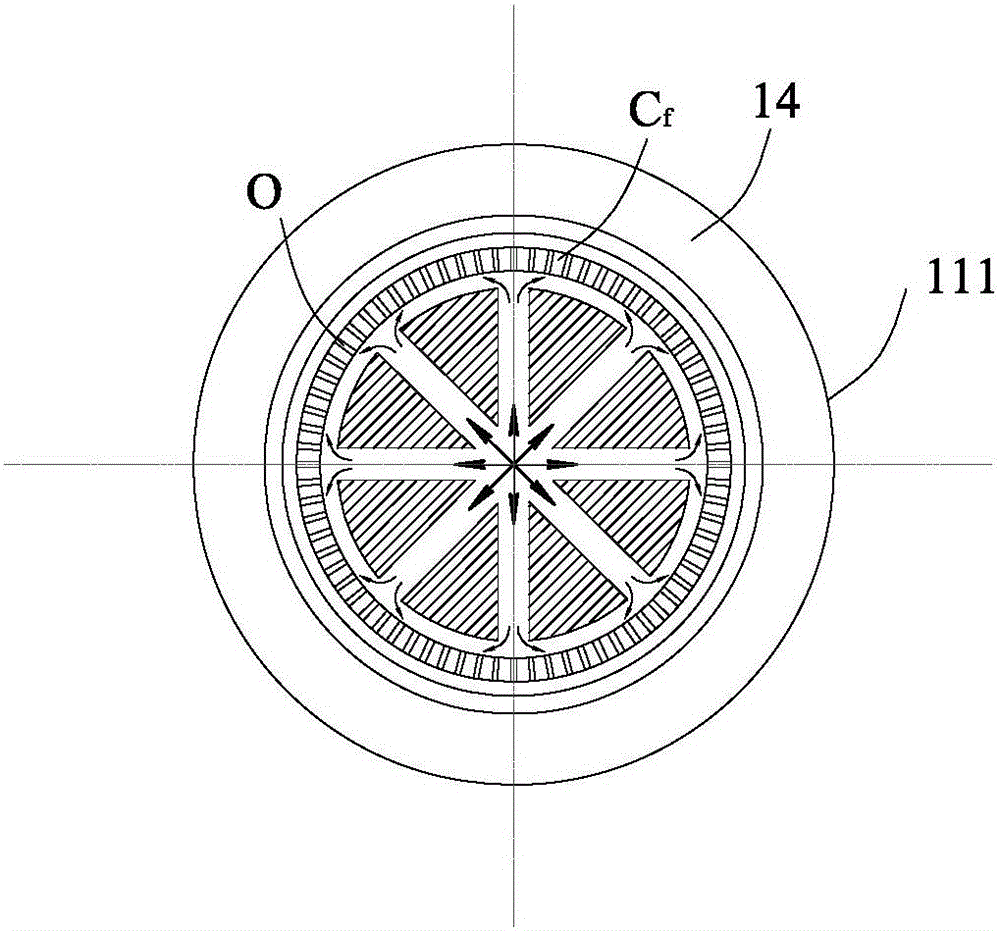

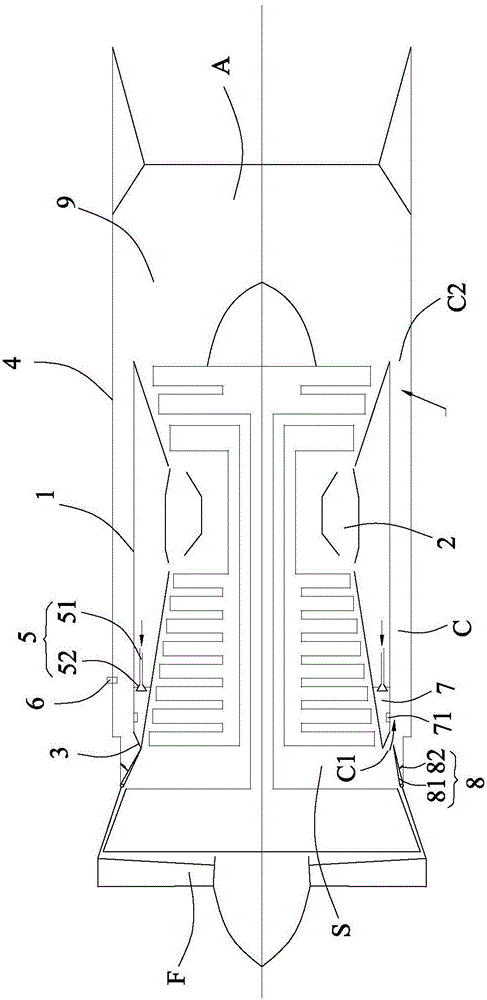

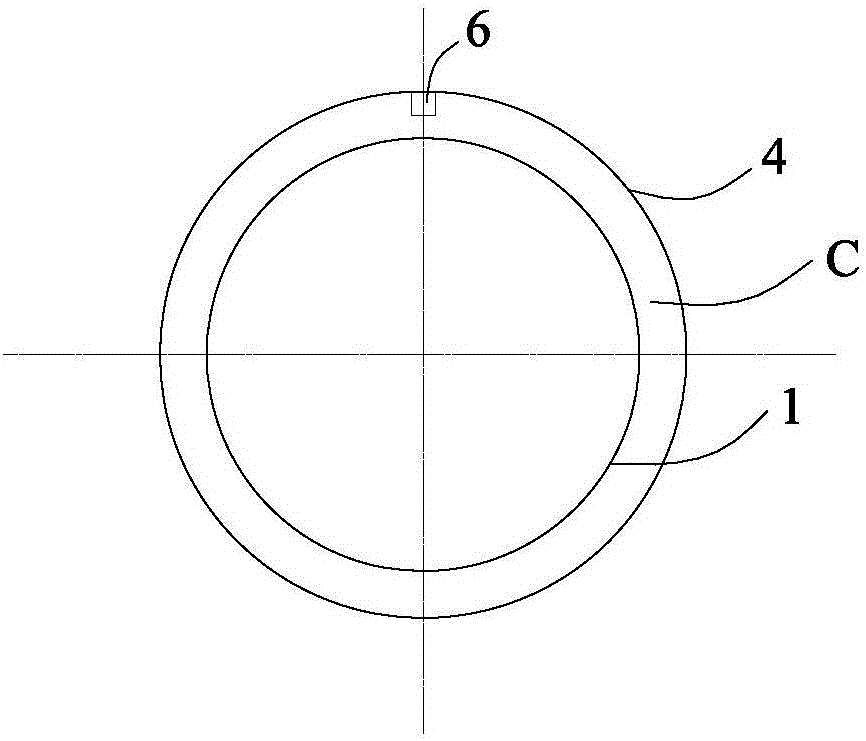

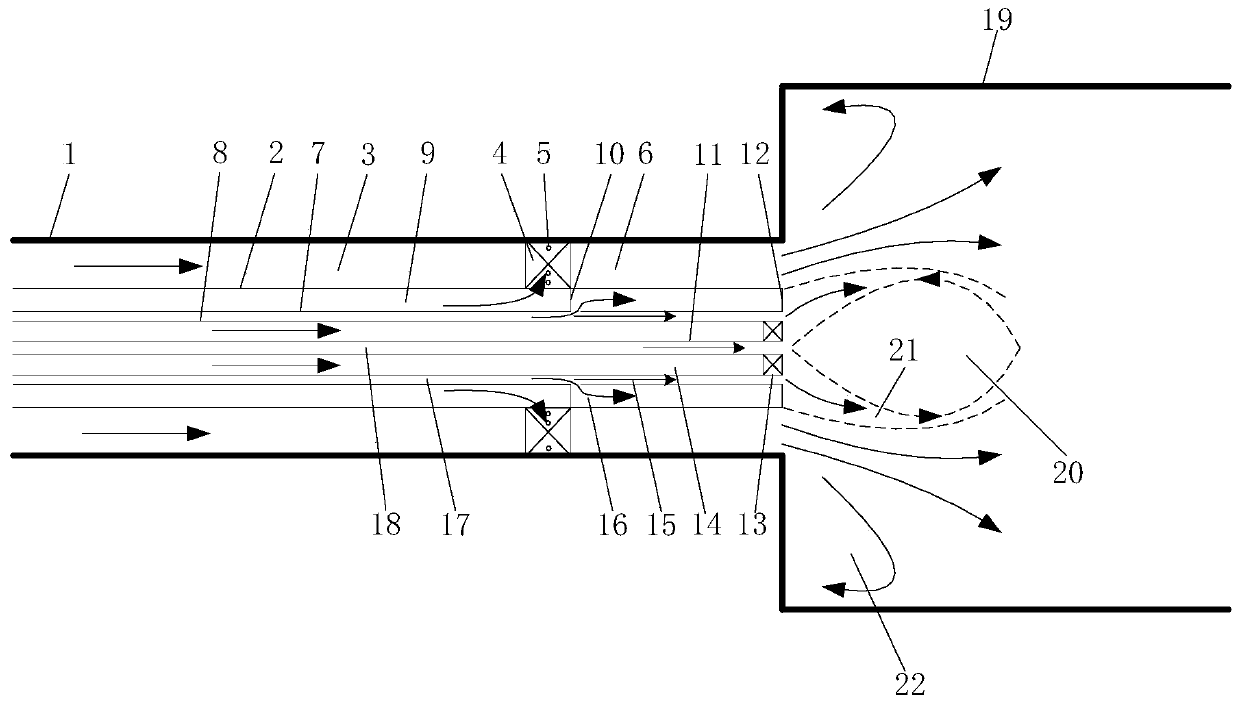

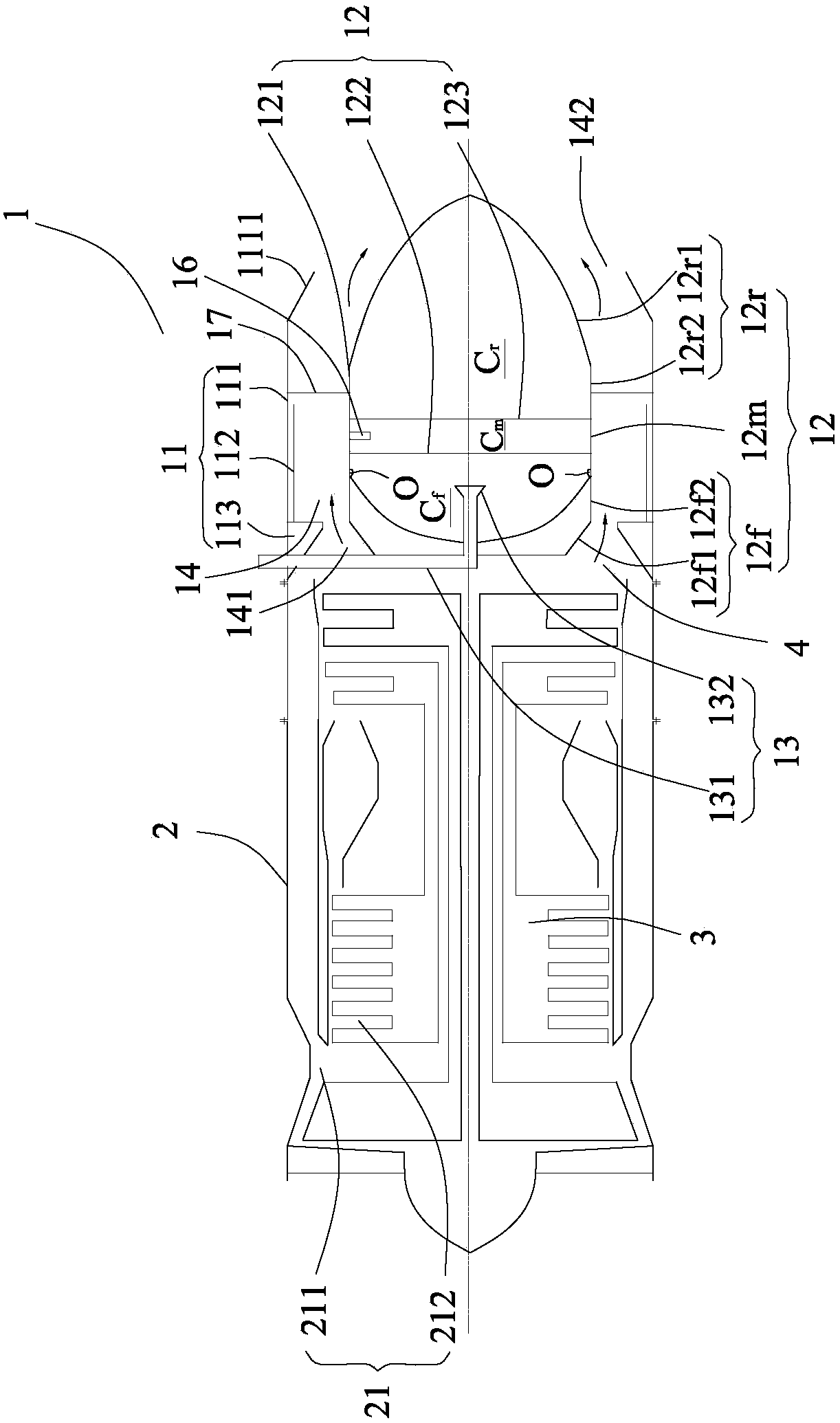

Afterburner and turbine engine

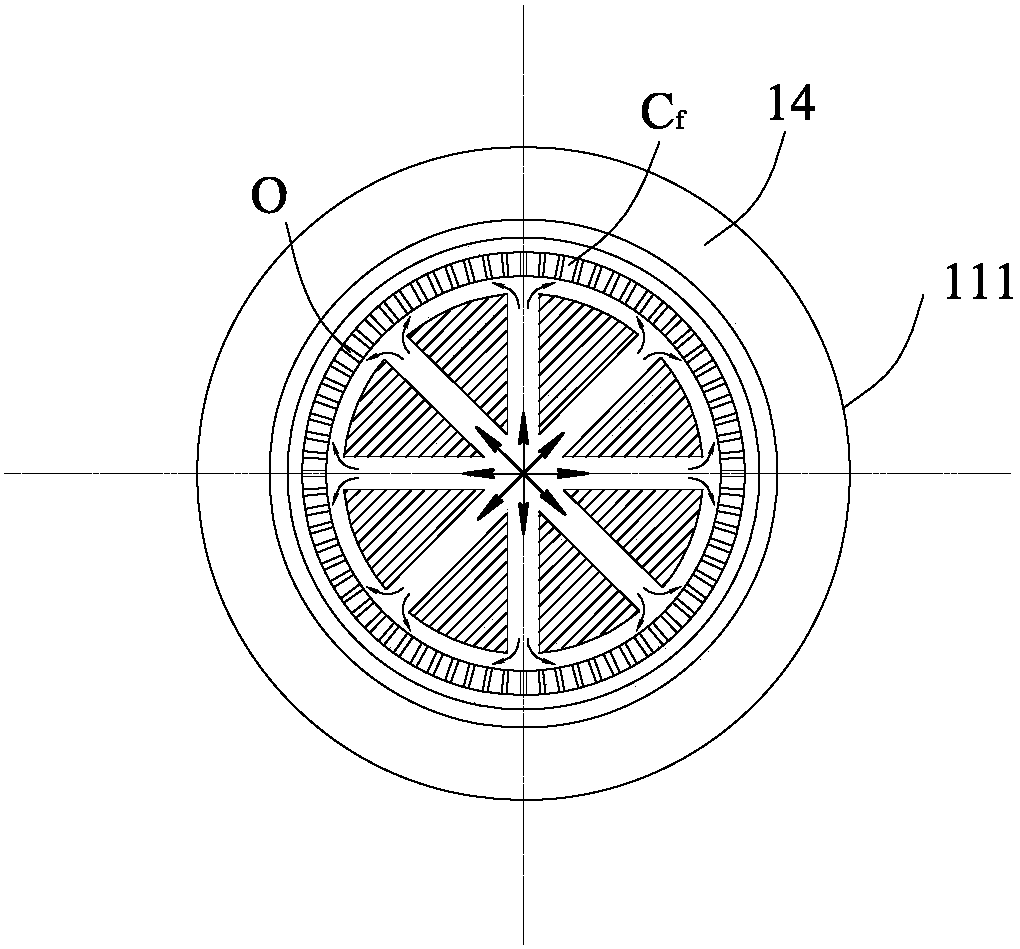

ActiveCN105698219ASolve combustion instabilityImprove efficiencyGas turbine plantsExplosive combustion chamberAutomotive engineeringCombustion chamber

The invention provides an afterburner and a turbine engine. The afterburner comprises an outer cylinder assembly, a center body assembly, an oil way assembly, an annular combustion chamber and an igniter; the center body assembly comprises a front body, a middle body and a rear body, wherein the front body is located at the axial front end of the afterburner and forms a gas inlet, accepting entry of oxygen-containing gas, of the annular combustion chamber with the outer cylinder assembly, the middle body is located behind the front body along the axis and is connected to the front body and integrated with the front body, and the rear body is located behind the middle body in the axial direction, is arranged in the middle body in a slid and sleeved mode and forms a gas outlet of the annular combustion chamber with the outer cylinder assembly; the igniter is arranged at the corresponding part, forming the annular combustion chamber with the outer cylinder assembly, of the center body assembly and is used for igniting fuel gas formed by fuel and the oxygen-containing gas entering the annular combustion chamber, then rotation and knocking combustion of the fuel gas are realized, and therefore the problem that combustion of the afterburner is instable is solved, the heat efficiency of combustion is improved, and the power capability of working media is improved.

Owner:清航空天(浙江)科技有限公司

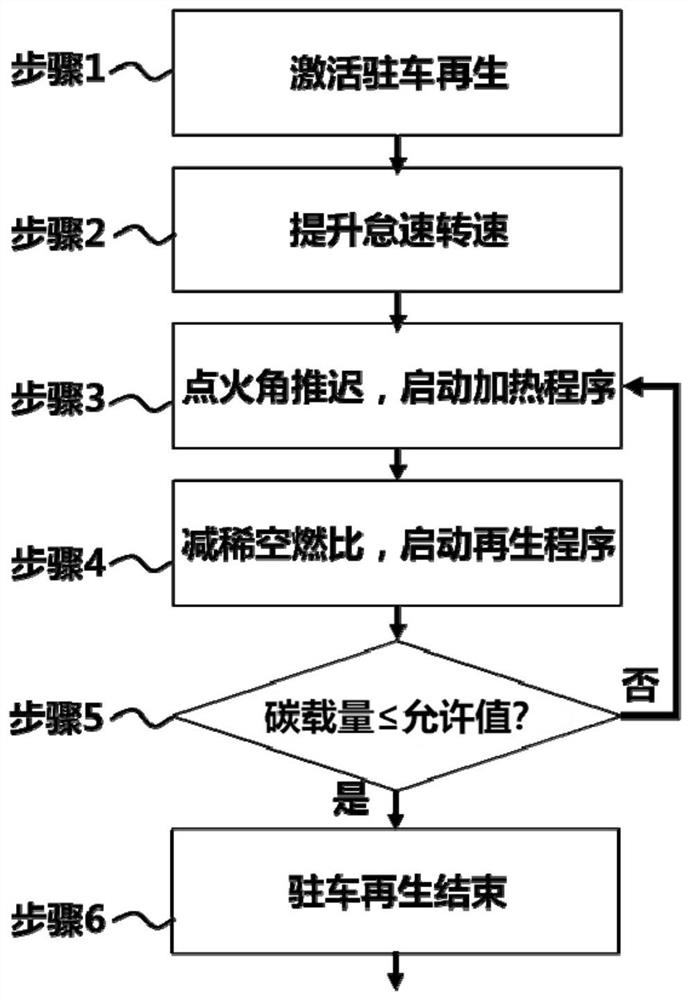

Gasoline engine particulate filter regeneration control method

ActiveCN111749803ASolve combustion instabilityNo extensionElectrical controlInternal combustion piston enginesGasolineProcess engineering

The invention provides a gasoline engine particulate filter regeneration control method. According to the method, through alternately carrying out an exhaust gas heating process and a gasoline engineparticulate filter regeneration process, an air-fuel ratio and / or an ignition advance angle can be adjusted in each independent process, so that the combustion stability and the regeneration speed aregreatly improved, the occurrence of the fire happened in the regeneration process is avoided, the risk of the temperature runaway of an exhaust system caused by fire is reduced, and a higher industrial application value is achieved.

Owner:CHINA FIRST AUTOMOBILE

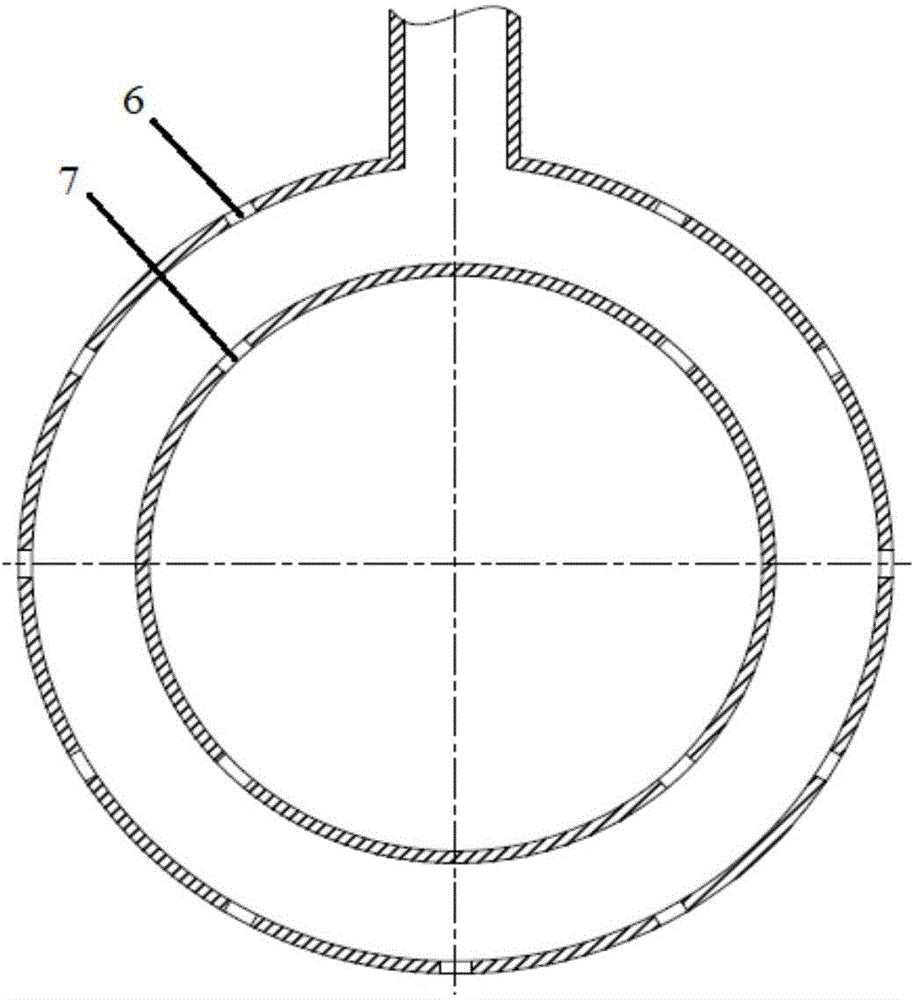

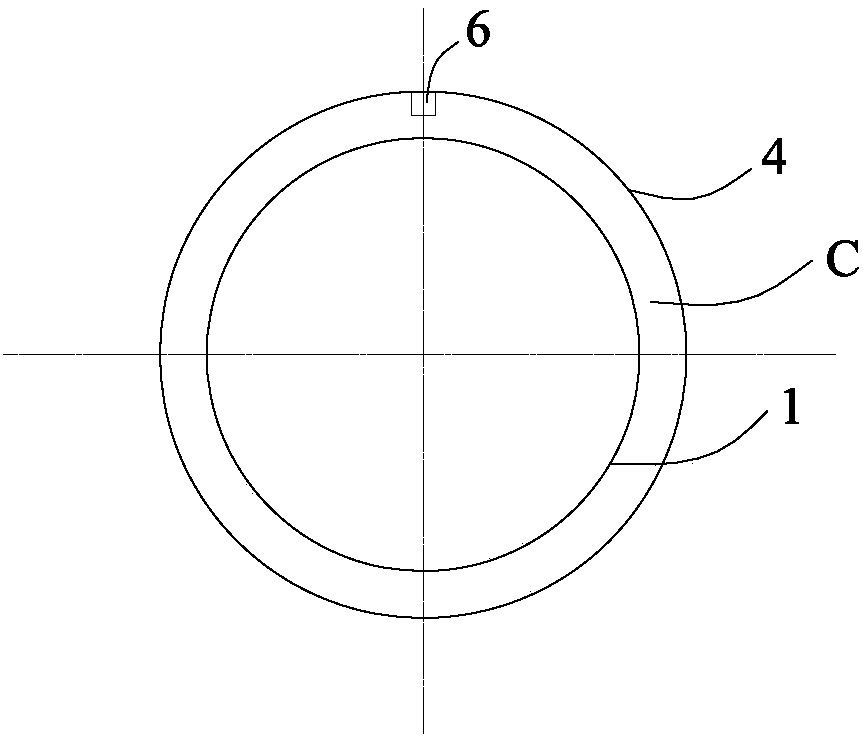

Opening circular road whirling premixing upward-spraying backflow preheat burner

InactiveCN101749706ASolve combustion instabilityImprove combustion intensityGaseous fuel burnerCurrent limitingAirflow

The invention relates to an opening circular road whirling premixing upward-spraying backflow preheat burner, which effectively solves the problems that the fuel consumption is high, combustion is instable, the combustion intensity is low, combustion air velocity temperature distribution is non-uniform, the efficiency is low and the environment is polluted; the structure is that: a semisphere top cylindrical shape with closed upper end and a downward opening is formed by a cylindrical wall body and an arch top at the upper part of the cylindrical wall body, a combustion chamber is arranged at the upper part in the cylindrical wall body in the arch top, a pre-mixing circular road with an opening at the upper part is circularly distributed on the inner wall of the cylindrical wall body, the pre-mixing circular road is respectively communicated with a coal gas inlet pipe and an air inlet pipe through a coal gas diversion channel and an air diversion channel, diversion guiding blocks are uniformly distributed in the coal gas diversion channel and the diversion channel, a current-limiting ring is communicated with the opening at the upper part of the premixing circular road; the opening circular road whirling premixing upward-spraying backflow preheat burner effectively solves the problems low-heat value gas combustion is instable, the combustion intensity is low and the combustion temperature is low, and simple structure of the invention is obviously superior to the structures of a flameless burner and a staggering injection rapid mixing combustor which are arranged in an airflow spray pipe.

Owner:刘世聚

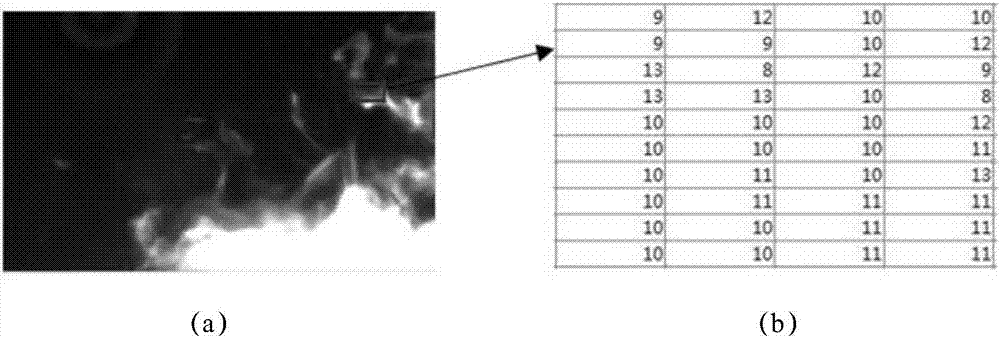

Combustion chamber combustion instability test measuring method based on image processing

InactiveCN106971388AAvoid high-frequency phase synchronization problemsSolve combustion instabilityImage enhancementImage analysisCombustion instabilityCombustion chamber

The invention discloses a combustion chamber combustion instability test measuring apparatus and method based on image processing. The apparatus comprises a combustion chamber, a high-frequency pressure transducer or a microphone, an acquisition card, a charge amplifier, a computer and a high-speed photographic instrument, the high-frequency pressure transducer or the microphone measures pressure pulsation signals in the combustion chamber in real time, the acquisition card acquires the measured pressure pulsation signals in the combustion chamber, the charge amplifier amplifies the pressure pulsation signals and transmits the pressure pulsation signals to the computer, and the high-speed photographic instrument or another high-speed CCD camera performs high-frequency shooting on a flame change process in the combustion chamber. By employing the combustion instability test measuring method based on image processing, test measurement of the combustion instability in the combustion chamber can be performed, the generation reasons of the combustion instability thereof can be preliminarily obtained, and the problem of combustion instability in the combustion chamber can be solved by employing an active or passive suppression method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Ignition optimal control method for sintering machine

ActiveCN108507365AGuaranteed uptimeAvoid wastingFurnace safety devicesGas emission reductionOptimal controlTemperature control mode

The invention discloses an ignition optimal control method for a sintering machine. The ignition optimal control method comprises the steps that valves controlling natural gas and air flow are connected with PLC / DCS systems correspondingly, and PID closed-loop control is adopted; a flow follow-up regulation mode is used, an air-fuel ratio and natural gas flow are set, and according to the formulathat natural gas flow*air-fuel ratio=air flow, the set air flow is obtained; then an ignition temperature control mode is used, and according to the deviation of target temperature and the current temperature, a new natural gas flow target value is calculated; then an ignition strength control module is used, the current ignition strength is obtained, and then target ignition strength is given according to the current ignition strength; and then according to the target ignition strength, the natural gas flow needing to be achieved is obtained, and then air flow is obtained through the air-fuelratio. According to the ignition optimal control method, a waste or flameout phenomenon of natural gas is avoided, meanwhile stability of PID closed-loop control in the regulation process is ensured,instable burning is prevented, and thus operation of the sintering machine is safer, more reliable and more stable.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

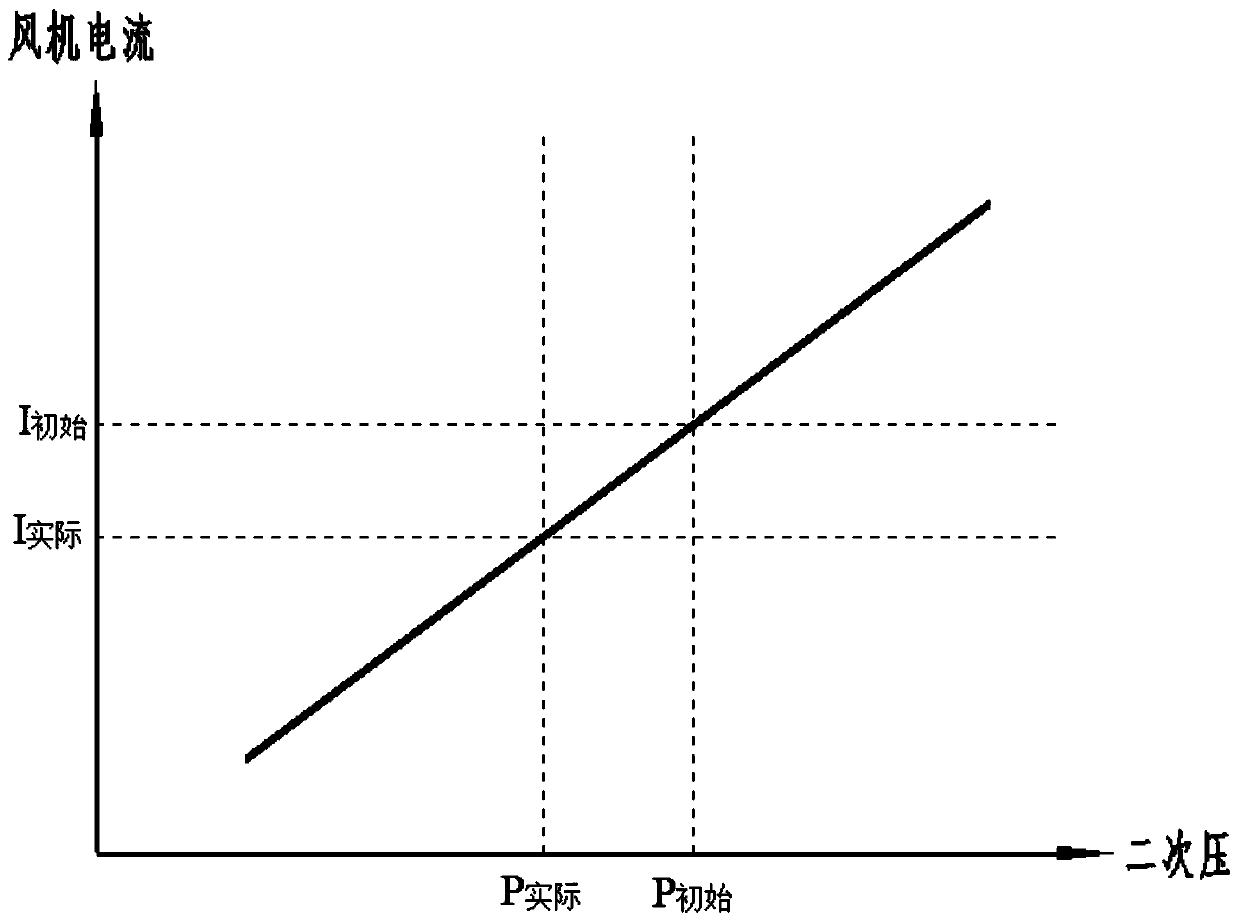

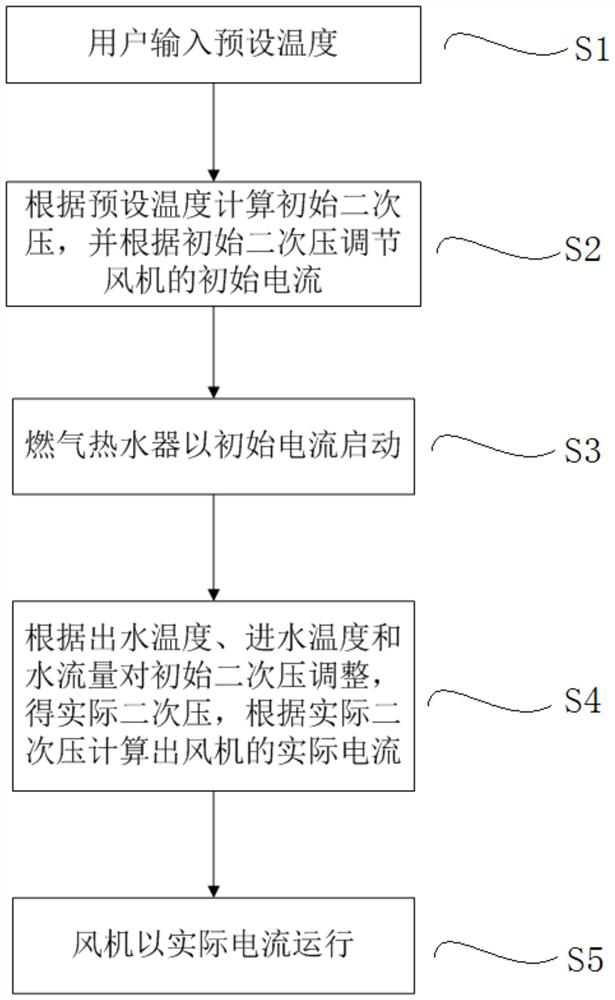

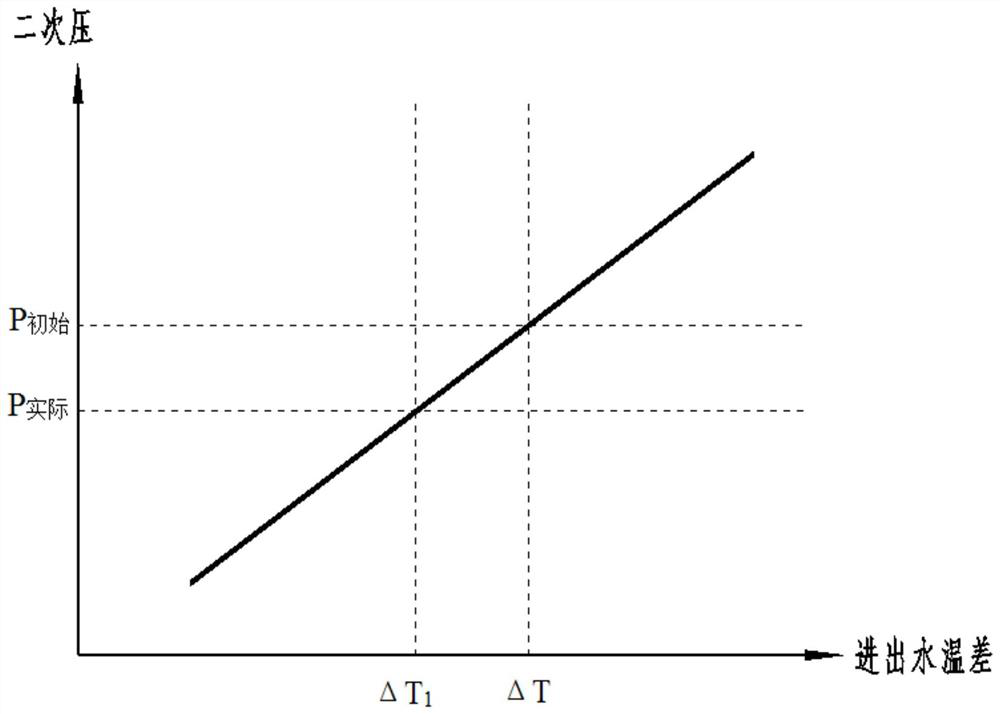

Fan air volume adjusting method for gas water heater and gas water heater

ActiveCN110926032ASolve combustion instabilityNo additional costFluid heatersInitial currentInlet temperature

The invention discloses a draught fan air volume adjusting method for a gas water heater. The method is specifically implemented through the following steps: S1, enabling a user to input a preset temperature T preset; S2, calculating the initial secondary pressure P<initial> according to the preset temperature T<preset> at step S1, and adjusting the initial current I<initial> of a fan according tothe initial secondary pressure P<initial>; S3, starting the gas water heater at the initial current I<initial> at step S2; S4, adjusting the initial secondary pressure P<initial> according to the water outlet temperature, the water inlet temperature and the water flow to obtain the actual secondary pressure P<actual>, and calculating the actual current I<actual> of the fan according to the actualsecondary pressure P<actual>; S5, enabling the fan to actually operate at the actual current I<actual> at step S4. The invention further discloses the gas water heater. According to the method, extracost does not need to be increased, and the problem that an existing gas water heater is unstable in combustion under different pressures can be solved only by adjusting the current of the fan againaccording to the actual secondary pressure in a control program.

Owner:VATTI CORP LTD

Turbine engine

ActiveCN105697148AIncrease thrust-to-weight ratioImprove fuel economyTurbine/propulsion fuel supply systemsGas turbine plantsCombustion chamberRocket turbine engine

The invention provides a turbine engine. The turbine engine comprises a receiver, a turbine, a shunt ring, a shell, an oil way component and an igniter. The shunt ring is connected to the front end of the receiver, and coats the turbine with the receiver. The shell accommodates the receiver, and forms an outer culvert combustion chamber with the outer wall surface of the receiver; and the shunt ring and the internal of the receiver form an inner culvert airflow channel. The oil way component is controlled to communicate to the outer culvert combustion chamber. The igniter is arranged in the outer culvert combustion chamber for igniting gas to generate knocking combustion of the gas. In the turbine engine, the outer culvert combustion chamber is simple in structure and light in weight, so that the thrust-weight ratio of the engine is largely increased. As the igniter is arranged in the outer culvert combustion chamber, the gas entering the outer culvert combustion chamber can rotate to generate the knocking combustion, the problem of unstable combustion of a traditional turbine engine is solved, the combustion heat efficiency is improved, and the fuel economy and the working reliability of the turbine engine are improved.

Owner:清航空天(浙江)科技有限公司

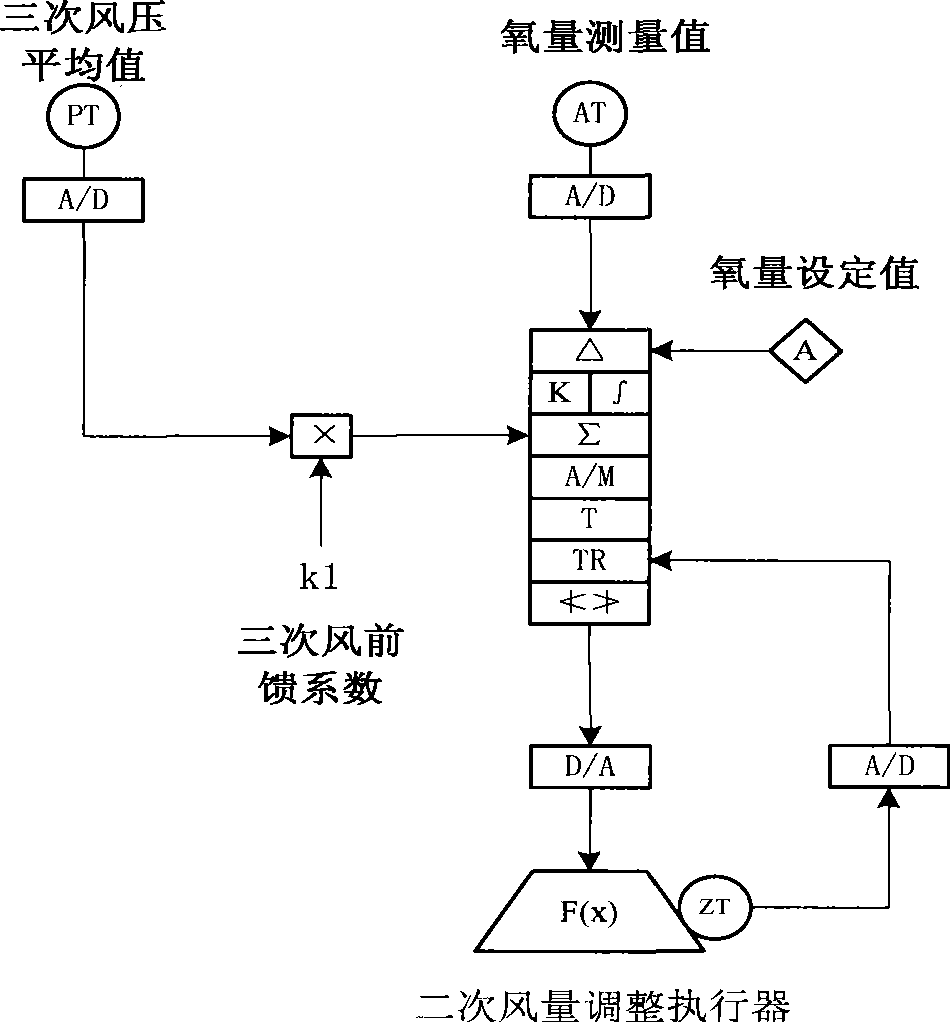

Control method and apparatus for combustion of storage type pulverized coal fired boiler

ActiveCN101504150ASolve combustion instabilityImprove stabilityAir supply regulationAir volumeProcess engineering

The embodiment of the invention discloses a method and a device for controlling combustion of an inter-bin pulverized coal fired boiler. The method comprises the following steps: acquiring an average value of the tertiary air pressure of the inter-bin pulverized coal fired boiler; according to the average value, a pre-set tertiary air feedforward coefficient, a measuring value for oxygen level in the boiler and a preset value for the oxygen level, generating a secondary air quantity adjusting instruction; and sending the secondary air quantity adjusting instruction to a secondary air quantity adjustment executor so as to control the combustion of the inter-bin pulverized coal fired boiler by the secondary air quantity adjustment executor according to the secondary air quantity adjusting instruction. The method and the device have the advantages of solving the problem of unstable combustion of the boiler due to the drastic change of the tertiary air quantity existing in the prior art and improving the combustion stability of the inter-bin pulverized coal fired boiler.

Owner:ZHEJIANG SUPCON TECH

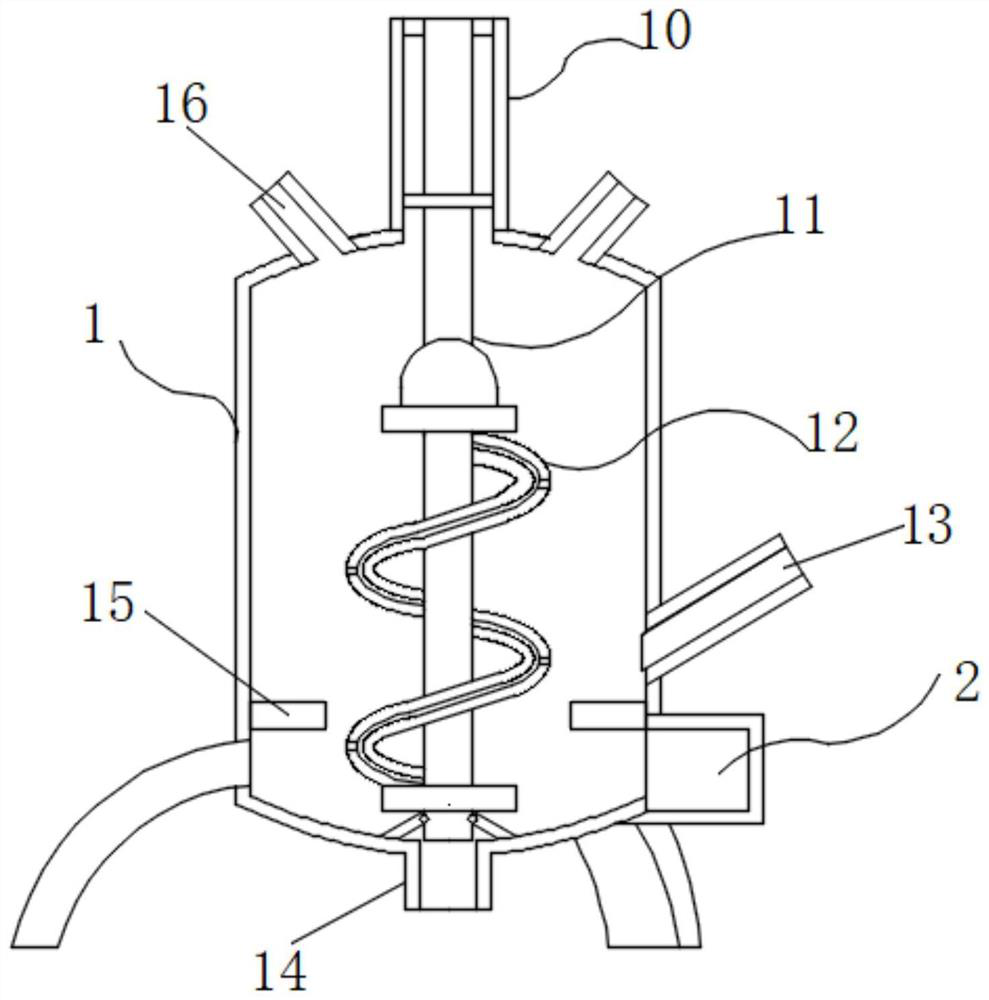

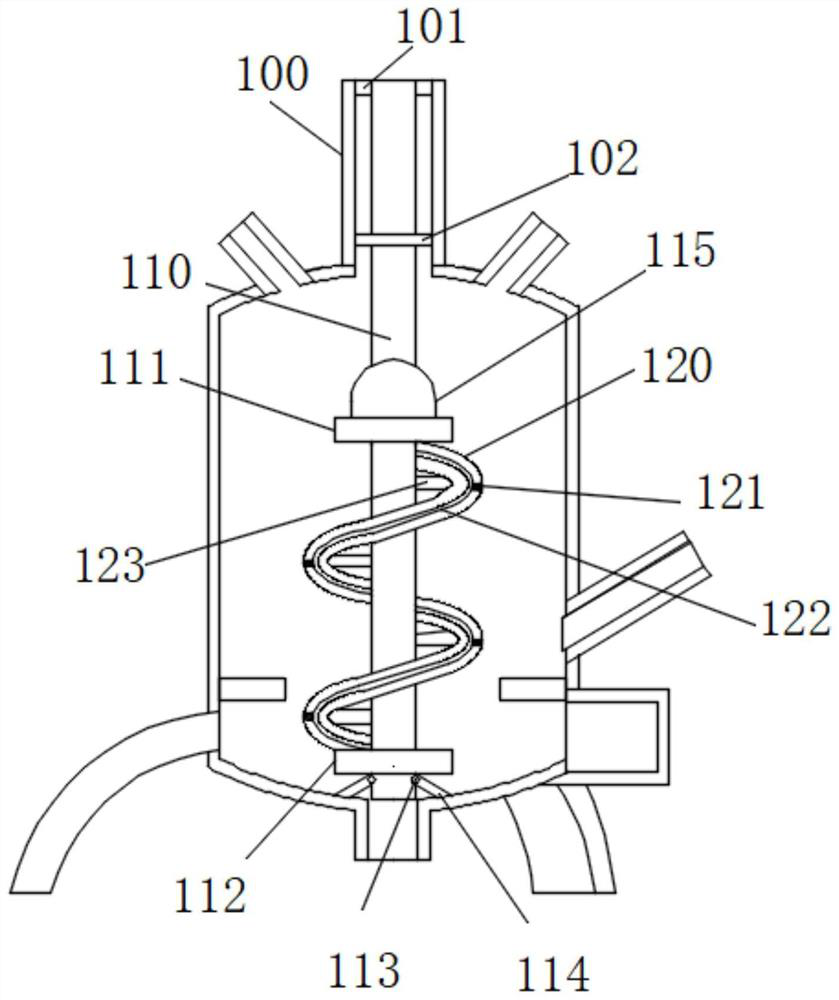

Efficient pyrolysis garbage incinerator

ActiveCN112856437AShorten the timeFix slow responseBlast-producing apparatusAir/fuel supply for combustionAir volumeDrive shaft

The invention discloses an efficient pyrolysis garbage incinerator. The efficient pyrolysis garbage incinerator comprises an incinerator body, an air blower is welded to the right side of the incinerator body, a combustion-supporting pipe is welded to the front face of the incinerator body, the incinerator body comprises a reciprocating mechanism, and the bottom of the reciprocating mechanism is movably connected with a driving mechanism. According to the efficient pyrolysis garbage incinerator, a downward-pressing rotating disc is installed inside the incinerator body, when a driving shaft rotates, the air blower blows out mixed gas of a combustion improver sprayed out of the combustion-supporting pipe and air from an air pipe through a gas guide pipe, under the reversing effect of a reversing pipe, the mixed gas is sprayed downwards, mixed gas at the bottom is sprayed upwards, the driving shaft and the rotating disc form an eccentric mechanism due to the fact that an extrusion spring pushes out a limiting pin, the volumes of air entering the air pipe in unit time are different, a rotating speed difference exists between the downward-pressing rotating disc and a driving rotating disc all the time, the mixed gas and to-be-incinerated objects are fully mixed in combination with a stirring mechanism, and therefore the incineration efficiency is improved, and the problem that incinerated objects close to the middle of a traditional incinerator are not easy to incinerate is solved.

Owner:北京碧海能源装备有限公司

Dry type low-nitrogen staged combustion system for isolating diffusion combustion flame surface

ActiveCN111322636AIncrease temperatureImprove combustion stabilityContinuous combustion chamberNon-combustible gases/liquids supplyCombustion systemThermodynamics

The invention discloses a dry type low-nitrogen staged combustion system for isolating a diffusion combustion flame surface. The dry type low-nitrogen staged combustion system comprises a combustion chamber, a purge gas channel, a diffusion combustion fuel channel, a diffusion combustion isolation gas main channel, a premixed combustion fuel channel and a premixed combustion air channel, wherein the purge gas channel, the diffusion combustion fuel channel, the diffusion combustion isolation gas main channel, the premixed combustion fuel channel and the premixed combustion air channel communicate with the combustion chamber and are sequentially arranged from inside to outside; a premixed channel cyclone is arranged in the premixed combustion air channel; the premixed combustion fuel channelcommunicates with a premixed cavity through the premixed channel cyclone; the diffusion combustion isolation gas main channel is divided into two paths on the downstream portion of a premixed combustion fuel channel stop partition plate, one path is a diffusion combustion isolation gas main channel, and the other path is a diffusion combustion isolation gas sub-channel communicating with the diffusion combustion isolation gas main channel through an open hole; and a diffusion combustion fuel cyclone is arranged at the tail end of the diffusion combustion fuel channel. According to the dry type low-nitrogen staged combustion system, N2 in premixed combustion air can be isolated from the diffusion combustion flame surface, NOx emission is reduced, and the problem that combustion instabilityis likely to happen to lean-burn premixed combustion of an existing gas turbine is solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

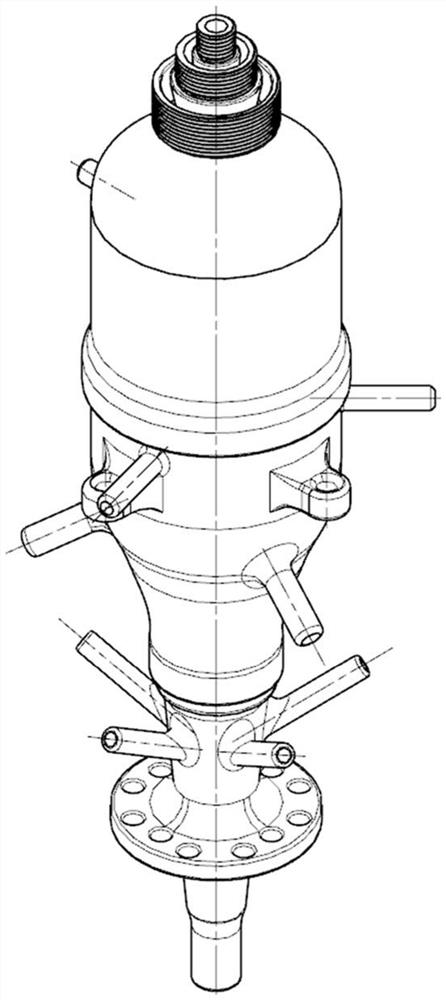

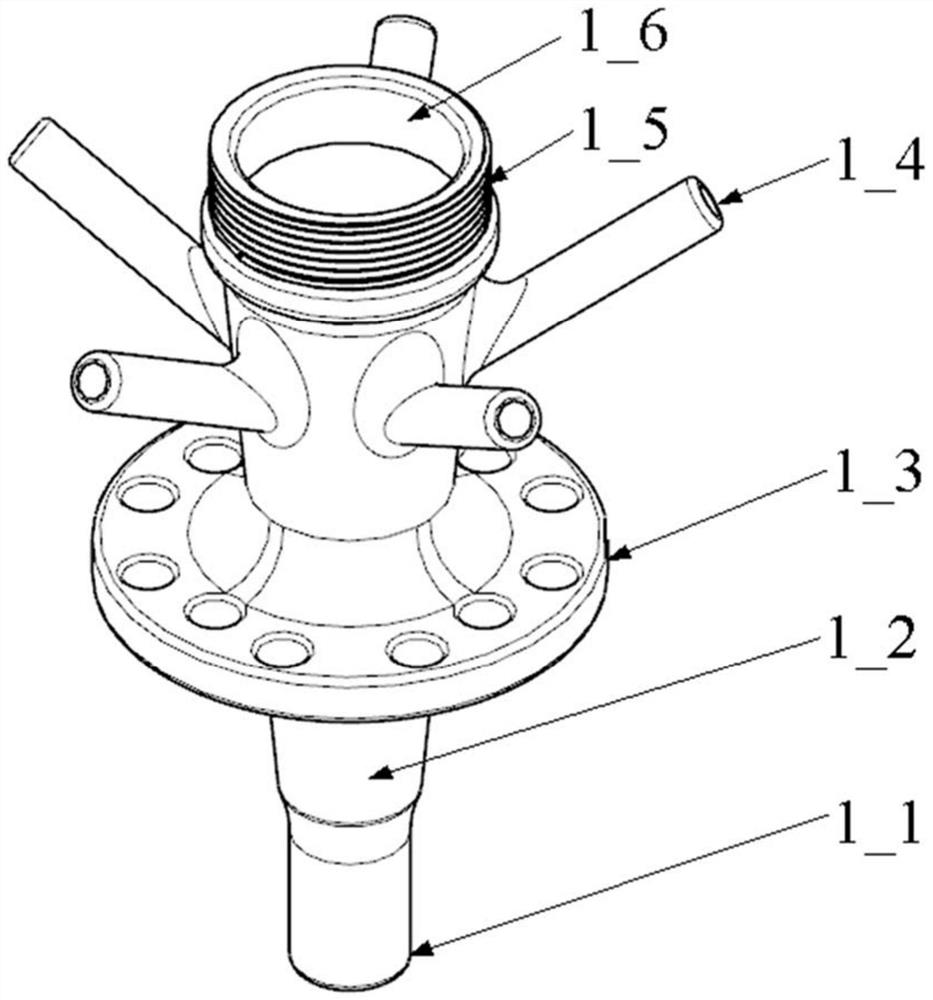

Oxygen injector used for oxygen-enriched combustion

InactiveCN104315534AFlexible selectionWell mixedIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyCombustionFlange

The invention discloses an oxygen injector used for oxygen-enriched combustion. The oxygen injector comprises an oxygen injection ring pipe; the oxygen injection ring pipe is provided with an oxygen inlet end; the oxygen inlet end is provided with a second flange; a plurality of oxygen injection ring inner side spray orifices are formed in the ring inner side wall of the oxygen injection ring pipe, and a plurality of oxygen injection ring outer side spray orifices are formed in the ring outer side wall of the oxygen injection ring pipe; the oxygen injector also comprises an oxygen straight flow pipe; one end of the oxygen straight flow pipe is provided with a first flange, and the other end of the oxygen straight flow pipe is communicated with an outside oxygen source. After the first flange and the second flange are fixed, outside oxygen enters the oxygen injection ring pipe through the oxygen straight flow pipe, and is sprayed in a direction vertical to the wall of an air or smoke pipeline through the oxygen injection ring inner side spray orifices and the oxygen injection ring outer side spray orifices to realize uniform mixing. According to the oxygen injector disclosed by the invention, the problems that local high temperature is caused and the combustion is insufficient due to the fact the oxygen and air or smoke are not mixed uniformly are effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Combustor

ActiveCN113418209ASpeed up the flowPlay the role of airflow regulatorContinuous combustion chamberIndirect carbon-dioxide mitigationCombustorMechanical engineering

The invention provides a combustor which comprises a first wall face, a second wall face, a third wall face, a first flow channel, a second flow channel, a third flow channel, a first air inlet pipe and a second air inlet pipe. The first flow channel is arranged between the first wall face and the second wall face; the second flow channel is arranged between the second wall face and the third wall face, and a third flow channel is arranged in the third wall face; the third wall face further comprises a first cavity used for stabilizing fluid in the third flow channel and a second cavity arranged below the first cavity and used for stabilizing fluid in the second flow channel; a partition plate is arranged between the first cavity and the second cavity; a rectifying column body is arranged in the second cavity, is arranged between the partition plate and the second wall face and is used for integrating fluid in the second cavity; and the first air inlet pipe and the second air inlet pipe both penetrate through the first wall face, the second wall face and the third wall face, an outlet of the first air inlet pipe is formed in the first cavity, and an outlet of the second air inlet pipe is formed in the second cavity.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Afterburner and turbine engines

ActiveCN105698219BSolve combustion instabilityImprove working abilityGas turbine plantsExplosive combustion chamberPower capabilityCombustion chamber

The invention provides an afterburner and a turbine engine. The afterburner comprises an outer cylinder assembly, a center body assembly, an oil way assembly, an annular combustion chamber and an igniter; the center body assembly comprises a front body, a middle body and a rear body, wherein the front body is located at the axial front end of the afterburner and forms a gas inlet, accepting entry of oxygen-containing gas, of the annular combustion chamber with the outer cylinder assembly, the middle body is located behind the front body along the axis and is connected to the front body and integrated with the front body, and the rear body is located behind the middle body in the axial direction, is arranged in the middle body in a slid and sleeved mode and forms a gas outlet of the annular combustion chamber with the outer cylinder assembly; the igniter is arranged at the corresponding part, forming the annular combustion chamber with the outer cylinder assembly, of the center body assembly and is used for igniting fuel gas formed by fuel and the oxygen-containing gas entering the annular combustion chamber, then rotation and knocking combustion of the fuel gas are realized, and therefore the problem that combustion of the afterburner is instable is solved, the heat efficiency of combustion is improved, and the power capability of working media is improved.

Owner:清航空天(浙江)科技有限公司

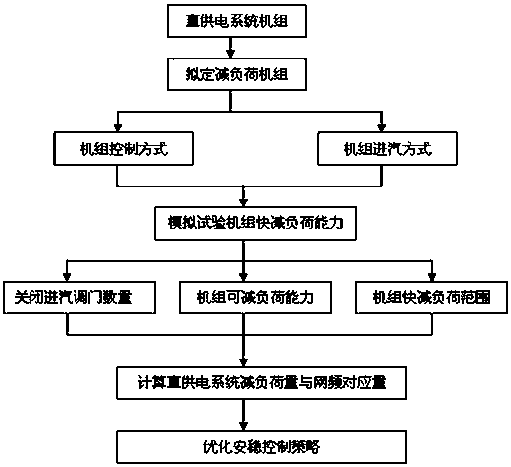

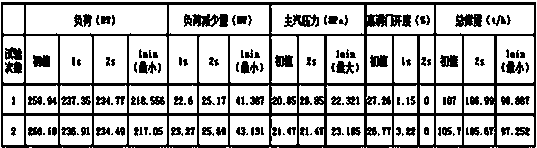

A network frequency adjustment method for rapid load reduction of generator sets

ActiveCN104779615BReduce the number of non-stopsPrevent overpressureSingle network parallel feeding arrangementsPower oscillations reduction/preventionControl mannerPower grid

Owner:JIUQUAN IRON & STEEL GRP

Low NOx burner for resource utilization of ultra-low heating value associated gases and carbon black burnout

ActiveCN111649342AImprove gas utilization efficiencyImprove fire stability and economyIncinerator apparatusActivated carbonCarbon black

The invention discloses a low NOx burner for resource utilization of ultra-low heating value associated gases and carbon black burnout. The Low NOx burner for resource utilization of ultra-low heatingvalue associated gases and carbon black burnout comprises a smoke inlet for the entry of the ultra-low heating value gases generated in the activated carbon manufacturing process, wherein the outputend of the smoke inlet is connected to a pilot combustion chamber; a primary air inlet is formed in the pilot combustion chamber; and low heating value gases burning in the pilot combustion chamber are completely burned in a concave heat gathering combustion chamber and a hearth through the cooperation of a vortex channel heat storage burner and over firing air fed by an over firing air inlet. Thelow NOx burner realizes the integrated treatment of industrial ultra-low heating value associated gas combustion, carbon black elimination and low NOx combustion, effectively utilizes the heat of theultra-low heating value gases, greatly improves the utilization efficiency of energy sources, can provide heat for subsequent enterprise transformations such as smoke whitening or heating transformation, and eliminates environmental pollution such as carbon black.

Owner:XI AN JIAOTONG UNIV

An AGC control method for 660mw supercritical unit under deep peak regulation

Owner:MAANSHAN DANGTU POWER GENERATION

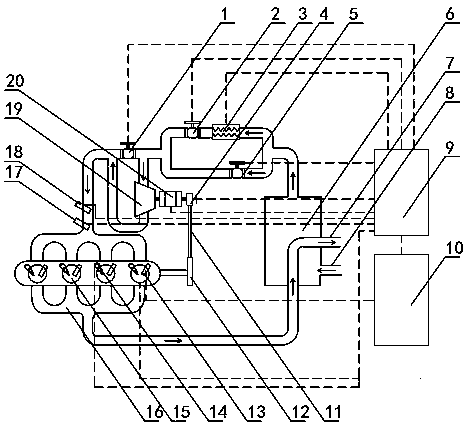

Control method and system for improving combustion stability of gasoline compression ignition in small-load working condition

ActiveCN111173635AImprove combustion stabilitySolve combustion instabilityElectrical controlInternal combustion piston enginesIn vehicleGasoline

The invention discloses a control method and system for improving combustion stability of gasoline compression ignition in a small-load working condition, and belongs to the technical field of engines. The system is characterized in that a main gas inlet pipe (8) is simultaneously connected with a gas inlet heater (3) and a gas inlet flow control valve (5), the gas inlet heater (3) is connected with a gas inlet heater flow control valve (2) in series, then the gas inlet heater (3) and the gas inlet flow control valve (5) are connected with an engine (16), an in-cylinder pressure sensor (13) and an in-cylinder direct injection oil injector (14) are installed in a variable valve (15), and the gas inlet heater flow control valve (2), the gas inlet heater (3), the gas inlet flow control valve(5), the in-cylinder direct injection oil injector (14) and the variable valve (15) are connected with a vehicle-mounted computer (9). Through the control method and system for improving the combustion stability of the gasoline compression ignition in the small-load working condition, the combustion stability of a gasoline compression ignition combustion mode in the small-load working condition isimproved, and the problem that at present, combustion of the gasoline compression ignition combustion mode in the small-load working condition is unstable is solved.

Owner:SHANDONG UNIV OF TECH

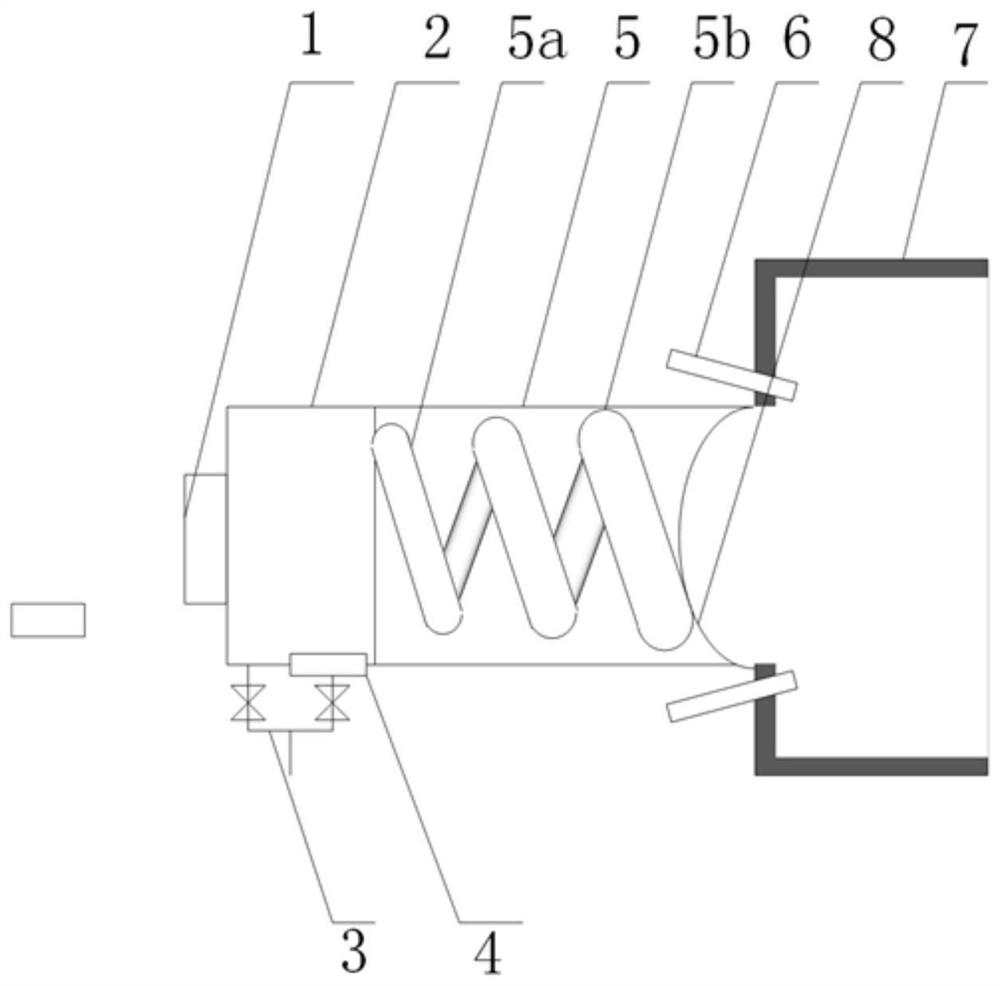

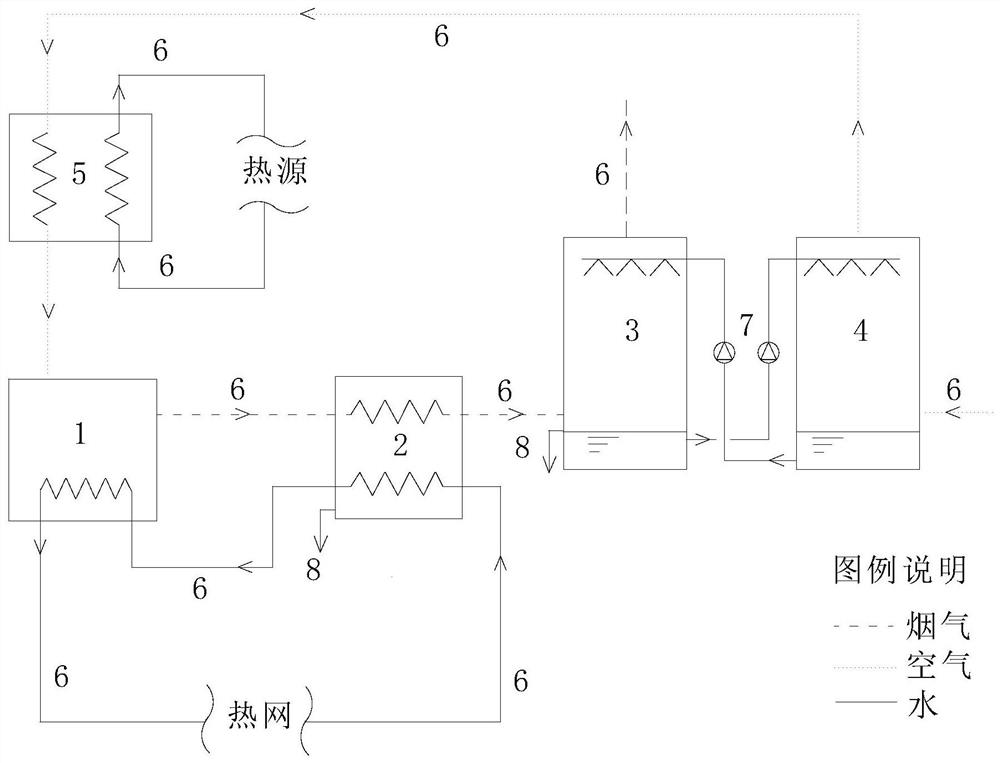

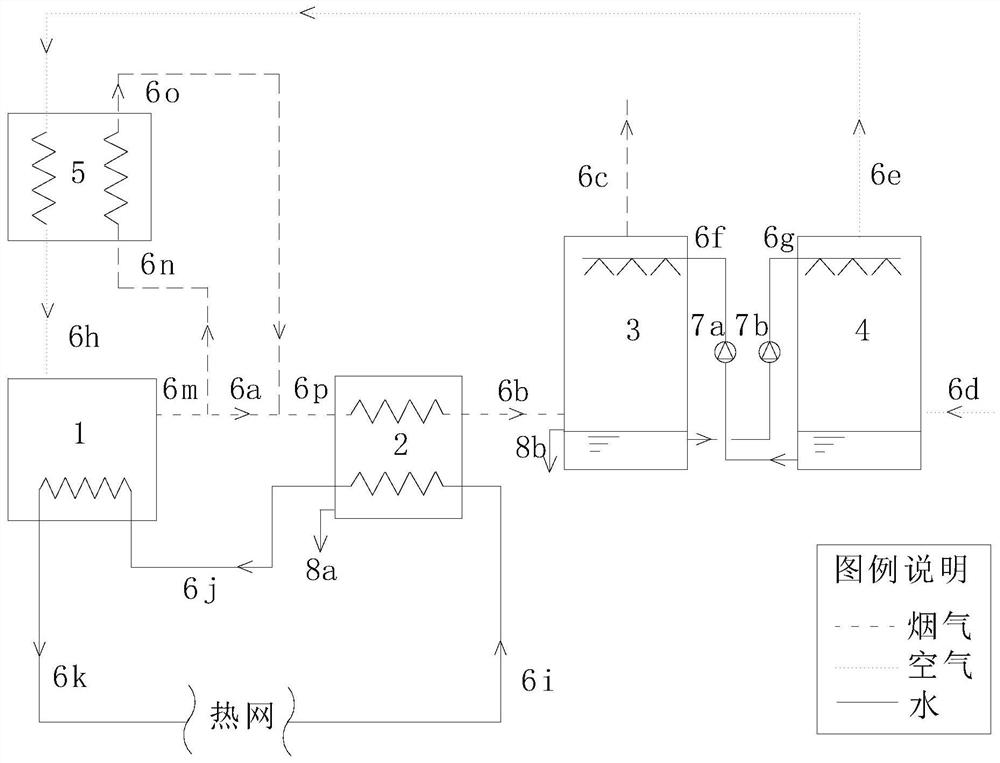

A deep recovery device for boiler flue gas waste heat

ActiveCN106918050BRaise the dew point temperatureEmission reductionFluegas recirculationIndirect carbon-dioxide mitigationCombustionFlue gas

The invention relates to a deep recovery device for boiler flue gas waste heat, comprising a boiler, a steam-water heat exchanger, a flue gas-water heat exchanger, an air-water heat exchanger and an air reheater; the flue gas outlet of the boiler is connected to the steam-water heat exchange The flue gas inlet of the steam-water heat exchanger is connected to the flue gas inlet of the flue gas-water heat exchanger, and the air outlet of the air-water heat exchanger is connected to the air inlet of the air reheater. The air outlet is connected to the air inlet of the boiler; one water outlet of the steam-water heat exchanger is used for outward overflow, the other water outlet is connected to the water inlet of the boiler, and the water outlet of the boiler is connected to the return water inlet of the steam-water heat exchanger through the heat network; One water outlet of the air-water heat exchanger is used for outward overflow, the other water outlet is connected to the water inlet of the air-water heat exchanger, and the water outlet of the air-water heat exchanger is connected to the inlet of the flue gas-water heat exchanger. water outlet. The invention can increase the dew point temperature of the flue gas, recover more waste heat of the flue gas, lower the combustion temperature and reduce the NOx emission at the same time.

Owner:TSINGHUA UNIV

Opening circular road whirling premixing upward-spraying backflow preheat burner

InactiveCN101749706BSolve combustion instabilityImprove combustion intensityGaseous fuel burnerCombustorCombustion chamber

The invention relates to an opening circular road whirling premixing upward-spraying backflow preheat burner, which effectively solves the problems that the fuel consumption is high, combustion is instable, the combustion intensity is low, combustion air velocity temperature distribution is non-uniform, the efficiency is low and the environment is polluted; the structure is that: a semisphere topcylindrical shape with closed upper end and a downward opening is formed by a cylindrical wall body and an arch top at the upper part of the cylindrical wall body, a combustion chamber is arranged atthe upper part in the cylindrical wall body in the arch top, a pre-mixing circular road with an opening at the upper part is circularly distributed on the inner wall of the cylindrical wall body, thepre-mixing circular road is respectively communicated with a coal gas inlet pipe and an air inlet pipe through a coal gas diversion channel and an air diversion channel, diversion guiding blocks are uniformly distributed in the coal gas diversion channel and the diversion channel, a current-limiting ring is communicated with the opening at the upper part of the premixing circular road; the opening circular road whirling premixing upward-spraying backflow preheat burner effectively solves the problems low-heat value gas combustion is instable, the combustion intensity is low and the combustiontemperature is low, and simple structure of the invention is obviously superior to the structures of a flameless burner and a staggering injection rapid mixing combustor which are arranged in an airflow spray pipe.

Owner:刘世聚

A low-nox burner for resource utilization of extremely low calorific value associated gas and carbon black burnout

ActiveCN111649342BImprove utilization efficiencyImprove stabilityIncinerator apparatusActivated carbonCombustor

The invention discloses a low-NOx burner for resource utilization of extremely low calorific value associated gas and carbon black burnout, which includes a flue gas inlet for entering the extremely low calorific value gas generated during the production process of activated carbon, and the flue gas inlet is output The end is connected to the pilot combustion chamber, and the primary air inlet is set on the pilot combustion chamber, and the low calorific value gas combusted in the pilot combustion chamber passes through the swirl channel regenerative burner and the exhaust air sent in by the exhaust air inlet. Complete combustion in the concave heat-gathering combustion chamber and furnace. The invention realizes the integrated treatment of industrial extremely low calorific value associated gas combustion, carbon black elimination and low NOx combustion. The heat of extremely low calorific value gas is effectively used, which greatly improves the efficiency of energy utilization. It can provide heat for subsequent enterprise transformation such as flue gas whitening or heating transformation, and eliminate environmental pollution such as carbon black.

Owner:XI AN JIAOTONG UNIV

Ignition optimization control method for sintering machine

ActiveCN108507365BGuaranteed uptimeAvoid wastingFurnace safety devicesGas emission reductionOptimal controlClosed loop

The invention discloses an ignition optimal control method for a sintering machine. The ignition optimal control method comprises the steps that valves controlling natural gas and air flow are connected with PLC / DCS systems correspondingly, and PID closed-loop control is adopted; a flow follow-up regulation mode is used, an air-fuel ratio and natural gas flow are set, and according to the formulathat natural gas flow*air-fuel ratio=air flow, the set air flow is obtained; then an ignition temperature control mode is used, and according to the deviation of target temperature and the current temperature, a new natural gas flow target value is calculated; then an ignition strength control module is used, the current ignition strength is obtained, and then target ignition strength is given according to the current ignition strength; and then according to the target ignition strength, the natural gas flow needing to be achieved is obtained, and then air flow is obtained through the air-fuelratio. According to the ignition optimal control method, a waste or flameout phenomenon of natural gas is avoided, meanwhile stability of PID closed-loop control in the regulation process is ensured,instable burning is prevented, and thus operation of the sintering machine is safer, more reliable and more stable.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

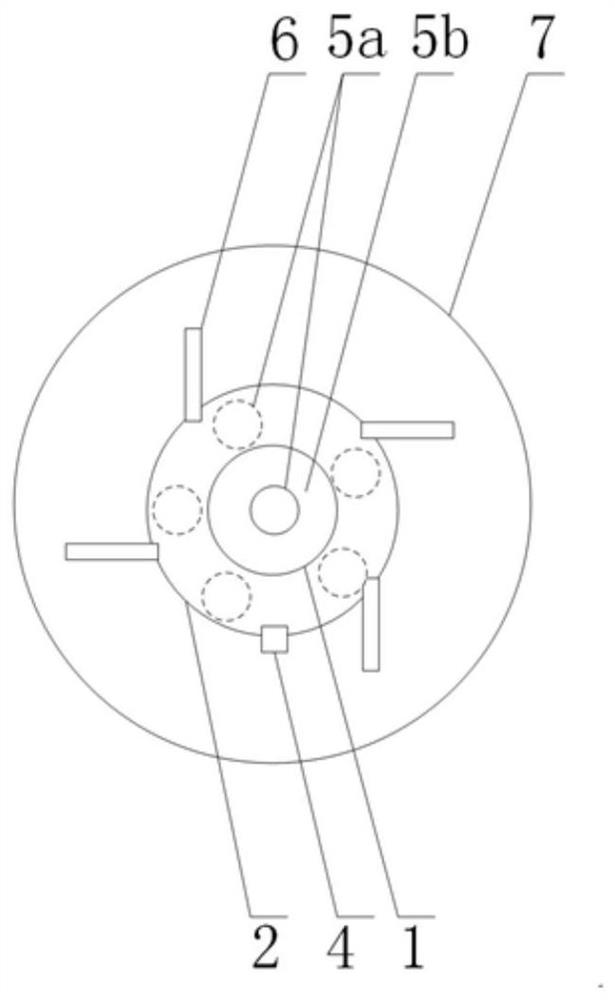

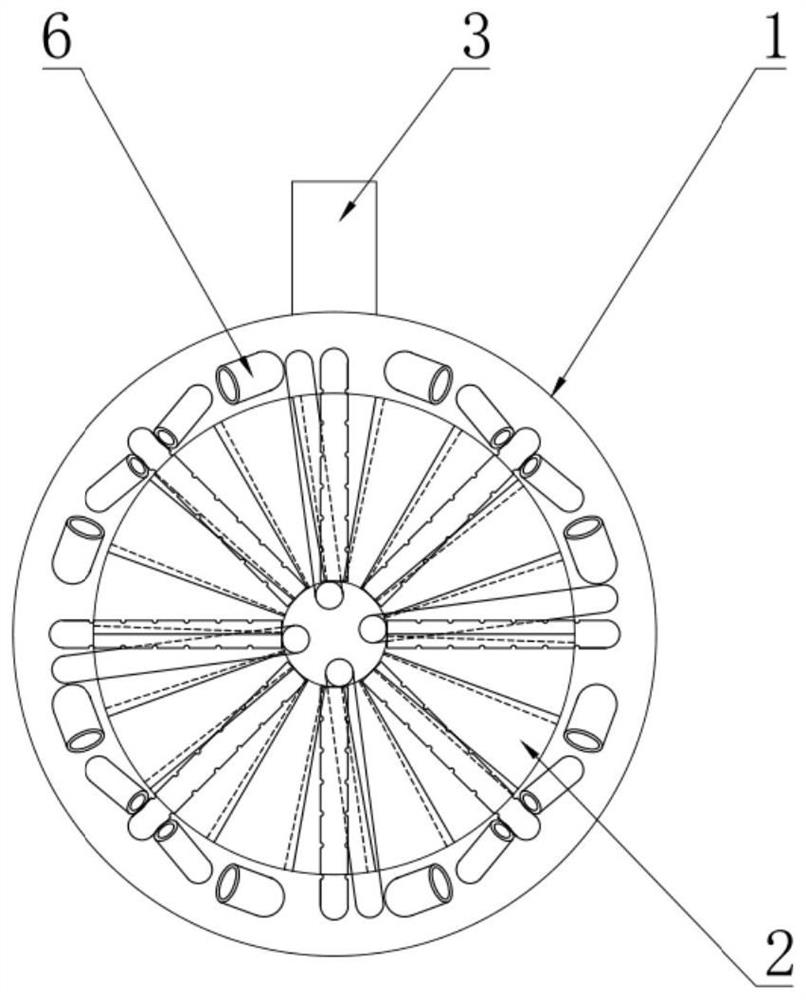

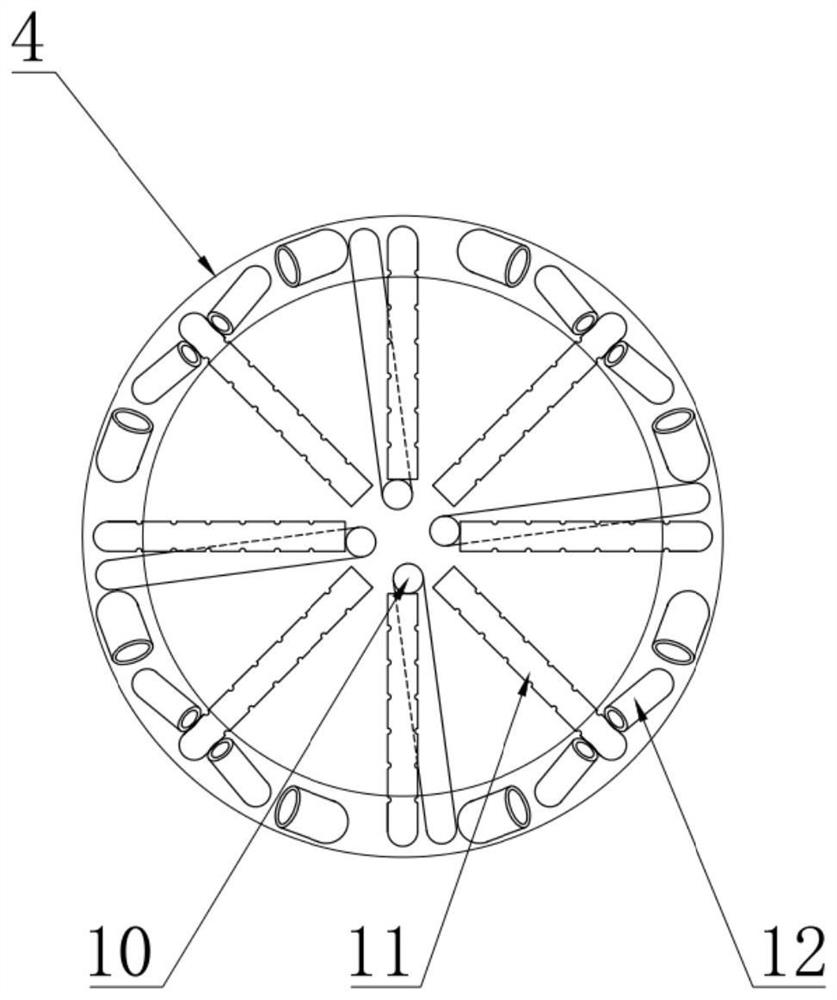

Nozzle-adjustable low-NOx burner suitable for medium-low calorific value fuel gas

ActiveCN112628732ASolve combustion instabilitySuppress generationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorNitrogen oxides

The invention provides a nozzle-adjustable low-NOx burner suitable for medium-low calorific value fuel gas, and aims to solve the problems that a conventional fuel gas burner adopted for recycling the medium-low calorific value fuel gas is difficult to ignite, unstable in burning and low in burning efficiency, and nitric oxide generated in the burning process is difficult to effectively restrain. The nozzle-adjustable low-NOx burner comprises a fuel gas inlet flow channel, an air flow channel, an air rotational flow device and a fuel gas shunt ring, wherein the fuel gas inlet flow channel penetrates through the upstream side wall of the air flow channel; the fuel gas shunt ring is sleeved with the upstream portion of the air flow channel and is communicated with the fuel gas inlet flow channel; the end face of the fuel gas shunt ring is connected with a plurality of first fuel gas branch pipes, a plurality of second fuel gas branch pipes and a plurality of third fuel gas branch pipes; the air rotational flow device comprises a rotational flow inner ring, a rotational flow outer ring and a plurality of rotational flow blades arranged between the rotational flow inner ring and the rotational flow outer ring in the circumferential direction; and the three fuel gas branch pipes are arranged in a staggered mode from the center to the outer side, and supplies fuel gas in a graded mode in the radial direction and the circumferential direction.

Owner:XI AN JIAOTONG UNIV

A biomass low-temperature carbon-gas cogeneration device, a biomass low-temperature carbon-gas cogeneration device, and a biomass low-temperature carbon-gas cogeneration method

Owner:HUNAN MORDEN ENVIRONMENT TECH

Turbine engine

ActiveCN105697148BIncrease thrust-to-weight ratioImprove fuel economyTurbine/propulsion fuel supply systemsGas turbine plantsCombustion chamberRocket turbine engine

Owner:清航空天(浙江)科技有限公司

Fan air volume adjustment method for gas water heater and gas water heater

The invention discloses a method for adjusting the air volume of a fan used in a gas water heater, which is specifically implemented according to the following steps: S1, the user inputs a preset temperature T 预设 ; S2, according to the preset temperature T in the S1 预设 Calculate the initial secondary pressure P 初始 , and according to the initial secondary pressure P 初始 Adjust the initial current I of the fan 初始 ; S3, gas water heater with the initial current I described in S2 初始 start; S4, according to the outlet water temperature, inlet water temperature and water flow rate to the initial secondary pressure P 初始 Adjust to obtain the actual secondary pressure P 实际 , and according to the actual secondary pressure P 实际 Calculate the actual current I of the fan 实际 ; S5, blower fan with the actual current I in the said S4 实际 run. The invention also discloses a gas water heater. The method for adjusting and controlling the fan air volume of the present invention does not need to increase additional costs, and only needs to adjust the fan current again according to the actual secondary pressure in the control program to solve the problem of unstable combustion of existing gas water heaters under different pressures.

Owner:VATTI CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com